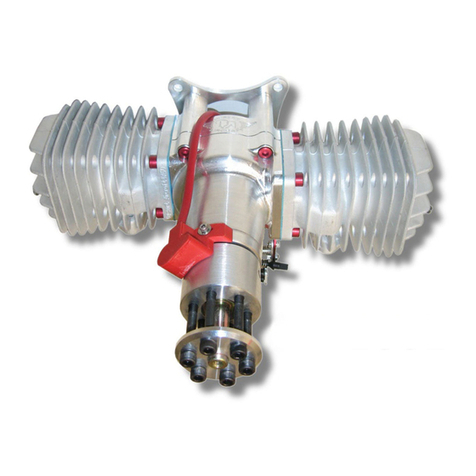

Desert Aircraft DA-215 User manual

T

TM

M

D

DA

A2

21

15

5

Owners Manual 10/19

Safety Instructions

READ THIS!

WARNING!

This motor can cause severe harm to you, and/or others, if misused or if these safety

precautions and instructions are not observed. Desert Aircraft is not responsible for

any loss, injury or damage resulting from the misuse of its products.

You alone are responsible for the safe operation of your motor.

This motor can stop at any time, for a variety of reasons. Do not fly your plane in such

a way that damage or harm will result if the motor stops running. If you cannot fly your

plane safely if the motor stops running for any reason, do not fly the plane.

Do not operate the motor if you do not want to be completely responsible for any damage or injury

incurred or caused during its operation.

Read all instructions before operating your motor.

If you have any questions about any aspect of operating this motor, do not attempt to start or

operate it.

Never operate the motor, or fly, alone.

When operating the motor, never stand, or allow anyone else to stand, in front of, or to the side of

the propeller. Always stand behind the propeller.

Keep away from the prop while operating the motor. Do not wear loose clothing near the motor or

prop. Do not run the motor near loose material such as dirt, gravel, power cords, ropes, sand, etc.

Loose material can be drawn into the turning prop causing injury or damage.

Always operate the motor in an open area. Do not operate indoors.

This motor can develop tremendous thrust. Make sure the aircraft is properly secured when starting

or operating the motor.

Inspect motor mount bolts and firewall integrity before operating the motor.

Anyone in the immediate area of the motor should use eye protection during operation of the motor.

Keep spectators at least 30 feet away when operating the motor.

Turn off the motor before making any adjustments.

Always use the proper size propeller. Never use a damaged, modified, or repaired propeller.

Always use the correct length propeller bolts. Do not use spacers behind the propeller.

Spinner cones must not touch the propeller.

Thinner props may require using shorter prop bolts, especially if not using a spinner back plate.

Make sure your prop bolts do not bottom out in the propeller hub.

Check that the propeller bolts are tight before every flight.

Always install an ignition kill switch to stop the motor.

Adjust the carburetor linkage so that the motor will stop when the carburetor is completely closed.

Gasoline is extremely flammable. Be careful of any sparks from electrical contacts such as fuel

pumps, battery chargers, etc. Do not allow smoking in the area of your fuel supply or motor. Store

fuel in approved containers and in well ventilated areas.

Allow the motor to cool before touching or fueling.

Always turn the prop a few revolutions after running the motor to discharge the ignition system.

The ignition system develops extremely high voltage. Do not touch it during operation.

Never use a damaged or repaired prop, or a prop that has struck the ground or any other object.

Damage that can be hard to see, could turn into disaster when the prop is turning at thousands of

RPM.

1

Motor Installation

Mount the motor using high grade 1/4" or 6mm dia. bolts with washers and locking nuts on the rear

of the firewall. Make sure your firewall is structurally sound. The crankshaft centerline is in the exact

center of the rear mounting plate bolt pattern.

Make sure the carburetor's idle set screw is removed or set so that the carb can be fully closed by

the servo at low trim. Use a high quality servo for the throttle. A poor quality servo or linkage will not

provide accurate and repeatable throttle settings. Don't use metal to metal linkages.

You can un-hook, but don't remove, the throttle return spring if the motor is not going to be bench

run. The spring helps to limit shaft wear due to vibration.

Do not try to rotate the carburetor 180 deg. on the mounting block, or remove the butterfly shaft

assembly.

The carburetor should have at least 1”(25mm) of clearance between the intake and the bottom of the

cowl. If there is less than 1", make an opening in the cowl below the carb at least as large as the

carb intake diameter.

Since the carburetor must often be adjusted differently with the cowl on as compared to off, we

recommend small access holes be made in the cowl for adjusting the needle valves with a long,

narrow, screw driver. Sometimes the needles can be reached through the cowl's openings for the

exhaust system.

A 50 oz. fuel tank (Approx 10 minute flight time) is the minimum size recommended. The tank must

be vented. The carb has a strong pump, so the tank can be mounted almost anywhere in the

airframe. The fuel line and tank stopper must be gas compatible. Do not use any silicone sealers on

the fuel system. Gas can break it down and carry it into the carb.

The inner diameter of the fuel tubing should be the same or larger than the carburetor's fuel inlet

fitting's inner diameter. 1/8” I.D. is recommended. Make sure all fuel line connections are secure.

Small nylon zip ties work well to keep the fuel line on the metal fittings. Make sure the fuel line is

secure and not touching the exhaust or cylinder fins. An inline fuel filter can be used, but we prefer

filter the fuel entering the fuel tank from your field container.

Cooling is critical to motor performance and longevity. Allow as much cooling air as

possible in through the front inlets of the cowl. Provide an outlet opening approximately 2

1/2 times larger than the intake at the bottom rear of the cowl for the hot air to escape. Most

factory outlet openings are not large enough! A lip or air dam protruding down and rearward

from the leading edge of the air out let will create negative air pressure (suction) to help pull

hot air out of the cowl.

Air must flow through the cylinder fins, not just inside the cowl, to properly cool the motor.

Don't let the air take the easy way out! Use ducting to make it go through the fins. Round

cowls with large frontal openings still need ducting to direct the air through the cylinder fins

Air ducts can be made from thin plywood, balsa, fiberglass, or aluminum sheet to guide and force air

from the front inlets to and through the cylinder fins.

Depending on the location of the exhaust system, and cowl airflow, the carburetor may need some

air cooling also. A hot carb can be erratic in flight or make the motor hard to restart. Sometimes

placing heat shielding material between the exhaust and carburetor can help.

Keep components like the ignition system, fuel tank, fuel lines, receivers, etc, shielded from heat

generated by canister and tuned pipe exhaust systems. Hot fuel tanks and fuel lines can cause

frustrating tuning issues, and over heated electronic components can have intermittent problems or

total failures.

2

Ignition System

When making electrical connections to the ignition system, use the same gauge wire (or larger) as

used on the red and black power leads on the ignition module, all the way to the battery pack. Keep

wire length to a minimum. Heavy-duty plugs, as supplied on the ignition, or as used on electric cars

and planes, are recommended.

Use a high quality switch such as a heavy duty R/C receiver switch.

Make sure the charge current does not reach the ignition module. In other words don’t “charge” the

ignition module.

Keep ignition components and wiring separated, as much as possible, from your receiver, receiver

battery, servos, wiring and switches.

Don’t use metal-to-metal linkages to operate the throttle.

Always perform a radio range check before flying. Range should be at least 300 Ft. with the plane

on the ground and the motor running. If there are “glitches”, DON’T FLY! Check for holes in the

braided shielding, loose connections, etc.

The ignition can be powered directly by 4 cell (4.8 volt) or 5 cell (6 volt) NiCd orNiMH batteries. You

can also use 6.6 volt A123/LiFe batteries. If using batteries rated at more than 6.6 volts, a 5.5 or 6

volt regulator must be used. Higher voltage will damage the ignition system and will void the

warranty.

We recommend an 1800 mAh or larger capacity pack. With this size pack, the ignition should last

longer than your receiver pack will. If meter test shows 5.0 volts or less at the ignition module, don’t

fly, re-charge.

When connecting the red pick-up sensor to the ignition module, make sure that the polarity of

the wires entering the connectors is correct (Brown to brown, orange to orange)

Unlike some ignitions, the Desert Aircraft ignition is designed to spark only when the prop is flipped

at a high speed. If the prop is not turned over at a sufficient "starting" speed, the ignition will not

produce a spark. This helps to prevent the motor from firing accidentally. The ignition coils can store

energy for a short period of time after shut off. A few firm flips of the prop with the ignition off will

expend any energy held in the coils by firing for one revolution.

When removing the spark plug caps, PULL STRAIGHT out on the caps. Do not pull on the

shielded ignition wires!

To prevent radio interference, the spark plug caps must have the split retainer ring around the base

to insure a tight fit. –DON’T FLY WITHOUT THEM! If the spark plug caps seem loose and are not

making a solid metal to metal contact with the spark plug base, use a small hose clamp around the

base of the cap to keep them firmly attached to the base of the plug.

Protect the shielded plug wires from rubbing against fiberglass or sharp edges of wood or

metal. Rubber grommets and plastic “spiral wrap” insulation from automotive or electronic supply

stores work well. Holes in the braided shielding can emit R/F noise or loose connections (spark plug

caps, connectors and switches).

Timing is set at the factory and should not need adjustment. Contact Desert Aircraft if you have any

questions regarding timing.

Only use NGK CM-6 spark plugs. Other plugs may not fit the plug caps firmly.

Plug gap is .018” to .020" (.38 to .50 mm)

Never operate the ignition without a spark plug in the plug caps! This can permanently damage the

ignition coil.

3

Fuel and Oil Mix

For the DA215, use Premium pump gas, such as 91 to 93 octane.

We recommend purchasing your fuel from “name brand” gas stations. We often see problems with

cheaper gas from some discount type outlets.

We recommend filtering your fuel between your fuel container and your plane’s fuel tank when

fueling your plane.

Make sure the plane’s tank is well vented and the fuel clunk moves freely.

Use of any other fuel or additives such as nitro formulas, aviation gas, white gas, etc., can

harm the motor and void the warranty.

Do not use silicone sealers on the fuel system. Gas can break it down and carry it into the carb.

Use a high quality synthetic oil. Red-line Two Stroke Racing Oil, mixed at 40 to 1, is strongly

recommended. We have not tested a better oil for our engines than Red Line Two Stoke Racing Oil

(We do not recommend the Red Line Smokeless Oil). If Redline Two Stroke Racing Oil is not

available, Motul 800 (50 to 1) is a short term option. Use these oils during and after break-in. Do not

use a lower quality oil to speed the break-in process.

Break-in

We do not recommend breaking the engine in on a test stand. The stationary load and lack of air

ducting can lead to severe engine overheating.

Special break in props are not required. Just don't start with something beyond the recommended

sizes. Over loading the engine creates excessive heat. Peak rpm should be over 5,400 during the

break-in process.

Adjust the needles as needed and give the engine a few easy flights. Maneuvers like

“Hammerheads” help to cycle the engine temperatures during break-in. The needles may need

adjustment as the engine settles in or when other things change such as different props, exhaust,

weather, and altitude.

The engine should run well from the beginning and improve as flight hours accumulate.

Engine temperatures

Temperatures can vary greatly at different locations on the engine and can change quickly at

different throttle settings. Near the spark plug, max temp at full throttle is approx. 325 F (162 C). All

other locations should be cooler.

Recommended Props

Always check and tighten prop bolts before each flight! Loose prop bolts allow prop movement,

which will shear the bolts.

Always use the correct length prop bolts. If a spinner back plate is not used, the prop bolts may be

too long and can bottom out in the hub before they fully tighten against the prop washer.

While special/small break-in props are not required, avoid over loading/heating the motor with large

props that limit RPM to 5,400 or less. The recommended max operating rpm during break-in is

approx. 5,800.

Some recommended props during and after break-in are:

Wood: 34x12, 32x14

Carbon: 32x14, 33x13, 34x12

Smaller diameter props with more pitch, especially 3 blades, can reduce tip speed and noise.

Always use a drill guide to drill your props.

Always check the balance of your prop.

For safety, we recommend painting the tips of your props (front and back) with a bright color,

especially on black props.

4

Table of contents

Other Desert Aircraft Engine manuals

Desert Aircraft

Desert Aircraft DA100-I User manual

Desert Aircraft

Desert Aircraft DA120 User manual

Desert Aircraft

Desert Aircraft DA170 User manual

Desert Aircraft

Desert Aircraft DA85 User manual

Desert Aircraft

Desert Aircraft DA35 User manual

Desert Aircraft

Desert Aircraft DA200 User manual

Desert Aircraft

Desert Aircraft DA 100 EFI User manual

Desert Aircraft

Desert Aircraft DA100 User manual

Desert Aircraft

Desert Aircraft DA50 EFI User manual