10

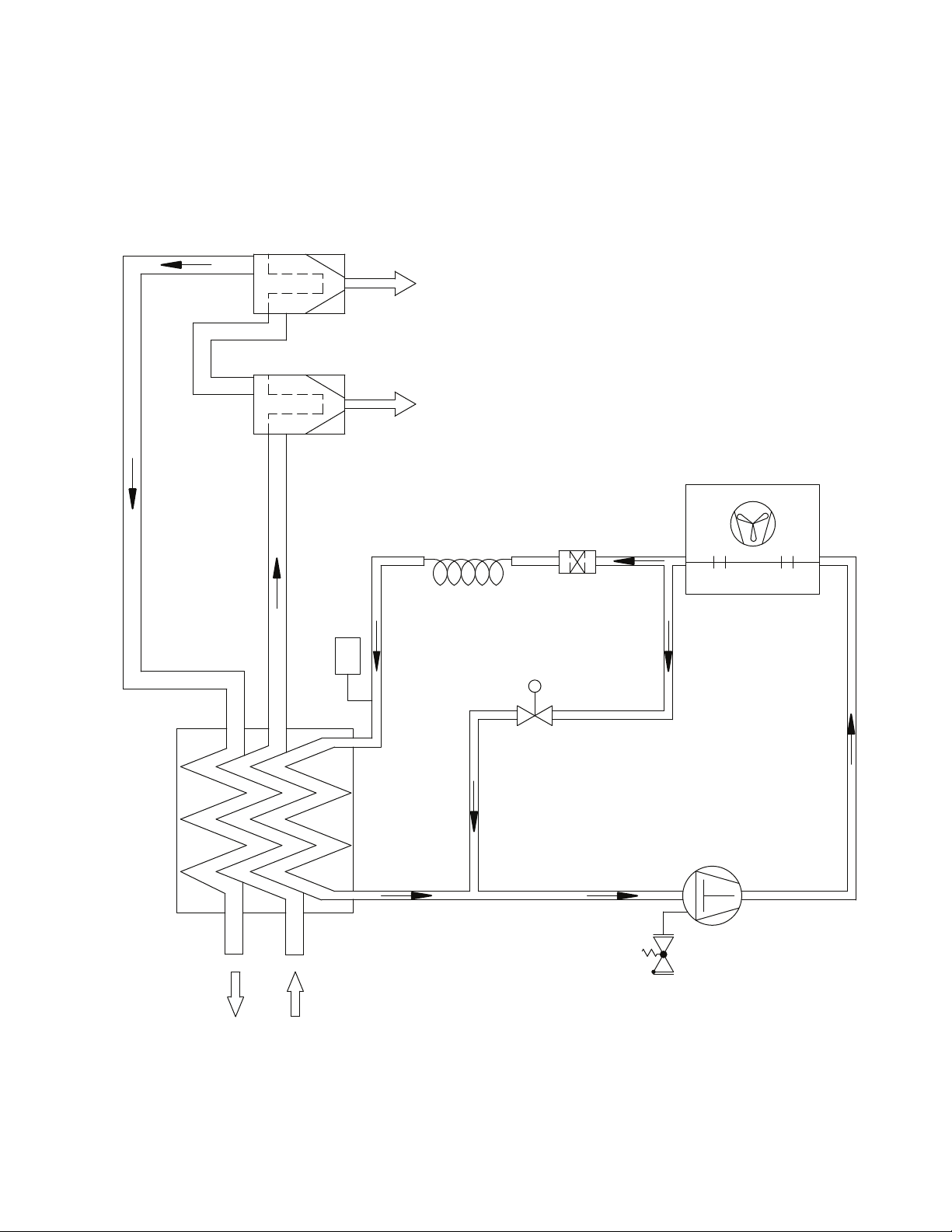

TROUBLESHOOTING GUIDE

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

A. Water downstream of

dryer.

1. Residualfreemoistureremainingin

downstream pipelines.

2. Airby-passsystemisopen.

3. Inletandoutletconnectionsare

reversed.

4. Temperatures surrounding air lines

downstreamofdryerhavedropped

below dryer’s dew point rating.

5. Excessivefreemoisture(bulkliquid)

at dryer inlet.

6. Condensatenotbeingautomatically

drained.

Drainmechanismiscloggedor

inoperative.

Drainlineisrestrictedorfrozen.

7. Dryeroverloadedresultingin

elevated dew point.

8. Refrigerationsystemnot

functioningproperlyresultingin

elevated dew point.

Blow out system with dry air.

Checkvalvepositions.

Checkforcorrectconnection.

Insulateorheattraceairlinesexposedto

low ambients or dry air to lower dew point.

Installseparatoraheadofdryer.

Replacedrainmechanismifinoperative.

Open drain line.

Checkinletairtemperatureandpressure,

owrate(compressorcapacity)and

ambient air temperature.

SeeDbelow.

B. High pressure drop

across dryer.

1. Excessiveairow.

2. Freezingofmoistureinevaporator

becauseofrefrigerationsystem

improperlyfunctioning.

3. Separatororoptionaloilremoval

lterelementclogged.

Checkowrate.

SeeDbelow.

Replacelterelement(s).

C. Dew point indicator

in red area.

1. Dryeroverloadedresultinginhigh

air outlet temperature.

2. Refrigerationsystemnot

functioningproperlyresultingin

high air outlet temperature.

3. Temperature sensor not properly

attached,uninsulated,or

malfunctioning.

SeeA7.

SeeDbelow.

Checksensorbulb.

D. Refrigeration system

not functioning

properly.

1. Poweronlightoff.

2. Refrigerantcompressor

cyclesonandoff.

a. ON/OFFswitchis“OFF”.

b. Linedisconnectswitchopen.

c. Blownfuses,openbreaker.

d. Faultywiring,looseterminals.

a. Highorlowambientconditions.

b. Dirty,cloggedcondenserns,

obstructedairowacross

condenser,ornonfunctioningfan

motor.

Turnswitch“ON”.

Close disconnect switch.

Checkforcontinuity.

Haveelectriciancheckelectrical

connections.

Checkmin./max.temperatureranges

Cleancondenserandcheckforfreeair

ow,ifproblempersistscontactqualied

refrigerationrepairmanormanufacturer’s

service department.