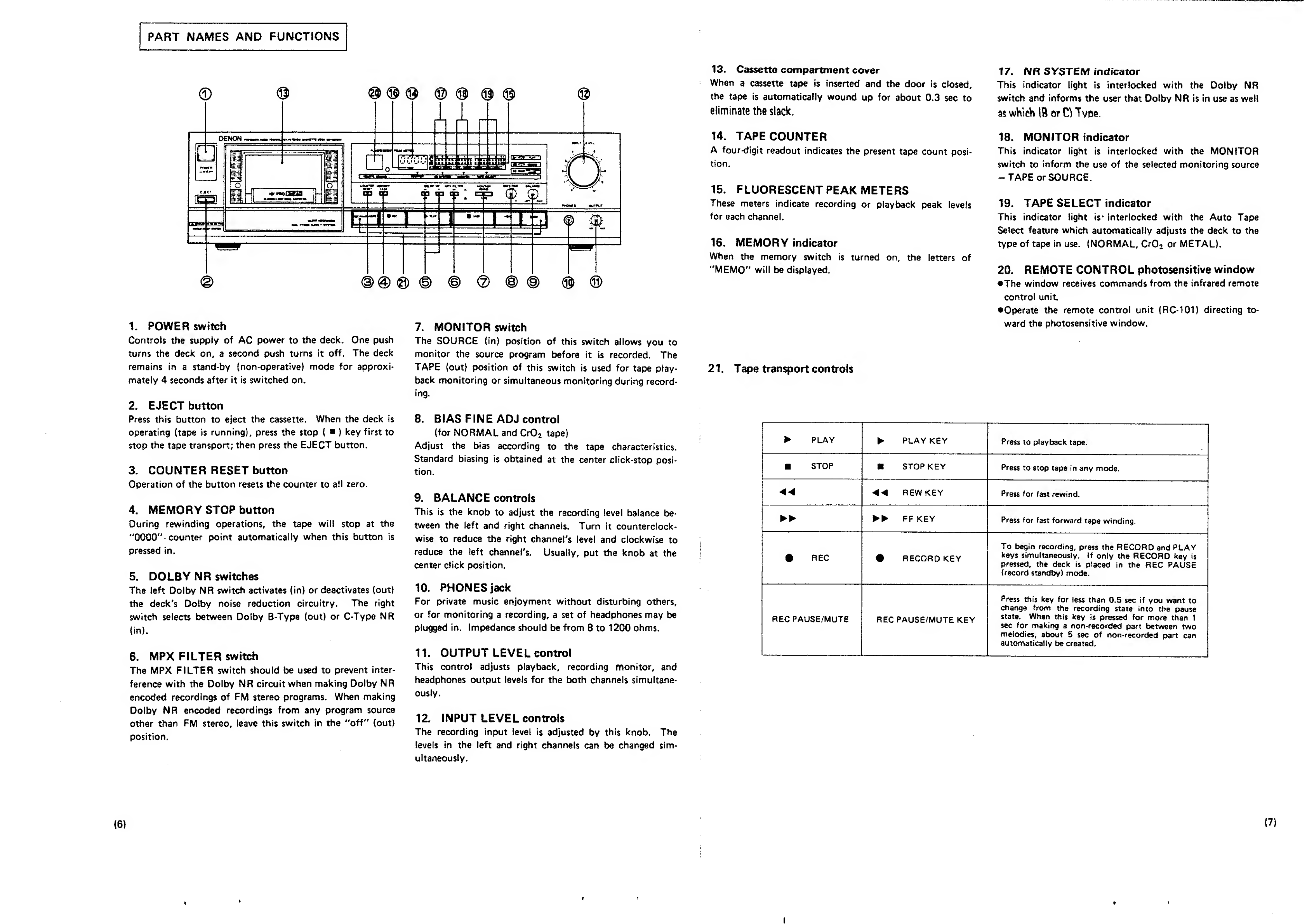

Denon DR-M3QHX User manual

Other Denon Stereo Receiver manuals

Denon

Denon AVR-2311CI User manual

Denon

Denon AVR-S940H User manual

Denon

Denon DRA-1035R User manual

Denon

Denon DRA-700AEDAB User manual

Denon

Denon AVR-S510BT User manual

Denon

Denon AVR-1507 User manual

Denon

Denon AVR-1604 User manual

Denon

Denon S-5BD User manual

Denon

Denon AVR-2311CI User manual

Denon

Denon AVR-X4200W User manual

Denon

Denon AVR-S770H User manual

Denon

Denon AVR-S940H User manual

Denon

Denon MULTEQXT AVR-4306 User manual

Denon

Denon AVR-884 User manual

Denon

Denon AVR-1708 User manual

Denon

Denon AVR-4802 User manual

Denon

Denon AVR-886 User manual

Denon

Denon AVR-550SD User manual

Denon

Denon DRR-201SA User manual

Denon

Denon AVR-S530BT User manual

Popular Stereo Receiver manuals by other brands

Sony

Sony XAV-1500 operating instructions

Radio Shack

Radio Shack DX-399 owner's manual

Sony

Sony STR-DE535 - Fm Stereo/fm-am Receiver operating instructions

Pioneer

Pioneer SX-1000TA operating instructions

Yamaha

Yamaha MusicCast TSR-5B3D owner's manual

Sony

Sony STR-DE335 - Fm Stereo/fm-am Receiver operating instructions