Table of Contents

Table of Contents .........................................................................................................................................2

Important Safety Instructions.............................................................................................................3

Set-Up Procedures

1. Package contents .........................................................................................................................4

2. Unpacking instructions ................................................................................................................5

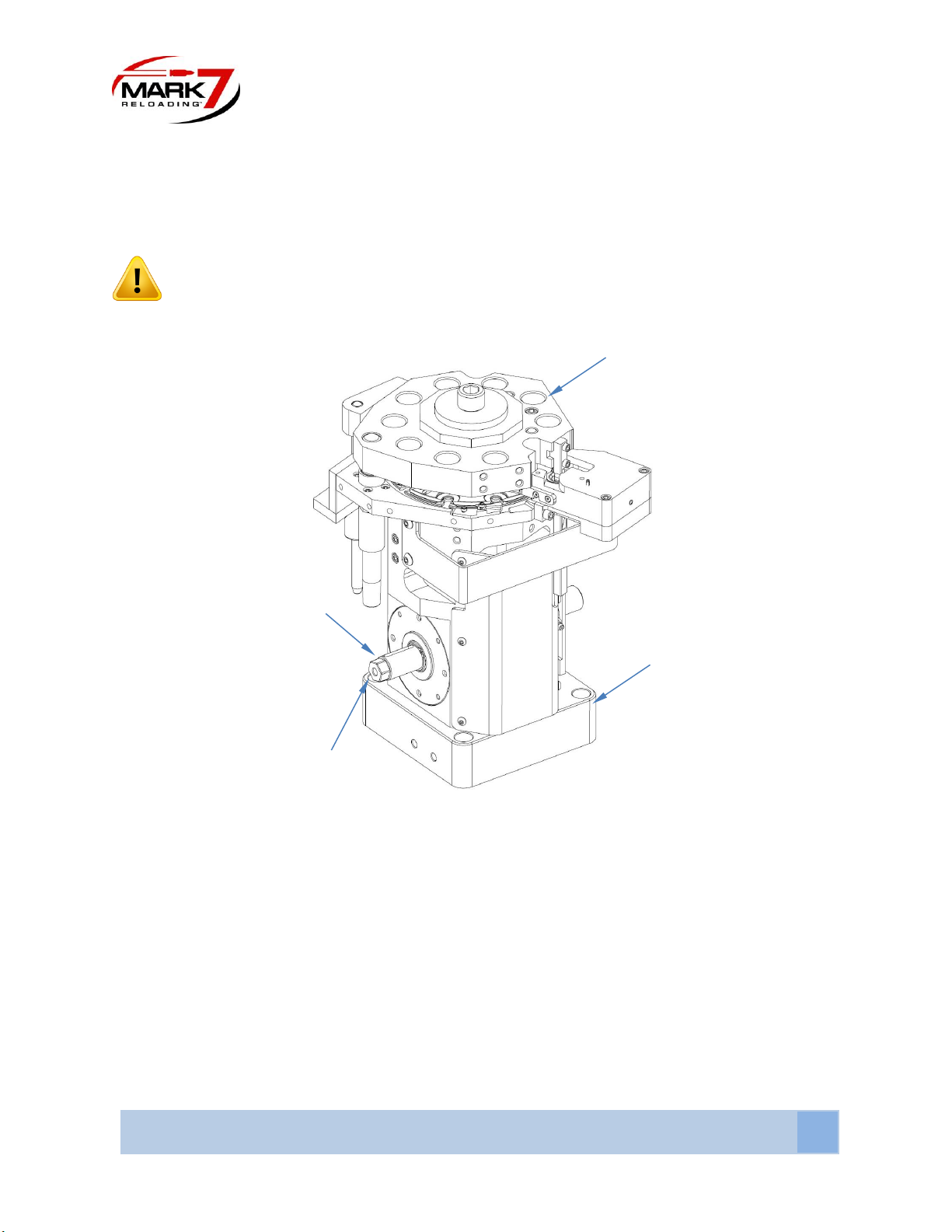

3. Installing Base Plate Feet .............................................................................................................6

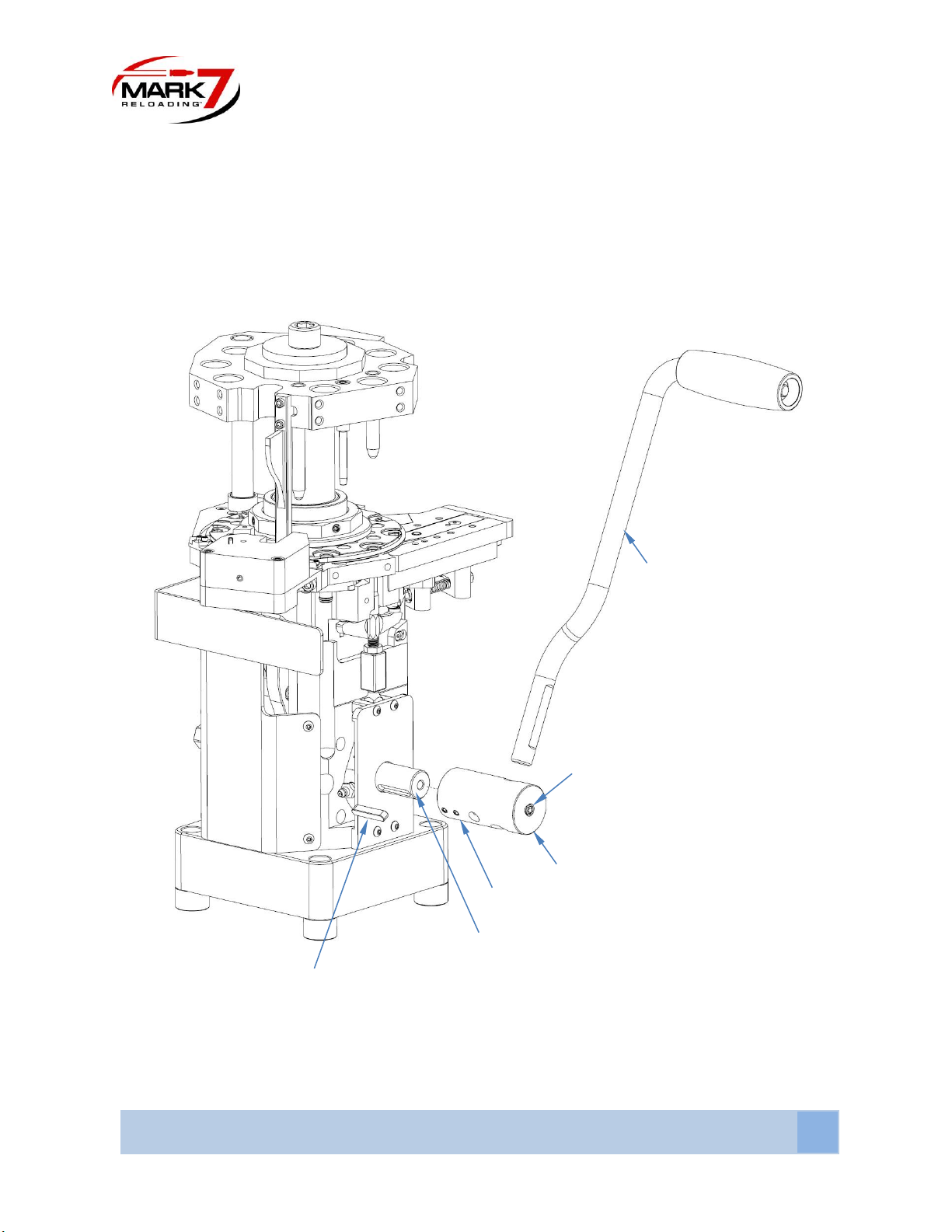

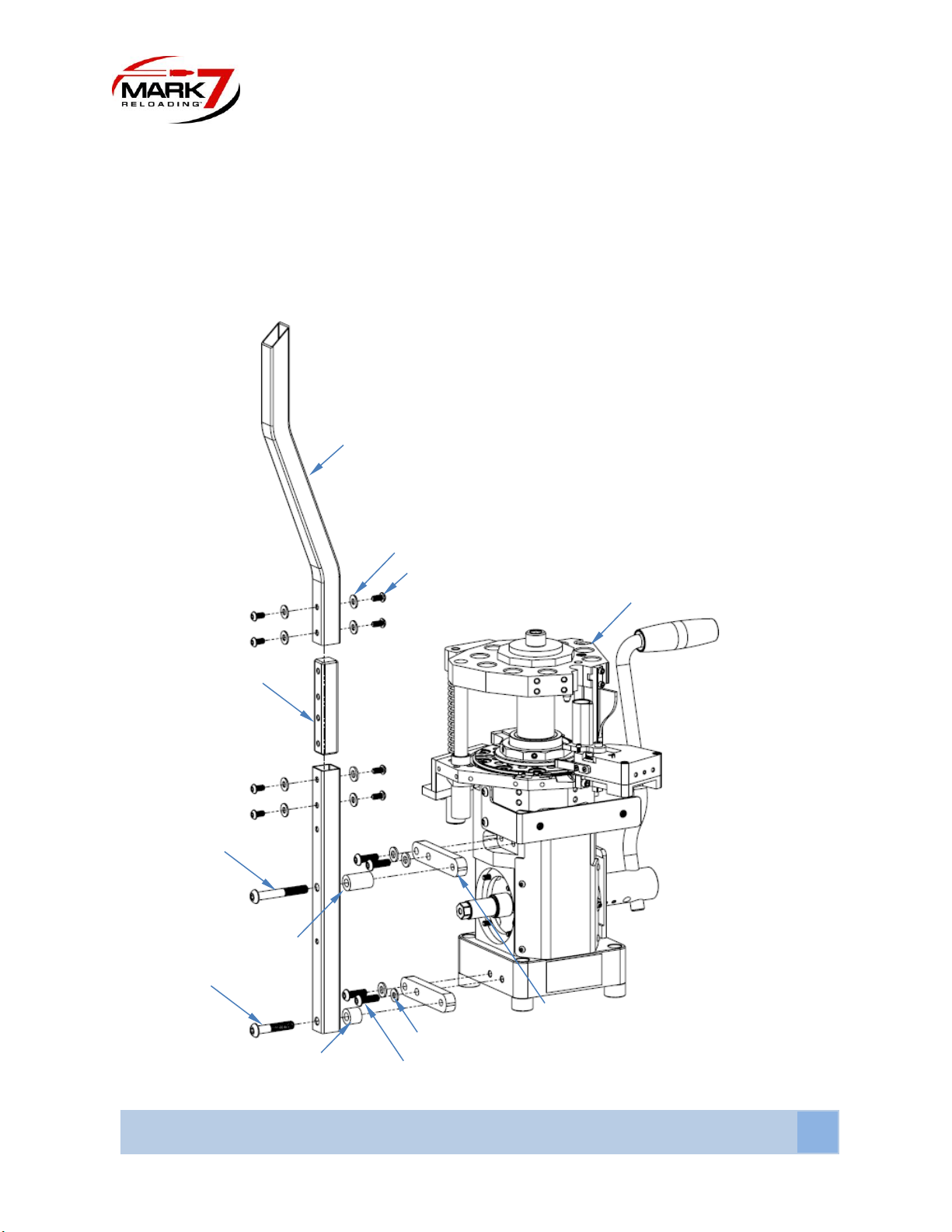

4. Handle Installation and Workbench Mounting ...........................................................................7

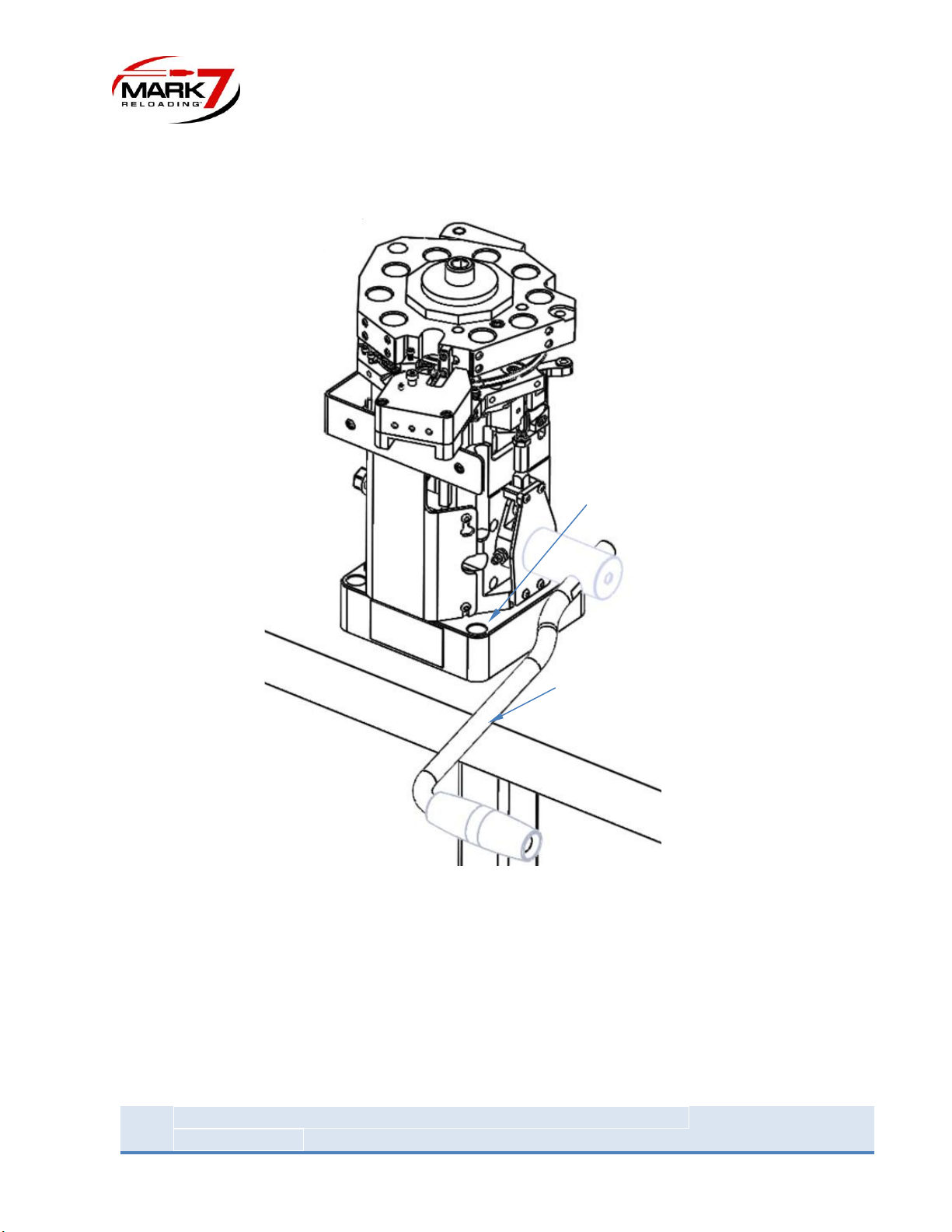

5. Case Feeder Installation...............................................................................................................9

6. Installing Case Feeder Spring Flipper Assy.................................................................................11

7. Case Feeder Adapter and Drop Tube Assy.................................................................................12

8. Installing Primer Tube Stack Assy and Low Primer Alarm .........................................................14

9. Powder Measure installation.....................................................................................................16

10. Tool Head Recommended Die Position ...................................................................................16

Operating Instructions

1. Case Feed Univeral Decap or Sizing/Decap - Station 1 and 2....................................................17

2. Swage setup - Station 3..............................................................................................................18

3. Priming seating ..........................................................................................................................18

4. Case Neck Expansion..................................................................................................................19

5. Powder Measure Die hieght and Powder Charge Adjustment..................................................20

6. Setting up Mr.Bulletfeeder and Bullet Drop Assy......................................................................21

7. Bullet Seating/Crimping setup...................................................................................................22

Mark 7 EvolutionTM Recommended Maintenance ...................................................................................23

Shellplate indexing adjustments ...............................................................................................................29

Storage Recommendations........................................................................................................................32

Troubleshooting .......................................................................................................................................32