Page 9

12/23/08

DKY

DATE

DATE

4010 320TH ST. PO BOX 189

BOYDEN, IOWA 51234

THE DRAWING AND ALL

INFORMATION THERE

ON ARE THE PROPERTY OF

DEMCO

TOLERANCES

pp2manclutch

DRAWN BY

ENG APPOV.

DESCRIPTION

DRAWING. NO.

REV

SCALE: 1:8

SHEET 1 OF 1

_

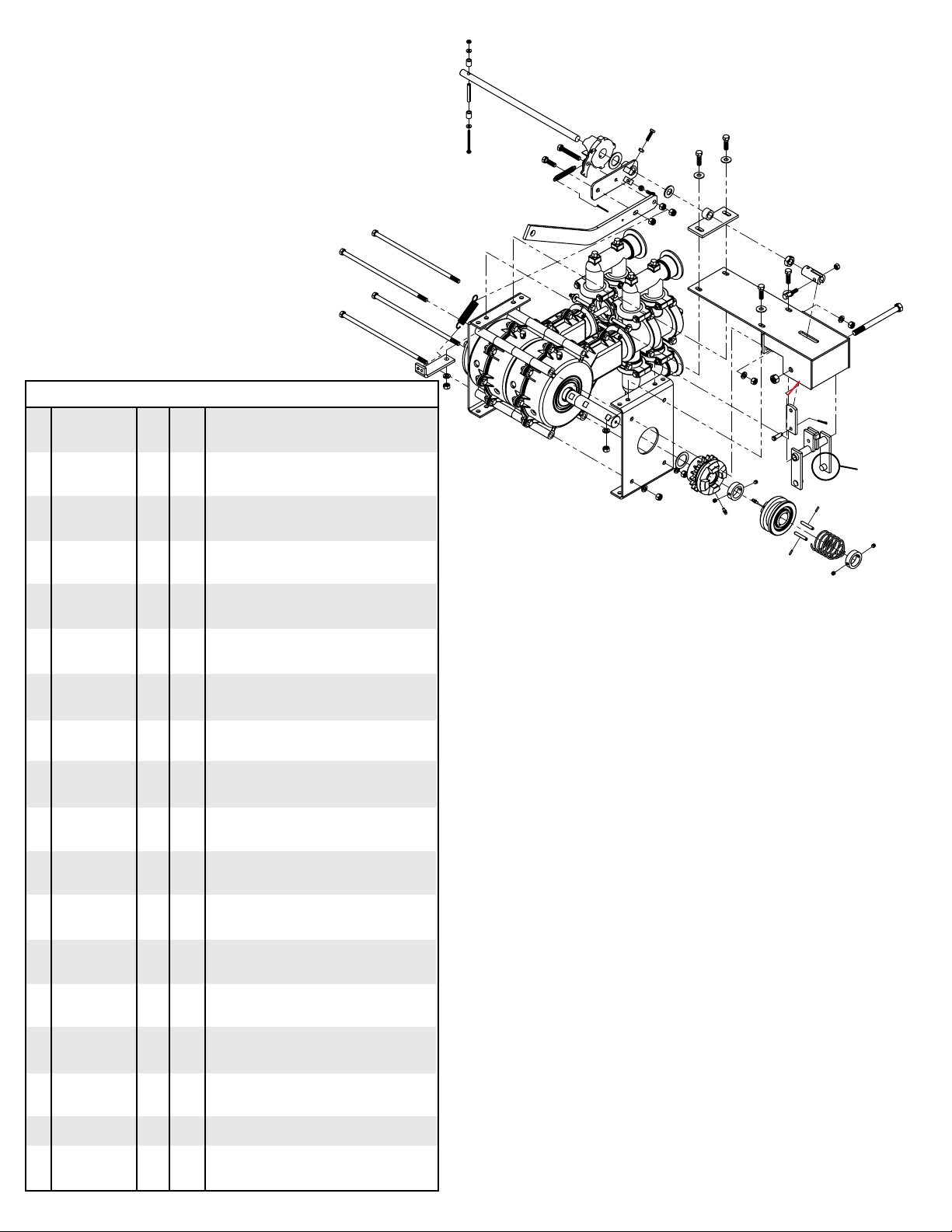

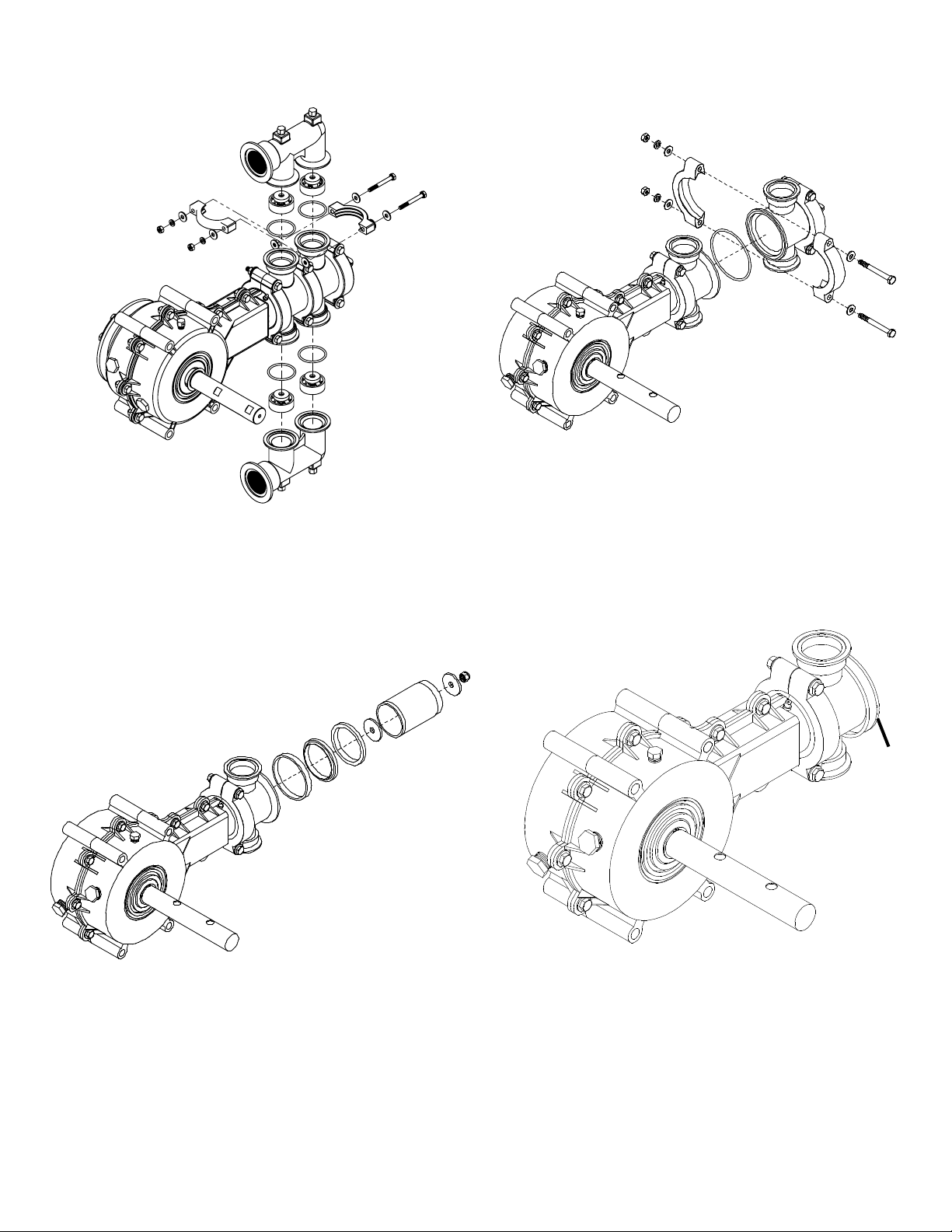

DOUBLE PISTON PUMP W/ CLUTCH

.X =

.060 MIN. MACHINE SURFACE 250

.XX = ±.030 BREAK ALL SHARP EDGES

.XXX = ±.010 BEND AND DRAFT

±1°

UNLESS OTHERWISE

SPECIFIEDALL DIMENSIONS

ARE IN INCHES

THIRD ANGLE

PROJECTION

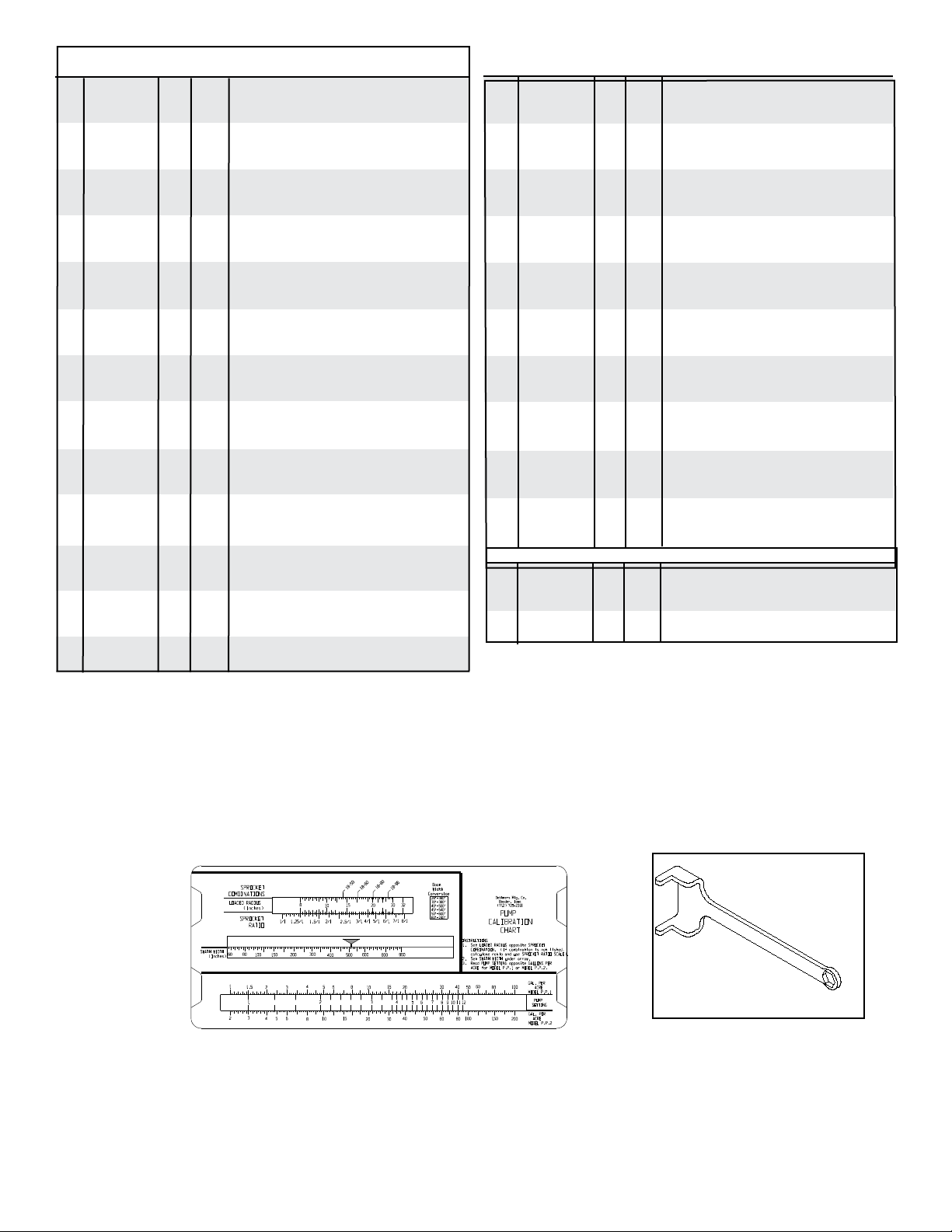

MANUAL CLUTCH PARTS

BREAKDOWN

REF. PART QTY.

NO. NO. PP1 PP2 DESCRIPTION

1

1

1

24

26

29

46

40

15

43

33

23

34

35

38 15

16

16

37

37

45

41 1

42

44

18

13 A

10

11

9

9

87

2

16

5

53

2

11

10

4

4

31

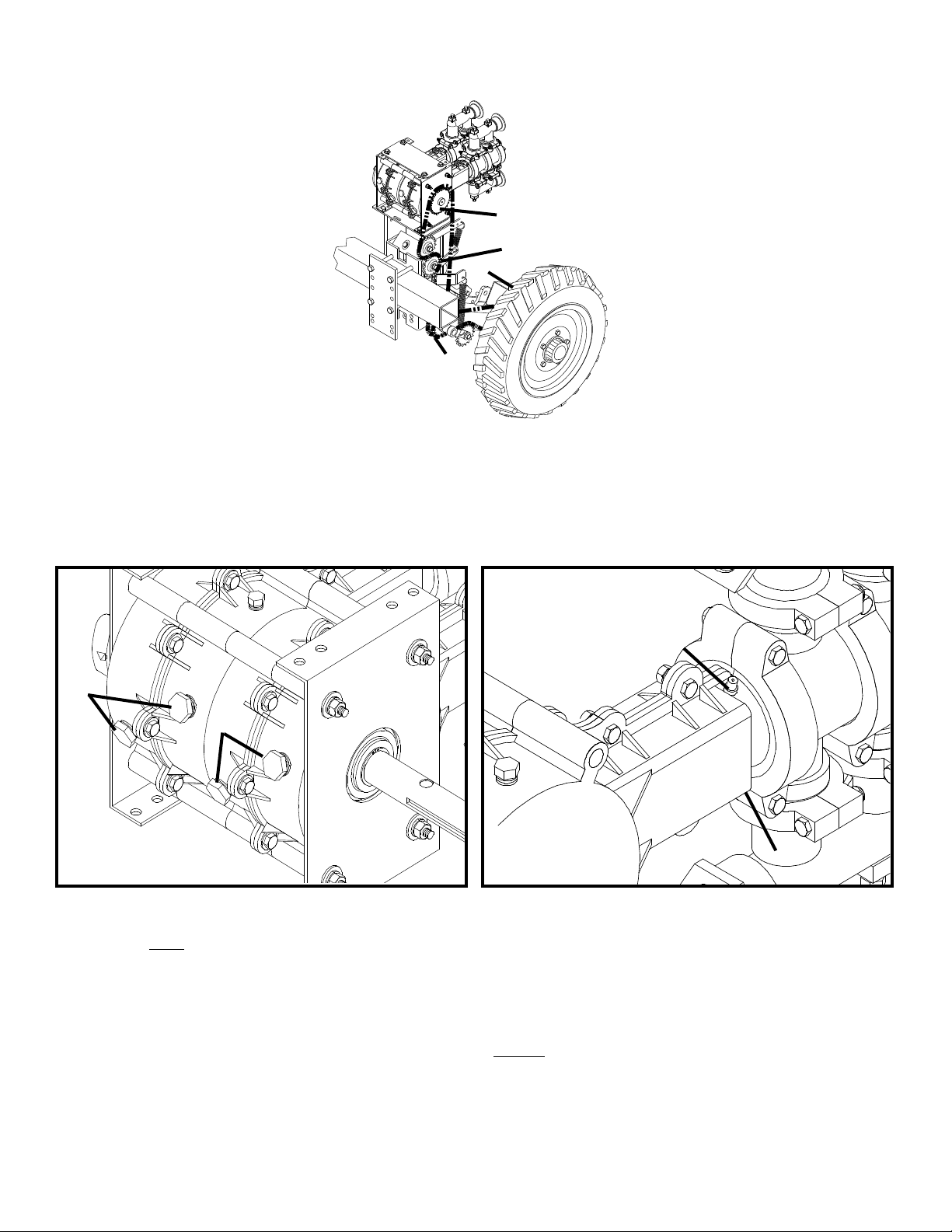

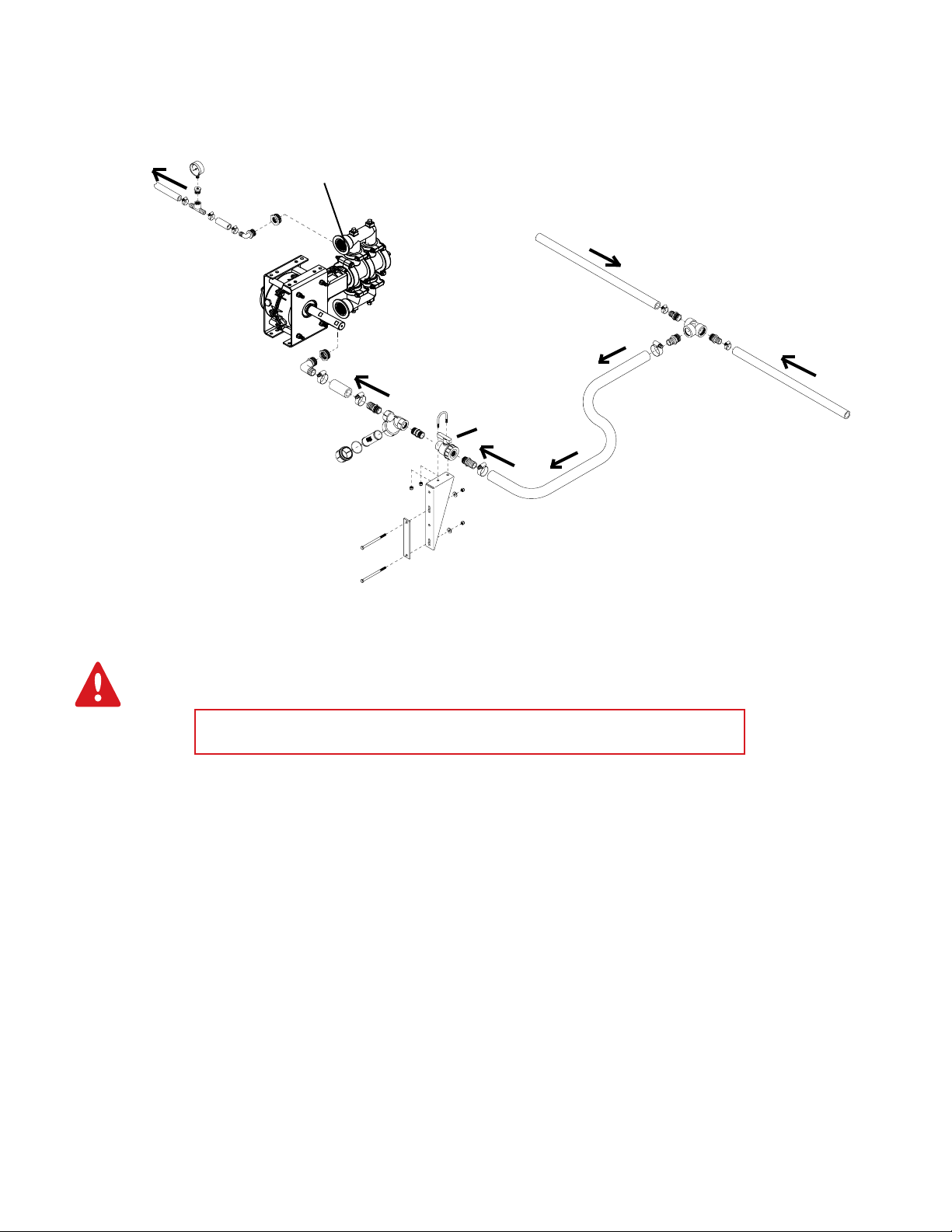

Bolt the throw out arm bracket (#40) and arm assembly (preas-

sembled at factory) to the top of the pump using two 3/8” bolts.

The 1-1/2” long bolt should be used to attach the return spring

bracket (#20). Connect the return spring (#21) and remove

any remaining shipping tape from the assembly. Loosen set

screw (#1) in clutch throw out shaft connector (#42). Turn

connector, not the shaft, until holes align for the 5/16” x 1-1/2”

bolt (#44) to pass through connector and Yoke (#14). Lock

connector in place by tightening jam nut (#41). Grease the

zerk in the throw out ratchet casting (#33) before using the

pump and as needed thereafter. An occasional drop of oil to

the other moving parts of the clutch will prevent unnecessary

wear. Check to make sure the clutch completely disengages.

The sprocket casting should turn freely. The handle should

return to engage the next cog in the throw out ratchet casting

when the clutch is tripped.

Important: Make sure the clutch throw out yoke pegs fit

loosely in the groove in the clutch yoke casting when the

clutch is engaged.

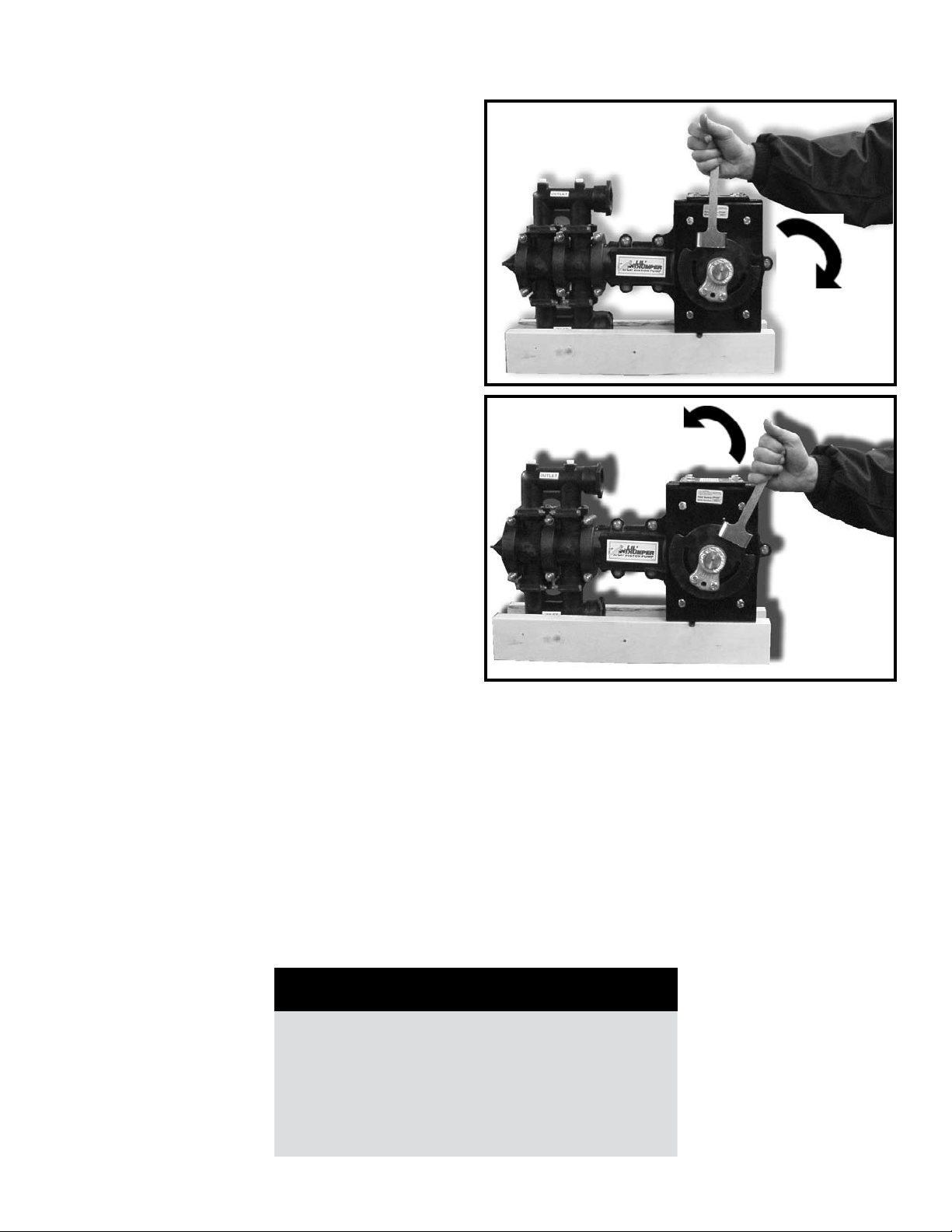

Attach the pull rope to the eye in the throw out handle to permit

operation of clutch from the tractor cab. To change the direc-

tion of pull for the clutch handle, simply remove the handle

and install it in the opposite position. Then re-hook the throw

out pawl spring in the other hole in the throw out pawl and

move the spring return bracket to the other side of the handle

assembly and re-hook the return spring. Make sure the pawl

works freely on the side of the throw out arm plate.

ADJUSTMENT INSTRUCTIONS

YOKE

PEG

16

28

25

26

27

25

10

17

15

16

10

11

14

10

11

12

20

21

19

22

36

32

30

NOTE: Clutch Throw out Yoke must be positioned as

shown, with block “A” facing the pump.

45 45

45

1. 00087 5 5 5/16” x 5/16” Cup Point Set Screw

2. 01598-95 2 2 1-1/4” I.D. Lock Collar

3. 01193 1 1 Clutch Spring

4. 01976 2 2 1/8” x 1/2” Roll Pin

5. 01549 2 2 1/4” x 1/4” x 1-5/8” Key

6. 01184 1 1/4-30 1 1 1-1/4” I.D. Clutch Yoke

7. 01183 1 1/4-30 1 1 1-1/4” I.D. Sprocket Casting (18 tooth)

8. 01979 1 1 1-1/4” I.D. 18 Ga. Machine Washer

9. 01498-30 2 2 Pump Side Plate

10. 00061 9 9 3/8”-16UNC Hex Nut

11. 00060 8 8 3/8” Lockwasher

12. 02056 - 2 3/8”-16UNC x 11-1/2” Hex Head Bolt

12. 00613 2 - 3/8”-16UNC x 6” Hex Head Bolt Gr. 5

13. 00173 1 1 1/2”-13UNC Locknut

14. 01576-30 1 1 Clutch Throw Out Yoke

15. 00059 4 4 3/8” Flatwasher

16. 00523 5 5 3/8”-16UNC x 1.25” Hex Head Bolt Gr. 5

17. 00349 1 1 1/2”-13UNC x 6” Hex Head Bolt Gr. 5

18. 01525-30 1 - Piston Pump Top Bracket

18. 01526-30 - 1 Piston Pump Top Bracket

19. 02057 - 2 3/8”-16UNC x 12” Hex Head Bolt

19. 04219 2 - 3/8”-16UNC x 6-1/2” Hex Head Bolt Gr. 5

20. 01527-30 1 1 Throw Out Arm Return Spring Bracket

21. 01547 1 1 Throw Out Arm Return Spring

22. 01211-30 1 1 Throw Out Arm Extension Handle

23. 01982 1 1 3/32” x 1-1/4” Cotter Key

24. 01983 1 1 #10 x 2-1/2” Round Head Stove Bolt

25. 07490 2 2 3/16” Flatwasher

26. 01212-95 2 2 Throw Out Roller

27. 01985 1 1 5/16” x 2” Roll Pin

28. 01986 1 1 #10 Nut

29. 01214-95 1 - Throw Out Shaft

29. 01565-95 - 1 Throw Out Shaft

30. 01548 1 1 Throw Out Pawl Spring

31. 01987 1 1 3/8”-16UNC x 2-1/2”FullThread Hex Head Bolt

32. 01185 1 1 Throw Out Pawl

33. 01186-30 1 1 Throw Out Pawl Ratchet Casting

34. 00062 2 2 1/4”-20UNC Hex Nut

35. 04055 2 2 1/4”-20UNC x 1” Hex Head bolt

36. 01213-30 1 1 Throw Out Arm Plate

37. 02592 2 2 3/8”-16UNC Nylon Insert Locknut

38. 00496 1 1 5/8” Machine Washer

39. 00914 1 1 3/8”-16UNC x 1-1/2” Hex Head Bolt Gr.5

40. 01216-30 1 1 Throw Out Arm Bracket

41. 00489 1 1 5/8”-11UNC Jam Nut

42. 01215-95 1 1 Clutch Throw Out Shaft Yoke Connector

43. 02802 1 1 5/16”-18UNC Nylon Insert Locknut

44. 00372 1 1 5/16”-18UNC x 1-1/2” Hex Bolt Gr. 5

45. 05023 4 4 3/16”Grease Zerk

46. 05587 1 1 1.00”X 14GA Machine Washer

47. 01575-30 1 1 Top Pivot Yoke Link

48. 02528 1 1 Clevis Pin

49. 00009 1 1 1/8” Cotter Pin

47

48

49