Demiriz Electronic 250 User manual

USER MANUAL

Electronic 250

Turbo 250

Turbo 400

Turbo 500

AC ARC WELDING MACHINES

2 AC Arc Weldin Machine User Manual

INDEX

CE DECLARATION OF CONFORMITY 3

SAFETY RULES 7

ELECTROMAGNETIC COMPATIBILITY (EMC) 8

CAUTIONS BEFORE TRANSPORTATION 9

CAUTIONS DURING DELIVERY 9

1. TECHNICAL INFORMATIONS 10

1.1. STANDARD FEATURES 10

1.2. MACHINE’S LABEL 10

1.3. TECHNICAL PROPERTIES 11

2. INSTALLATION 11

2.1. INSTALLATION AND WORKING TIPS 11

2.2. DUTY CYCLE AND OVER-USAGE 11

2.3. MAINS POWER CONNECTION 12

3. PROPER OPERATION 13

4. MAINTENANCE AND FAULT INFORMATIONS 14

4.1. PERIODIC MAINTENANCE 14

4.2. NONPERIODIC MAINTENANCE 14

4.3. BASIC FAULTS AND FIXES 14

5. MANUFACTURER AND AUTHORIZED SERVICES 15

This Document can be chan ed without a further notice.

AC Arc Weldin Machine User Manual 3

AT UYGUNLUK BEYANI

EU DECLARATION OF CONFORMITY

Firma / Company

Demiriz Elektrik İnşaat Sanayi ve Ticaret Limited Şirketi

Ortaköy Sanayi Bölgesi Tiftik Sokak No 16 Silivri/İstanbul

Fabrika / Factory

Demiriz Elektrik İnşaat Sanayi ve Ticaret Limited Şirketi

Ortaköy Sanayi Bölgesi Tiftik Sokak No 16 Silivri/İstanbul

Ürün / Product

Örtülü Elektrod Kaynak Makinası

MMA Welding Machine

Marka - Model / Brand - Model

DEMİRİZ - Electronic 250

Yukarıda tanımlanan beyanın nesnesi, ilgili uyumlaştırılmış AB mevzuatı ile uyumludur.

The object of the declaration described above, is in conformity with the relevant union

harmonisation legislation.

Direktifler / Directives

2014/35/AB LVD Yönetmeliği

LVD Directive 014/35/EU

Uyumlaştırılmış Standartlar / Harmonised Standards

TS EN 60974-1 2012

__________________________________________________________________________________

İstanbul, 01.06.2017 Burhan DEMİRİZ

Beyan No CED.005 Elektronik Mühendisi

Declaration No : CED.005 Electronics Engineer

Yazılı iznimiz olmaksızın makina üzerinde yapılan değişiklikler bu belgeyi geçersiz kılacaktır.

This declaration loose its validity in case of modification on the machine without our written authorization.

4 AC Arc Weldin Machine User Manual

AT UYGUNLUK BEYANI

EU DECLARATION OF CONFORMITY

Firma / Company

Demiriz Elektrik İnşaat Sanayi ve Ticaret Limited Şirketi

Ortaköy Sanayi Bölgesi Tiftik Sokak No 16 Silivri/İstanbul

Fabrika / Factory

Demiriz Elektrik İnşaat Sanayi ve Ticaret Limited Şirketi

Ortaköy Sanayi Bölgesi Tiftik Sokak No 16 Silivri/İstanbul

Ürün / Product

Örtülü Elektrod Kaynak Makinası

MMA Welding Machine

Marka - Model / Brand - Model

DEMİRİZ - Turbo 250

Yukarıda tanımlanan beyanın nesnesi, ilgili uyumlaştırılmış AB mevzuatı ile uyumludur.

The object of the declaration described above, is in conformity with the relevant union

harmonisation legislation.

Direktifler / Directives

2014/35/AB LVD Yönetmeliği

LVD Directive 014/35/EU

Uyumlaştırılmış Standartlar / Harmonised Standards

TS EN 60974-1 2012

__________________________________________________________________________________

İstanbul, 01.06.2017 Burhan DEMİRİZ

Beyan No CED.006 Elektronik Mühendisi

Declaration No : CED.006 Electronics Engineer

Yazılı iznimiz olmaksızın makina üzerinde yapılan değişiklikler bu belgeyi geçersiz kılacaktır.

This declaration loose its validity in case of modification on the machine without our written authorization.

AC Arc Weldin Machine User Manual 5

AT UYGUNLUK BEYANI

EU DECLARATION OF CONFORMITY

Firma / Company

Demiriz Elektrik İnşaat Sanayi ve Ticaret Limited Şirketi

Ortaköy Sanayi Bölgesi Tiftik Sokak No 16 Silivri/İstanbul

Fabrika / Factory

Demiriz Elektrik İnşaat Sanayi ve Ticaret Limited Şirketi

Ortaköy Sanayi Bölgesi Tiftik Sokak No 16 Silivri/İstanbul

Ürün / Product

Örtülü Elektrod Kaynak Makinası

MMA Welding Machine

Marka - Model / Brand - Model

DEMİRİZ - Turbo 400

Yukarıda tanımlanan beyanın nesnesi, ilgili uyumlaştırılmış AB mevzuatı ile uyumludur.

The object of the declaration described above, is in conformity with the relevant union

harmonisation legislation.

Direktifler / Directives

2014/35/AB LVD Yönetmeliği

LVD Directive 014/35/EU

Uyumlaştırılmış Standartlar / Harmonised Standards

TS EN 60974-1 2012

__________________________________________________________________________________

İstanbul, 01.06.2017 Burhan DEMİRİZ

Beyan No CED.007 Elektronik Mühendisi

Declaration No : CED.007 Electronics Engineer

Yazılı iznimiz olmaksızın makina üzerinde yapılan değişiklikler bu belgeyi geçersiz kılacaktır.

This declaration loose its validity in case of modification on the machine without our written authorization.

6 AC Arc Weldin Machine User Manual

AT UYGUNLUK BEYANI

EU DECLARATION OF CONFORMITY

Firma / Company

Demiriz Elektrik İnşaat Sanayi ve Ticaret Limited Şirketi

Ortaköy Sanayi Bölgesi Tiftik Sokak No 16 Silivri/İstanbul

Fabrika / Factory

Demiriz Elektrik İnşaat Sanayi ve Ticaret Limited Şirketi

Ortaköy Sanayi Bölgesi Tiftik Sokak No 16 Silivri/İstanbul

Ürün / Product

Örtülü Elektrod Kaynak Makinası

MMA Welding Machine

Marka - Model / Brand - Model

DEMİRİZ - Turbo 500

Yukarıda tanımlanan beyanın nesnesi, ilgili uyumlaştırılmış AB mevzuatı ile uyumludur.

The object of the declaration described above, is in conformity with the relevant union

harmonisation legislation.

Direktifler / Directives

2014/35/AB LVD Yönetmeliği

LVD Directive 014/35/EU

Uyumlaştırılmış Standartlar / Harmonised Standards

TS EN 60974-1 2012

__________________________________________________________________________________

İstanbul, 01.06.2017 Burhan DEMİRİZ

Beyan No CED.008 Elektronik Mühendisi

Declaration No : CED.008 Electronics Engineer

Yazılı iznimiz olmaksızın makina üzerinde yapılan değişiklikler bu belgeyi geçersiz kılacaktır.

This declaration loose its validity in case of modification on the machine without our written authorization.

AC Arc Weldin Machine User Manual 7

SAFETY RULES

•Apply all safety regulations in this manual.

•The manufacturer cannot be held responsible for any injury or damage to the machine as a result

of non-compliance with the warnings and modifications to the machine.

•Keep everyone except operators, especially children, away from the work site when operating

the machine.

• Do not operate your machine in an open environment, especially in rainy weather. Disconnect

the machine from the mains. Failure to do so may result in electric shock.

•Wear dry and insulated gloves and work clothes. Do not use wet or damaged gloves and work

clothes. Synthetic materials should be avoided due to their flammable nature.

•Never touch electrical parts.

•Do not wear watch, ring, metal accessories etc. when operating the machine.

•Protect yourself from possible shocks by isolating yourself from the work surface and the floor.

Use electrically insulating, dry and undamaged insulation material on the floor that is large

enough to cut off contact with the work surface.

•Check all cables frequently for possible damage. If a damaged or insulated cable is detected,

repair it immediately or replace it with the same diameter and type cable.

•Always connect the mains cord of the machine to a grounded outlet. Make sure that the

electrical outlet you are connecting to be properly grounded.

•If the mains cable of the machine has a three-phase plug, firmly connect the grounding line on

your machine to the earth screw on the machine.

•Make sure that the power line to which the mains cable is connected is protected by a protective

automatic fuse.

•Keep all cover, panel etc. of the machine closed and locked.

•Keep the machine switched off when not in use.

•Wear metal-toed work shoes for the possibility of heavy objects falling.

•Always use the handles when moving the machine. Never attempt to move by pulling the cables.

•Place your machine on a floor with a maximum of 10 degrees of slope so that it does not fall or

fall over.

•Always ensure good ventilation in the environment where the machine is operated.

•Always keep fire extinguishers and materials in order to protect against fire. Combustible

materials, gasoline, oil, thinner etc. keep materials away from the machine.

•Long-term inhalation of fumes and gas when welding is very dangerous. Create a natural or

forced ventilation system in the work area. If necessary, use a suitable smoke extraction system

at the welding site.

•If you are working in narrow and enclosed areas, or if you are welding lead, beryllium, cadmium,

zinc, zinc coated or painted materials, use masks that provide fresh air in addition to the above

precautions.

•Arc welding light will damage your eyes and skin. Processes such as welding, grinding or brushing

can cause sparks and splash of metal particles. Wear a suitable protective mask (4 to 13

according to EN 379) and a suitable protective mask to protect your eyes and face. Hot parts can

cause severe burns. Never touch hot parts with bare hands. When you need to keep hot parts,

use suitable tools, high thermal insulation and high-flammability gloves.

•Ensure that the working area of the machine complies with electromagnetic compatibility (EMC).

Electromagnetic interference during operation may cause unwanted effects on your electronic

devices and the network. The effects of these interventions that may occur during use are the

responsibility of the user.

•If any electromagnetic interference occurs, to ensure compliance; extra measures such as the use

of short mains cable, the use of shielded cables, move the machine to another location, remove

8 AC Arc Weldin Machine User Manual

the cables from the affected device and / or zone, or use filter or protection at the working area

for EMC.

•Operate the machine as far away from your sensitive electronic equipment as possible to prevent

possible EMC damage.

•Electric current passing through any conductor generates regional electric and magnetic fields

(EMF). EMF may disrupt the operation of medical implants (such as pacemakers), such as

pacemakers. Keep people with medical implants away from the work environment of the

machine.

ELECTROMAGNETIC COMPATIBILITY (EMC)

•This machine is designed to comply with all relevant regulations and norms. However, it may still

produce effects that may affect other systems, such as communication devices (telephone, radio,

television, etc.) and security devices. These effects can cause safety problems on exposed

systems. Carefully read and understand this section to reduce or eliminate the amount of effects

that can be generated by this machine.

•This machine is designed for operation in the industrial zone and according to CISPR11, the 2nd

group is a class A device. The use of the grid in residential areas can cause difficulties in terms of

noise transmitted or emitted in ensuring electromagnetic compatibility. The user must install and

operate this machine as described in the manual. If any electromagnetic interference is detected

due to the operation of this machine, the user should take corrective measures to reduce or

eliminate these effects.

•Before installing the machine, it should be checked whether there are any devices that may

malfunction due to electromagnetic effects in the working area. In this context

- Input and output cables, control cables, signal cables, telephone cables in the work area of the

machine,

- radio and / or television transceivers, telecommunication devices, computers or computer

control vehicles / machines,

- Safety and control equipment for industrial operations, calibration and measurement devices,

- medical devices such as heart rhythm devices and hearing aids,

- Check the electromagnetic immunity of equipment’s operating near the working area.

•The user must ensure that all equipment in the work area is compatible. Otherwise, additional

protection measures may be required. These measures will depend on the size of the work area,

the shape of the building and other activities in the work area.

•In order to reduce the electromagnetic emissions that may arise from the machine, the items

outlined below should be taken into consideration.

- Connect the machine to the input network according to the operating instructions. If effects

occur, it may be necessary to take additional measures, such as filtering the input source.

- The output cables should be held short and possible side by side. If possible, the workpiece

must be grounded to reduce electromagnetic emissions. The user should ensure that grounding

the workpiece will not cause problems for personnel and equipment or cause unhealthy working

conditions.

- The shielding of cables in the work area may be a method to reduce electromagnetic emissions.

This may be necessary in specific application areas.

CAUTIONS BEFORE TRANSPORTATION

•AC welding machines; the main machine and the cables connected to the main machine are

packaged with air bubble packing material.

•Carry the Electronic 250 and Turbo 250 models with the handle.

AC Arc Weldin Machine User Manual 9

•Turbo 400 and Turbo 500 models are wheeled. Be very careful about tipping during transport.

Move the machine upwards.

•Do not place anything on the machine during transport. Do not stack even if the machine is to be

used in a constant place.

•Do not displace the machine by pulling it from its cables or apparatus.

•Do not attempt to move the machine carelessly. Protect the machine from impact.

•Outside the machine; avoid moving and using with wind, rain, snow. Protect the machine from

getting wet.

•

If there are elements that could damage the machine during transportation, keep it in its

packaging.

CAUTIONS DURING DELIVERY

•First remove all packing material on the machine.

•Make sure that all the items you have ordered have arrived. If any material is missing or

damaged, contact your place of purchase immediately.

•In case of damaged or incomplete delivery; Keep a record, take a picture of the damage and

report to the carrier with a copy of the transport note.

• The standard package for the electronic 250 electrode welding machine includes

- Mains cable and its connected plug

- Electrode holder cable connected to main machine and electrode holder

- Work cable attached to the main machine

- User guide

- Warranty certificate

•The standard package for the turbo 250 electrode welding machine includes

- Mains cable and its connected plug

- Electrode holder cable connected to main machine and electrode holder

- Work cable attached to the main machine

- User guide

- Warranty certificate

•The standard package for the turbo 400 covered electrode welding machine includes

- Mains cable and its connected plug

- Electrode holder cable connected to main machine and electrode holder

- Work cable attached to the main machine

- User guide

- Warranty certificate

•The standard package for the Turbo 500 covered electrode welding machine includes

- Mains cable and its connected plug

- Electrode holder cable connected to main machine and electrode holder

- Work cable attached to the main machine

- User guide

- Warranty certificate

10 AC Arc Weldin Machine User Manual

1. TECHNICAL INFORMATIONS

1.1. STANDARD FEATURES

•Electronic 250, Turbo 250, Turbo 400 and Turbo 500; They are welding machines designed for

welding work to burn rod welding electrodes with rutile character. It cannot be used for any

other purpose.

•Electronic 250 and Turbo 250 models, 1 phase 220 V (AC) 50 Hz. manufactured according to the

grid.

•Turbo 400 and Turbo 500 models, 2 phase 380 V (AC) 50 Hz. manufactured according to the

network.

•These machines are not suitable for use with long extension cables or long output cables. Under

these conditions low performance will occur.

Electronic 250 is fan-cooled and thermally protected against overheating.

•Turbo 250, Turbo 400 and Turbo 500 models are fan cooled.

•Welding can be done by connecting only one electrode to the electrode pin of the machine at the

same time.

•The lifetime of these products has been determined by the manufacturer and is 10 years.

1.2. MACHINE’S LABEL

Electronic 250 product label Turbo 250 product label

Turbo 400 product label Turbo 500 product label

AC Arc Weldin Machine User Manual 11

1.3. TECHNICAL PROPERTIES

TECHNICAL SPECIFICATION

Electronic 250

Turbo 250

Turbo 400

Turbo 500

Mains Voltage

U

1

220 V (AC)

220 V (AC)

38

0 V (AC)

38

0 V (AC)

Operating Frequency

Hz

50

50

50

50

Open Circuit Voltage

U

o

18 V

–

44 V

39 V

–

54 V

53 V

–

58 V

54 V

–

59 V

Maximum Output Current

I

omax

160 A

160 A

340 A

420 A

Recommended

Fuse

C

Type

40 A

40 A

63

A

63 A

Power Factor

cos

ϕ

0.7

0.7

0.7

0.7

Cooling

Fan

Fan

Fan

Fan

Voltage Range

-

5

-

-

Elec

trod

e

T

ype

Rutil

e

Rutil

e

Rutil

e

Rutil

e

Elec

trod

e

Diameter

1.6

-

2.5

-

3.25

2.5

-

3.25

2.5

-

3.25

-

4.0

3.25

-

4.0

-

5.0

Protection Class

IP 21

S

IP 21

S

IP 21

S

IP 21

S

Insulation Class

H

H

H

H

Dimensions

(

w

/d/

h

)

cm

17 x 32 x 27

25 x 36 x 29

52 x 61 x 71

52 x 61 x 71

Weight

15 kg

22 kg

96 kg

105 kg

2. INSTALLATION

2.1. INSTALLATION AND WORKING TIPS

•Place the machine on a hard, flat surface where it will not fall or fall over. The maximum

permissible slope for transport and installation is 10 °.

•For better performance, place the machine at least 30 cm away from objects around it. Pay

attention to the overheating, dust and moisture around the machine. Do not operate the

machine in direct sunlight. If the ambient temperature exceeds 40 ° C, operate the machine at

lower capacities.

•Avoid running the machine with windy and rainy outdoor conditions. If it is necessary to operate

the machine in such cases, protect the working environment and the machine with a cover.

•Ensure that the operator can easily access the control and connections of the machine.

•

Do not use an input fuse with a value greater than that specified on the product label.

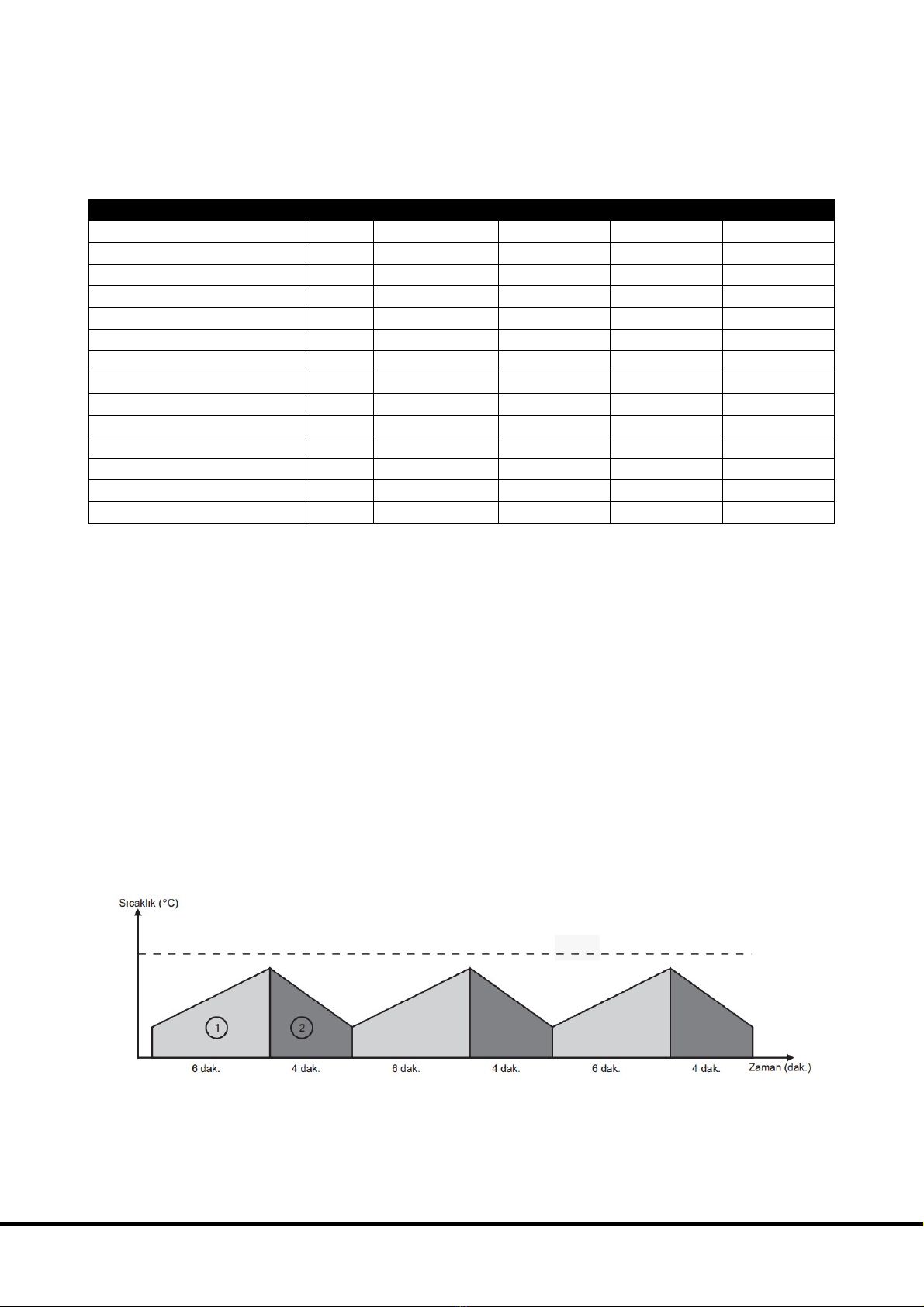

2.2. DUTY CYCLE AND OVER-USAGE

•

The operating cycle rate as defined in EN 60974-1 includes a time period of 10 minutes. For

example, if the machine is to be operated at 250 A in 60% of 250 A, the machine can weld

without stopping in the first 6 minutes of the 10 minute time period (zone 1). However, for the

next 4 minutes, the machine must be kept idle for cooling (zone 2).

12 AC Arc Weldin Machine User Manual

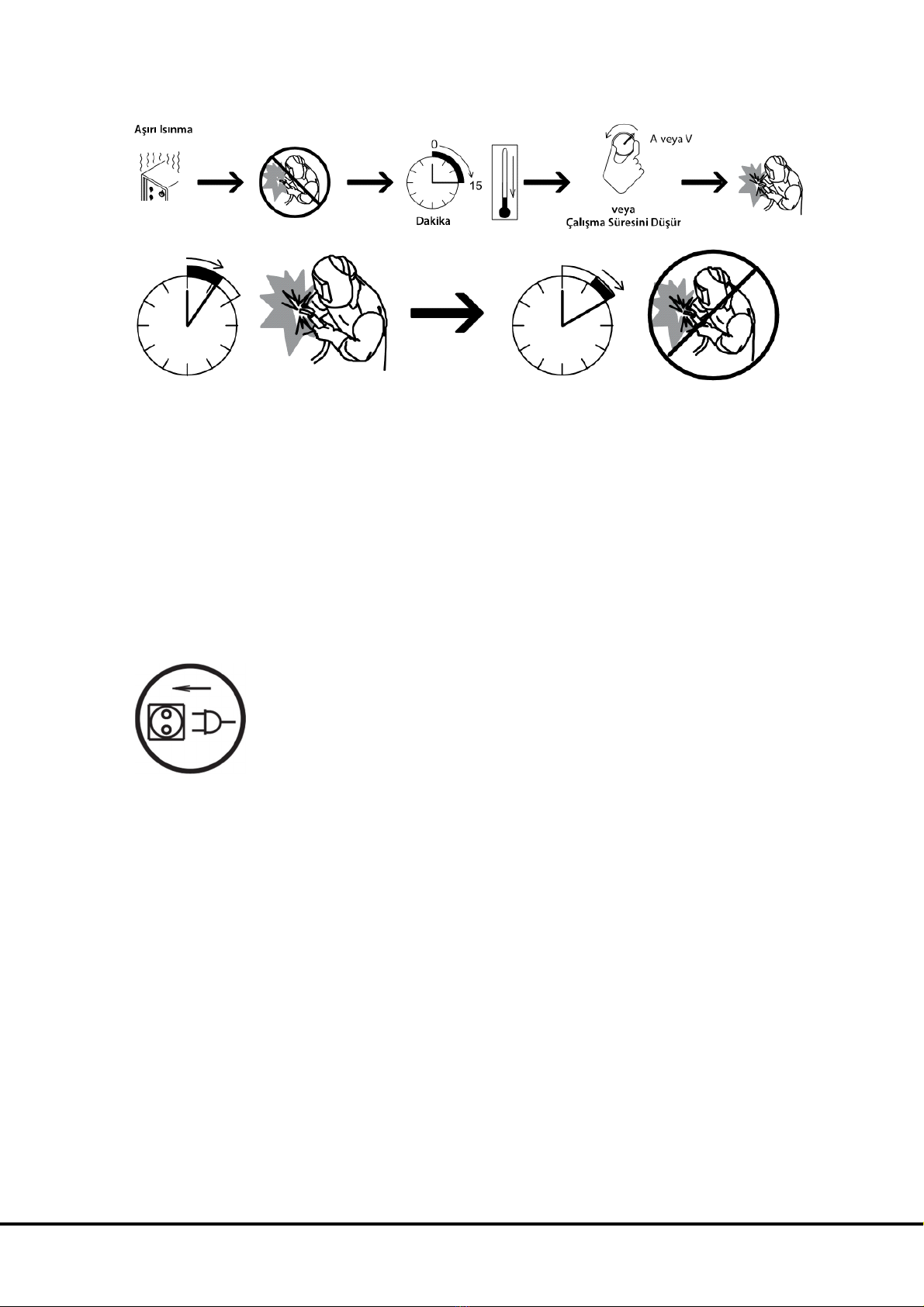

In the Electronic 250, overheating is carried out by welding 3-4 3.25 mm rutile electrodes

continuously. In this case, the overheat indicator on the front panel of the machine will be lit. After 5-

6 minutes the machine will cool down and the indicator will go off. Then it will return to working

condition.

Other models do not have a similar thermal protection system. When the machine is used within the

operating cycle specified above and indicated on the sign plate, cooling with the fan will prevent the

machine from overheat.

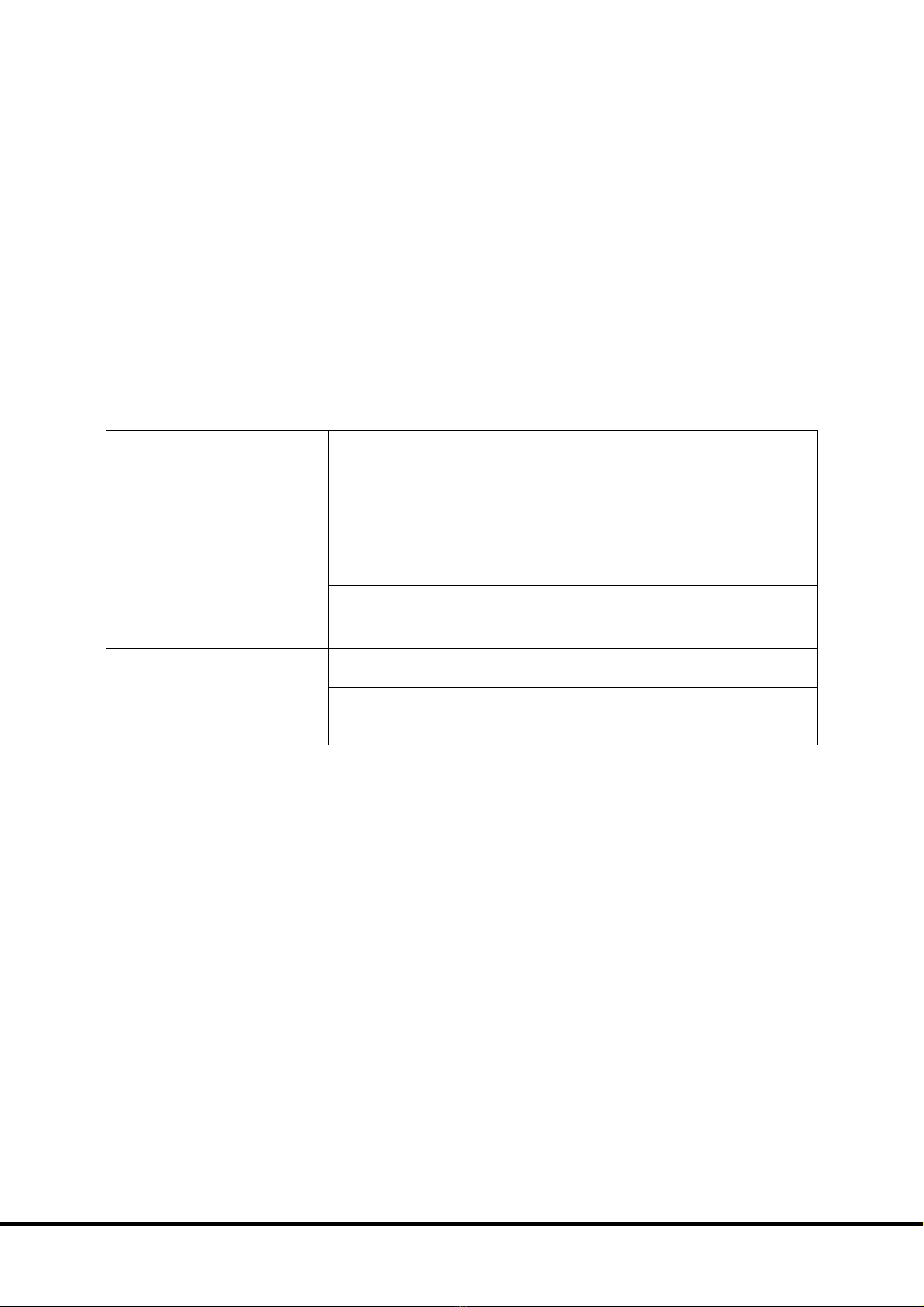

2.3. MAINS POWER CONNECTION

• For your safety, never use the machine without a plug on the end of the

mains cable.

• For the Electronic 250 and Turbo 250 models, check that the mains voltage is

220 V before connecting the machine to the mains. If the input cable is

connected to 2 phases, the machine will be subjected to 380 V voltage. This

type of user error causes the warranty of the machine to be avoided.

• Make sure that the mains supply to the machine is grounded.

• At the end of the factory, there is a CEE 7/4 plug with 1 Phase + 1 Neutral + Earth Line at the end of

the machine's power cord.

• If the plug of the machine is damaged and becomes unusable, it may need to be replaced.

Disconnect the machine from the mains before replacing the plug. Replace the plug with a new plug

of the same type (CEE 7/4). When doing this change, do not leave the yellow earth ground blank and

connect the ground line to the new plug ground point.

• Turbo 400 and Turbo 500 models are produced with three phase plug. Since these models operate

with 2 phase 380 V mains voltage, only 2 phase connections are connected to the plug. Do not

modify the plug.

• You will see the ground screw on the rear panel of the Turbo 400 and Turbo 500 models. Ground

the ground by using a diameter and length of cable that conforms to the grounding regulations.

AC Arc Weldin Machine User Manual 13

3. PROPER OPERATION

4. MAINTENANCE AND FAULT INFORMATIONS

Always apply safety rules during maintenance and repair. The machine

must be disconnected from the mains before any maintenance or repair

work.

4.1. PERIODIC MAINTENANCE

•Periodic maintenance ensures the machine is safe, convenient and long-lasting.

•Clean all labels on the machine once every 3 months.

•Review all ports and cables every 3 months. Repair or replace any broken, worn out or

completely lost cables.

•Check every 3 months if all the moving mechanical components are fulfilled. Clean these parts

and make sure they are tight.

•Open the top cover of the machine once every 6 months and clean it with dry air. Clean the

windings of the transformer inside the machine with a soft, dry cloth if necessary. When cleaning

14 AC Arc Weldin Machine User Manual

windings, never sanders and so on. Do not use, this situation causes permanent damage such as

short circuit conditions.

•The above times are the maximum periods that should be applied if there are no problems with

your machine. Depending on the density and pollution of your work environment, you can repeat

the above-mentioned operations more frequently.

•Never connect the machine to the mains when the cover is open and do not use it.

4.2. NONPERIODIC MAINTENANCE

•The welding machine's electrode holder and earth connection must be kept clean at all times. If

these parts are dirty, rusty or oily, it is difficult for the electrode to stick to the workpiece. If this

part is damaged due to intensive use, replace it with a new one.

4.3. BASIC FAULTS AND FIXES

Problem Possible Cause Action

Cannot set output current

Potentiometer Malfunction /

(Electronic 250)

Malfunction Switch / (Turbo250)

Moving Core Fault / (Turbo400)

Disconnect the machine from

the network, then call for

service.

Output current is not good even

when lamp is on

Low mains voltage

Check if your network is rated

at the input voltage on the

rating plate.

Output cables are too long or worn

Reduce the cables to a

reasonable level and replace

with a new one if worn.

Arc starting problem, electrode

sticks to material

Dirty, oiled or painted workpiece Clean the workpiece and allow

the chassis to be transported.

The tip of the welding gun is dirty

Clean the welding pin and

ensure good conduction to the

electrode.

AC Arc Weldin Machine User Manual 15

5. MANUFACTURER AND AUTHORIZED SERVICES

MANUFACTURER : Demiriz Elektrik İnşaat San. ve Tic. Ltd. Şti.

Address : Ortaköy Sanayi Bölgesi Tiftik Sk. No 16 Silivri/İstanbul

Tel : 0212 734 39 24 – 25

Fax : 0212 734 39 28

web : www.demirizelektrik.com.tr

AUTHORIZED SERVICES

MERKEZ

SERVİS

Demiriz Elektrik İnş. San. ve Tic. Ltd. Şti.

Ortaköy Sanayi Bölgesi Tiftik Sk. No 16

Silivri/İstanbul

0212 734 39 24 – 25

HATAY

Mirioğlu Elektrik Bobinaj

Sanayi Sitesi 6. İniş 8. Cadde No 15

Antakya/Hatay

0326 221 41 12

ADANA

Öz Teknik Kaynak Mak.İnş.Malz.San.Tic.Ltd.Şti.

Yeşiloba Mah. Yeni Metal Sanayi Sitesi 46023 Sk.

No 35/A – 35/1-A Seyhan/Adana

0322 429 39 85

İSTANBUL

1

Froser Kaynak Ekp.Paz.San.ve Dış Tic.Ltd.Şti.

İ.O.S.B. Demirciler San. Sit. C1 Blok No 198

İkitelli/İstanbul

0212 549 50 70

ANKARA

Tezcan Elek. Bob. İç ve Dış Tic. Ltd. Şti. 1230/1.

Sokak No 38 Ostim Yenimahalle/Ankara

0312 354 80 21

İSTANBUL

2

Serkaynak Kaynak Mlz. ve Hırdavat

İ.O.S.B. Tormak San. Cami Pasajı No 8

Başakşehir/İstanbul

0212 485 71 20

ANTALYA

Faz Makina Bobinaj San. Tic. İnş. Ltd. Şti.

Cumhuriyet Mah. Sanayi Sitesi 663. Sk. No 18

Antalya

0242 346 58 76

İZMİR

Önder Kaynak Mak.

Ve Mlz.San.Tic.Ltd.Şti.

Kazım Dirik Mah. 340. Sk. No 15

2. Sanayi Sit. Bornava/İzmir

0232 435 43 07

BURSA

Özduran Ticaret

Küçük Sanayi Sitesi 48. Sokak No 23

Nilüfer/Bursa

0224 441 46 08

KAYSERİ

Merkez Kaynak San. Tic. Ltd. Şti.

Yeni Sanayi Bölgesi Zuhal Caddesi 20. Sokak No 3

Kayseri

0352 331 82 80

DÜZCE

Doğan üç Teknik

Kültür Mahallesi 791. Sokak No 17

Merkez/Düzce

0380 524 94 92

SAMSUN

Çalışkan Bobinaj

Eski Sanayi Sitesi Yeni Mahalle Yurtsever Cad.

No 52 Canik/Samsun

0362 228 12 14

GAZİANTEP

Tütüncüler Teknik Makine

Sanayi Mah. 60014 Nolu Cadde No 115

Şehitkamil/Gaziantep

0553 941 76 90

VAN

Özen Elektrik & Bobinaj

Koçibey Cad. No 3

Van

0432 214 22 27

Please visit our website www.demirizelektrik.com.tr for our current service list.

This manual suits for next models

3

Other Demiriz Welding System manuals

Popular Welding System manuals by other brands

Ferm

Ferm WEM1035 Original instructions

Cebora

Cebora POWER ROD 250T instruction manual

Leister

Leister FUSION 1 operating instructions

ESAB

ESAB Caddy Tig 2200i AC/DC instruction manual

Lincoln Electric

Lincoln Electric LN IM311-E Operator's manual

Lincoln Electric

Lincoln Electric Flextec 650x Operator's manual