8

English

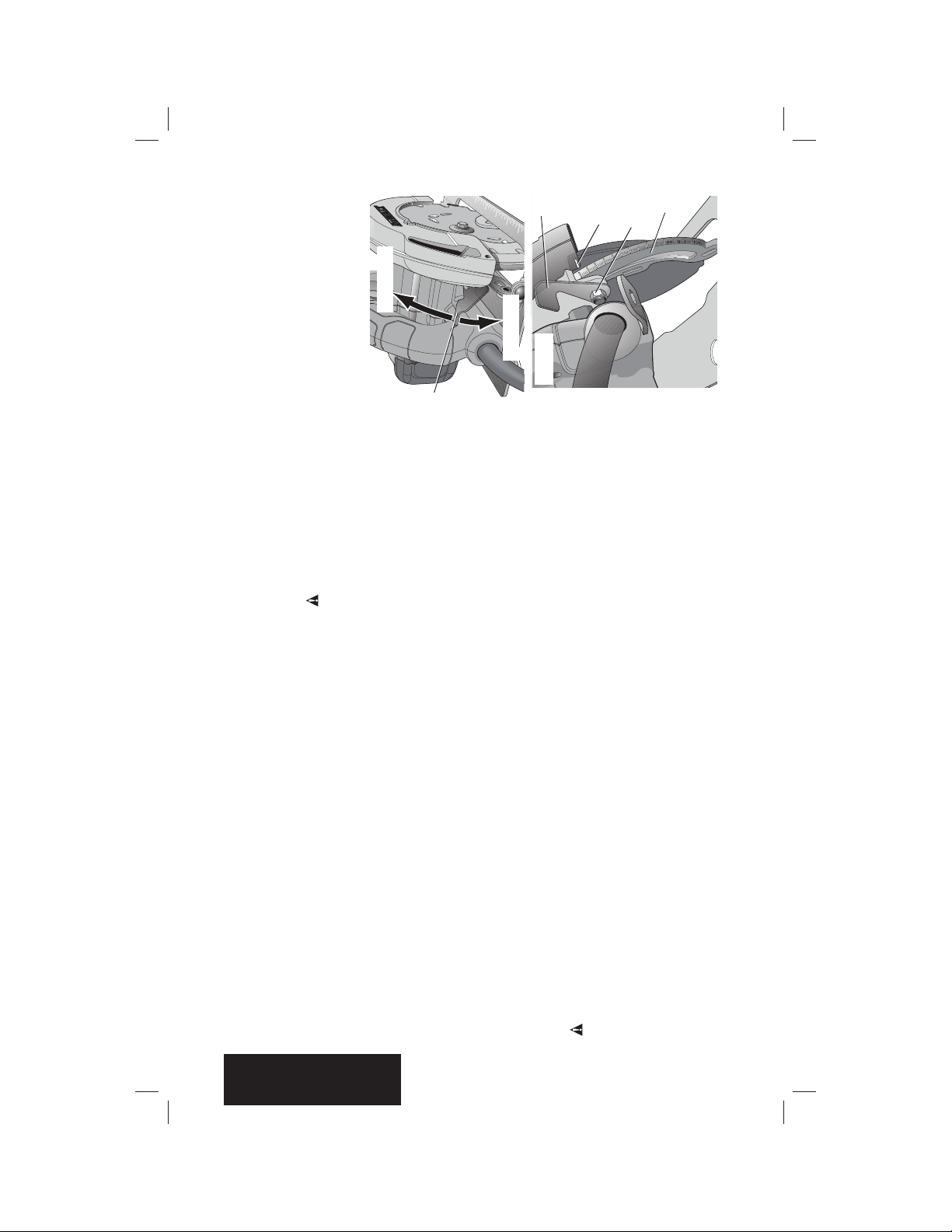

TO REPLACE THE BLADE (FIG. 2, 4, 5)

1. To loosen the blade clamping screw (J), depress the blade lock

(C) and turn the saw spindle with the blade wrench (O), stored

underneath the main handle (B), until the blade lock engages

and the blade stops rotating. With the blade lock engaged,

turn the blade clamping screw counterclockwise with the blade

wrench (screw has right-hand threads and must be turned

counterclockwise to loosen).

2. Remove the blade clamping screw (J) and outer clamp washer (N).

Remove old blade.

3. Clean any sawdust that may have accumulated in the guard or

clamp washer area and check the condition and operation of the

lower blade guard as previously outlined. Do not lubricate this area.

4. Select the proper blade for the application (refer to Recommended

Blade Types under Blades). Always use blades that are the

correct size (diameter) with the proper size and shape center hole

for mounting on the saw spindle. Always assure that the maximum

recommended speed (rpm) on the saw blade meets or exceeds

the speed (rpm) of the saw.

5. Follow steps 1 through 5 under To Install the Blade, making sure

that the blade will rotate in the proper direction.

LOWER BLADE GUARD

WARNING: The lower blade guard is a safety feature which

reduces the risk of serious personal injury. Never use the saw if

the lower guard is missing, damaged, misassembled or not

working properly. Do not rely on the lower blade guard to

protect you under all circumstances. Your safety depends on

following all warnings and precautions as well as proper

operation of the saw. Check lower guard for proper closing

before each use as outlined in Additional Safety Rules for

Circular Saws. If the lower blade guard is missing or not

working properly, have the saw serviced before using. To

assure product safety and reliability, repair, maintenance and

adjustment should be performed by an authorized service

center or other qualified service organization, always using

identical replacement parts.

Cutting Depth Adjustment (Fig. 6–8)

WARNING: To reduce the risk of injury, turn unit off and

disconnect it from power source before installing and removing

accessories, before adjusting or when making repairs. An

accidental start-up can cause injury.

Your saw is equipped with a LOOSEN

TIGHTEN

P

FIG. 6

carbide tipped saw blade for

long life and efficient cutting.

Setting the saw at the proper

cutting depth keeps blade

friction to a minimum, removes

sawdust from between the

blade teeth, results in cooler,

faster sawing and reduces the

chance of kickback.

1. Hold the saw firmly. Raise the FIG. 7

R

Q

P

S

depth adjustment lever (P) to

loosen and move foot plate to

obtain the desired depth of

cut, as shown. Make sure the

depth adjustment lever has

been retightened (lowered)

before operating the saw.

2. Align the appropriate mark on

the depth adjustment strap (R)

with notch (Q) on the upper

blade guard. Your depth is set.