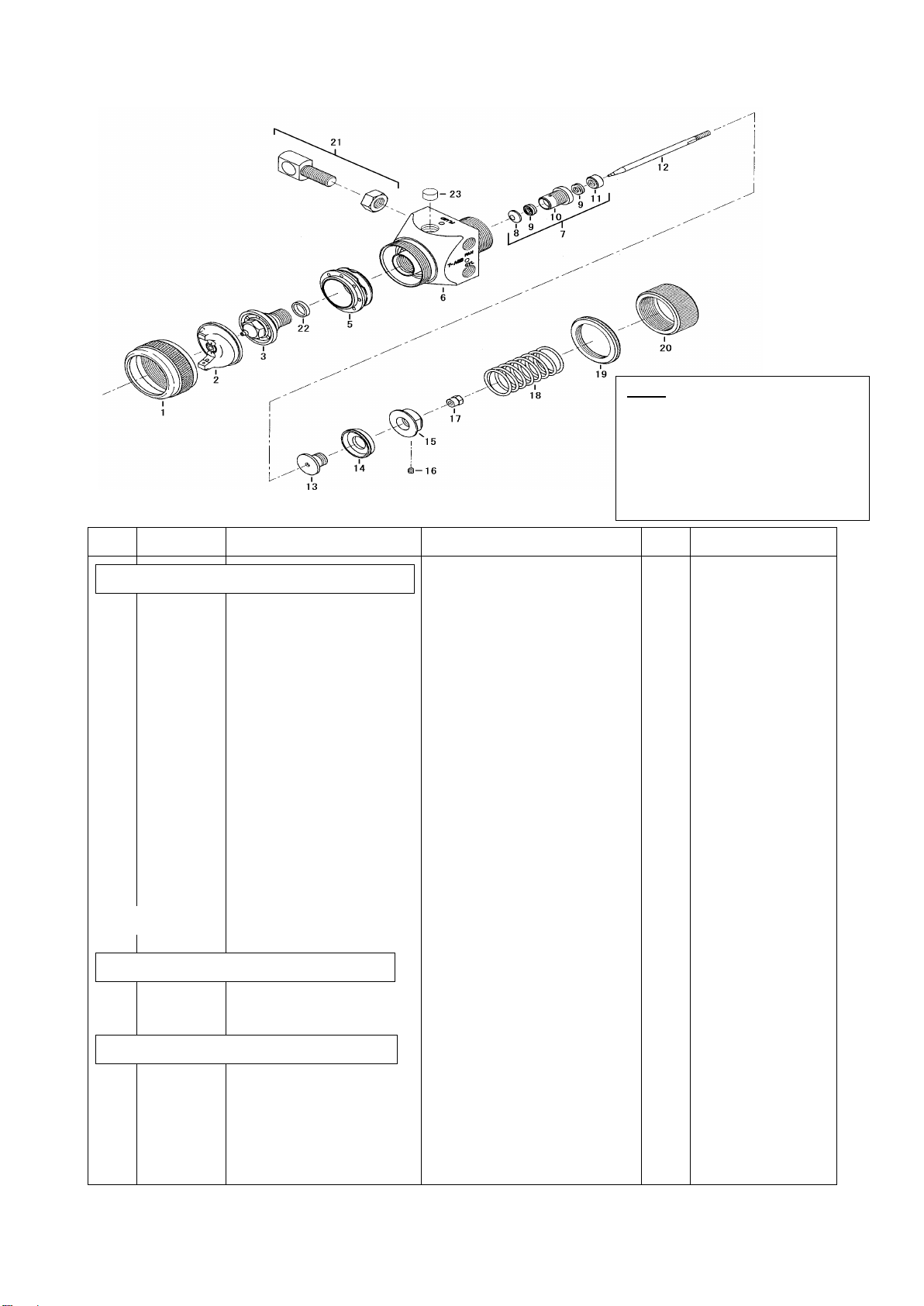

T-AGB-862/872/873/874/879/882

1301A

T-AGB(1/2)

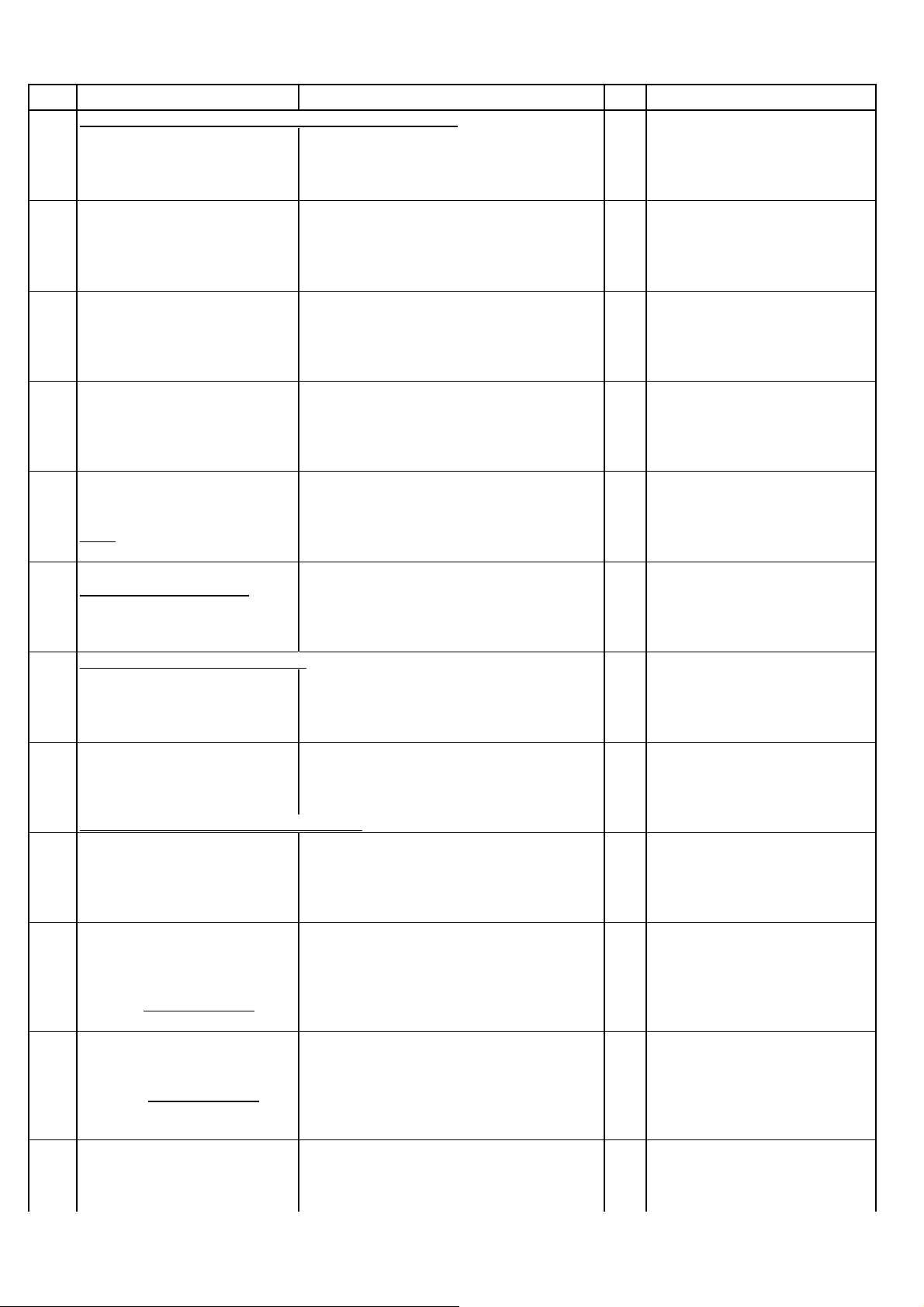

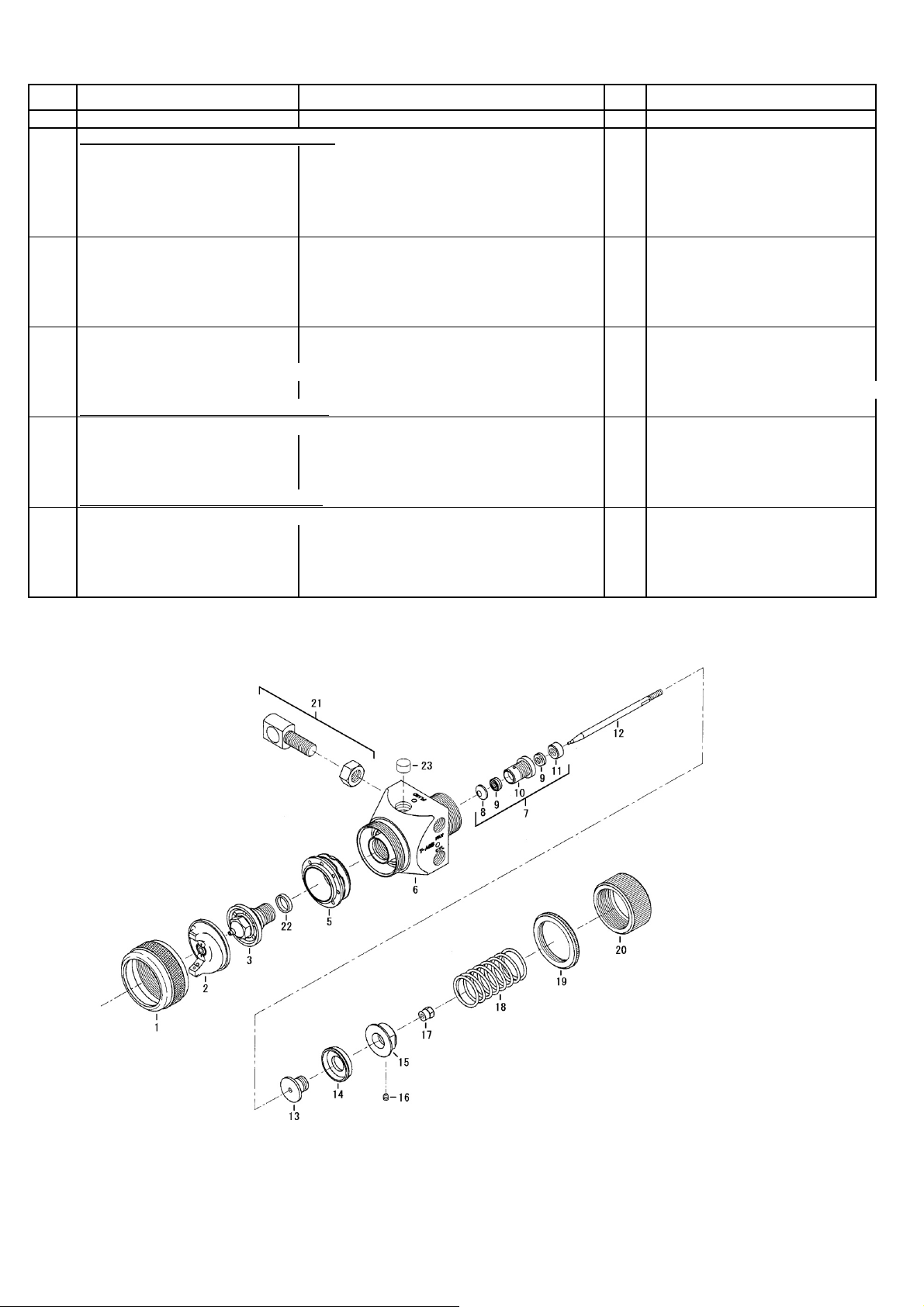

Part Number Description Qty Remarks

872,873,874 Stainless Body (Standard &Common Parts)

1MBC-368 Retaining Ring 1

2See Below Air Cap 1

3See Below Fluid Tip 1

5MBC-142-1 Plastic Baffle 1

6------- Gun Body (SUS303) 1Not for sale

7T-AGB-10-1 Needle Seal Kit 1

8T-AGB-11-3 Seal Washer 1

9T-AGB-12 Seal 2

10 T-AGB-13-2 Housing 1

11 T-AGB-14 Gland 1

12 See Below Needle 1

13 T-AGB-101 Piston Flange 1

14 T-AGB-102 Piston Cup 1

15 T-AGB-103 Retainer 1

16 T-AGB-104-K5 Set Screw Kit of 5 1

17 T-AGB-105 Lock Nut 1

18 T-AGB-106 Needle Spring 1

19 T-AGB-127 Lock Nut (SUS303) 1

20 T-AGB-128 Adjusting Screw (SUS303) 1

21 T-AGB-109 Gun Stud (with Lock Nut) 1

22 T-AGB-120-K5 Nozzle Gasket Kit of 5 1

23 T-AGB-121-K5 Fluid Plug Kit of 5 1

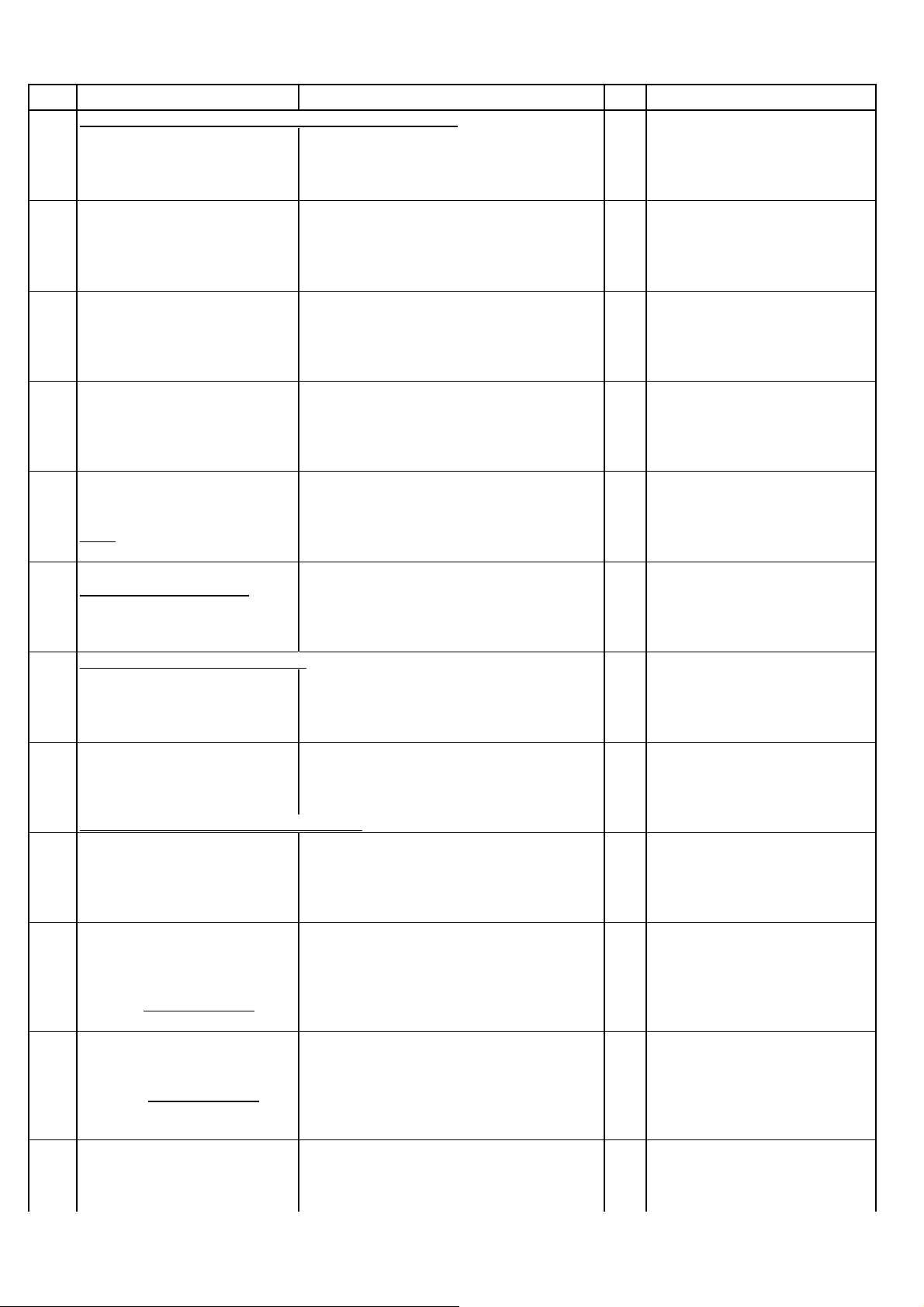

T-AGB-GRT-1 Grand Removal Tool

T-AGB-HW-1 Housing Wrench

6------- Gun Body (With Blue Anodized Aluminum) 1Not for sale

19 T-AGB-117 Lock Nut (With Blue Anodized Aluminum) 1

20 T-AGB-118

Adjusting Screw (With Blue Anodized Aluminum

1

879 All Stainless Steel Body Type

1T-MBC-368-SUS Retaining Ring (SUS303) 1

7T-AGB-10-1-SUS Needle Seal Kit (SUS303) 1

10 T-AGB-13-2-SUS Housing (SUS303) 1

11 T-AGB-14-SUS Gland (SUS303) 1

13 T-AGB-101-SUS Piston Flange (SUS303) 1

15 T-AGB-103-SUS Retainer (SUS303) 1

17 T-AGB-105-SUS Lock Nut (SUS303) 1

21 T-AGB-109-SUS Gun Stud (SUS303, with Lock Nut) 1

882 High Grade Stainless Steel Body Type

1T-MBC-368-SUS Retaining Ring (SUS303) 1

6------- Gun Body (SUS316) 1Not for sale

7T-AGB-10-1-SUS Needle Seal Kit (SUS303) 1

10 T-AGB-13-2-SUS Housing (SUS303) 1

11 T-AGB-14-SUS Gland (SUS303) 1

13 T-AGB-101-SUS Piston Flange (SUS303) 1

15 T-AGB-103-SUS Retainer (SUS303) 1

17 T-AGB-105-SUS Lock Nut (SUS303) 1

21 T-AGB-109-SUS Gun Stud (SUS303, with Lock Nut) 1

2

(with Retaining Ring)

MB-4039-62 (AC Fluid Tip)

MB-4039-64 (D Fluid Tip)

MB-4039-67 (EE, E Fluid Tip)

2

(without Retaining Ring)

AV-1239-265R-1 (FX,FF,E Fluid Tip)

AV-1239-704 (G,FX,FF,E Fluid Tip)

AV-1239-705 (G,FX,FF Fluid Tip)

AV-1239-765 (FX,FF,E Fluid Tip)

31767-777 (FX,FF,E Fluid Tip)