1

Introduction

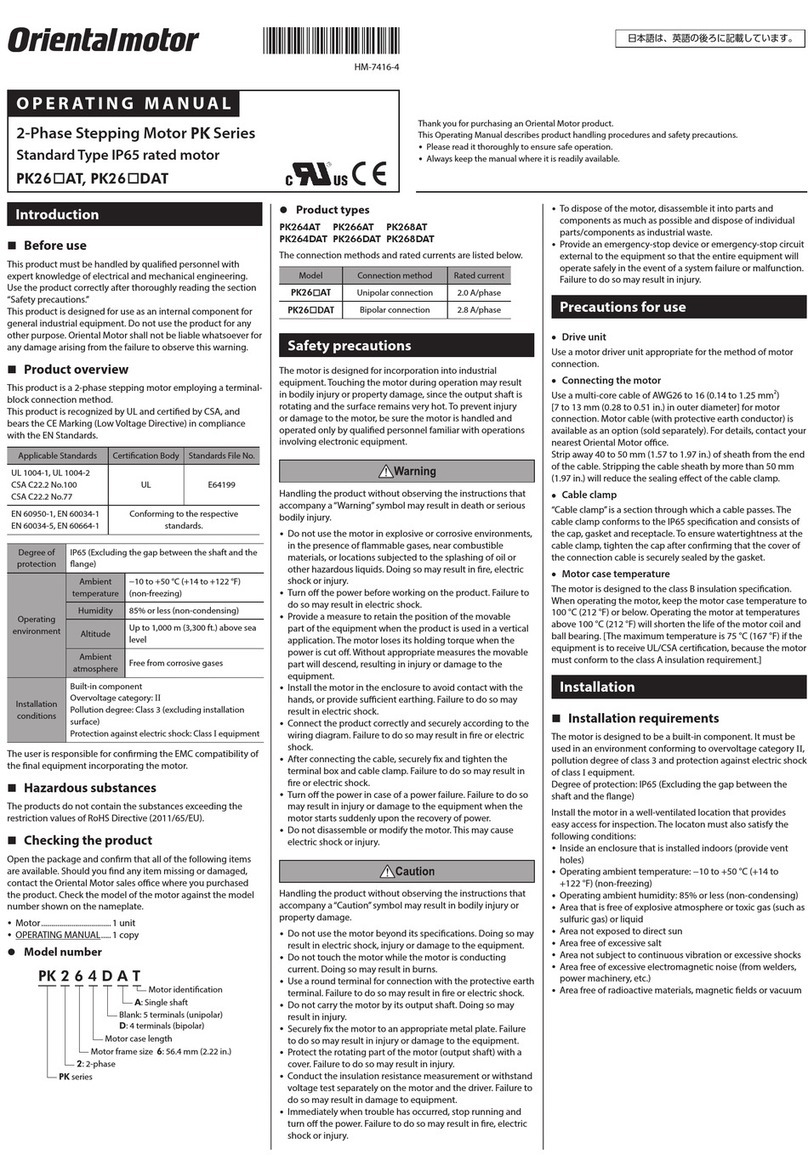

Before using the motor

Only qualied personnel should work with the product. Use the product correctly

after thoroughly reading the section “Safety precautions.” In addition, be sure to

observe the contents described in warning, caution, and note in this manual.

The product described in this manual has been designed and manufactured

to be incorporated in general industrial equipment. Do not use for any other

purpose. Oriental Motor Co., Ltd. is not responsible for any damage caused

through failure to observe this warning.

Standard and CE Marking

This product is recognized by UL under the UL and CSA standards.

Also, it conforms to the China Compulsory Certication System (CCC System).

The motor is afxed the CE Marking under the Low Voltage Directive.

Refer to p.4 for details.

RoHS Directive

The products do not contain the substances exceeding the restriction values of

RoHS Directive (2011/65/EU).

Safety precautions

The precautions described below are intended to prevent danger or injury to

the user and other personnel through safe, correct use of the product. Use the

product only after carefully reading and fully understanding these instructions.

Warning

Handling the product without observing the instructions that accompany a

"Warning" symbol may result in serious injury or death.

Do not use the product in explosive or corrosive environments, in the presence

of ammable gases, or near combustibles. Doing so may result in re, electric

shock or injury.

Only qualied and educated personnel should be allowed to perform

installation, connection, operation and inspection/troubleshooting of the

product. Handling by unqualied and uneducated personnel may result in re,

electric shock, injury or equipment damage.

Do not transport, install the product, perform connections or inspections

when the power is on. Always turn the power off before carrying out these

operations. Failure to do so may result in electric shock.

The motor is Class І equipment. Install the motor so as to avoid contact with

hands, or ground it to prevent the risk of electric shock.

Keep the input power voltage within the specied range. Failure to do so may

result in re or electric shock.

Securely connect the cables in accordance with the connection examples.

Failure to do so may result in re or electric shock.

Do not forcibly bend, pull or pinch the lead wires (cable). Doing so may result

in re and electric shock.

Turn off the power in the event of a power failure. Or the motor may suddenly

start when the power is restored and may cause injury or damage to

equipment.

Do not disassemble or modify the motor. This may cause electric shock or

injury.

Caution

Handling the product without observing the instructions that accompany a

"Caution" symbol may result in injury or property damage.

Do not use the motor and driver beyond its specications. Doing so may result

in electric shock, injury or damage to equipment.

Do not touch the motor during operation or immediately after stopping. The

surface is hot and may cause a skin burn(s).

Do not lift the motor by holding the motor output shaft or motor lead wires.

Doing so may result in injury.

Keep the area around the motor free of combustible materials. Failure to do so

may result in re or a skin burn(s).

Do not leave anything around the motor that would obstruct ventilation. Doing so

may result in damage to equipment.

The motor does not have a built-in overheat protection device. Provide an

overload protection device externally.

Do not touch the rotating part (output shaft) while operating the motor. Doing

so may result in injury.

When an abnormality is noted, turn off the power immediately. Failure to do so

may result in re, electrical shock or injury.

The motor surface temperature may exceed 70 °C (158 °F)

even under normal operating conditions. If the operator is

allowed to approach the running motor, attach a warning

label as shown in the gure in a conspicuous position.

Failure to do so may result in a skin burn(s). Warning label

Dispose the product correctly in accordance with laws and regulations, or

instructions of local governments.

HM-9396-3

OPERATING MANUAL Thank you for purchasing an Oriental Motor product.

This Operating Manual describes product handling procedures and safety

precautions.

Please read it thoroughly to ensure safe operation.

Always keep the manual where it is readily available.

KⅡS Series Induction Motor

Right angle geared type

Preparation

Checking the product

Verify that the items listed below are included. Report any missing or damaged

items to the branch or sales ofce from which you purchased the product.

Geared motor .................................... 1 unit

Hexagonal socket head screw set ..... 1 set

Hexagonal socket head screws, washers, spring washers 4 pieces each

Parallel key ........................................ 1 piece

(Fixed to the output shaft for the solid shaft type)

Safety cover ....................................... 1 piece (only for hollow shaft type)

OPERATING MANUAL ...................... 1 copy (this document)

Checking the model name

Check the model number against the number indicated on the product.

Enter the gear ratio in the box (o) within the model name.

Terminal box type

Type Model Model name for standards

Hollow shaft

type

5IK100VJST2-GHRo5IK100VHP-JST2

5IK100VEST2-GHRo5IK100VHP-EST2

7IK200VJST2-GHRo7IK200VHP-JST2

7IK200VEST2-GHRo7IK200VHP-EST2

7IK200VEUT2-GHRo7IK200VHP-EUT2

Solid shaft

type

5IK100VJST2-GARo5IK100VHP-JST2

5IK100VEST2-GARo5IK100VHP-EST2

7IK200VJST2-GARo7IK200VHP-JST2

7IK200VEST2-GARo7IK200VHP-EST2

7IK200VEUT2-GARo7IK200VHP-EUT2

5IK100VJST2-GALo5IK100VHP-JST2

5IK100VEST2-GALo5IK100VHP-EST2

7IK200VJST2-GALo7IK200VHP-JST2

7IK200VEST2-GALo7IK200VHP-EST2

7IK200VEUT2-GALo7IK200VHP-EUT2

Lead wire type

Type Model Model name for standards

Hollow shaft

type

5IK100VJS-GHRo5IK100VHP-JS

5IK100VES-GHRo5IK100VHP-ES

Solid shaft

type

5IK100VJS-GARo5IK100VHP-JS

5IK100VES-GARo5IK100VHP-ES

5IK100VJS-GALo5IK100VHP-JS

5IK100VES-GALo5IK100VHP-ES

Model name that conforms to the UL Standards and CSA Standards

Installation

Location for installation

Install it in a well-ventilated location that provides easy access for inspection.

[ Common conditions ]

Operating ambient temperature 0 to +40 °C (+32 to +104 °F) (non-freezing)

Operating ambient humidity 85%, maximum (non-condensing)

Area that is free from an explosive atmosphere or toxic gas (such as sulfuric

gas) or liquid

Area not exposed to direct sun

Area free of excessive amount dust, iron particles or the like

Area free of excessive salt

Area not subject to continuous vibration or excessive shocks

Area free of excessive electromagnetic noise (from welders, power machinery,

etc.)

Area free of radioactive materials, magnetic elds or vacuum

Altitude Up to 1000 m (3300 ft.) above sea level

[ Terminal box type ]

Indoors

Not exposed to oil (oil droplets) or chemicals.

The motor can be used in an environment that is splashed with water.

Not available for use under high pressure jets of water or immersion in water.