10

1.4 Safety measures

For your safety, the RD series Compressed Air Dryer are equipped with all necessities for safety and can be

operated continuously.

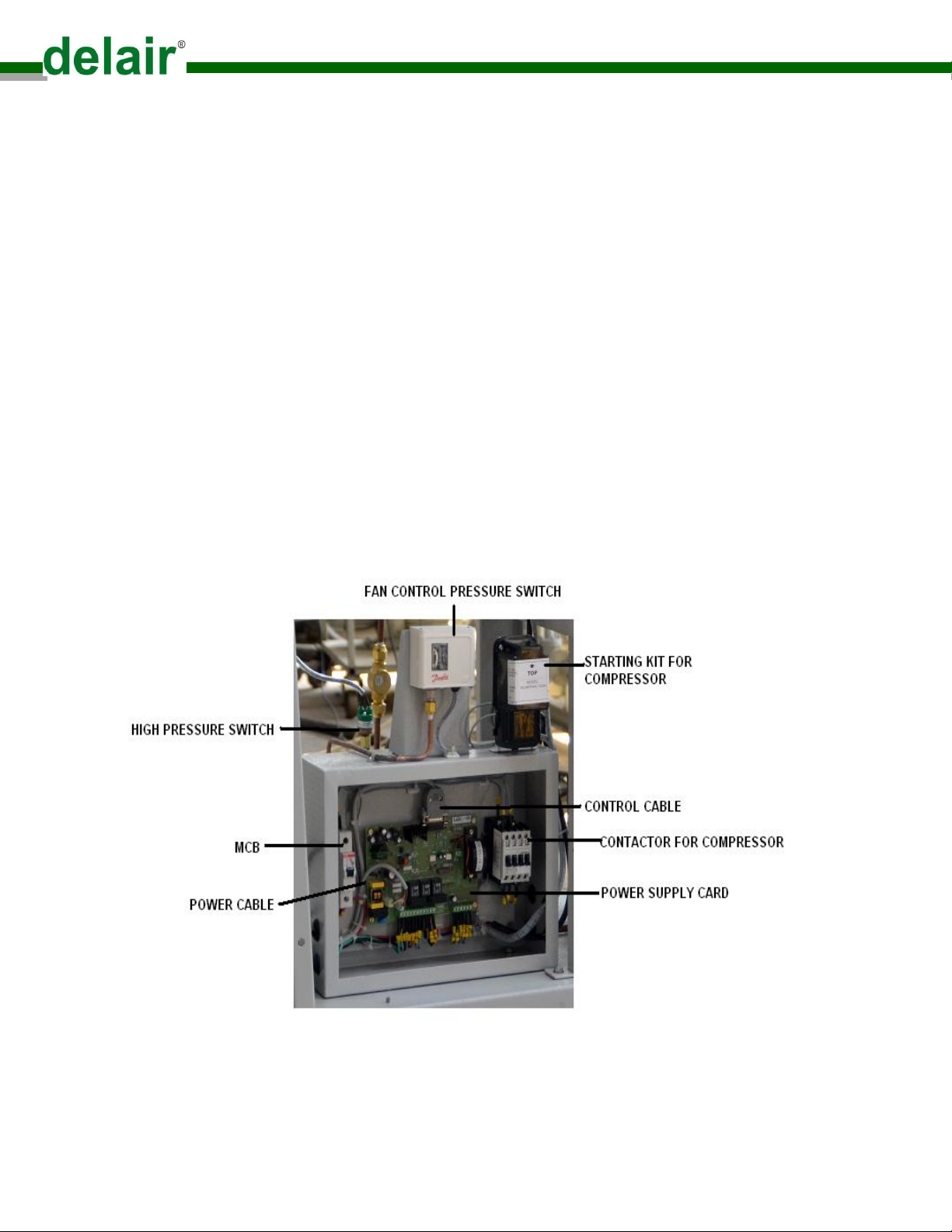

Miniature circuit breaker

( MCB )

MCB is located in the control panel box. It is help to protect

our Dryer unit against flow overcurrent.An Overcurrent

(insert MCB image) can be either an overload current or a

short circuit (insert MCB image)

High pressure control

switch

Pressure control switch is located in the field. In addition to

pressure control switches for refrigeration system have

pressure controls. Pressure control switch directly affect the

main mass flow of the refrigeration circuit by opening &

closing (insert pressure control switch image)

Fan control pressure

switch

Use on the high pressure side to a variable speed fan control

for ensuring that the condensing pressure does not drop too

low, especially in cold weather. (insert fan pressure control

switch image)

Single phase preventer

( motor protection relay )

( in case of 3 phase

supply unit )

Is located in the control panel box. It is help motor protection

in Following conditions :-

Overloading condition.

Phase failure condition.

Phase reversal condition

Unbalanced current condition

Dry running condition

(insert MPR image)

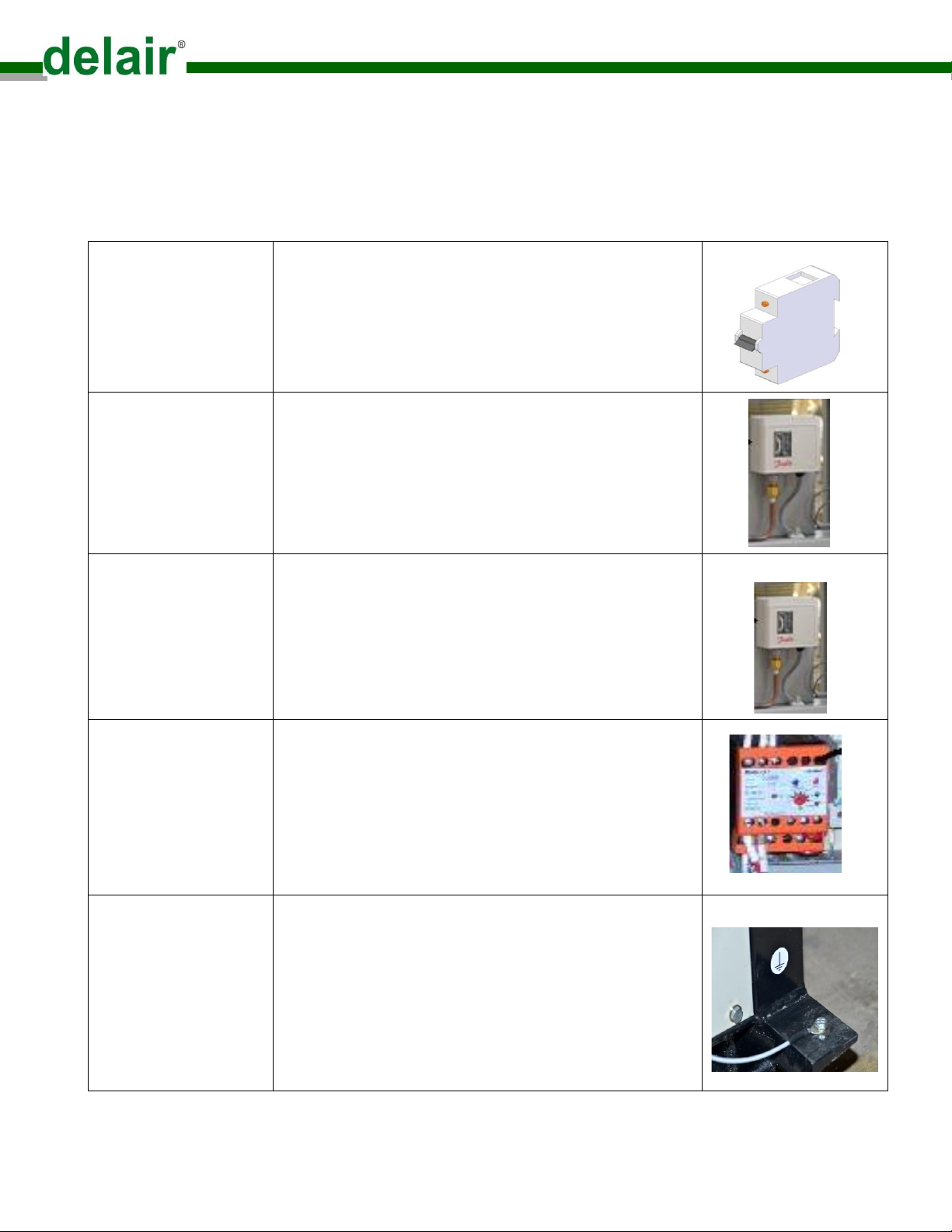

System earthing is essential to the proper operation of the

system, whereas equipment earthing concerns the safety of

personnel and plant. A key function of equipment earthing is

to provide a controlled method to prevent the build up of stat-

ic electricity, thus reducing the risk of electrical discharge in

potentially hazardous environments. Generally, a resistance

to earth of less than 10.6 ohms will ensure safe dissipation of

static electricity in all situations.