2

Do not hold the motor output shaft or motor lead wires. This may

cause injury.

Keep the area around the motor free of combustible materials in

order to prevent fire or a skin burn(s).

To prevent the risk of damage to equipment, leave nothing around

the motor that would obstruct ventilation.

To prevent bodily injury, do not touch the rotating parts (output

shaft, cooling fan) of the motor during operation.

When an abnormality is noted, turn off the power immediately, or

fire, electric shock or injury may occur.

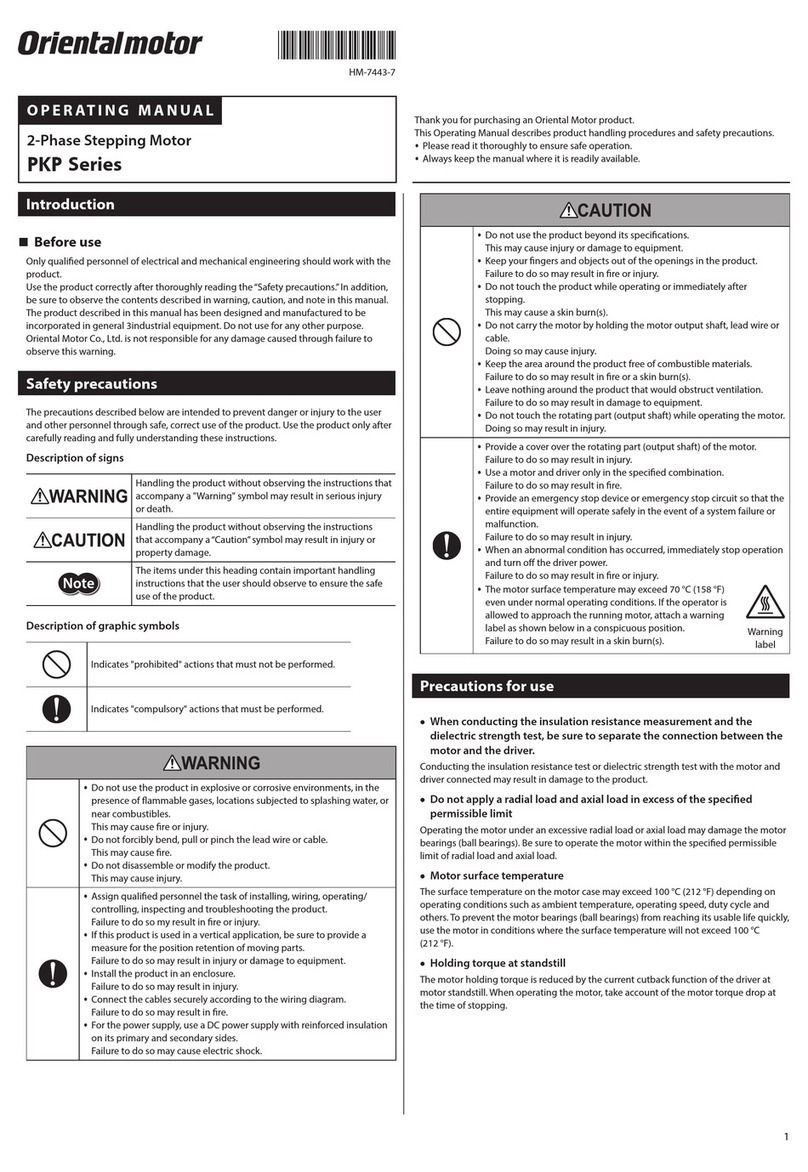

The motor’s surface temperature may exceed 70 °C

(158 °F), even under normal operating conditions. If a

motor is accessible during operation, post the

warning label shown in the figure in a conspicuous

position to prevent the risk of skin burn(s).

Warning

label

To dispose of the motor, disassemble it into parts and components

as much as possible and dispose of individual parts/components

as industrial waste.

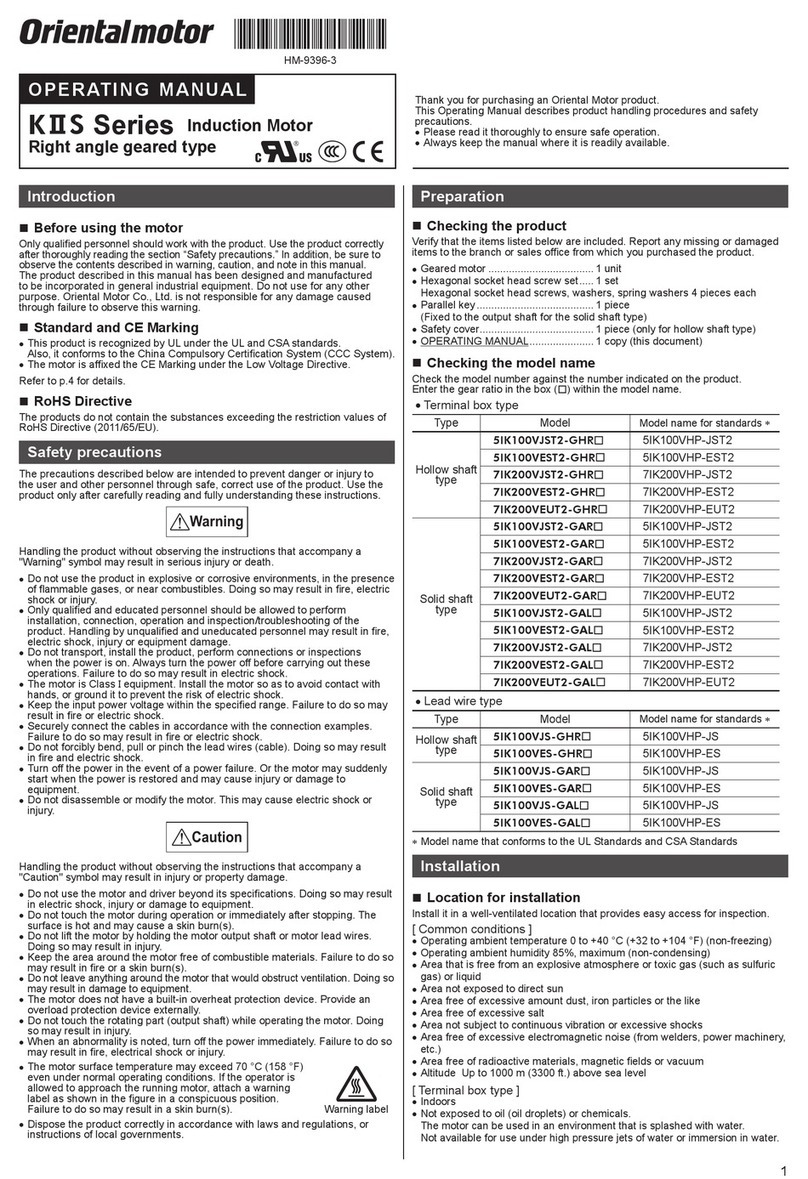

Preparation

Checking the product

Verify that the items listed below are included. Report any missing or

damaged items to the branch or sales office from which you purchased the

product.

• Motor............................... 1 unit

• Capacitor.........................1 piece (only for single-phase motors)

• Capacitor cap..................1 piece (only for single-phase motors)

• Operating manual...........1 copy

Checking the model name

Check the model number against the number indicated on the product.

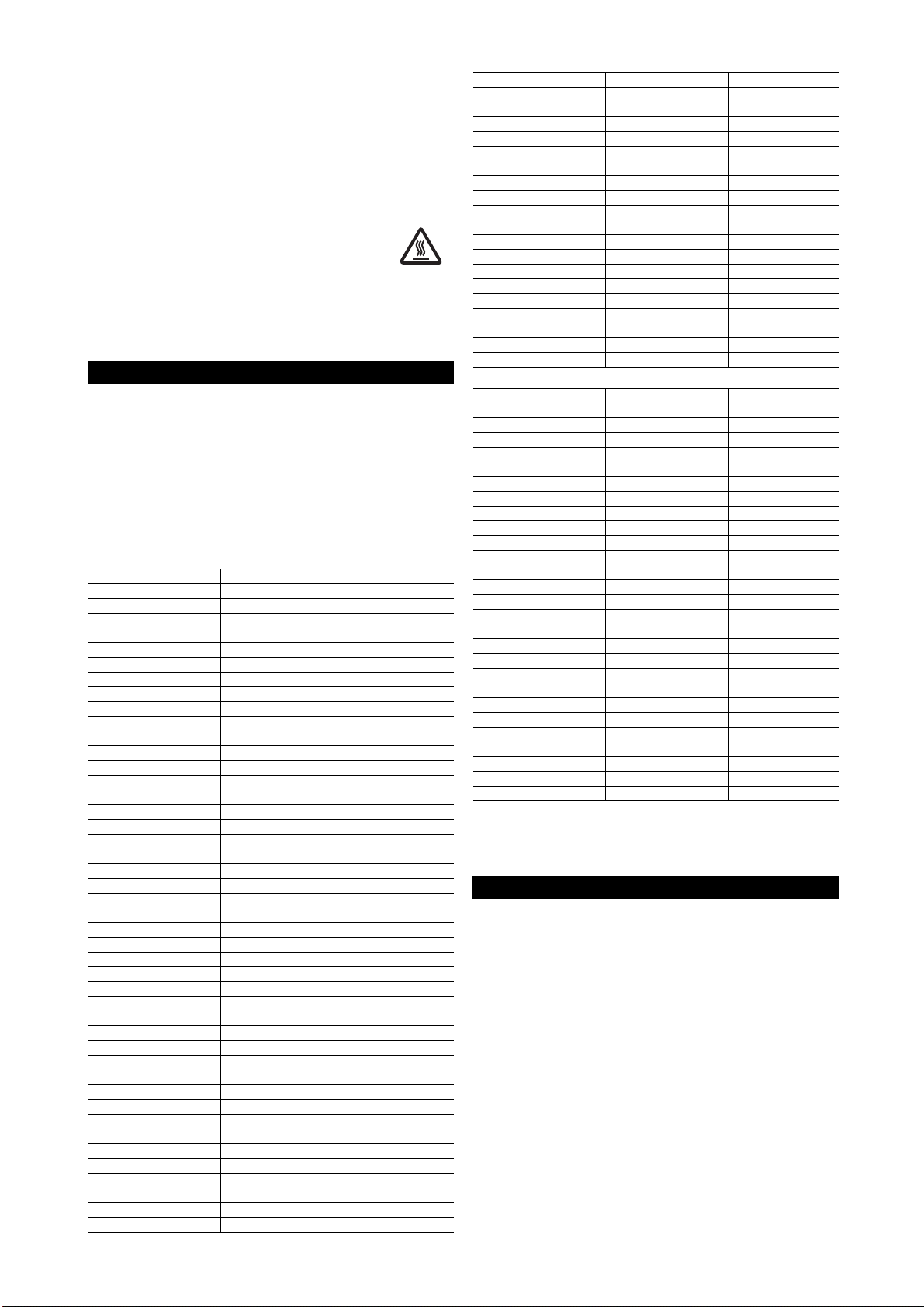

●Induction motors

Model Motor model Capacitor model

0IK1GN-AW2J 0IK1GN-AW2 CH15FAUL

0IK1GN-AW3U 0IK1GN-AW3 CH10FAUL

0IK1GN-CW2J 0IK1GN-CW2 CH035BFAUL

0IK3GN-BW2J 0IK3GN-BW2 CH18FAUL

0IK3GN-BW3U 0IK3GN-BW3 CH15FAUL

0IK3GN-DW2J 0IK3GN-DW2 CH045BFAUL

2IK6GN-AW2J 2IK6GN-AW2 CH35FAUL2

2IK6GN-AW2U 2IK6GN-AW2 CH25FAUL2

2IK6GN-CW2J 2IK6GN-CW2 CH08BFAUL

2IK6GN-CW2E 2IK6GN-CW2 CH06BFAUL

3IK15GN-AW2J 3IK15GN-AW2 CH55FAUL2

3IK15GN-AW2U 3IK15GN-AW2 CH45FAUL2

3IK15GN-CW2J 3IK15GN-CW2 CH15BFAUL

3IK15GN-CW2E 3IK15GN-CW2 CH10BFAUL

4IK25GN-AW2J 4IK25GN-AW2 CH80CFAUL2

4IK25GN-AW2U 4IK25GN-AW2 CH65CFAUL2

4IK25GN-CW2J 4IK25GN-CW2 CH20BFAUL

4IK25GN-CW2E 4IK25GN-CW2 CH15BFAUL

4IK40A-BW2J∗4IK40A-BW2∗CH90CFAUL2

4IK40A-BW2U∗4IK40A-BW2∗CH75CFAUL2

4IK40A-DW2J∗4IK40A-DW2∗CH23BFAUL

4IK40A-DW3E∗4IK40A-DW3∗CH18BFAUL

4IK60A-BW2J∗4IK60A-BW2∗CH140CFAUL2

4IK60A-BW2U∗4IK60A-BW2∗CH100CFAUL2

4IK60A-DW2J∗4IK60A-DW2∗CH30BFAUL

4IK60A-DW3E∗4IK60A-DW3∗CH25BFAUL

5IK40GN-AW2J 5IK40GN-AW2 CH110CFAUL2

5IK40GN-AW2U 5IK40GN-AW2 CH90CFAUL2

5IK40GN-CW2J 5IK40GN-CW2 CH30BFAUL

5IK40GN-CW2E 5IK40GN-CW2 CH23BFAUL

5IK60GE-AW2J 5IK60GE-AW2 CH200CFAUL2

5IK60GE-AW2U 5IK60GE-AW2 CH180CFAUL2

5IK60GE-CW2J 5IK60GE-CW2 CH50BFAUL

5IK60GE-CW2E 5IK60GE-CW2 CH40BFAUL

5IK60A-BW2J∗5IK60A-BW2∗CH160CFAUL2

5IK60A-BW2U∗5IK60A-BW2∗CH140CFAUL2

5IK60A-DW2J∗5IK60A-DW2∗CH40BFAUL

5IK60A-DW3E∗5IK60A-DW3∗CH30BFAUL

5IK90GE-AW2J 5IK90GE-AW2 CH280CFAUL2

5IK90GE-AW2U 5IK90GE-AW2 CH200CFAUL2

5IK90GE-CW2J 5IK90GE-CW2 CH70BFAUL

5IK90GE-CW2E 5IK90GE-CW2 CH60BFAUL

5IK90A-BW2J∗5IK90A-BW2∗CH280CFAUL2

5IK90A-BW2U∗5IK90A-BW2∗CH250CFAUL2

Model Motor model Capacitor model

5IK90A-DW2J∗5IK90A-DW2∗CH70BFAUL

5IK90A-DW3E∗5IK90A-DW3∗CH60BFAUL

5IK150A-BW2J∗5IK150A-BW2∗CH400CFAUL2

5IK150A-BW2U∗5IK150A-BW2∗CH300CFAUL2

5IK150A-DW2J∗5IK150A-DW2∗CH100BFAUL

5IK150A-DW3E∗5IK150A-DW3∗CH80BFAUL

2IK6GN-SW2 2IK6GN-SW2 −

3IK15GN-SW2 3IK15GN-SW2 −

4IK25GN-SW2 4IK25GN-SW2 −

4IK25GN-UW2 4IK25GN-UW2 −

5IK40GN-SW2 5IK40GN-SW2 −

5IK40GN-UW2 5IK40GN-UW2 −

5IK60GE-SW2 5IK60GE-SW2 −

5IK60GE-UW2 5IK60GE-UW2 −

5IK60A-TW2∗5IK60A-TW2∗−

5IK90GE-SW2 5IK90GE-SW2 −

5IK90GE-UW2 5IK90GE-UW2 −

5IK90A-TW2∗5IK90A-TW2∗−

5IK150A-TW2∗5IK150A-TW2∗−

●Reversible motors

Model Motor model Capacitor model

0RK1GN-AW2J 0RK1GN-AW2 CH18FAUL

0RK1GN-AW3U 0RK1GN-AW3 CH12FAUL

0RK1GN-CW2J 0RK1GN-CW2 CH045BFAUL

2RK6GN-AW2J 2RK6GN-AW2 CH45FAUL2

2RK6GN-AW2U 2RK6GN-AW2 CH35FAUL2

2RK6GN-CW2J 2RK6GN-CW2 CH10BFAUL

2RK6GN-CW2E 2RK6GN-CW2 CH08BFAUL

3RK15GN-AW2J 3RK15GN-AW2 CH75CFAUL2

3RK15GN-AW2U 3RK15GN-AW2 CH60CFAUL2

3RK15GN-CW2J 3RK15GN-CW2 CH18BFAUL

3RK15GN-CW2E 3RK15GN-CW2 CH15BFAUL

4RK25GN-AW2J 4RK25GN-AW2 CH100CFAUL2

4RK25GN-AW2U 4RK25GN-AW2 CH80CFAUL2

4RK25GN-CW2J 4RK25GN-CW2 CH30BFAUL

4RK25GN-CW2E 4RK25GN-CW2 CH25BFAUL

5RK40GN-AW2J 5RK40GN-AW2 CH160CFAUL2

5RK40GN-AW2U 5RK40GN-AW2 CH120CFAUL2

5RK40GN-CW2J 5RK40GN-CW2 CH40BFAUL

5RK40GN-CW2E 5RK40GN-CW2 CH35BFAUL

5RK60GE-AW2J 5RK60GE-AW2 CH250CFAUL2

5RK60GE-AW2U 5RK60GE-AW2 CH200CFAUL2

5RK60GE-CW2J 5RK60GE-CW2 CH60BFAUL

5RK60GE-CW2E 5RK60GE-CW2 CH50BFAUL

5RK90GE-AW2J 5RK90GE-AW2 CH350CFAUL2

5RK90GE-AW2U 5RK90GE-AW2 CH300CFAUL2

5RK90GE-CW2J 5RK90GE-CW2 CH80BFAUL

5RK90GE-CW3E 5RK90GE-CW3 CH70BFAUL

The list above shows pinion shaft motors.

For the round shaft motor, “GN” and “GE” in the model and motor model

are replaced by “A” (The models and motor models indicated by ∗are only

available in the round shaft specification).

Installation

Location for installation

The motor is designed and manufactured for installation in equipment.

Install it in a well-ventilated location that provides easy access for inspection.

The location must also satisfy the following conditions:

• Inside an enclosure that is installed indoors (provide vent holes)

• Operating ambient temperature

−10 to +40 °C (+14 to +104 °F) (non-freezing)

−10 to +50 °C (+14 to +122 °F) for 100 V/200 V (Excluding the 1 W and

3 W types)

• Operating ambient humidity 85%, maximum (non-condensing)

• Area that is free from an explosive atmosphere or toxic gas (such as

sulfuric gas) or liquid

• Area not exposed to direct sun

• Area free of excessive amount dust, iron particles or the like

• Area not subject to splashing water (storms, water droplets), oil (oil

droplets) or other liquids

• Area free of excessive salt

• Area not subject to continuous vibration or excessive shocks

• Area free of excessive electromagnetic noise (from welders, power

machinery, etc.)

• Area free of radioactive materials, magnetic fields or vacuum

• 1000 m (3300 ft.) or less above sea level