Desert Aircraft DA85 User manual

O

Ow

wn

ne

er

r’

’s

sM

Ma

an

nu

ua

al

l

7-

07

Safety Instructions

WARNING!

This motor can cause severe harm to you, and/or others, if misused or if

these safety precautions and instructions are not observed. Desert Aircraft is not

respons

ible for any loss, injury or damage resulting from the miss

-

use of

this product.

You alone are responsible for the safe operation of your motor.

Do not operate the motor if you do not want to be completely responsible for any damage or injury

incurred or

caused during its

operation.

Read all instructions before operating your motor.

If you have any questions about any aspect of operating this motor, do not attempt to start or

operate it.

Never operate the motor, or fly, alone.

When operating the motor,

never stand, or allow anyone else to stand, in front of, or to the side of

the propeller. Always stand behind the propeller.

Keep away from the prop while operating the motor. Do not wear loose clothing near the motor or

prop. Do not run the motor near l

oose material such as dirt, gravel, power cords, ropes, sand, etc.

Loose material can be drawn into the turning prop causing injury or damage.

Always operate the motor in an open area. Do not operate indoors.

This motor can develop tremendous thrust. Make sure the aircraft is properly secured when starting

or operating the motor.

This motor can stop at any time, for a variety of reasons. Do not fly your plane in a way that damage

or harm will result if the motor stops running.

Inspect motor mount bolts a

nd firewall integrity before operating the motor.

Anyone in the immediate area of the motor should use eye protection during operation of the motor.

Keep spectators at least 30 feet away when operating the motor.

Turn off the motor before making any adjust

ments.

Always use the proper size propeller. Never use a damaged, modified

,

or repaired propeller.

Always use the correct length propeller bolts. Do not use spacers behind the propeller.

Spinner cones must not touch the propeller.

Thin

ner props may r

equ

ire using shorter prop bolts, especially if not using

a spinner back plate.

M

ake sure your prop bolts do not bottom out in the propeller hub.

Check that the propeller bolts are tight before every flight.

Always install an ignition kill switch to stop the

motor.

Adjust the carburetor linkage so that the motor will stop when the carburetor is completely closed.

Gasoline is extremely flammable. Be careful of any sparks from electrical contacts such as fuel

pumps, battery chargers, etc. Do not allow smoking

in the area of your fuel supply or motor. Store

fuel in approved containers and in well ventilated areas.

Allow the motor to cool before touching or fueling.

Always turn the prop a few revolutions after running the motor to discharge the ignition system.

The ignition system develops extremely high voltage. Do not touch it during operation.

1

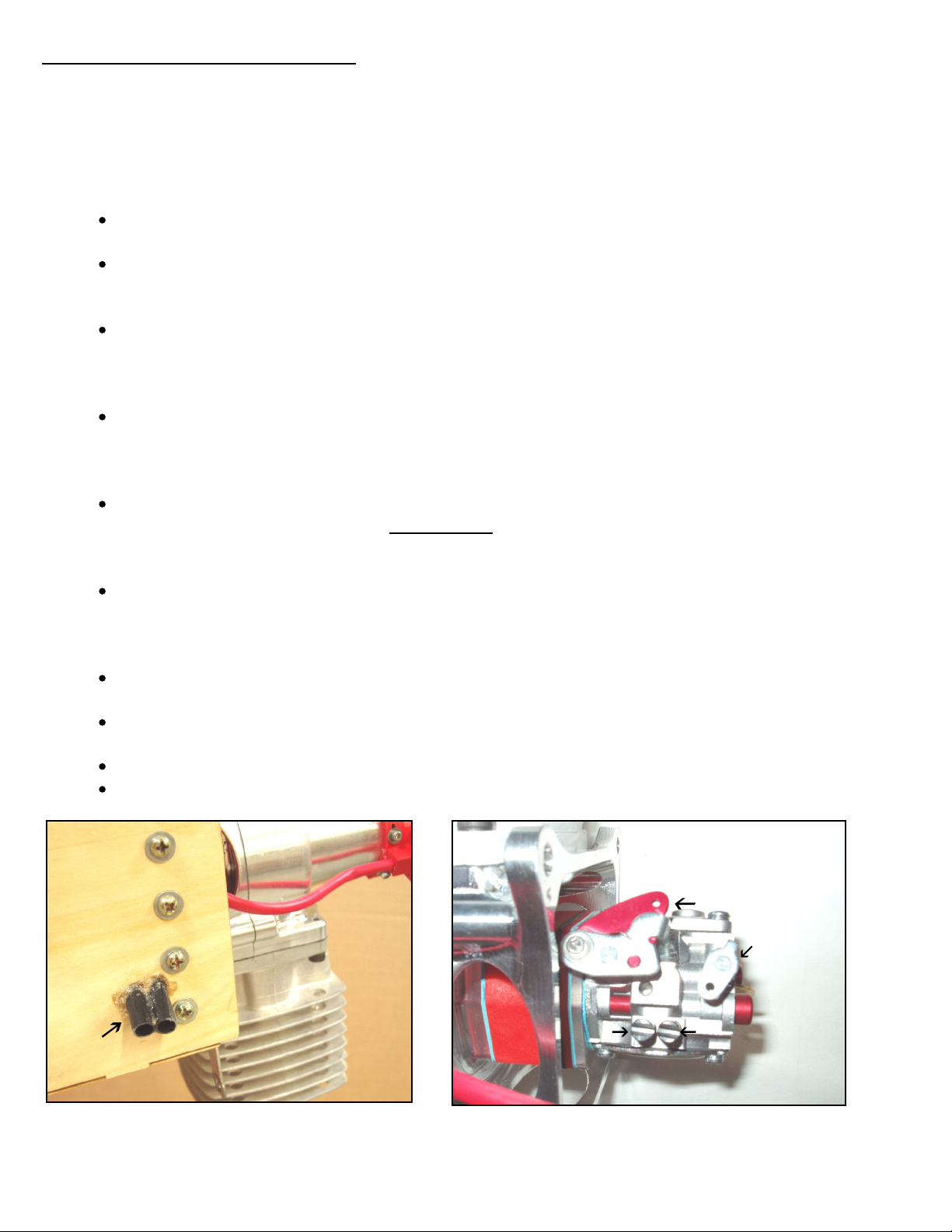

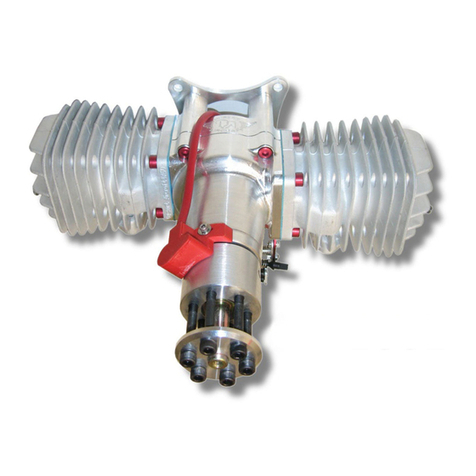

Mounting the Engine

The DA85

features a rear induction carburetor tha

t is intended to protrude or breath

e

through the fire wall.

While mounting and initial setup of the engine and with the carb through the firewall can take some extra

work, t

his carburetor location provides a stable air environment for consistent high perf

ormance, while

greatly reducing

carburetor noise

.

If the firewall/motor box is to far back, it can be extended using by adding a layer or layers of

aircraft plywood, or extending the motor box with aircraft plywood.

We do not recommend using standoffs o

r spacers to mount the DA85.

Vibration and stress to

the engine case increase when standoffs are used. Damage from using standoffs or spacers will

not be covered under warranty.

If you still elect to use

shims or spacers between the rear of the engine and

the firewall

, make

sure that the

mounting faces of all the spacers or shims

are flush

with the rear of the engine

. If

the

face of all spacers

are not in the same plane

or

perfectly flush with the rear mounting face of

the motor, the crankcase

may be

damag

ed.

Again, this will not be covered under warranty.

Make sure the carburetor has adequate clearance near the inlet to allow an unobstructe

d airflow

into the carburetor. If the carburetor is located in front of

a former or firewall,

be sure there is at

lea

st

1” (25mm) of clearance from the carburetor inlet. If

there is less than 1” clearance,

make a

hole larger than the carburetor inlet diameter in the

former or

firewall.

The throttle arm is tapped for a 2

-

56 SA

E ball link.

If you wish, the

throttle

return

spring can be

released

or cut on one end, but

not removed

.

Without the spring,

vibration will wear and damage

the shaft and carb plate

. This wear/damage will allow air and fuel to enter the engine when in the

closed position

, resulting in an unreliable id

le and

er

ratic throttle control

.

The choke lever can be actuated

by

hand with a small light weight pus

hrod

or by a small servo

behind the firewall. There are two arms on the choke shaft. One is re

-

moveable and can be

repositioned to give proper geom

etry fo

r

linkage access from the bottom or rear.

Do not remove

the detent ball and spring on the choke shaft.

We do not recommend soft mounting the engine as it can cause

problems with exhaust systems

and carburetor linkages.

If the carb

ure

tor is enclosed, guide

tubes

pointed directly at each needle

can be installed to

allow easy needle adjustments with a narrow screw driver. (

See photo

)

Make sure firewall and/or motor box are secure.

Check the mounting bolts regularly to insure they are tight.

Throttle arm

C

hoke arm

s on b

oth sides

L

H

Needle valve adjustment

guide tubes

2

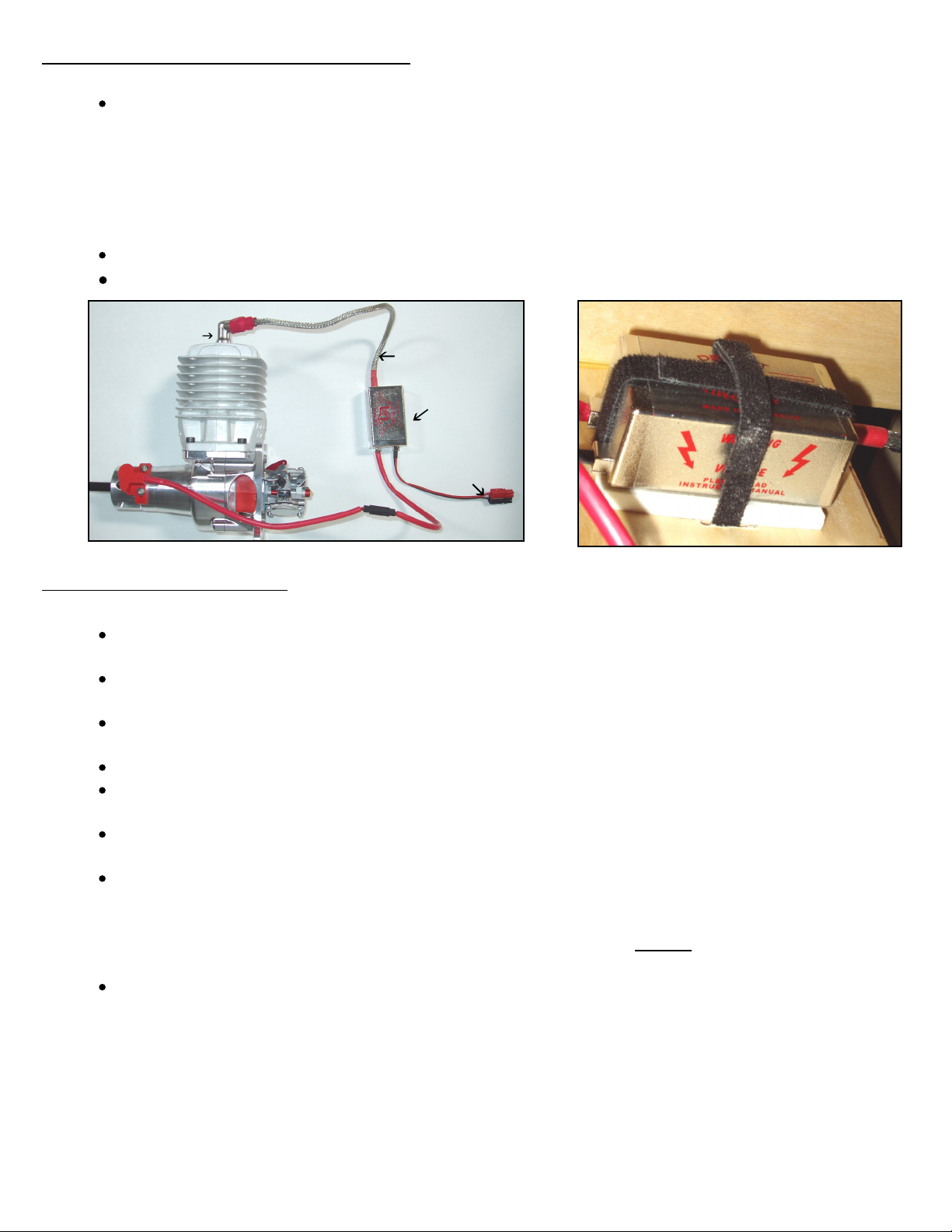

Ignition System

When making electrical connections to the ignition system, use the same gauge wire (or larger

)

as

used on the red and black power leads on the ignition module, all the way to the battery pack.

Keep wire lengths to a minimum. Please use the heavy

-

duty connector plugs supplied with the

ignition or something similar.

Use

a high quality switch such as a Futaba or JR heavy

-

duty switch.

Small

size R/C receiver

switches are not recommended.

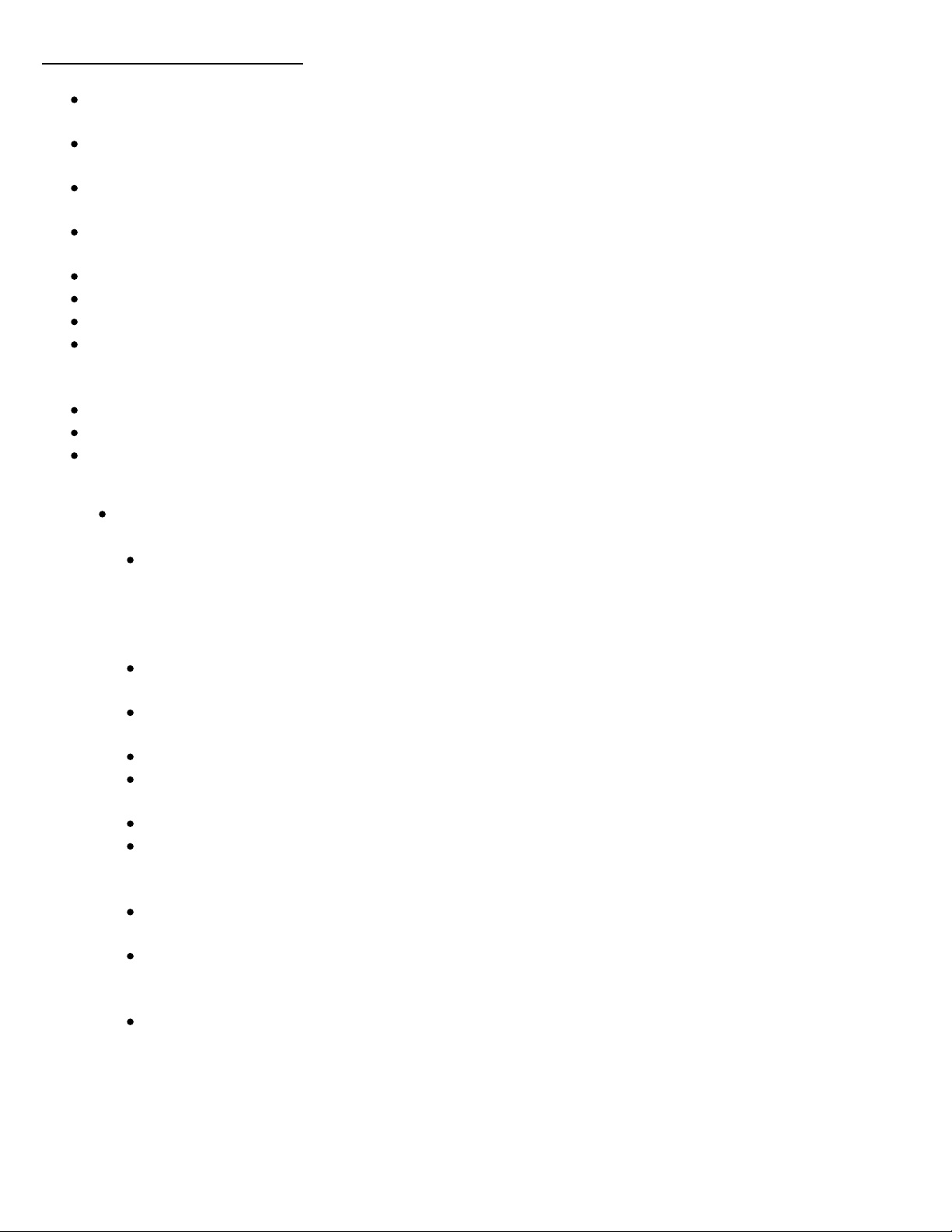

The ignition module must be soft mounted to prevent vibration damage.

DO NOT HARD

MOUNT OR USE DOUBLE SIDED TAPE!

Zip ties can also be to

o firm.

We recommend Velcro

fabric

s

traps (

T

he sew on type material). Slots are cut in the motor box, bulkhead, or mounting

plate

allowing the Ve

l

cro strapping to be threaded through and then wrapped around the

module.

Place a piece of high density foam

rubber between the ignition and the mounting

surface.

If Zip tie

s

are going to be used, wrap the module in foam rubber first.

Isolate the charge circuit from the ignition while charging the batteries. In other words, don’t

“charge” the ignition module

while charging the battery.

Most receiver switches do this

automatically

.

Use 4.8

volt 4 cell,

or 6.0 volt

5 cell battery pack

s only.

(We see

no

significant difference in

engine performance between the two.)

While the ignition

unit is rated for 4.8 to 6 vo

lt packs

, it

will handle

the

higher voltage they actually produce, including the high “peak” voltage right after

charging.

Higher voltage

batteries

will damage the ignition system and will void the warranty.

We recommend a 1500 mAh or larger pack. With t

his size pack, the ignition pack should

typically

last longer tha

n your receiver pack will. If a standard no load

meter shows 5.0 volts or

less, don’t fly. Re

-

charge.

Use a 5.2 to 6.0 volt regulator on pack

s

rated above 6.0 volts.

When connecting the red

pick

-

up sensor to the ignition module, make sure that the

polarity of the wires entering the connectors is correct (Brown to brown, orange to

orange)

Unlike some ignitions, the Desert Aircraft ignition is designed to spark only when the prop is

flipped at

a high speed. If the prop is not turned over at “starting” speed, the ignition will not fire.

This helps to prevent the motor from firing accidentally. Unless you are having problems starting

the motor,

we

don’t

recommend

“testing” the ignition with t

he plug removed from the cylinder.

Do not operate the ignition without a spark plug properly installed in the cap! Doing so

will damage the ignition!

W

hen removing the spark plug cap

, PULL STRAIGHT out on the cap,

not the shielded ignition

wire!

Do not us

e pliers to grip the plug cap! If the cap seems loose, and is not making a solid

metal-

to

-metal contact with the spark plug base, contact Desert Aircraft for a replacement.

To

prevent radio interference, the spark plug caps must have the split retainer ri

ng around their

base

–

DON’T FLY WITHOUT THEM!

Protect t

he shielded plug wire

from rubbing against fiberglass

or sharp edge

s

of wood or

metal!

Rubber grommets and plastic “spiral wrap” insulation from automotive or electronic

supply stores work well

to pr

otect your braided shielding

. Holes in the braided shielding can

emit R/F noise (i.e: RADIO INTERFERENCE!) Damaged plug wires are not replaceable and

may require the ignition to be replaced!

Protect them!

Keep ignition components and wiring separated as

much as possible from your receiver,

receiver battery, servos, wiring and switches.

Don’t use metal

-

to

-

metal l

inkages to operate the throttle or choke.

Timing is set at the factory and should not need adjustment. Contact Desert Aircraft if you have

any qu

estions regarding timing.

Only use

NGK CM-6

spark plugs. Other plugs may not fit the plug caps firmly and cause poor

running or radio interference.

3

Ignition System

(Cont’d)

Always per

form a radio range check before flying.

Range

check the radio system according

to the radio manufacturer’s guidelines

with the

engine off, then with the engine running. The

operational radio range should be nearly the same.

If there are “glitches”, DON’T FLY!

Check for holes in the braided shielding or lo

ose connections (spark plug cap to spark plug

,

all

connectors, and switches). If that doesn’t solve the problem, re-

locate your ignition and receiver

components farther apart. If the problem persists,

return the ignition to Desert Aircraft for

inspection.

If your radio has a failsafe, program the throttle to close in Failsafe mode.

Plug gap is .018” to .020” (.45mm to .50mm)

Soft mount ignition module

Plug cap

S

hiel

ded plug wire

Velcro

Module

Timing sensor

Connector to switch and battery

Foam

Sensor c

onnector

Fuel and Oil Mix

Low octane

pump

gas

oline

is recommended. High

er

octane gasoline can actually lower

performance unless a

tuned exhaust system

is used.

We recommend purchasing your fuel from “

name

brand” gas stations. We have seen problems

with

cheaper

gas from some discount type outlets.

We recommend filtering your fuel between your fuel container and your plane’s fuel tank.

A high

flow filter, or clunk/

filter, between the tank and motor is also a good idea.

Make sure the plane’s tank is well vented and the fuel clunk moves

freely.

Use of any other fuel or additives such as

nitro formulas, aviation gas, white gas, etc.,

can harm the motor and void the war

ranty.

Do not use any silicon sealers on the fuel system. Gas can break it down and carry it into the

carburetor.

For Break

-

in

, we recommend a petroleum

-

based oil such as Lawn Boy

Ashless

or Pennzoil Air

Cooled 2 stroke oil at 32:1 ratio. Run at least 2

to 4 gallons of petroleum oil/gas mix for break

-

in.

This allows the ring

to seat quickly without blow by.

Use a pr

op that allows peak RPM

over

6,2

00

d

uring the break

-

in process.

The High needle can be s

et

just

slightly

rich during break

-

in.

Too

rich will

cause problems with excess

residue and

carbon

build up.

After the break

-

in process,

we recommend a high quality synthetic oil. As for brand of oil,

there are many good ones on the market. Some oils, and their mix ratios, that Desert Aircraft

recommends

are: Amsoil Saber Professional (100 to 1),

Red

-line Two Stroke Racing Oil (40 to

1)

, Bel

-

Ray H1

-

R (50 to 1).

Mobil

MX2T (32 to 1) These oils can be found at most motorcycle

shops.

4

Recommended Props

Always tighten prop bolts and inspect your prop and spinner before each flight!

A

void large/heavy load props during the break

-

in period.

Regardless of siz

e or brand, it is important

to not overload the engine during break-

in. Check the rpm on the first run

and make sure it is

around

6,200 rpm

or higher

. B

e

more concerned about overloading the engine than over revving it.

The optimum prop for your aircraft w

ill depend on exhaust type, airframe weight, airframe size/drag,

altitude, and your flying style.

After break

-in, we have found the optimum static RPM range for good

performance is 6,000

to 6,700 depending on prop and exhaust selection.

Some recommend

ed

break

-

in props are:

Menz 26x10, Mejzlik

26x10, Mejzlik

27x10TH, 24x10 Mejzlik 3 blade

Some recommended props after break

-i

n are all of the above as well as

:

26x12 Mejzlik, 26x12 Menz, 26x10 Xoar,

25x12 AirModels 3 blade

.

If a tuned pip

e system is used, all props listed above can be used along with:

27x10 Mejzlik, 27x10 Menz,

27x10, Xoar,

28x10 Mejzlik

, 24x12 Mejzlik 3 blade, 24x12W Mejzlik

3 blade.

Lower rpm normally equals less prop and engine noise, but less power.

A 3

blade prop just over

6,000 RPM can be very quiet.

Smaller diameter props (less tip speed) and more pitch (more

load/less rpm) will reduce noise. 3 blade props normally have less diameter and more load from the

pitch and extra blade. This normally makes the

m the quietest props.

2 blade prop

s

above 6,

4

00 rpm will develop a lot of power.

You may find that you prefer the higher

revving break

-in size props, even after break-

in.

A general rule of thumb

for good flight performance

is the larger and/or heavier t

he plane, the lighter

the prop load to allow the engine to create more horse power. On a lighter/smaller/cleaner airframe

horsepower requirements are not as critical

. Y

ou may enjoy the benefits of a larger prop disc

for

better down line braking, torque rol

ling, etc.

Always use a drill guide to drill your props.

We normally drill from the back side, then again from the

front to insure the screws don’t bind in the holes.

Always check the balance of your prop.

For safety, we recommend painting the tips of y

ou props (front and back) with a bright color,

especially black props.

Never use a damaged or repaired prop, or a prop that has struck the ground or any other object.

Damage that can be hard to see could turn into disaster when turning at thousands of RP

M.

5

Starting

Avoid

running the engine without the wings installed on the fuselage. Without the mass of the

wings, vibration will be very pronounced.

Check that prop bolts are tight and spinner is secure.

Mak

e sure the starting area is free of dirt, sand, gavel, or other loose debris

Always wear a heavy leather glove when starting the engine.

Turn on the radio system and check the throttle operation and position.

Have someone (with eye protection) firmly hold

the plane.

1.

Close the choke completely.

2.

Open the throttle to approximately 1/8 position.

3.

Turn on the ignition.

ALWAYS BE PREPARED FOR THE ENGINE TO START ON ANY FLIP OF

THE PROP, whether the ignition switch is on or off! Flipping the prop with the ignit

ion off may flood

the engine.

4.

Give the prop a quick, firm, flip counter clockwise. Follow through quickly as you flip the prop so

your hand swings out of the props path. Repeat until the engine fires or “pops”.

Flip the prop

one

more time.

5.

Open the chok

e.

6.

Set throttle to idle position. (carburetor butterfly plate

just

slightly open)

7.

Flip the prop again until the engine

fires and

runs.

8.

Let the engine warm up for 15 to 20 seconds before advancing the throttle.

Th

e engine may not need to be cho

ked

if the

engine is re

-started shortly after the previous run.

If the engine becomes flooded, removing or “pinching

”

the fuel line

while flipping the prop quickly will

help to dry things out. The spark plug can also be removed to speed the process.

Needle Adjustme

nts

The needle farthest

to the rear of

the engine is the “High End” needle. The needle closest to the

engine is the “Low End” needle. Turning the needles clockwise “leans” the fuel mixture. Turning

the needles counter

-

clockwise “richens” the fuel mixtu

re.

Settings will vary with altitude, temperature, humidity, fuel, carburetor variances, etc. A general

starting point is:

1-1/2

open on the

L

ow needle,

1-1/2

open on the

H

igh needle.

Adjust the High needle to peak rpm. A tachometer is a great help, but

remember that the

peak

RPM

usually

drop

s

a little bit after every start due to heat build up. Don’t lean the mixture any more

than necessary. If the rpm steadily drops at full throttle or fades on long vertical maneuvers, the

engine is too lean and is ov

er heating.

Adjust the Low needle until you achieve a smooth idle and a reliable transition to high throttle.

Generally if the engine “stutters” or “coughs” in the mid range or when the throttle is advanced, the

Low end is too rich and possibly even the High needle. If the engine dies quickly

or sags during

transition

, the Low end is probably lean.

Note: The low needle flows a small amount of fuel through

the entire RPM range. Adjusting the low needle can have a slight effect on the higher RPM range.

Wh

ile it is possible for the DA85 to idle below 1,000 RPM, an idle setting around 1,500 RPM insures

a more reliable idle and throttle transition. Prop size has a big effect on the idle characteristics.

Set the High needle

only

slightly rich during break

-

in.

Operating the engine overly rich

not only

reduces power, it creates other problems such as poor transition, pre-

mature carbon build

-

up,

fouled plugs, excessive exhaust residue, sticking rings, and overall rough running.

6

Trouble Shooting

Motor w

on’t start

:

Possibly flooded:

The DA

85

normally only needs to be choked for the first start of the day. Over

choking can cause flooding.

Check battery voltage (should be at least 5.0

+ volts) and all ignition connections, wiring, and

switches.

Check for breaks near all connectors, crimp joints or solder joints.

Voltage regulators can fail intermittently or totally. If using a voltage regulator

, try

testing with a 4 or

5 cell pack witho

ut the

regulator

.

Check tank venting, clunk position, and fuel flow.

Check all fuel lines for kinks, pin holes,

or damage.

Does fuel move toward the carburetor when the prop is flipped?

If fuel isn’t moving towards the carburetor, is the choke plate comple

tely closing? Is the carburetor

or carburetor mount loose causing an air leak? Look for fuel

seepage around the carburetor

mounting area.

Is the throttle set at idle or slightly higher after engine “pops”

and choke is opened?

Make sure prop is flipped over with authority. The ignition won’t fire at low speed.

If a lot of fuel drips from the carburetor, the engine may be flooded. If so, remove and dry

spark

plug

, or replace it

. Try starting again without using the choke

.

Motor runs poorly

or stops

:

R

ough running can be an indication that t

he engine might be too rich. Make sure both

needle

s

are adjusted to peak performance. Due to changes in air pressure and air flow in

the cowl when the plane is flying, the needles may need to be adjusted to deal wi

th

in flight

performance, not just the way the engine runs on the ground.

This may take several ground

adjustments and flight tests.

Make sure carburetor has not come loose causing an air leak in the carburetor mounting

area. Look for fuel seepage.

If you

r radio has a Battery Failsafe option

, the throttle can stop working momentarily when

the receiver battery voltage drops.

Check that the fuel clunk is intact and can move freely to the correct tank position.

Check all ignition connections and switches care

fully. Faulty switches and contacts can

cause momentary loss of ignition power due to vibration and harness movement during flight.

Check Ignition battery voltage.

If the engine

runs poorly and the

RPM tops out at

3,000 to 4,000 RPM

, make

sure that the

po

larity of the wires entering the connectors is correct (Brown to brown, orange to orange)

.

The connectors can be forced together the wrong way.

Make sure

your

fuel is fresh. Changes in atmospheric cond

itions can cause water

condensation in gas cans and ta

nks. Look for water in your fuel can and plane’s fuel tank.

Needle settings may need adjustment when the engine is moved from one plane to another

or cowl configurations

are

changed.

This is because even slight changes in air flow can

change the tuning of

the carburetor.

Make sure the choke stays open during flight. Vibration and a heavy unsecured choke

linkage can cause the choke to close under high G

-

loads.

7

Maintenance

Being a high performance 2 stroke engine, certain parts can wear quickly. Under normal operation,

pistons, piston rings, needle bearings, spark plugs, etc. may need occasional non

-

warranty

replacement to insure peak p

erformance.

Screws can come loose!

After a few flights check that all screws are secure.

Periodically check

that

all screws are tighten

ed t

o the correct torque rating.

Size

Torque spe

cifications

Spark plug:

CM

-

6, 10mm 90 in. lbs.

Steel p

rop bolts:

M5x 50mm

65 in. lbs.

/

wood props, 80 in. lbs.

/

carbon props.

Steel c

rankcase bolt

s:

M5x

16

mm

130 in. lbs.

Steel c

ylinder base bolts:

M5x

16

mm

160 in. lbs.

Alum. alloy c

arb mount bolts:

M5x

75mm

6 in. lbs.

*

*Caution

:

Care must be taken to not over tighten the

carb mounting

bolts. Over tig

htening can

distort and damage the injected molded reed valve parts and rubber gaskets.

Use a 4m hex wrench for all M5 screws.

For spinner mounting, the crankshaft extension is threaded for M5 screws. In this application (steel

to steel) the 10

-

32 SAE screws supplied with most spinners will work fine in the M5 threaded hole.

Do not substitute 10

-

32 screws for any other screws on the engine!

Inspect the engine periodic

al

ly for any signs of fuel seepage. This can indicate an air l

eak which can

create a lean fuel/

air ratio, which in turn can caus

e er

ratic running and engine damage.

If tightening

the appropriate screws does not cure the problem, contact Desert Aircraft.

After prolonged use, carbon deposits can build up on top of the

piston and on the combustion dome

of the cylinder. Great care must be taken when trying to remove these carbon deposits to avoid

damaging the parts. Once an attempt is made to remove carbon has been made, the task must be

completed, as any remaining carbo

n may be loosened and can dislodge while the engine is

running. This can damage the engine and/or bridge the spark plug.

Manuals may be updated with additional tips and trouble shooting info from time to time

. Please

check our web site for downloadable m

anuals and

updates.

IF ANY PROBLEM PERSISTS, PLEASE CONTACT

DESERT AIRCRAFT FIRST!

We designed and manufactured your engine and have serviced and trouble shooted thousands more. We

cover your engine’s warranty, not someone at the field or a stranger on t

he Internet. Please give us the

opportunity to help!

8

DA85 WARRANTY

Your DA85

engine and ignition system are covered with a 2 year warranty by Desert

Aircraft, starting from

the date of purchase.

This warranty covers defects in workmanship and materials only.

Being a high

performance 2 stroke engine, certain parts can wear quickly. Under normal operation,

pistons, piston rings, needle bearings, spark plugs, etc. may need occa

sional non

-

warranty replacement to insure peak performance.

Do not disassemble the engine or ignition system

. Disassembly of th

e engine or

ignition system can

void the warranty on that item.

Any modifications to the engine, or the ignition system, other than those authorized by

Desert Aircraft, will void this warranty.

This warranty does not cover the following:

Normal wear of any parts.

Damage caused by improper handling, operation, modifications, or maintenance.

Damage caused by a crash.

Damage caused b

y using improper fuel or additives.

Damage incurred during transit to Desert Aircraft (pack carefully!)

Shipping expenses to and from Desert Aircraft for warranty service.

DESERT AIRCRAFT WILL NOT SHIP ANY

WARRANTY

REPLACEMENT

ITEMS

UNTIL DEFECTIVE ITEMS

IN QUESTION ARE RECEIVED BY

DESERT AIRCRAFT

Please be sure to pack any items sent us carefully

to prevent any shipping damage

.

Enclose the item(s) in a plastic bag(s) and then wrap with protective bubble wrap. Bagged

parts, ignitions, etc, can be taped

to larger items so they don’t get “lost” in the packing

material. Use a box with ample room.

Be sure to include your contact information as well as

a description of the problem.

Desert Aircraft

1815 S. Research Loop

Tucson, AZ 85710

Ph 520 722 0607

Fax

520 722 5622

Email

Web

www.desertaircraft.com

Office hours are 9 am to 5 pm Arizona time.

9

Repair/Return For

m

Please make copy

P

lease fill out and enclose this form when shipping items for service

Customer Name_________________________________ Date___________

Address________________________________________________________

City______________________ State______ Zip_________ Co

untry________

Phone #_________________ Cell #__________________

Email _________________________

Items in Box:

DA

50 Serial #

__________ DA8

5 Serial #__________DA100 Serial #__________

DA

150

Serial

#__________

Single

Ignition

Serial # ________

Twin

Ignition S

erial # ________

Prop Bolts? __________

Prop washer? ________

Muffler(s)? ___________

Standoffs? ____________

Other Items? __________

REASON FOR RETURN? ___________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

______________________________________________________________

__________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

Oil used? ___________

Gas t

ype? _____________

Exhaust system type? ____________

Has the engine been sent in for service before? _______Why?

__________________

________________________________________________________________________

________________________________________________

________________________

DESERT AIRCRAFT

1815 S. Research Loop

Tucson, AZ 85710

520 722 0607

www.desertaircraft.com

Table of contents

Other Desert Aircraft Engine manuals

Desert Aircraft

Desert Aircraft DA120 User manual

Desert Aircraft

Desert Aircraft DA170 User manual

Desert Aircraft

Desert Aircraft DA35 User manual

Desert Aircraft

Desert Aircraft DA100 User manual

Desert Aircraft

Desert Aircraft DA-215 User manual

Desert Aircraft

Desert Aircraft DA200 User manual

Desert Aircraft

Desert Aircraft DA50 EFI User manual

Desert Aircraft

Desert Aircraft DA100-I User manual

Desert Aircraft

Desert Aircraft DA 100 EFI User manual