DETRO 2400D Datasheet

I

N

D

U

S

T

R

Y

S

T

A

N

D

A

R

D

S

I

N

C

E

1

9

3

4

MODEL 2400D

AIR OPERATED PAINT SHAKER

INSTRUCTIONS PARTS LIST WARRANTY

WARNING

!! 1. For professional use only

2. Keep out of reach of children

3. Use only air tool oil

4. Do not shake aerosols for more than one minute

5. Do not shake if temperature of aerosol can exceeds 100 F

5. Do not use in enclosed areas

6. Maintain proper ventilation at all times

! SAFETY PRECAUTIONS !

O

OPERATING INSTRUCTIONS

1. Clamp can securely, use caution not to crush can.

2

3. Shake aerosols cans a of one minute.

4. shake aerosol can if temperature exceeds 100. F

5. Recommended air pressure 100 -140 PSI.

. Quickly open control valve. If shaker fails to start close valve for 5

seconds then reopen.

MAXIMUM

DO NOT

To start shaker:

OPERATION

1. To adjust shaking speed slightly open or close air control valve (#2401).

2.

.

3. For Quart & Pint cans close control valve until shaker runs .

4. For gallon cans open control valve slightly to achieve full stroke.

RUNNING AIR PRESSURE HIGHER THAN REQUIRED FOR THE SIZE OF CAN WILL

RESULT IN SHORTER LIFE SPAN OF SHAKER AND WILL NOT INCREASE EFFICIENCY

QUIETLY

SPEED CONTROL

LUBRICATION

1. Use air tool oil in motor never use motor oil or grease in motor.

2.

3. use oils that contain petroleum distillates.

4. Grease shafts once every 10 hrs. or every 30 days ( ).

5. Oil main shaft once every 30 days with air tool oil (10 drops).

6. Failure to follow lubrication specifications will cause premature failure of the

machine and VOID the warranty.

ONLY

ADJUST OILIER TO 1 DROP OF OIL EVERY 30 SECONDS

DO NOT

1 PUMP

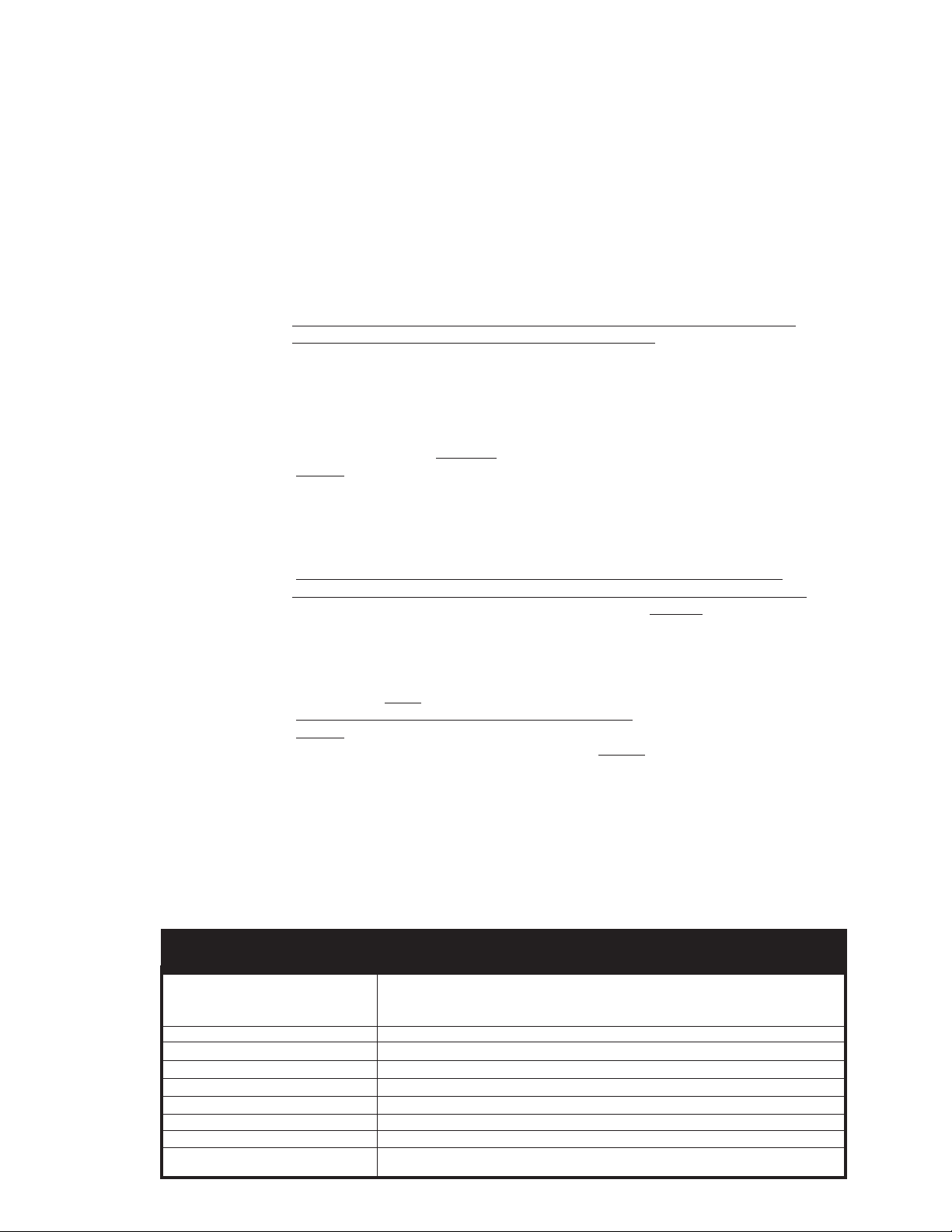

Specifications and Recommendations

Air Consumption

Air Pressure

Air Tool Oil

Capacity

Grease

Oil Consumption

Shaking Speed

Shaking time

Approximately 3.5 cfm

1 -140 PSI

Non-detergent, rust inhibiting, 5w to 10w

1 pint - 1 gallon

lithium or calcium based multipurpose chassis grease

Up to 00 cycles per minute

2-3 minutes average with quart

00

1 drop air tool oil every 30 seconds

10

ASSEMBLY

1. Connect automatic oilier (#2403) to bulk head fitting (#2405) in motor cover (#2406)

USE OF THREAD SEALING COMPOUND IS RECOMMENDED.

2. Then connect air control valve (#2401) using brass nipple (#2404) as shown in

diagram on page 3.

3.

Mount shaker securely to optional shaker stand (#2465) using bolts (#2459). Shaker

stand must be firmly mounted to floor using suitable fasteners (not Inc). Shaker may

also be mounted to a sturdy bench or other platform by replacing bolts (#2459) with

suitable fasteners.

4. FAILURE TO INSTALL AND ADJUST OILIER AS PER INSTRUCTIONS WILL RESULT IN

DAMAGE TO THE SHAKER AND WILL VOID THE WARRANTY.

USE CAUTION NOT TO ALLOW BULK HEAD FITTING TO TURN WHEN INSTALLING

AIR CONTROL VALVE.

CAUTION: SHAKER MUST BE FIRMLY SECURED AS FOLLOWS

2401

2403

2404

2405

2405-2

2406

2407

2408

2409

2412

2413D

2413-1

2414D

2414D-1

2416D

2416-1

2417

2418

2420

2421

2413-2

D

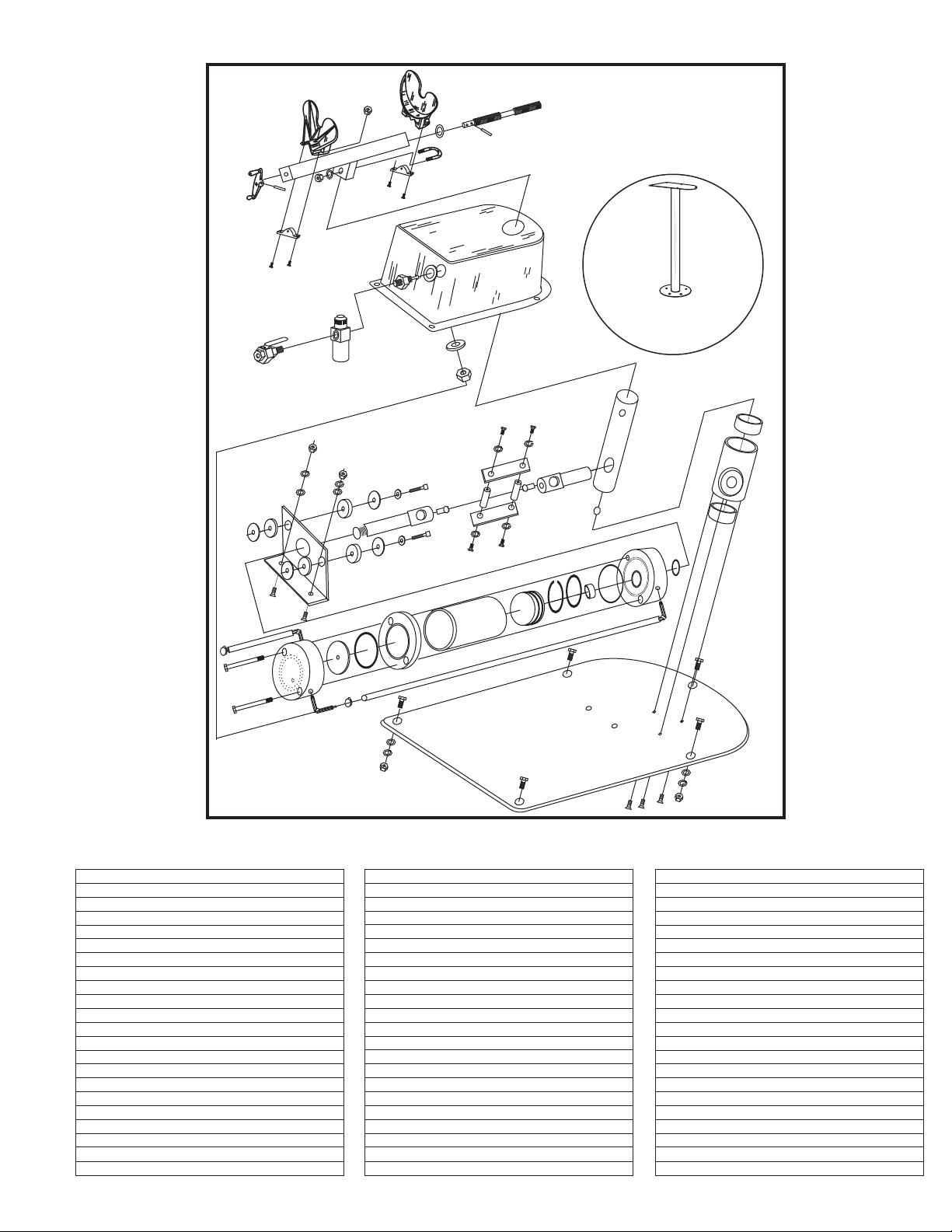

Air Control Valve

Automatic Oiler

Brass Nipple

Bulk Head Fitting

1 1/16” OD x ½” ID

Motor Cover

Hose Clamp

Air Hose Assembly

Inlet Ell Fitting

1/4'' x 4''-20 Hex Cap Screw

Motor Back Plate

Rear Valve Body

Motor Body

Motor Body O-Ring

Piston O-Ring

Piston Wear Ring

Piston

3/8'' Ball Bearing

Valve Body O-ring

Motor Front Plate

Valve Disc

1

1

1

1

1

2

2

2

1

1

1

1

1

1

1

1

1

2

2

1

Part # Description Qty

2422

2423

2424

2425

2426

2427

2428

2429

2430D

2430D-1

2431

2432

2433

2434

2435

2436

2437

2438

2439

2441

2443

1/4" Flat Washer Zinc

1/4'’ X 1 3/4'' Socket Cap Bolt

Motor Mounting Bracket

5/16'' X 1'' Flat HD Socket Bolt

1/4’'x1'' Fender Washer Zinc

1'' X 3/8’' Rubber Bushing

Motor Shaft

Motor Shaft Bushing

Zert-1/8" Drive

1/4" X ½"-20 Hex Tap Bolt

Connector Bars

Connector Pins

57 Degree Zert-1/8" NPT

Main Shaft Connector Rod

Main Shaft Bushings

Main Shaft Tube

Main Shaft

5/16" U Bolt Zinc

5/16''-14 Hex Lock Nut Zinc

Motor Shaft O-Ring

1/4'' Lock Washer Zinc

1

4

2

2

1

2

4

4

1

1

1

4

2

2

1

1

2

1

1

1

2

Part # Description Qty

3/8'' x 1 1/4''-16 Hex Tap Bolt

Clamp Nut (LH)

Clamp Nut (RH)

Handle Roll Pin

Clamp Handle

Clamp Frame

7/16" SAE Flat Washer

Clamp Screw Roll Pin

Clamp Screw

Jaw

3/8'' Lock Washer Zinc

3/8''-18 Hex Nut Zinc

Shaker Base Plate

#10x5/8” Flat HD Socket Bolt

5/16'' X 1''-18 Hex Tap Bolt

5/16'' SAE Flat Washer

5/16'' Lock Washer

5/16"-18 Hex Nut Zinc

Motor Complete

Main Shaft Tube Assembly

Paint Shaker Stand

2444

2445

2446

2448

2449

2450

2451

2452

2453

2454

2455

2456

2457D

2458

2459

2460

2461

2462

2463

2464

2465

1

1

1

1

1

1

1

1

1

2

4

4

1

3

5

7

7

7

28(2)

28(2)

29(2)

24(2)

25(2)

01

07(2)

13D

14

18

06

09

62(2)

12(2)

16-1 16D

17D

21

22

23(4)

61(2)

VVVVVVV

V

VV

VVVVV

VVV

V

V

60(2)

27(2)

26

32(4)

33D(2)

34(2)

37(2)

35

41

44(4)

44(4)

43 42

45

48

49

54(2)

52

PART# 2400D

AIR OPERATED

PAINT SHAKER

05

05-2

05-2

43

38

50

30D

46

51

56(4)

57

58(3)

62(5)

61(5)

59(5)

60(5)

31

39

36D

53

03

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

29-1(2)

PART# 2465

SHAKER STAND

(OPTIONAL)

30-1

20

08(2)

07

08

13-2

14D-1

(2)

13-1

2

1 Year Limited Warranty

Detro manufacturing warrants this equipment to be free from defects in material and

workmanship for a period one year from the date of purchase. This warranty is limited

to the original purchaser and is not transferable. Detro Manufacturing’s responsibility

is limited solely to the replacement or repair of defective part(s) and labor.

Warranty does

FAILURE TO

INSTALL, MAINTAIN AND ADJUST OILIER AS PER INSTRUCTIONS WILL RESULT IN

DAMAGE TO THE SHAKER AND WILL VOID THE WARRANTY. not cover

any damage consequential, incidental or otherwise.

WARRANTY CONDITIONS:

VOIDS

REPAIRS or SERVICE:

1. Applies to original purchaser only and is not transferable.

2. Covers defects in material and workmanship only.

3. Whether to repair or replace defective parts is the sole discretion of the manufacturer.

4. All repairs must be preformed by Detro Manufacturing Inc. or an authorized agent.

5. Repairs made by anyone other than those stated above this warranty.

6. Paint shakers sent in for repairs must include copy of original invoice showing purchase date.

7. Warranty does not cover damage caused by misuse, abuse or failure to follow recommended maintenance

procedures .

Return shaker to:

Detro Manufacturing Inc.

1721 SE Grace Ave. Unit E

Battle Ground, WA. 98604

PH: (360) 687-9960

TOLL FREE: (877) 883-2869

FAX: (360) 687-7184

I

N

D

U

S

T

R

Y

S

T

A

N

D

A

R

D

S

I

N

C

E

1

9

3

4

MODEL 2400D

AIR OPERATED PAINT SHAKER

Table of contents