MAN1348-01-EN_OEE_UM

August 10, 2022 3 | P a g e

Table of Contents

PREFACE............................................................................................................................................2

LIMITED WARRANTY AND LIMITATION OF LIABILITY ...........................................................................2

Table of Contents ......................................................................................................................................3

1 SAFETY AND COMPLIANCE.............................................................................................................5

1.1 Safety Warnings and Guidelines.................................................................................................5

2 INTRODUCTION..............................................................................................................................7

2.1 OEE Overview..............................................................................................................................7

2.2 Production Data Availability .......................................................................................................8

2.3 Types of Reports .........................................................................................................................8

2.4 Contractual Requirements..........................................................................................................8

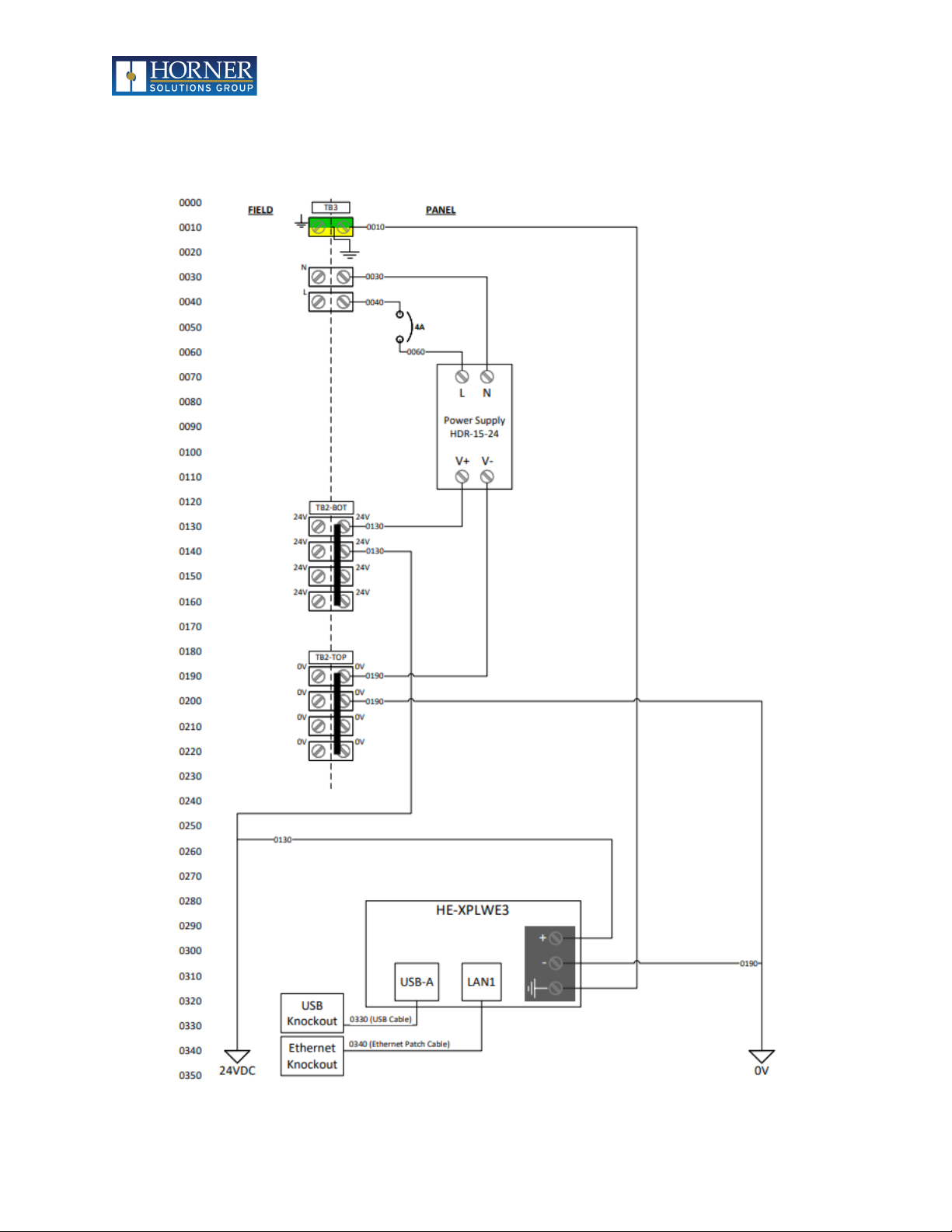

3 ELECTRICAL INSTALLATION ............................................................................................................9

3.1 OEE Power Wiring.......................................................................................................................9

3.2 OEE Electrical I/O......................................................................................................................10

4 ELECTRICAL - GROUNDING...........................................................................................................11

4.1 Grounding Definition ................................................................................................................11

4.2 Ground Specifications...............................................................................................................11

4.3 How to Test for Good Ground ..................................................................................................11

5 OEE SYSTEM NAVIGATION...........................................................................................................12

5.1 Home.........................................................................................................................................12

5.2 Trends .......................................................................................................................................14

5.3 Summary...................................................................................................................................17

5.4 Events........................................................................................................................................17

5.5 Downtime Accumulators ..........................................................................................................18

5.6 Call Accumulators .....................................................................................................................18

6 CALLS............................................................................................................................................19

6.1 Placing a Call .............................................................................................................................19

6.2 Acknowledging a Call................................................................................................................20

6.3 Clearing a Call............................................................................................................................20

7 CONFIGURATION..........................................................................................................................22

7.1 Configuration Overview............................................................................................................22

7.2 Cell Configuration .....................................................................................................................23

7.3 Shift Configuration....................................................................................................................26

7.4 Part Editor/Viewer....................................................................................................................28

7.5 Downtime Code Configuration .................................................................................................32

7.6 Ethernet Configuration.............................................................................................................33

7.7 Email Configuration ..................................................................................................................36

7.8 System Information ..................................................................................................................38

8 OEE SCORE CALCULATION OVERVIEW.........................................................................................39

8.1 Availability.................................................................................................................................39

8.2 Performance .............................................................................................................................39

8.3 Quality.......................................................................................................................................39

8.4 Overall Equipment Effectiveness..............................................................................................39

8.5 Scheduled Breaks and Changeover; Effect on Scoring .............................................................39

9 LOGIN / LOGOUT..........................................................................................................................41

9.1 Log In.........................................................................................................................................41