3

Reprocessing Instructions

Warnings:

Limitations on

reprocessing: Do notimmerse the handpiece in water other than when automatic

reprocessing, and only then, when fitted the correct washing caps.

Do not exceed temperatures 140°C.

Do notclean any part of the equipment in an ultrasonic cleaner.

Long narrow cannulations and blind holes require particular

attention during cleaning.

Repeated processing has minimal effect on these instruments. End of life

is normally determined by wear or damage during use.

Instructions

Point of Use Do not operate the equipment while still warm

Containment

and

transportation:

It is recommended that instruments be reprocessed immediately following

surgical use. The handling, collection and transportation of soiled

equipment should be strictly controlled to minimise risks.

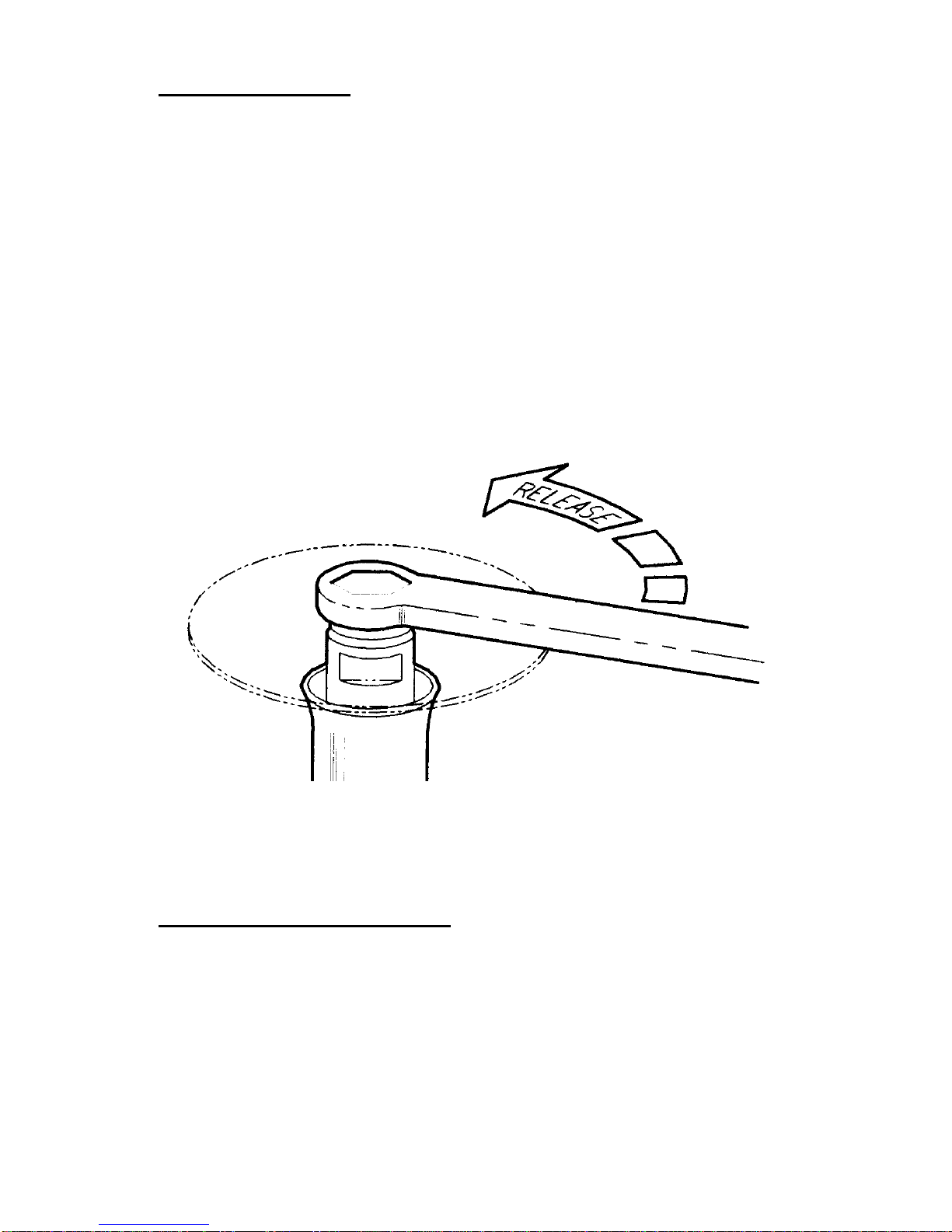

Preparation for

cleaning: Remove all attachments and accessories for cleaning, wash separately, or

dispose of as per instructions.

Manual

Cleaning Equipment:

Manual cleaning should only be carried out where automatic

washer/disinfection is not available. It should be conducted in a dedicated

area by trained personnel wearing protective clothing e.g. gloves,

waterproof apron and goggles or visor. Use Neutral pH Enzymatic

detergents such as Klerzymeand Nylon scrubbing brushes. Dedicated

sinks with temperature controlled water, ideally de-ionized or distilled and a

Lint-free cloth for drying.

Method:

1. Wash off excess contaminant with running water (maximum 35°C)

avoiding fluid ingress via the air hose inlet. Scrub the components

thoroughly using a neutral pH enzymatic detergent and nylon brushes to

remove all visible traces of contaminant. Pay attention to recesses,

blind holes and cannulations.

Note: Manually open and close chucks and blade clamps. Use suitable

nylon brushes to reach difficult surfaces and inside cannulations. Flush

through these areas to ensure any trapped contaminants are removed.

2. Rinse off all traces of the detergent with de ionized or distilled running

water (45-65 °C).

3. Shake off excess water and dry surfaces with a lint-free cloth.

4. Visually inspect each item to verify that all contaminants are removed in

accordance with local reprocessing guidelines.