Denyo DCA-800SPK User manual

m o m l o i

111П1 l l l i l l i

FOR

DIESEL ENGINE-DRIVEN

AC GENERATING SET

MODEL : DCA-800SPK

По вопросам продаж и поддержки обращайтесь:

Эл. почта: dne@nt-rt.ru || Сайт: https://denyo.nt-rt.ru/

Архангельск (8182)63-90-72

Астана +7(7172)727-132

Астрахань (8512)99-46-04

Барнаул (3852)73-04-60

Белгород (4722)40-23-64

Брянск (4832)59-03-52

Владивосток (423)249-28-31

Волгоград (844)278-03-48

Вологда (8172)26-41-59

Воронеж (473)204-51-73

Екатеринбург (343)384-55-89

Иваново (4932)77-34-06

Ижевск (3412)26-03-58

Иркутск (395) 279-98-46

Киргизия (996)312-96-26-47

Казань (843)206-01-48

Калининград (4012)72-03-81

Калуга (4842)92-23-67

Кемерово (3842)65-04-62

Киров (8332)68-02-04

Краснодар (861)203-40-90

Красноярск (391)204-63-61

Курск (4712)77-13-04

Липецк (4742)52-20-81

Магнитогорск (3519)55-03-13

Москва (495)268-04-70

Мурманск (8152)59-64-93

Набережные Челны (8552)20-53-41

Нижний Новгород (831)429-08-12

Казахстан (772)734-952-31

Новокузнецк (3843)20-46-81

Новосибирск (383)227-86-73

Омск (3812)21-46-40

Орел (4862)44-53-42

Оренбург (3532)37-68-04

Пенза (8412)22-31-16

Пермь (342)205-81-47

Ростов-на-Дону (863)308-18-15

Рязань (4912)46-61-64

Самара (846)206-03-16

Санкт-Петербург (812)309-46-40

Саратов (845)249-38-78

Севастополь (8692)22-31-93

Симферополь (3652)67-13-56

Таджикистан (992)427-82-92-69

Смоленск (4812)29-41-54

Сочи (862)225-72-31

Ставрополь (8652)20-65-13

Сургут (3462)77-98-35

Тверь (4822)63-31-35

Томск (3822)98-41-53

Тула (4872)74-02-29

Тюмень (3452)66-21-18

Ульяновск (8422)24-23-59

Уфа (347)229-48-12

Хабаровск (4212)92-98-04

Челябинск (351)202-03-61

Череповец (8202)49-02-64

Ярославль (4852)69-52-93

This instruction Manual gives a detailed description of the

operation, routine inspection, maintenance, and troubleshooting

of the generator, and other items required for proper operation.

We therefore recommend that all users read this manual carefully

before actually operating the generator to ensure proper operation.

For detailed operation, disassembly, reassembly and repair of the

engine, please refer to the ’’ngine Instruction Manual” supplied

by the engine manufacture.

CONT NTS

1. PR CAUTIONS FOR SAF OP RATION

.............

1

2. SP CIFICATIONS 5

3. PARTS D SIGNATION

...........................

-

.............

8

4. PR PARATION FOR OP RATION

...............................

15

5. OP RATION

....................................................

22

6. PARALL L OP RATION

.......................................

26

7. STORAG

.......................................................

28

8. INSP CTION AND MAINT NANC — - 29

9. TROUBL SHOOTING

............................................

30

10. OUTLIN DRAWING

............................................

31

11. CONTROL AND OP RATING PAN L

...........................

32

12. G N RATOR CONN CTION DIAGRAM

.........................

33

13. S QU NC DIAGRAM

.........................................

34

14. NGIN CONN CTION DIAGRAM

..............................

35

15. SAF TY PR CAUTIONS FOR DI S L G N RATING

S TS AND QUIPM NT

.......................................

36

- 1 -

1 . PR CAUTIONS FOR SAF OP RATION

This machine is designed with highest consideration to safety.

Safest and most efficient operation, however, can be attained

by paying attention to the following items.

(1) Operate Properly

Operate the machine properly according to the Instruction

Manual to ensure- safety.

Give proper guidance in operation

In allowing other personnel to use the machine, be sure

to give them proper guidance in its operation and advise

them to read the ’’Instruction Manual” before actually

operating it.

(2) Keep Free From Moisture

The operation of the machine in a place exposed to rain,

moisture or wetness may cause electrocution. For opera

tion under such conditions, be sure to ground the machine

and the load side.

(3) Housekeeping, The First Step

Do not place any unnecessary items around the machine.

When the machine is to be located on an uneven or soft

surface, install it horizontally so that it will not

tilt during operation.

(4) Clean Carefully And Frequently

The machine must be treated properly as your business

partner. Note that the insulation of the generator may

deteriorate depending on the place where it is used. If

it is to be used in a place where dust and moisture are

excessive, be sure to clean and dry it periodically.

- 2 -

(5) Pay Attention To Sufficient Ventilation

The exhaust gas discharged from the machine contains

hazardous substances. When the machine is to be used

in such a place as a tunnel, ventilate the place thor

oughly during operation. When it is to be operated on

the road, take care that the exhaust is away from pedes

trians, nearby buildings, etc.

(6) Shut Down Operation Immediately If Any Abnormality Occurs

If the machine is found to operate improperly, or produce

any abnormal odor, noise, or vibration, immediately shut

down the operation for troubleshooting to correct the ab

normal i ty.

(7) Maintain lectrical Instrument Cables Properly

Damaged cables of the electrical instruments are very

dangerous, causing electrocution and leakage. Therefore,

if such a cable is found, immediately repair or replace it.

(8) Avoid Overloading

The generator is provided with a breaker

for overload protection, which is

breaker has been actuated, reduce the

load before restarting the machine.

(9) Never Touch The Output Terminal

Never touch the output terminal during the operation.

Be sure to shut down the operation before touching the

terminal for wiring, etc.

(10) Pay Attention To Storage And Transportation

During Inclement Weather

actuated when it is overloaded. When the

The machine is designed for dripproofing,

but not for rainproofing. When it is to be

stored or transported on an inclement day,

take care to cover it.

- 3 -

(11) Wash The Machine Carefully

Wash the machine taking care that the control panel and

the inlet and outlet ports are not exposed to water to

prevent possible failure of the internal instruments.

(12) Take Precautions Against Fire

Handle fuel, oils and antifreeze (undiluted) with care

because they are dangerous materials with high flammabili-

ty. Do not bring any naked light such as lit tobacco or a

burning match close to them. In addition, do not install

and store the machine in a place near where fire is used.

(13) Connect Securely

Damaged cables and loosened screws result in machine failu

re and electrocu-tion. Therefore, immediately repair such

cables and tighten such screws securely, if any.

(14) Perform Inspection And Maintenance Work Perfectly

Keep the machine clean and its inside

free from dust and moisture. In addition,

perform its inspection and maintenance

perfectly in accordance with the ’’Inst

ruction Manual”.

- 4 -

2 . SP CIFICATION

2-1 AC Generator

Generator model

Type

xcitation

Continuous duty rating

Vo 1 tage

Current

Frequency

Speed

Power factor

Phase

Winding connection

Insulation

Cooling system

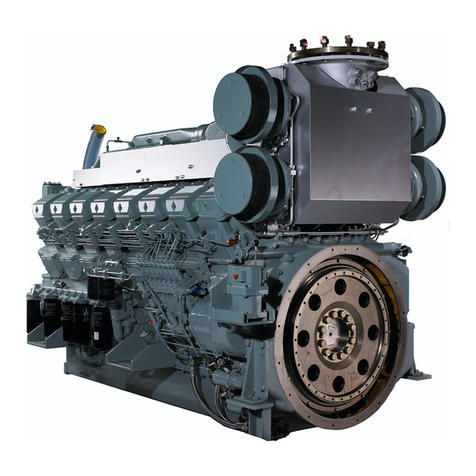

2-2 Diesel ngine

Maker and model

Rated output

No.of cylinders

Bore X Stroke

D isp 1 acement

Direction of rotation

Governor

Coo ling system

Lubricating system

Starting motor

Charging generator

Battery

Fuel

Fuel tank

Lubr i cat i ng oil

DF-8800

Rotating-field,protection type(JP20)

synchronous generator

Brushless type (with AVR)

700 / 800 KVA

200 / 220 V or (380) {415) 400 / 440 V

2021 / 2100 A or (1063){974)1010 / 1050 A

50 / 60 Hz

1500 / 1800 rpm

0.8 (lagging)

3 (4 wires)

Star

Armature-winding -- F class

Field-winding -- F class

Se 1 f-vent i1 at i on

KOMATSU LTD. SA 12V 140

4 cycle.water cooled diesel engine,direct

injection,turbocharged with aftercooler.

834 / 1000 ps. 1500 / 1800 rpm

12

140mm X 165mm

30480 cc

Clockwise (viewed from the fan side)

lectronic governor

Water cooling by radiator with fan

Gear pump

24 V - 7.5 kW X 2

24 V - 25 A

12 V - 2 0 0 A H X 4

Diesel fuel (JIS No.2 or equivalent)

Approx. 490 1

API service class (CD class or higher)

-5 -

3. PARTS D SIGNATION

3-1. Description of Devices

(1) Starter Switch

OFF/STOP

Ф STOP

Keep the switch at this position except

during operation.

This position allows the key to be inserted

into and removed from the switch.

Keep the switch standing at this position

during operation.

® START

Turn the switch to this position for start

up. When the key is released after startup,

it automatically returns to “RUN” position.

© For startup at low air temperature,set the switch at this position

until the “ PR H AT ” lamp becomes red-heated just before turning

the key to “ START ’’position.

(2) Tachometer

The tachometer indicates engine revolu

tions per minute. Set the engine speed so

that the meter indicates 1500rpm at 50Hz

and 1800rpm at 60Hz. The tachometer has

a builtin integrating hour meter.

The integrating hour meter has been set for use at 1500rpm.

Accordingly, when the meter is used at 1800rpm, it indicates

an integrated hour value approximately 20% more than the

actual operation time.

- 6 -

(3) Cooling Water Temperature Gauge

If machine is in normal operation, the in

dicator should between 75 - 95 °C . If it

indicates temperature above this range,

turn off the load and turn the speed-change

over switch to ’’L O W ” position for cold operat

ion to reduce the cooling water temperature.

(4) Lubricating Oil Pressure Gauge

If the machine is in normal operation,

the pressure gauge indicates 3~5 kg/cnf.

When the engine is cold, the pressure may

rise aboye this range just after startup.

In such cases, perform warming-up until

the normal pressure is attained.

(5) Lubricating Oil Temperature Gauge

Indicates the oil temperature of the engine oi

The temperature of 100 °C or less is recommen

ded.

(6) Fuel Level Gauge

rs ' . ■ ’ f 4

■ B*

,и»Ч

. i

fU ffc W

Indicates the fuel level in the fuel tank,

(7) Charging Ampere Meter

If the machine is normal operation, the

meter points to 0 or + range values (ind

icating its changed state ).

- 7 -

(8) Preheat Lamp

This lamp,when the key switch is turned to

“PR H AT” position,goes red-heated in about

30 seconds, indicating that the machine has

been preheated.

(9) Dust Indicator

Reset button

Red piston

When the air cleaner element is clogged,the

dust indicator’ s red piston sticks out of its

transparent portion.

In such cases,immediate 1 у replace or clean the

e 1 ement.After replacement or с Ieaning,press the

indicater button to return the red piston to

its original position.

(10) Throttle Lever

144

IUK Q I lt-E. L m K

i,i imH

O

Turn the handle toward the ’’HIGH” side to

increase the speed and toward the ’’L O W ”

side to decrease it.

(11) Battery Switch

During operation, never turn the switch to

’’O F F ” position, keeping it at ”o n ”.

If the engine is shut down, be sure to

place the switch in "OFF” position.

OFF ON

Ш - S T A R T

aibT'f v'jy?

AUTO. IDLING

(12) Speed Changeover Switch

® AUTO. IDLING

When the engine is started with the ’’SP D”

changeover switch set at this position, the

engine idles for about 20 seconds and then

automatically changes over to high-speed

operation. When starting the engine, set the

sw i tch in this position.

© LOW

When the switch is turned to this posi

tion, the engine continues to idle.

© HIGH

Turning the switch to this position relea

ses the ”automatic idling” function, allowing

the engine to be run at the speed set by the

thrott le handle.

(13) Running Caution Lamp

This lamp goes on during low-speed operation.

(14) mergency Stop Button

This is a pushbutton to stop the engine urgently on emergency

case.

Do not push the button without emergency case.

(15) Oil Filter Alarm Lamp

This lamp will go on when the oil filter is blinded.If the lamp

lights up,replace the filter element immediately.

(16) OK Monitor

This monitor indicates the following failures, if any one of them

occurs. □G2

- 9 -

© Overheat

This lamp goes on when the cooling water

temperature rises abnormally. If the lamp

goes on during operation, the emergency

stop device immediately operates to-shut

down the engine automatically.

*2».

Oi 1 Pressure Failure

If the machine is in normal operation,

this lamp stays off. When the starter

switch is turned to ’’R U N ” position to

start the engine, the lamp goes on, and

when the oil pressure rises after startup,

it goes off. If this lamp goes on during

operation ,the emergency stop device imme

diately operates to shut down the engine automatically.

After the engine stops, the lamp stays on unless the starter

switch is turned to ’’S T O P ” position.

® Fuel Leve 1 Failure

When fuel is running low, this lamp goes

И on, and the tank should be filled.

© Battery Fluid Level Failure

When battery fluid runs low, this lamp

goes on, and distilled water should be

1ЖЭР supplied to the battery.

- 10 -

(17) Frequency Meter

(18) AC Ammeter

This meter indicates the power frequency.

Make sure that the meter pointer stands

at 50 or 60Hz during operation.

The ammeter indicates the value of curr

ent flowing in the load connected. Make

sure that the current value is below that

rated. Use the ammeter change-over switch

to check each phase for current Yalue.

(19) AC Voltmeter

The voltmeter indicates the output volt

age. Make sure that the voltmeter pointer

stands at the rated voltage. Use the

voltmeter change-over switch to check

each phase for voltage value.

...

i' ' ■

\ V ' - o -

® 0 ®

(20) Voltage Regulator

This regulator is used to control the

output voltage. Turn the regulator

clockwise to increase the voltage and

counter-clockwise to decrease it.

Adjust the voltage to the rated voltage

with this regu 1 ator.

(21) Air Circuit Breaker

Refer to the item 3-2

- 11 -

(22) AC Wattmeter

Indicates output(kW) of the generator. Always

operate the generator at the rated output or less

The rated output is shown below:

50 Hz • • • • 560 kW

60 Hz .... 640 kW

Should the generator power be reversed during parallel operation,

the wattmeter will indicate negative values.

(23) Stator thermometer

Indicates the temperature of the generator

armature.

Measurement range : 30 *C to 110 *C

(24) Bearing thermometer

Indicates the temperature of the generator

bear i ng.

Measurement range : -20 'C to 60 °C

Note 1. Their thermometers display errors as below.

■ Error Displays

Temperature is below the thermometer’s measurable range.

FFF Temperature is above the thermometer’s measurable range.

Flashing — Temperature sensor’s lead wire has broken.

Flashing FFF Temperature sensor has short circuited.

Note 2. Their' s battery life is 10 years min.

Only battery cannot be changed. If the battery is dis

charged , change a complete set(disp1 ay,sensor and leadline)

- 12 -

(25) Overcurrent Relay

a) ach set value for the overcurrent relay factory-adjusted with

the performance of the generator. Do not modify any set values.

b) When the relay is actuated,the indicator(orange)is lit on to

display the cause of such actuation. Display of tripping indi

cates the phase at which the trouble current was largest. Should

the indicator display “instantaneous” .there is a large possi

bility of short circuit. In any case, check the cause.

Display of the indicator Indicator

Troubles Tr i p p i ng Instant

aneous

Phase R Phase T

Over

load

Between R and S (U-V) •——

Between S and T (V-*) —•—

Between T and R (W-U) •

(IR>IT) •

(IT>IR)

—

Between R.S and T(U-Y-ff) —

Short

с i rcu i t

Between R and S (U-V) •—•

Between S and T (V-tf) —• •

Between T and R (If-U) •

(IR>IT) •

(IT>IR) •

Between R,S and T(U-V-W) •

Note: IR=current in phase.R. IT=current in phase T.

c) A set of five L D’s provided on the surface of the relay will

indicate the operating conditions of the relay.

3-2 HANDLING TH AIR CIRCUIT BR AK R

® Circuit breaker ON button

® Circuit breaker OFF button

® Circuit breaker ON lamp

© Circuit breaker OFF lamp

( lectromagnetic operation)

1) С1 osing

The circuit breaker is closed by pressing the push button switch

“ON” on the control panel,and the circuit breaker ON lamp is lit.

- 13 -

2) Opening

The circuit breaker is opened by pressing the push button switch •

“OFF” on the control'panel,and the circuit breaker OFF lamp is lit

(Manual operation)

The air circuit breaker may be manually operated. However,limited

the manual operation to maintenance and inspection prosedures and

to emergency where it cannot be e1ectromagnetica11 у operated.

The air circuit breaker is located on the right side of the control

box. First,remove the protective cover from the control box.

•

W - i i

Ш

gzz

:o J •

Charging handle

Front panel of breaker

Ф Charging handle

© OP N-CLOS D indicator

® Spring charged indicator

© PUSH TO CLOS button

© PUSH TO OP N button

© Open position padlock lever

© Charging motor power switch

1) Spring charging operation

Pump the charging handle. When the closing springs are fully

charged,a metallic “click” will be heard and no further pumping

of the charging handle of the charging handle will be possible.

When the charging handle is pumped with its maximum stroke,about

four pumping cycles will complete the charging. Check that the

spring charged indicator shows “CHARG D” .

2) Closing operation

Open the clear shutter upward and press the PUSH TO CLOS button.

This release the charged closing springs and the breaker is closed

The OP N-CLOS D indicator shows “CLOS D” ,and the spring charged

indicator shows “DISCHARG D”

3) Opening operation

Open the clear shutter upward and press the PUSH TO OP N button.

This trips open the breaker,and the OP N-CLOS D indicator shows

“OP N” .

- 14 -

4. PR PARATION FOR OP RATION

4-1. Precautions In Installation

Install the machine horizontally on solid ground,

in addition, when the machine is to be installed in a place

where dust and salt are excessive, pay close attention to

its maintenance and care to prevent radiator clogging and

failure, and electrical-part insulation failure possibly

caused by operation under such circumstances.

(1) Precautions In Outdoor Installation

When the machine is to be install outdoors such as on the

road, pay attention to the wind direction and the exhaust

port position so that the exhaust gas it away from pedest

rians and nearby' bu i ldings.

(2) Precautions In Indoor Installation

Ф Leave enough space for easy operation and control on the

contrо 1-pane 1 side ( at least 1 m )

© Leave enough space for engine inspection, lubrication,

connection of cable to the load, fuel supply and other

operations both on the right and left sides viewd from

the control panel (at least 1 m ).

® Install an exhaust pipe so that exhaust gas is discharged

through it to an open area.

® Leave enough space for exhaust of warm air discharged

through the radiator, supply of water to the radiator,

and arrangement of the exhaust pipe above the machine.

© Note that the connection of the generator to indoor

wiring not only infringe the law, but also may cause

electrocution or generator failure.

© Note that the machine can be installed directly on a found

ation such as concrete.

© Install the machine in such a place as can be thoroughly

ventilated to prevent a considerable rise in the indoor

temperature, which has an adverse effect on the engine

generator.

- 15 -

4-2. Check Before Startup

Be sure to check the Machine especially for the follwing

points before startup to minimize machine failure.

(1) Check Oil

ж Be sure to check the oil level before startup every day.

rll

L m

L

О

Good Too high Too low

Note : Some engine manufactures provide a level gauge with

such 11/L marks on both sides, which allows the oil

level to be checked during idling. When using such

a level gauge, carefully check which of the two H/L

marks is used at downtime or during idling,

ж Check engine oil with an oil level gauge to see that the

oil level is in between marks H and L of the level gauge,

and replenish or replace it if necessary,

ж For oil replenishment, supply a given amount of oil from

the oiling port provided on the engine.

ж After a specified amount of oil engine is supplied, run

the engine for several minutes and then stop it to check

again to see that the oil level stands in between marks

H and L of a level gauge.

Notes : For specified quantity of lubricating oil,refer

to the Specifications Table.

(2) Check Cooling Water

Put water

to ’’F U L L ”

- 16 -

In checking or supplying cooling water, make sure that the

engine is cold. For cooling water in winter, refer to the

’’n g i n e Instruction Manual”.

Use tap water as cooling water and put it up to the root of

the filling port, some machines are provided with a reserve

tank, put tap water in it up to the ’’F U L L ” mark.

In setting the radiator cap after the cooling water check

or supply, take.care to turn it clockwise to full position

so that the radiator can be used with its inside kept in a

pressurized state. Insecurely-tightend radiator cap may

result in serious engine trouble.

Notes : For specified quantity of cooling water, refer to

the Specifications Table.

(3) Check Fan Belt

Check the belt for tention and elongation. Adjust them if

necessary. If any abnormality is found on the belt, re

place it. Perform the adjustment and replacement as dire

cted in ’’ngine Instruction Manual”.

The belt tention is considered to be

proper if the flexing level is within

10-15 mm when the arrow-indicated portion

(belt center) is pressed with the thumb

(approximately 6kg).

(4) Check Fuel

Be sure to check the fuel level before startup to prevent

fuel shortage during operation. Occasionally remove sedi

ment and contaminated water collected in the bottom of the

fuel tank by loosening its drain plug.

Frequency 50Hz 6011z

Fuel Consumption(1/hr) 138 165

- 17 -

(5) Check Generator Case Grounding

When the generator is installed in a moist place, or on

highly conductive material such as iron plates or steel

work, be sure to connect the grounding wire terminal

provided near the output terminal block and bury the wire

50 cm or deeper in the ground securely.

Do not directly ground terminal ”0 ”.

Recomended grounding wire sectional area: 5.5 ш nf or larger

(6) Check For Water And Oil Leakage

Check the engine periphery for water and oil leakage. If

such leakage is found, identify the leak spot and repair it

(7) Check Bolts And Nuts For Looseness

Check bolts and nuts, especially on the air cleaner,

muffler and turbo-charger mounting portion, for looseness

and tighten them if necessary.

(8) Check lectrical Wiring For Disconnection, Short And Ter

minal Looseness.

50cm or more

Grounding wire

Case grounding terminal

18 -

4-3. Load Connection

In connecting a load, tighten locking bolts securely with

a spanner, etc. to prevent burning.

(1) Three-phase Output

Use U/V/ff for three-phase load

200/220V or 400/440V

(380V)

{415V}

U V W

V V V

Use 0/U,0/V,0/W for single-phase load

115/127V or 231/254V

(220V)

{240V}

Use U/V,V/ff,W/U for single-phase load

200/220V or 400/440V

(380V)

{415V}

- 19 -

Table of contents