DewAir RH-CUBE 18 CZ Supplement

RH-CUBE 18

CZ & HH OUTDOOR UNITS

INSTALLATION & SERVICE MANUAL

All safety information must be followed as provided.

Important! Refer to page 10 in regards to refrigerant charge

This manual is to be used by qualified professionally trained HVAC technicians only.

DewAir does not assume any responsibility for property damage or personal injury due to improper

service procedures or services performed by an unqualified person.

It is the owner's and installer's responsibility to read and comply with all safety warnings information and

instructions. Failure to heed safety information increases the risk of personal injury property damage

and/or product damage.

Copyright © 2019 DewAir Corporation 1 RHC18O-IM v2.11 Sep , 2019

CZGSX14018

HHGSX14024

SAFETY INSTRUCTIONS

READ THE INSTALLATION OPERATION AND MAINTENANCE INSTRUCTIONS CAREFULLY

BEFORE INSTALLING AND OPERATING THIS DEVICE. PROPER ADHERENCE TO THESE

INSTRUCTIONS IS ESSENTIAL TO OBTAIN MAXIMUM BENEFIT FROM YOUR WHOLE

HOUSE DEHUMIDIFIER.

WARNING

WARNING

THIS SYMBOL MEANS IMPORTANT INSTRUCTIONS. FAILURE TO HEED THEM CAN

RESULT IN SERIOUS INJURY OR DEATH.

WARNING

WARNING

THIS SYMBOL MEANS IMPORTANT INSTRUCTIONS. FAILURE TO HEED THEM CAN

RESULT IN SERIOUS INJURY OR DEATH FROM ELECTRIC SHOCK.

CAUTION

CAUTION

THIS SYMBOL MEANS IMPORTANT INSTRUCTIONS. FAILURE TO HEED THEM CAN

RESULT IN INJURY OR MATERIAL PROPERTY DAMAGE

Copyright © 2019 DewAir Corporation 2 RHC18O-IM v2.11 Sep , 2019

Table of Contents

!

"#$!

$$"!

"$$!

$!

$$!

"$%

$%

$&

$'(")&

*+&

$$$

,$

$$-

+-

+$.

$+$.

*.

$

"

/

Copyright © 2019 DewAir Corporation 3 RHC18O-IM v2.11 Sep , 2019

WARNINGS

WARNING

WARNING

DISCONNECT ALL POWER BEFORE SERVICING OR INSTALLING THIS UNIT. MULTIPLE POWER SOURCES MAY BE PRESENT.

FAILURE TO DO SO MAY CAUSE PROPERTY DAMAGE PERSONAL INJURY OR DEATH.

WARNING

WARNING

EVEN THOUGH THIS UNIT IS MECHANICALLY SIMILAR TO A STANDARD SPLIT-AIR AIR CONDITIONER CONDENSER SYSTEM

ITS OPERATION CONDITIONS SUCH AS PRESSURE AND REFRIGERANT CHARGE ARE DIFFERENT. IT IS CRITICAL THAT THE

REFRIGERANT CHARGE PROCEDURE BE FOLLOWED CAREFULLY.

WARNING

WARNING

DEWAIR WILL NOT BE RESPONSIBLE FOR ANY INJURY OR PROPERTY DAMAGE ARISING FROM IMPROPER SERVICE OR

SERVICE PROCEDURES. IF YOU INSTALL OR PERFORM SERVICE ON THIS UNIT YOU ASSUME RESPONSIBILITY FOR ANY

PERSONAL INJURY OR PROPERTY DAMAGE WHICH MAY RESULT. MANY JURISDICTIONS REQUIRE A LICENSE TO INSTALL

OR SERVICE HEATING AND AIR CONDITIONING EQUIPMENT.

WARNING

WARNING

ONLY INDIVIDUALS MEETING (AT A MINIMUM) THE REQUIREMENTS OF AN "ENTRY LEVEL TECHNICIAN" AS SPECIFIED BY

THE AIR-CONDITIONING HEATING AND REFRIGERATION INSTITUTE (AHRI) MAY USE THIS INFORMATION. ATTEMPTING

TO INSTALL OR REPAIR THIS UNIT WITHOUT SUCH BACKGROUND MAY RESULT IN PRODUCT DAMAGE PERSONAL INJURY

OR DEATH.

WARNING

WARNING

THE UNITED STATES ENVIRONMENTAL PROTECTION AGENCY (“EPA”) HAS ISSUED VARIOUS REGULATIONS REGARDING

THE INTRODUCTION AND DISPOSAL OF REFRIGERANTS INTRODUCED INTO THIS UNIT. FAILURE TO FOLLOW THESE

REGULATIONS MAY HARM THE ENVIRONMENT AND CAN LEAD TO THE IMPOSITION OF SUBSTANTIAL FINES. THESE

REGULATIONS MAY VARY BY JURISDICTION. SHOULD QUESTIONS ARISE CONTACT YOUR LOCAL EPA OFFICE.

WARNING

WARNING

TO PREVENT THE RISK OF PROPERTY DAMAGE PERSONAL INJURY OR DEATH DO NOT STORE COMBUSTIBLE MATERIALS

OR USE GASOLINE OR OTHER FLAMMABLE LIQUIDS OR VAPORS IN THE VICINITY OF THIS

APPLIANCE.

Copyright © 2019 DewAir Corporation 4 RHC18O-IM v2.11 Sep , 2019

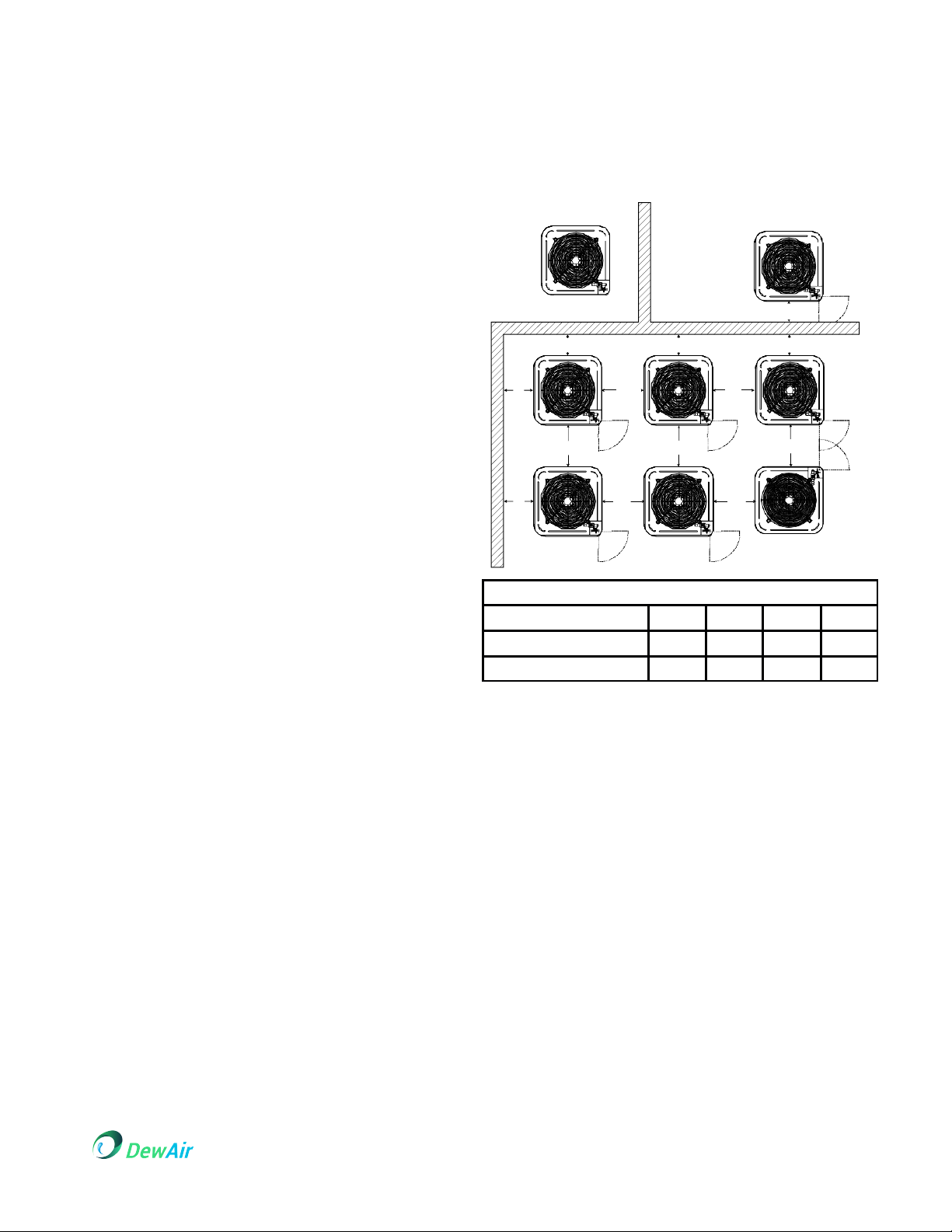

NOT RECOMMENDED

BOK!

B B B

A AA AA

CCOK!

AAAAAA

OK!

AAA AA

C C

SHIPPING

INSPECTION

Always keep the unit upright; laying the unit on its side or top

may cause equipment damage. Shipping damage and

subsequent investigation is the responsibility of the carrier.

Verify the model number specifications electrical

characteristics and accessories are correct prior to

installation. The distributor or manufacturer will not accept

claims from dealers for transportation damage or installation

of incorrectly shipped units.

CODES &

REGULATIONS

This product is designed and manufactured to comply with

national codes. Installation in accordance with such codes

and/or prevailing local codes/regulations is the responsibility

of the installer. The manufacturer assumes no responsibility

for equipment installed in violation of any codes or

regulations.

Rated performance is achieved after 72 hours of operation.

Rated performance is delivered at the specified airflow. See

Condensing Unit Specifications section for details

The United States Environmental Protection Agency (EPA)

has issued various regulations regarding the introduction

and disposal of refrigerants. Failure to follow these

regulations may harm the environment and can lead to the

imposition of substantial fines. Should you have any

questions please contact the local office of the EPA.

Outdoor units are approved for operation above 55°F in

cooling mode. Operation below 55°F requires the use of an

approved low ambient kit.

Damage to the unit caused by operating the unit in a

structure that is not complete (either as part of new

construction or renovation) is not covered under the

warranty.

INSTALLATION

CONSIDERATIONS

This unit can be located at ground floor level or on flat roofs.

GROUND INSTALLATION

At ground floor level the unit must be on a solid level

foundation that will not shift or settle. To reduce the

possibility of sound transmission the foundation slab should

not be in contact with or be an integral part of the building

foundation. Ensure the foundation is sufficient to support the

unit. A concrete slab raised above ground level provides a

suitable base.

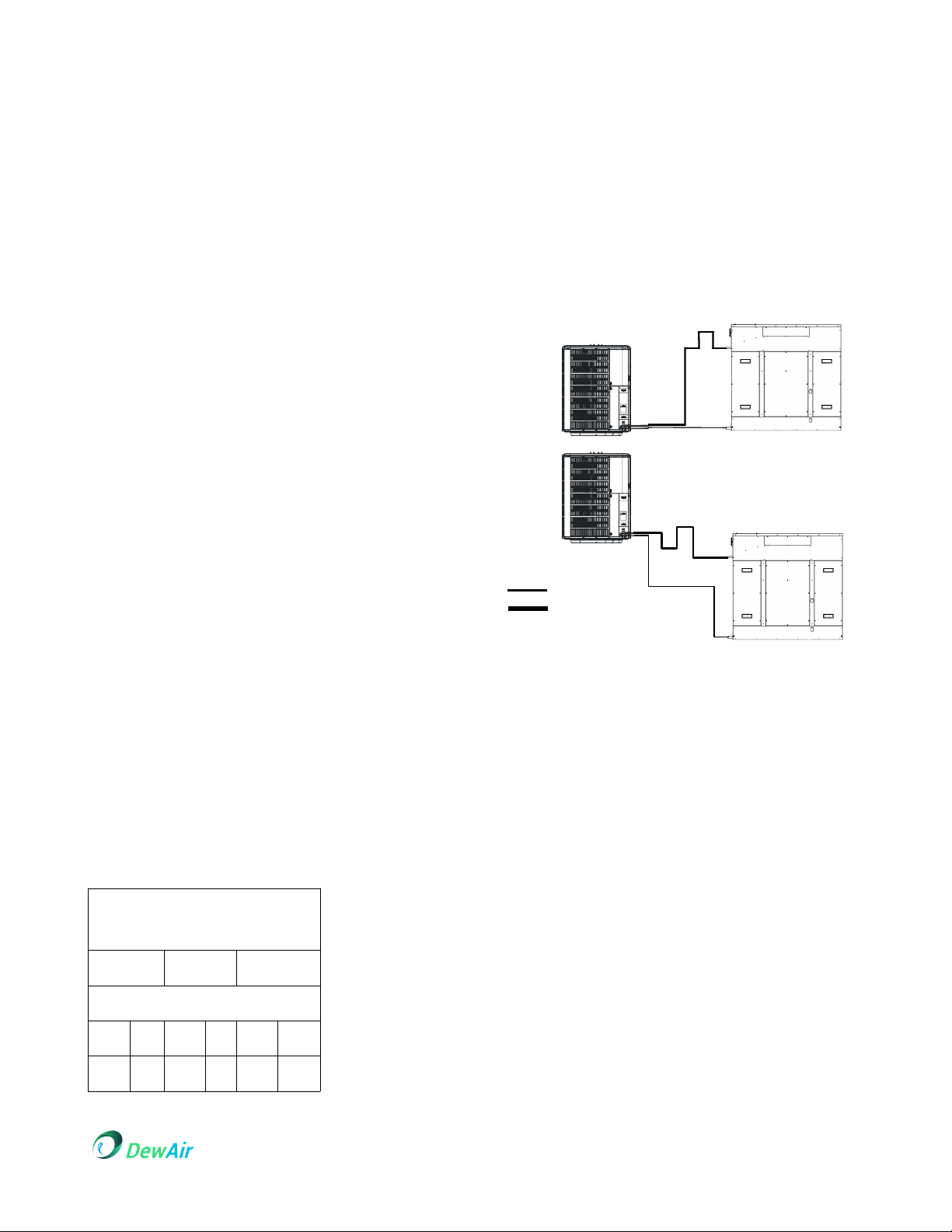

CLEARANCE

Minimum Airflow Clearance

APPLICATION

A B C

AA

Residen ial

10" 10" 18" 20"

Ligh Commercial

12" 12" 18" 24"

ROOFTOP INSTALLATIONS

If it is necessary to install this unit on a roof structure ensure

the roof structure can support the weight and that proper

consideration is given to the weather-tight integrity of the

roof. Since the unit can vibrate during operation sound

vibration transmission should be considered when installing

the unit. Vibration absorbing pads or springs can be installed

between the condensing unit legs or frame and the roof

mounting assembly to reduce noise vibration.

Special consideration must be given to location of the

condensing unit in regard to structures obstructions other

units and any and all other factors that may interfere with air

circulation.

Where possible the top of the unit should be completely

unobstructed; however if vertical conditions require

placement beneath an obstruction there should be a

minimum of 60 inches between the top of the unit and the

obstruction(s).

The specified dimensions meet requirements for air

circulation only. Consult all appropriate regulatory codes

prior to determining final clearances.

Copyright © 2019 DewAir Corporation 5 RHC18O-IM v2.11 Sep , 2019

DO NOT locate the unit:

•Directly beneath a gas appliance termination

vent

•Within 3 feet of a clothes dryer vent.

•Where the refreezing of defrost water would

create a hazard.

Where water may rise into the unit. Another important

consideration in selecting a location for the unit(s) is the

angle to obstructions. Either side adjacent the valves can be

placed toward the structure provided the side away from the

structure maintains minimum service clearance. Corner

ins alla ions are s rongly discouraged.

SAFE REFRIGERANT

HANDLING

While these items will not cover every conceivable situation

they should serve as a useful guide.

Use only refrigerant grade (dehydrated and sealed) copper

tubing to connect the condensing unit with the indoor

evaporator. After cutting the tubing install plugs to keep

refrigerant tubing clean and dry prior to and during

installation. Tubing should always be cut square keeping

ends round and free from burrs. Clean the tubing to prevent

contamination.

Do NOT let refrigerant lines come in direct contact with

plumbing duct work floor joists wall studs floors and

walls. When running refrigerant lines through a foundation or

wall openings should allow for sound and vibration

absorbing material to be placed or installed between tubing

and foundation. Any gap between foundation or wall and

refrigerant lines should be filled with a pliable silicon-based

caulk RTV or a vibration damping material. Avoid

suspending refrigerant tubing from joists and studs with rigid

wire or straps that would come in contact with the tubing.

Use an insulated or suspension type hanger. Keep both

lines separate and always insulate the suction line.

These sizes are recommended for line lengths of 79 feet or

less to obtain optimum performance. For alternate line sizing

options or runs of more than 79 feet contact your distributor

for assistance.

RECOMMENDED

INTERCONNECTING TUBING

0-24 25-49 50-79*

Line Diameter (in. OD)

Suct Liq Suct Liq Suct Liq

5/8 1/4 3/4 38 3/4 3/8

* Lines greater than 79 feet in length or vertical elevation changes

more than 50 feet contact your distributor for assistance.

Mounting the evaporator coil above the condensing

unit will require an inverted loop in the suction line

adjacent or near the connection to the evaporator. The

top of the loop must be slightly higher than the top of

the coil.

Mounting the condensing unit above the evaporator

coil will not require an oil trap in the suction line at the

evaporator except when the condensing unit is over

80 feet above the evaporator.

Insulation is necessary to prevent condensation from

forming and dropping from the suction line. Armflex (or

satisfactory equivalent) with 3/8” min. wall thickness is

recommended. In severe conditions (hot high

humidity areas) 1/2” insulation may be required.

Insulation must be installed in a manner which

protects tubing from damage and contamination.

Where possible drain as much residual compressor

oil from existing systems lines and traps; pay close

attention to low areas where oil may collect. NOTE:

Consult manufacturer before changing refrigerant

types.

BURYING REFRIGERANT LINES

If burying refrigerant lines can not be avoided use the

following checklist.

1. Insulate liquid and suction lines separately.

2. Enclose all underground portions of the refrigerant

lines in waterproof material (conduit or pipe) sealing

the ends where tubing enters/exits the enclosure.

Copyright © 2019 DewAir Corporation 6 RHC18O-IM v2.11 Sep , 2019

$010$0

2$0

3. If the lines must pass under or through a concrete

slab ensure lines are adequately protected and

sealed.

REFRIGERANT LINE CONNECTIONS

IMPORTANT

To avoid overheating the service valve TXV valve or

filter drier while brazing wrap the component with a

wet rag or use a thermal heat trap compound. Be

sure to follow the manufacturer's instruction when

using the heat trap compound. Note: Remove

Schrader valves from service valves before brazing

tubes to the valves. Use a brazing alloy of 2%

minimum silver content. Do not use flux.

Torch heat required to braze tubes of various sizes is

proportional to the size of the tube. Tubes of smaller

size require less heat to bring the tube to brazing

temperature before adding brazing alloy. Applying too

much heat to any tube can melt the tube. Service

personnel must use the appropriate heat level for the

size ofthe tube being brazed. Note: The use of a heat

shield when brazing is recommended to avoid burning

the serial plate or the finish on the unit.

1. The ends of the refrigerant lines must be cut

square deburred cleaned and be round and free

from nicks or dents. Any other condition increases the

chance of a refrigerant leak

2. "Sweep" the refrigerant line with nitrogen or inert

gas during brazing to prevent the formation of copper-

oxide inside the refrigerant lines. The POE oils used in

R410A applications will clean any copper-oxide

present from the inside of the refrigerant lines and

spread it throughout the system. This may cause a

blockage or failure of the metering device.

3. After brazing quench the joints with water or a wet

cloth to prevent overheating of the service valve.

4. Ensure the filter drier paint finish is intact after

brazing. If the paint of the steel filter drier has been

burned or chipped repaint or treat with a rust

preventative. This is especially important on suction

line filter driers which are continually wet when the unit

is operating.

NOTE: Be careful not to kink or dent refrigerant lines.

Kinked or dented lines will cause poor performance or

compressor damage.

Do NOT make final refrigerant line connection until

plugs are removed from refrigerant tubing.

NOTE: Before brazing verify indoor piston size by

checking the piston kit chart packaged with indoor

unit.

LEAK TESTING (NITROGEN OR NITROGEN-

TRACED)

WARNING

WARNING

TO AVOID THE RISK OF FIRE OR EXPLOSION NEVER

USE OXYGEN HIGH PRESSURE AIR OR FLAMMABLE

GASES FOR LEAK TESTING OF REFRIGERATION

SYSTEM.

WARNING

WARNING

TO AVOID POSSIBLE EXPLOSION THE LINE FROM

THE NITROGEN CYLINDER MUST INCLUDE A

PRESSURE REGULATOR AND A PRESSURE RELIEF

VALVE. THE PRESSURE RELIEF VALVE MUST BE SET

TO OPEN AT NO MORE THAN 150 PSIG.

Pressure test the system using dry nitrogen and soapy

water to locate leaks. If you wish to use a leak

detector charge the system to 10 psi using the

appropriate refrigerant then use nitrogen to finish

charging the system to working pressure then apply

the detector to suspect areas. If leaks are found

repair them. After repair repeat the pressure test. If no

leaks exist proceed to system evacuation.

SYSTEM EVACUATION

WARNING

WARNING

REFRIGERANT UNDER PRESSURE!

FAILURE TO FOLLOW PROPER PROCEDURES MAY

CAUSE PROPERTY DAMAGE PERSONAL INJURY OR

DEATH

Condensing unit liquid and suction valves are closed

to contain the charge within the unit. The unit is

shipped with the valve stems closed and caps

installed.

NOTE: Scroll compressors should never be used to

evacuate or pump down a heat pump or air

conditioning system.

NOTE: Prolonged operation at suction pressures less

than 20 psig for more than 5 seconds will result in

overheating of the scrolls and permanent damage to

the scroll tips drive bearings and internal seal.

NOTE: Holding charge must be removed before

brazing.

1. Open service valves before attaching vacuum

pump.

Copyright © 2019 DewAir Corporation 7 RHC18O-IM v2.11 Sep , 2019

2. Connect the vacuum pump with 250 micron

capability to the service valves.

3. Evacuate the system to 250 microns or less using

suction and liquid service valves. Using both valves is

necessary as some compressors create a mechanical

seal separating the sides of the system.

4. Close pump valve and hold vacuum for 10 minutes.

Typically pressure will rise during this period.

• If the pressure rises to 1000 microns or less and

remains steady the system is considered leak-free;

proceed to startup.

• If pressure rises above 1000 microns but holds

steady below 2000 microns moisture and/or non-

condensibles may be present or the system may have

a small leak. Return to step 2: If the same result is

encountered check for leaks as previously indicated

and repair as necessary then repeat evacuation.

• If pressure rises above 2000 microns a leak is

present. Check for leaks as previously indicated and

repair as necessary then repeat evacuation.

LINE SET

INSTALLATION

When installing the line set:

• Make sure the lines are suitable for use with R410a.

• Do not crush the lines and always allow a minimum

bend radius of 2 inches.

• Keep the ends of the lines covered to prevent dirt

and debris from entering the lines during installation.

• Secure the line set to the building with isolating

hardware to prevent vibration transmission to the

building.

• Seal and isolate the opening(s) where the line set is

routed into the building.

• Insulate the gas (suction) line to prevent water

condensation on the gas line.

• Flush the lines with an inert gas before and/or during

brazing to prevent oxidation inside the lines.

• Release the inert gas holding charge and remove the

plugs in the dehumidifier lines before brazing.

• Do not overheat the lines connected to the

dehumidifier or the condensing unit when brazing.

• Be aware of the relative location of the dehumidifier

(Indoor unit) and condensing unit (Outdoor Unit) when

installing the line set.

BRAZING THE LINE SET

WARNING

WARNING

POLYOL ESTER (POE) OILS USED WITH HFC-410A

REFRIGERANT ABSORB MOISTURE VERY QUICKLY. IT

IS VERY IMPORTANT THAT THE REFRIGERANT

SYSTEM BE KEPT CLOSED AS MUCH AS POSSIBLE.

DO NOT REMOVE LINE SET CAPS OR SERVICE

VALVE STUB CAPS UNTIL YOU ARE READY TO MAKE

CONNECTIONS

WARNING

WARNING

WHEN USING A HIGH PRESSURE GAS SUCH AS DRY

NITROGEN TO PRESSURIZE A REFRIGERATION OR

AIR CONDITIONING SYSTEM USE A REGULATOR

THAT CAN CONTROL THE PRESSURE DOWN TO 1 OR

2 PSIG.

CAUTION

CAUTION

BRAZING ALLOYS AND FLUX CONTAIN MATERIALS

WHICH ARE HAZARDOUS TO YOUR HEALTH. AVOID

BREATHING VAPORS OR FUMES FROM BRAZING

OPERATIONS. PERFORM OPERATIONS ONLY IN

WELL-VENTILATED AREAS. WEAR GLOVES AND

PROTECTIVE GOGGLES OR FACE SHIELD TO

PROTECT AGAINST BURNS. WASH HANDS WITH

SOAP AND WATER AFTER HANDLING BRAZING

ALLOYS AND FLUX.

TO PREVENT STRIPPING OF THE VARIOUS CAPS

USED THE APPROPRIATELY SIZED WRENCH SHOULD

BE USED AND FITTED SNUGLY OVER THE CAP

BEFORE TIGHTENING.

ALLOW BRAZE JOINT TO COOL BEFORE

REMOVING THE WET RAG FROM THE SERVICE

VALVE. TEMPERATURES ABOVE 2500 CAN

DAMAGE VALVE SEALS

USE SILVER ALLOY BRAZING RODS WITH 5%

MINIMUM SILVER ALLOY FOR COPPER-TO-COPPER

BRAZING. USE 45% MINIMUM SILVER ALLOY FOR

COPPER-TO-BRASS AND COPPER-TO-STEEL

BRAZING.

Copyright © 2019 DewAir Corporation 8 RHC18O-IM v2.11 Sep , 2019

CAUTION

CAUTION

THE DEHUMIDIFIER IS SHIPPED FROM THE FACTORY

PRESSURIZED WITH A CHARGE OF INERT GAS AND

WITH RUBBER PLUGS IN THE LINES. PURGE THE

INERT GAS FROM THE DEHUMIDIFIER BY REMOVING

THE RUBBER PLUGS IN THE LIQUID AND GAS LINES

TO RELEASE THE INERT GAS BEFORE CONNECTING

THE LINE SET.

Note: If there is no pressure in the dehumidifier when

the first plug is removed check the dehumidifier for

damage and leaks before continuing with the

installation.

WARNING

WARNING

WHEN CHARGING THE SYSTEM FOLLOW THE

INSTRUCTIONS IN SYSTEM STARTUP. THE

PROCEDURE VARIES FROM WHAT IS TYPICAL FOR A

CONDENSER.

Procedure to connect the line set to the Dehumidifier

1. Purge the inert gas from the dehumidifier by

removing the rubber plugs in the liquid and gas lines

to release the inert gas before connecting the line set.

2. Place a field-provided heat shield such as a wet

rag against the dehumidifier and around the piping

stubs. The heat shield must be in place to protect the

cabinet from heat damage.

3. Swage the liquid and gas lines (if necessary) to fit

onto the dehumidifier lines.

4. Purge the dehumidifier lines and the line set with

dry nitrogen (Inert gas) to prevent oxidation during

brazing. Flow dry nitrogen into the lines at a low

pressure of 1 to 2 psig.

5. Braze the line set lines to the dehumidifier lines.

6. Remove the heat shield after brazing and allow the

connections to cool.

ELECTRICAL

CONNECTIONS

WARNING

WARNING

DISCONNECT ALL POWER BEFORE SERVICING OR

INSTALLING THIS UNIT. MULTIPLE POWER SOURCES

MAY BE PRESENT. FAILURE TO DO SO MAY CAUSE

PROPERTY DAMAGE PERSONAL INJURY OR DEATH.

WARNING

WARNING

WIRING MUST CONFORM WITH NEC OR CEC AND

ALL LOCAL CODES. UNDERSIZED WIRES COULD

CAUSE POOR EQUIPMENT PERFORMANCE

EQUIPMENT DAMAGE OR FIRE.

TO AVOID THE RISK OF FIRE OR EQUIPMENT

DAMAGE USE COPPER CONDUCTORS.

The condensing unit rating plate lists pertinent

electrical data necessary for proper electrical service

and over-current protection. Wires should be sized to

limit voltage drop to 2% (max.) from the main breaker

or fuse panel to the condensing unit. Consult the NEC

CEC and all local codes to determine the correct wire

gauge and length.

Local codes often require a disconnect switch located

near the unit; do not install the switch on the unit.

Refer to the installation instructions supplied with the

indoor furnace/air handler for specific wiring

connections and indoor unit configuration. Likewise

consult the instructions packaged with the thermostat

for mounting and location information.

OVER-CURRENT PROTECTION

The following over-current protection devices are

approved for use.

• Time delay fuses

• HACR type circuit breakers

These devices have sufficient time delay to permit the

motor compressor to start and accelerate its load.

Copyright © 2019 DewAir Corporation 9 RHC18O-IM v2.11 Sep , 2019

HIGH VOLTAGE CONNECTIONS

Route power supply and ground wires through the

high voltage port and terminate in accordance with the

wiring diagram provided inside the control panel cover.

LOW VOLTAGE CONNECTIONS

For low voltage connections refer to the Indoor Unit

Installation Manual.

SYSTEM START

UP

WARNING

WARNING

REFRIGERANT UNDER PRESSURE!

• DO NOT OVERCHARGE SYSTEM WITH

REFRIGERANT.

• DO NOT OPERATE UNIT IN A VACUUM OR AT

NEGATIVE PRESSURE.

FAILURE TO FOLLOW PROPER PROCEDURES MAY

CAUSE PROPERTY DAMAGE PERSONAL INJURY OR

DEATH.

CAUTION

CAUTION

POSSIBLE REFRIGERANT LEAK

TO AVOID A POSSIBLE REFRIGERANT LEAK OPEN THE

SERVICE VALVES UNTIL THE TOP OF THE STEM IS 1/8”

FROM THE RETAINER.

When opening valves with retainers open each valve

only until The top of the stem is 1/8” from the retainer.

To avoid loss of refrigerant DO NOT apply pressure to

the retainer. When opening valves without a retainer

remove service valve cap and insert a hex wrench into

the valve stem and back out the stem by turning the

hex wrench counterclockwise. Open the valve until it

contacts the rolled lip of the valve body.

NOTE: These are not back-seating valves. It is not

necessary to force the stem tightly against the rolled

lip. The service valve cap is the secondary seal for the

valves and must be properly tightened to prevent

leaks. Make sure cap is clean and apply refrigerant oil

to threads and sealing surface on inside of cap.

Tighten cap finger-tight and then tighten additional 1/6

of a turn (1 wrench flat) or to the following

specification to properly seat the sealing surfaces.

1. 3/8” valve to 5 - 10 in-lbs

2. 5/8” valve to 5 - 20 in-lbs

3. 3/4” valve to 5 - 20 in-lbs

4. 7/8” valve to 5 - 20 in-lbs

Do not introduce liquid refrigerant from the cylinder

into the crankcase of the compressor as this may

damage the compressor.

CAUTION

CAUTION

POSSIBLE REFRIGERANT LEAK

To avoid a possible refrigerant leak open the service

valves until the top of the stem is 1/8" from the retainer.

1. Break vacuum by fully opening liquid and suction

base valves.

2. Set thermostat to call for cooling. Check indoor and

outdoor fan operation and allow system to stabilize for

10 minutes for fixed orifices and 20 minutes for

expansion valves.

CAUTION

CAUTION

THE CORRECT REFRIGERANT CRITICAL CHARGE IS

NEEDED FOR PROPER OPERATION

WARNING

WARNING

USE REFRIGERANT CERTIFIED TO AHRI STANDARDS.

USE OF USED REFRIGERANT MAY CAUSE

COMPRESSOR DAMAGE THAT IS NOT COVERED UNDER

WARRANTY. MOST PORTABLE MACHINES CANNOT

CLEAN USED REFRIGERANT TO MEET AHRI

STANDARDS..

CAUTION

CAUTION

OPERATING THE COMPRESSOR WITH THE SUCTION

VALVE CLOSED MAY CAUSE SERIOUS COMPRESSOR

DAMAGE.

Copyright © 2019 DewAir Corporation 10 RHC18O-IM v2.11 Sep , 2019

Open the suction service valve first! If the liquid

service valve is opened first oil from the compressor

may be drawn into the indoor coil TXV restricting

refrigerant flow and affecting operation of the system.

After the refrigerant charge has bled into the system

open the liquid service valve. The service valve cap is

the secondary seal for the valves and must be

properly tightened to prevent leaks. Make sure cap is

clean and apply refrigerant oil to threads and sealing

surface on inside of cap. Tighten cap finger-tight and

then tighten additional 1/6 of a turn (1 wrench fiat) or

to the following specification to properly seat the

sealing surfaces.

1. 3/8" valve to 5 - 10 in-Ibs

2. 5/8" valve to 5 - 20 in-Ibs

3. 3/4" valve to 5 - 20 in-Ibs

4.7/8" valve to 5 - 20 in-Ibs

Do not introduce liquid refrigerant from the cylinder

into the

crankcase of the compressor as this may damage the

compressor.

CRITICAL

REFRIGERANT

CHARGE

ADEQUATE REFRIGERANT CHARGE FOR THE EVAPORATOR

COIL AND 15 FEET OF LINESET IS SUPPLIED WITH THE

CONDENSING UNIT. IF LINESET EXCEEDS 15 FEET IN

LENGTH REFRIGERANT SHOULD BE ADDED AT 0.6 OUNCES

PER FOOT OF LIQUID LINE.

Copyright © 2019 DewAir Corporation 11 RHC18O-IM v2.11 Sep , 2019

OUTDOOR UNIT SPECIFICATIONS

NOTE: This data is provided as a guide it is important to electrically connect the unit and properly size fuses/ circuit breakers

and wires in accordance with all national and/or local electrical codes. Use copper wire only.

Part Number GSX14018

(CZ)

GSX14024

(HH)

Cooling Capacity BTUH 18,000 24,000

Compressor

R.L. Amps

L.R. Amps

Decibels

Low Pressure Switch

Open

Close

High Pressure Switch

Open

Close

6.0

37.5

75

22 PSI

50 PSI

6 1 0 P S I

4 2 0 P S I

7.7

38.0

74

22 PSI

50 PSI

6 1 0 P S I

4 2 0 P S I

Condenser Fan Motor

Horsepower

F.L. Amps

1/8

0.65

1/8

0.7

Refrigeration System

Line Size

Liquid Line, Inches O.D.*

Suction Line, Inches O.D.*

Connection Size

Liquid Valve Size (OD)

Suction Valve Size (OD)

Valve Type

Refrigerant Charge

Included Piston

Low Pressure Switch

High Pressure Switch

3/8"

3/4"

3/8"

3/4"

sweat

68

0.051

94 psi

150 psi

3/8"

3/4"

3/8"

3/4"

sweat

72

0.057

94 psi

150 psi

Electrical Data

Voltage-Phase (60 Hz)

Min/Max Volts

Max. Overcurrent Protection

Minimum Circuit Ampacity(1)

208/230-1

197/253

15 A

8.2 A

08/230-1

197/253

15 A

10.3 A

Weights

Equipment Weight

Shipping Weight

102 lb

117 lb

126 lb

141 lb W x D x H

Inches 26 x 26 x 27½

cm 66 x 66 x 70

Copyright © 2019 DewAir Corporation 12 RHC18O-IM v2.11 Sep , 2019

()003456780099:074929557095

;<70=:0:0551059>:003

()*9<088=772"=0?MUST08"59@

7@A0079BC74980397

DW

H

NOTES

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

Copyright © 2019 DewAir Corporation 13 RHC18O-IM v2.11 Sep , 2019

This manual suits for next models

3

Table of contents

Popular Dehumidifier manuals by other brands

Horizon Fitness

Horizon Fitness Titan XP90 Installation and operation manual

Tectro

Tectro TD 1010 operating manual

Royal Sovereign

Royal Sovereign RDH-045EA owner's manual

INVENTOR

INVENTOR DE-MDDF20 user manual

Humidex

Humidex CCC-103E Installation & owner's manual

Pahwa Group

Pahwa Group Delair RD Series Operating, installation and maintenance manual