DEZEGA P-70i User manual

COMPRESSED-OXYGEN

CLOSE-CIRCUIT

SELF-CONTAINED

BREATHING APPARATUS

P-70i

User manual

EN

SKTB.01.P70Y.00.00.000 РЭ

Red. 24.02.2023_V1

COMPLIES WITH:

IS 10245 (PART 1):1996 (REAFFIRMED 2006)

EN 60079-0:2018; EN 60079-11:2012

Eх I M1 Ех ia I Ma T4 Tamb -20˚C to +60˚C

TABLE OF CONTENTS

INTRODUCTION .......................................................................................................................4

1. SAFETY INSTRUCTIONS ...................................................................................................5

2. PURPOSE, DESIGN AND OPERATION PRINCIPLES

OF THE BREATHING APPARATUS...................................................................................6

3. TECHNICAL DATA ..............................................................................................................6

4. BREATHING APPARATUS CONFIGURATION...................................................................7

5. PREPARATION FOR USE ...................................................................................................8

6. BREATHING APPARATUS DISASSEMBLY........................................................................8

7. BREATHING APPARATUS CLEANING,

DISINFECTION AND DRYING .........................................................................................14

8. BREATHING APPARATUS MAINTENANCE ....................................................................15

9. BREATHING APPARATUS ASSEMBLY............................................................................17

10. CHECKING THE BREATHING APPARATUS ...................................................................20

11. DONNING AND OPERATING THE BREATHING APPARATUS.......................................22

12. WORKING IN THE BREATHING APPARATUS ................................................................24

13. POSSIBLE PROBLEMS AND TROUBLESHOOTING

OF THE BREATHING APPARATUS.................................................................................28

14. RULES OF STORAGE AND TRANSPORTATION

OF THE BREATHING APPARATUS.................................................................................31

15. MANUFACTURER’S WARRANTY, SERVICE LIFE..........................................................31

16. DISPOSAL .........................................................................................................................32

ANNEX 1

RECOMMENDATIONS FOR PERFORMING A QUICK CHECK

OF THE APPARATUS..........................................................................................................33

ANNEX 2

ELECTRONIC MEASURING DEVICE FOR THE P-70і

BREATHING APPARATUS ..................................................................................................35

1. TERMS AND DEFINITIONS ...........................................................................................34

2. DESCRIPTION AND OPERATION.................................................................................35

3. INTENDED USE ......................................................................................................... 41

Р-70i DEZEGA

4

INTRODUCTION

This User Manual introduces the device and the rules of use of the Compressed-oxygen close-

circuit self-contained breathing apparatus P-70і («breathing apparatus»). The Manual describes

the principles of operation, design and rules for the preparation of the breathing apparatus

for work as well as a quick procedure for technical condition checks and recommendations

for maintenance of the breathing apparatus.

The breathing apparatus is made in accordance with and satisfies all the requirements

of the IS 10245 part 1.

The breathing apparatus is a closed-circuit SCBA (CC SCBA) with the nominal working duration

(hereinafter referred to as the «NWD») of 2 hours and eective duration - 2,5 hours, and is PPE that

protects the respiratory organs from non-toxic dust and toxic substances.

The breathing apparatus is classified as a Class 2P.

The electronic measuring device (EMD) of the breathing apparatus is designed in accordance with

the following European standards: EN 60079-0:2012/A11:2012, EN 60079-11:2012 and Directive

2014/34/EU and classified as Ex I M1 Ex ia I Ma T4 Tamb –20 0С to +60 0С.

Breathing apparatuses must be used and maintained by persons who have the appropriate

qualifications. The breathing apparatus must undergo complete disassembly and maintenance

in accordance to maintenance intervals.

The manufacturer guarantees the correct operation of the breathing apparatus and its compliance

with the technical conditions and/or protection properties in case of appropriate repairs, maintenance,

inspection. Only trained and qualified personnel are permitted to inspect, repair and service the

product as specified in this user manual. Further maintenance work that is not specified in this user

manual must only be carried out by DEZEGA or personnel qualified by DEZEGA.

NOTE!

In case of violations in the maintenance, repair or service specified in the current User manual,

the owner or the user of the breathing apparatus shall bear full responsibility for the operation and

technical parameters of the breathing apparatus.

DEZEGA is not responsible for any consequences of the use of SCBA for purposes not specified

herein and failure to comply with the recommendations of this Manual.

The manufacturer has the right to implement minor structural changes that do not aect the operation

and do not impair the performance characteristics of the breathing apparatus without notice to the

users.

The Manual uses a series of symbols to draw the user’s attention to features, problems, and

dangerous situations as may be encountered in the course of the use and maintenance of the

breathing apparatus.

NOTE!

This symbol indicates additional information about the rules, methods, and recommendations for the

correct use of the breathing apparatus.

CAUTION!

This symbol indicates a dangerous situation that, if not eliminated, could result in equipment damage,

injury, death of the user or injury of the maintenance personnel.

DANGER!

This symbol indicates an inevitable dangerous situation that, if not eliminated, can lead to a serious

injury or death of the user.

DEZEGA Р-70i

5

1. SAFETY INSTRUCTIONS

NOTE!

The breathing apparatus must only be used for the purposes specified herein. You must fully understand

and strictly adhere to this manual.

CAUTION!

Only original spare parts and DEZEGA D-SORB soda lime must be used for the use, repair and

maintenance of the breathing apparatus.

Restrictions on the use of Personal Protective Equipment

The breathing apparatus supply a gas mixture for breathing for approximately 2 hours and isolates the

user from the ambient atmosphere that may be contaminated or have a lack of oxygen for breathing.

The use of the breathing apparatus is allowed only under the following conditions:

• the user has passed special training and is allowed to work using the breathing apparatus according

to medical indications as established;

• the oxygen cylinder is fully filled with oxygen (with a minimum degree of purification of 99.5 %

by volume);

• the absorption cartridge is filled with an absorber DEZEGA D-SORB;

• the breathing apparatus is regularly serviced and checked in accordance with this Manual;

• the user has no beard and the mask fits tightly to the skin of the face;

• it is forbidden to replace the battery in an explosion hazardous area. Only recommended batteries

should be used in the P-70i;

• do not disconnect the component parts of the EMD in the explosion hazardous area;

• do not leave the EMD for a long time under the action of direct sunlight as well as heat sources;

• do not attempt to disassemble, perform repair, maintenance or upgrade the EMD. To do this,

contact your supplier or manufacturer.

NOTE!

Actual NWD for a particular user may dier from the nominal NWD due to the impact of various factors.

The actual NWD may be aected by:

• physical fitness of the user (increased oxygen consumption);

• the nature of work performed (active oxygen consumption);

• emotional state of the user (an anxious or excited user can consume more oxygen);

• the condition of breathing apparatus (poorly serviced or badly adjusted breathing apparatuses may

have a leak);

• improperly filled absorption cartridge;

• cylinder pressure before use (if cylinder is not filled completely).

DANGER!

In some cases, the actual NWD of the breathing apparatus may be less than 2 hours. Users who are

unfit, stressed-out, with a large build, who work in dicult conditions, as well as uninformed users or

users who do not keep the breathing apparatus in a good condition, will spend oxygen faster.

DANGER!

The breathing apparatus is not intended for use underwater. Attempts to use breathing apparatus

underwater can cause serious injury or death.

Р-70i DEZEGA

6

2. PURPOSE, DESIGN AND OPERATION PRINCIPLES

OF THE BREATHING APPARATUS

The breathing apparatus is designed to protect the user’s respiratory system from the harmful

effects of respiration in an IDLH (immediately dangerous for life and health) atmosphere during

the performance of mine rescue, emergency rescue, and technical operations in coal mines, tunnels

and other industrial facilities.

The breathing apparatus ensures reliable protection of the human respiratory system in an atmosphere

that contains insucient oxygen or contains toxic gases and coal dust. It’s designed for operation at

an air temperature of minus 6 °C to plus 60 °C (it is allowed to operate the breathing apparatus at the

temperature of minus 20 °C, but when donning the temperature should not be below 10 °C), relative

humidity of up to 100 % and atmospheric pressure of 70-125 kPa.

The breathing apparatus is a self-contained device that supplies pure oxygen. The breathing gas

mixture circulates in a closed respiratory circuit. Soda-lime CO2absorber absorbs carbon dioxide

contained in a mixture of gases exhaled by the user. In the breathing bags, the gas mixture is

enriched with oxygen from an oxygen cylinder. At low and normal respiration frequency (resting state,

walking at a normal rate), oxygen is supplied to the breathing system only through a constant flow

dosing valve. At an increased breathing frequency, an additional amount of oxygen is fed through

the demand valve or the manual bypass valve. The breathing mixture heated by the regeneration

reaction and cools down in the separator and cooler. In order to reduce the temperature of the

inhaled gas mixture and thereby minimize the user’s discomfort and as well as during work at an

elevated ambient temperature, the cooling elements (water ice cube) are placed into the cooler of

the breathing apparatus.

The breathing apparatus is also equipped with electronic measuring device (EMD) that signals that

the cylinder valve is closed or that there is no oxygen in the system the cylinder pressure drops below

minimum set pressure. This device also has a number of additional information-related features,

which are described below.

The model of breathing apparatus may also be equipped with connecting device based on

medium-pressure between breathing apparatuses, which is available as an option for the customers.

3. TECHNICAL DATA

Nominal working duration, NWD, hours 2

Eective working duration, EWD, hours 2,5

Oxygen cylinder capacity, dm31,8

Pressure in the oxygen cylinder, MPa 20

Continuous oxygen supply, dm3/min 1,8±0,2

Oxygen capacity, not less dm3360

Weight of the soda lime CO2absorber, not less, kg 2,3

Weight of an equipped breathing apparatus, kg 13

Demand valve opening pressure, Pa ≥ 0

Relief valve opening pressure, Pa ≤1000

Breathing apparatus dimensions (DxWxH), mm (582х403х175)±3

DEZEGA Р-70i

7

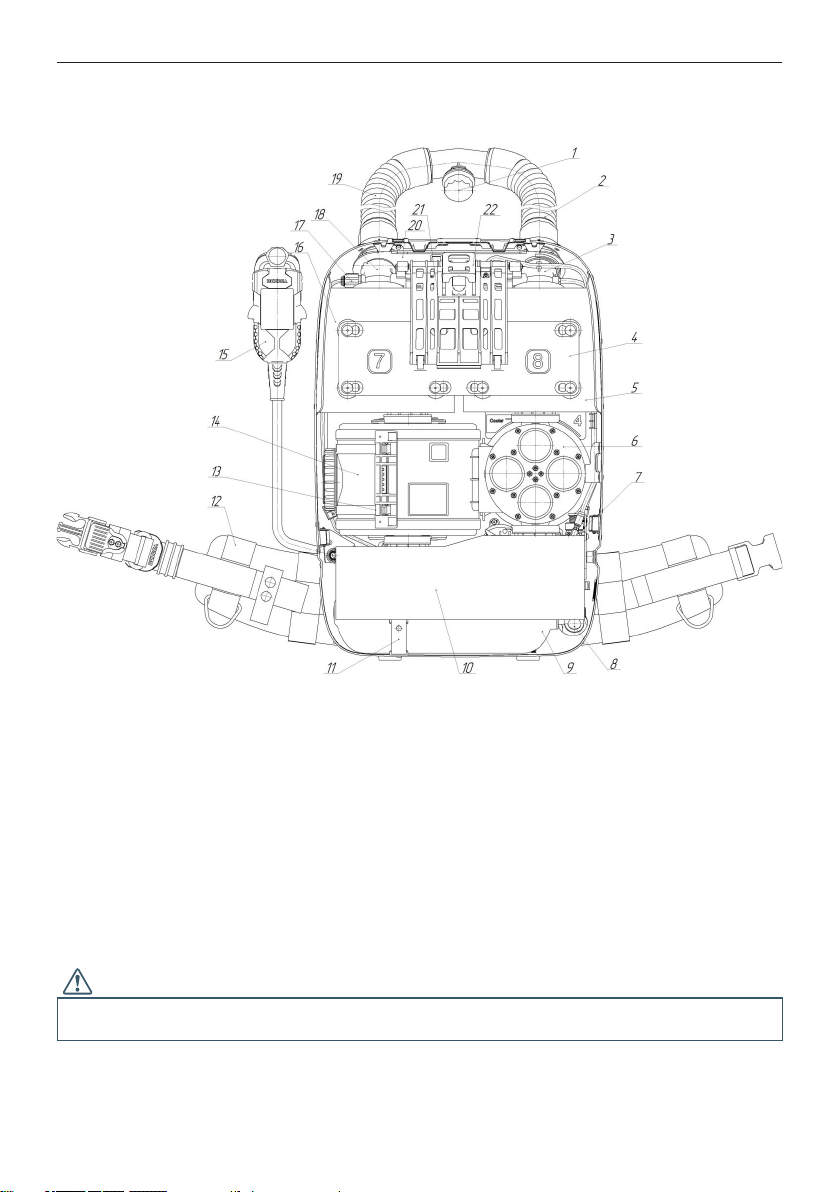

4. BREATHING APPARATUS CONFIGURATION

1 – face piece connector; 2 – inhalation hose; 3 – inhalation valve; 4 – crosstop’s slat;

5 – inhalation bag; 6 – cooler ; 7 – oxygen-distribution unit; 8 – cylinder valve; 9 – cylinder;

10 – separator; 11 – cylinder coupling strap; 12 – harness system (belt);

13 – clamp of absorption cartridge; 14 – absorption cartridge; 15 – CU EMD; 16 – exhalation bag;

17 – LP Sensor EMD; 18 – exhalation valve; 19 – exhalation hose; 20 - frame;

21 – crosstop`s lever; 22 – crosstop`s lever retainer;

Lid (cover) and the mask are not shown.

The list of spare parts and accessories supplied by the manufacturer as an option/by separate

order is given in catalog with list of spare parts and accessories.

The information about the EMD, which is an integral part of the breathing apparatus, is shown in

ANNEX 2.

NOTE!

You may order a catalogue of breathing apparatus parts and components from your local dealer

of ТМ DEZEGA or download it from the website www.dezega.com.

Р-70i DEZEGA

8

5. PREPARATION FOR USE

The breathing apparatus distributes to user as a complete assembly with empty regenerative

cartridge, empty oxygen cylinder and without battery in electronic measuring device.

The first use

Before starting the operations, wash your hands thoroughly with soap and wipe the tools with

desinfector or ethyl alcohol.

Before using the breathing apparatus for the first time, check the integrity of the seals, visually

absence of damages, fill the CO2absorption cartridge (see «Filling the CO2absorption Cartridge»),

install oxygen-filled cylinder, and test the breathing apparatus (see «Checking the Breathing

Apparatus»).

Disassembly, assembly, equipment, and check of the breathing apparatus using control devices

must be carried out in designated premises with the use of calibrated (verified) equipment.

DANGER!

To avoid serious injury or death, never allow contact of compressed oxygen with oil, grease, or similar

organic pollutants. This may lead to an explosion or a fire.

6. BREATHING APPARATUS DISASSEMBLY

CAUTION!

The semi-knock-down disassembly of the breathing apparatus must be carried out without the use of

tools, except where the use of a tool is unambiguously prescribed by this Manual. The use of tools for

the semi-knockdown disassembly and cleaning of the breathing apparatus may damage the breathing

apparatus and cause it to malfunction.

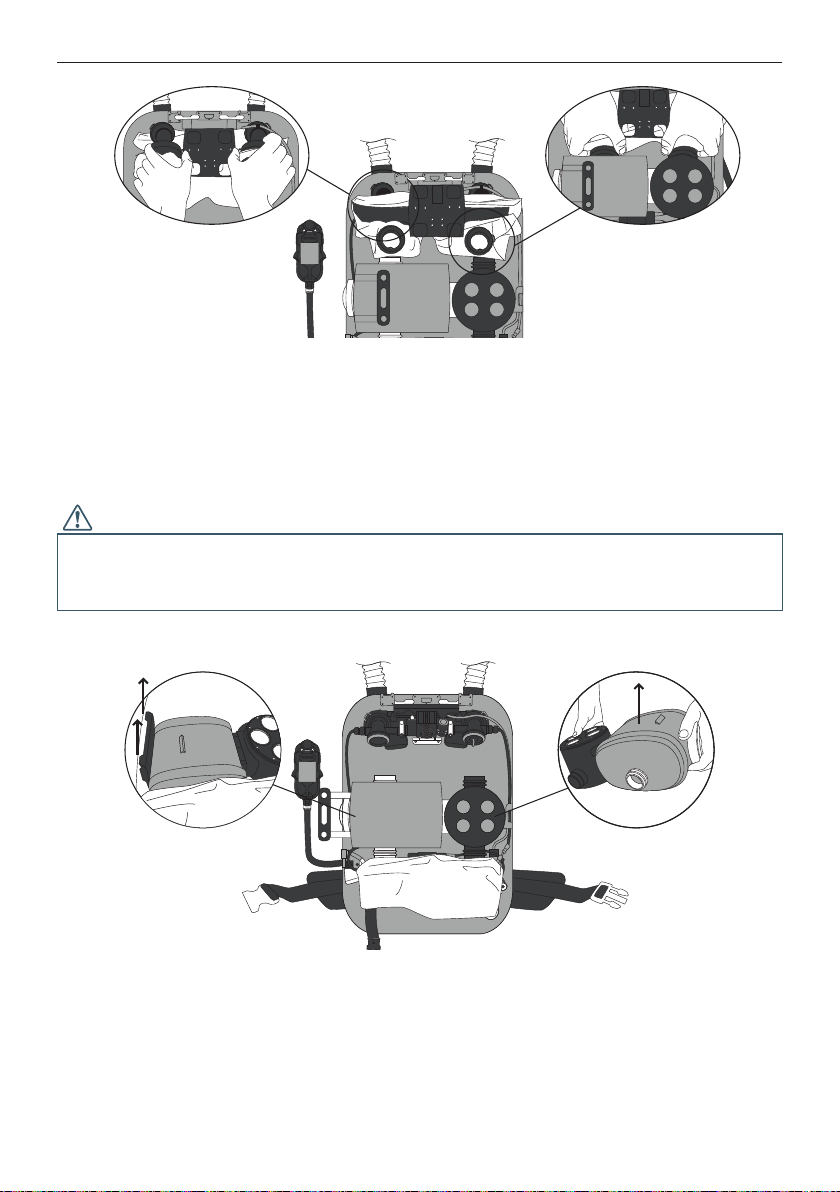

Breathing apparatus casing

• Place the breathing apparatus on the harness system horizontally on a solid surface in front

of you up with hoses facing away from you, simultaneously press the buttons located on the

sides of the breathing apparatus case and then move upwards and slightly forward to remove

the cover.

DEZEGA Р-70i

9

Oxygen cylinder

Make sure that the oxygen cylinder valve is closed and the connections are not contaminated with

oil or grease.

• Manually loosen the connection between the cylinder valve and the oxygen distribution unit

and disconnect them.

• Remove the edge of the strapping tape on cylinder left side from the pin and loosen it.

• Hold the cylinder by valve and take it out by moving aside from oxygen distribution unit. With

the help of another hand move the nut of oxygen distribution unit away from the valve by

squeezing the spring.

CAUTION!

Do not use tools to disconnect the cylinder. Only manual disconnection of the oxygen cylinder is

allowed.

Breathing system

The breathing system contains breathing hoses, inhalation and exhalation valves, a regenerative

cartridge, a cooler, and breathing bags.

• Disconnect crosstop’s lever and frame, by lifting the catch on the lever.

Р-70i DEZEGA

10

• Press the flange lock buttons of inhalation and exhalation bags located respectively on

fittings of cooler and absorption cartridge and disconnect the bags.

• Press the flange lock buttons of the inhalation and exhalation bags located respectively on

fittings of inhalation and exhalation valve boxes and disconnect the bags.

• Remove the bags, along with the crosstop’s slat and lever, from the case of the breathing

apparatus.

NOTE!

The inhalation and exhalation breathing bags have two flanges each, where the clips are located on the

relevant mating fitting. In day-to-day operation, the bags are secured to a crosstop’s slat where

a lever is mounted. The inhalation and exhalation bags have relevant markings that correspond to the

markings on the slat, which prevents their incorrect installation.

• Remove the holder of the absorption cartridge from the protrusion that is located on the

absorption cartridge.

• By pressing the spring retainer holding the cooler, remove the cooler together with the

absorption cartridge and separator.

DEZEGA Р-70i

11

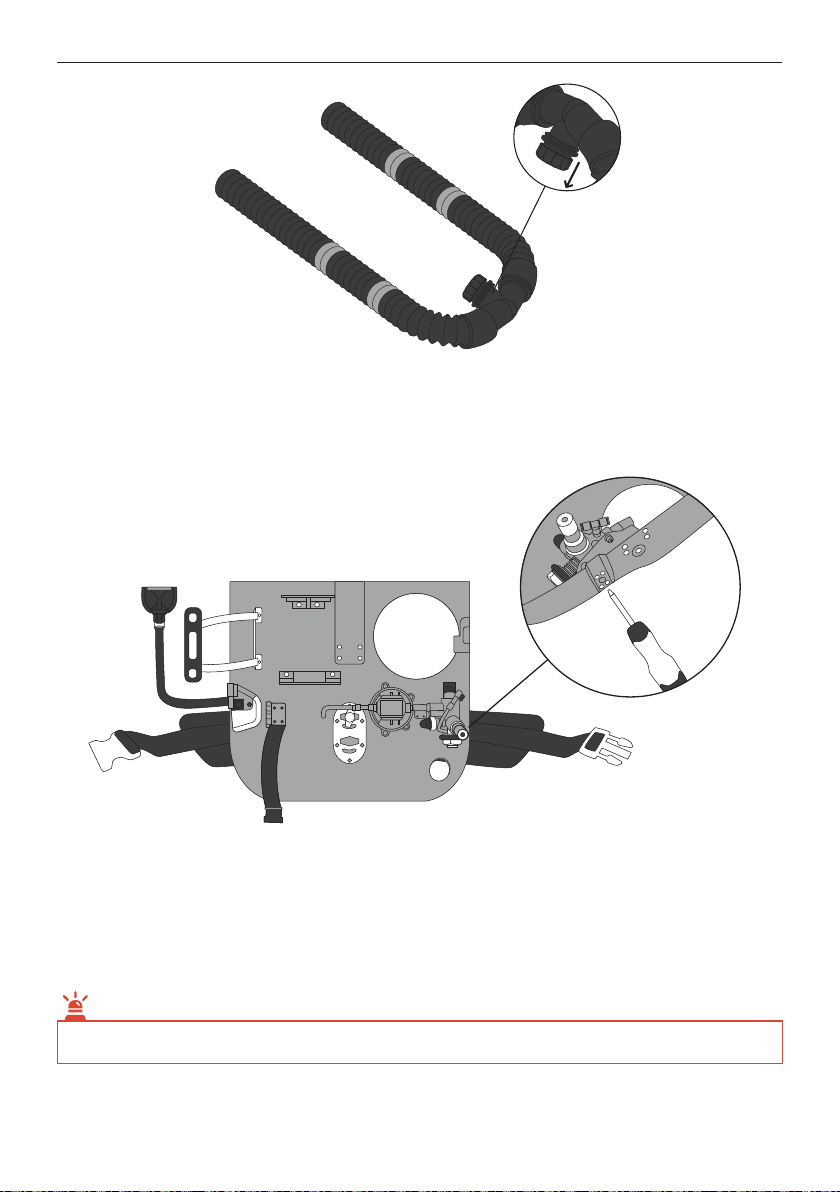

•Press the flange lock buttons of separator and disconnect it from cooler and absorption

cartridge.

•Separate the cooler and absorption cartridge by pulling out and turning the locks located on

the cooler.

•Rotate the levers of inhalation and exhalation valve locks inside the case.

•Remove the exhalation valve, together with the relief valve, by pulling it towards you inside

the case. For easier removal, rotate the exhalation hose fittings around the valve fitting.

•Separate the body of the exhalation valve and relief valve by pulling along the axis of fitting

connecting them.

•To remove the low-pressure sensor, unscrew the nut and remove it from the valve.

Р-70i DEZEGA

12

•Remove the inhalation valve together with the demand valve out of the seat by pulling it

towards you inside the case. For easier removal, rotate the inhalation hose fittings around

the valve fitting.

•Separate the inhalation valve and demand valve by pulling along the axis of fitting

connecting them.

•Disconnect the tubes of the constant supply and demand valve from the oxygen distribution

unit, or from the tee connecting breathing apparatuses via medium pressure,

•Plug their holes by connecting connectors between each other located at the ends

of the tubes.

•Release the locking springs located near the places of installation of inhalation and exhalation

valves that hold the frame on the body of the breathing apparatus. Pull the frame out of the

body by pulling it upwards and towards you.

•Remove fittings of the breathing hose system from the frame.

•Remove the breathing hose system from the case.

DEZEGA Р-70i

13

• Disconnect the plug of the face piece connector by pulling along the axis of the fitting.

Oxygen distribution unit

• If it is necessary to carry out the maintenance of the oxygen distribution unit, unscrew the

captive screw using a screwdriver and disconnect the unit from the body of the breathing

apparatus, the sensor cable from the connector of electronic module. If the breathing

apparatus is equipped with a device for connecting breathing apparatus via medium

pressure, then disconnect the line connected with the corresponding tee.

CAUTION!

It is allowed to set, maintain or repair the oxygen distribution unit by DEZEGA or accredited by DEZEGA

personnel only.

Р-70i DEZEGA

14

7. BREATHING APPARATUS CLEANING,

DISINFECTION AND DRYING

All parts of the breathing apparatus that come into contact with the breathing gas must be

thoroughly cleaned and disinfected by DEZEGA disinfector after use. Other parts that are not

exposed to a breathing gas must be cleaned as needed.

Disinfect the breathing apparatus after use according to the doctor’s instructions when an infectious

disease is detected in the user, and before delivery of the breathing apparatus for long-term storage

(for more than a month).

For cleaning parts contaminated with hazardous substances, use protective clothing, shoes, gloves,

and safety goggles.

CAUTION!

Only DEZEGA disinfector and detergent should be used for the disinfection and cleaning to avoid

damaging of the breathing apparatus components. Organic or industrial solvents, as well as cleaning

agents that contain bleaches, can damage parts of the breathing apparatus.

Cleaning

Wash all parts of the breathing apparatus in warm water at +30 –+40 °C with the addition

of DEZEGA liquid detergent.

Do not use organic solvents such as acetone, trichlorethylene, or similar industrial solvents. Never

use bleach-containing detergents.

Rinse parts of the breathing apparatus in warm clean water. Completely rinse all detergent residues

from all parts of the breathing apparatus.

Clean the EMD case only with a damp cloth.

Disinfection

To disinfect, place the breathing system units into DEZEGA disinfectant. Determine

the concentration of the solution according to the disinfector’s instructions.

CAUTION!

Prolonged treatment and high disinfectant concentrations can damage parts of the breathing apparatus.

The use of organic solvents (gasoline, kerosene, acetone) and chlorine-based bleachers for disinfection

is prohibited.

After disinfection, rinse the breathing system units with clean running water.

The flushing of constant supply and demand valve lines as well as the cavities of the demand valve

itself, by filling them with ethyl alcohol for 5 minutes. Then drain o the alcohol and dry the air tubes.

Immerse the LP sensor housing in a container with alcohol. Leave it in alcohol for 5 minutes, then

remove it and let it dry before installing in the breathing apparatus.

NOTE!

The sensor of electrical connector should not be cleaned.

Drying

Dry the breathing apparatus breathing system units using warm air at a maximum temperature

of +40 °C. Use a drying cabinet or an air dryer to dry the breathing apparatus parts.

Thoroughly dry all the units (especially breathing and relief valves) with warm air, since the residual

moisture aects the operation of these units.

DEZEGA Р-70i

15

If possible, it is better to purge by dry air the relief valve and demand valve by opening them. At the

same time, purge the demand valve from the side of oxygen supply sleeve.

After the complete assembly of the breathing apparatus, blow out the demand valve connection

sleeve by pushing the lever on the demand valve (when the cylinder is open), and the sleeve through

the continuous and emergency supply system by pressing the emergency oxygen supply button

(bypass).

Dry all parts of the breathing apparatus (especially the harness system belts and components) prior

to long-term storage in order to prevent the formation of mould and fungi.

CAUTION!

Drying the elements of the breathing system in direct sunlight or using radiant heat is strictly prohibited.

8. BREATHING APPARATUS MAINTENANCE

Filling of absorption cartridge

CAUTION!

The absorption cartridge must be filled with DEZEGA D-SORB CO2absorber only. Using of other

soda-lime may damage the breathing apparatus components and aect for the working duration and

protection properties.

Fill the cartridge by the following:

• Install the tamper on filling neck of the cartridge by screwing the nut.

• Remove the cover from tamper and pour the absorber into the cartridge up to the middle of the

filling neck. Cartridge filling should be carried out in three or four portions, compacting it with a

slight tap of the palms on the side of the cartridge casing.

• Close the cover of tamper and then tap until the stock goes all the way down.

• Install the cartridge vertically with the feeding hole facing upwards, remove the tamper and

close the feeding hole using cover and nut. In case when shaking the cartridge you hear a token

sound characterizing that the cartridge is not completely filled, then additional portion of an

absorber into the cartridge.

Р-70i DEZEGA

16

NOTE!

It is recommended to use disposable cartridges filled and sealed at the factory. To do so, remove the

cartridge from the factory packaging and sealed plugs from the fittings. After use, the cartridge must be

marked as «USED» and disposed of as soon as possible.

CAUTION!

Do not fill the cartridge with a used, unsieved, or expired soda lime absorber.

Filling the breathing apparatus with oxygen

The breathing apparatus cylinder must be filled with gaseous oxygen that is suitable for breathing

and has parameters of medical-grade oxygen with a minimum degree of purification of 99.5 %

by volume.

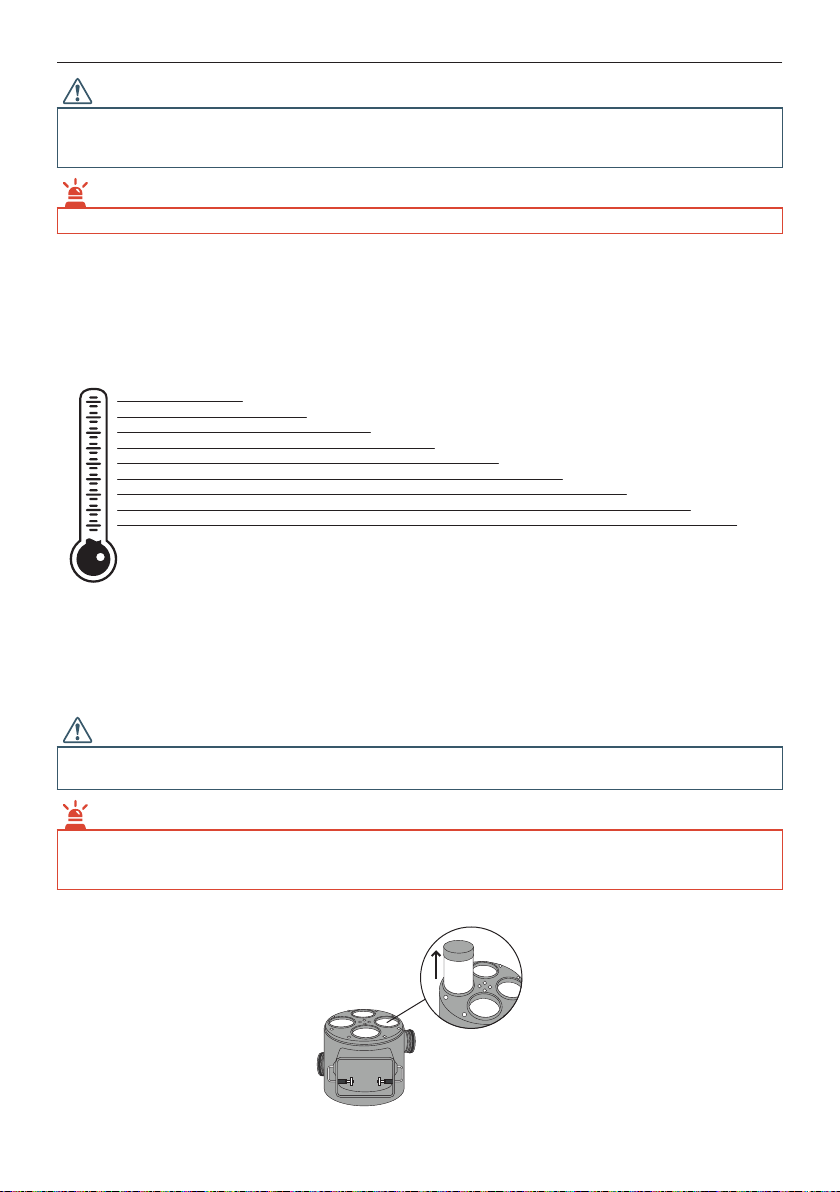

The oxygen pressure in the cylinder must correspond to the values given in the graph below for

dierent temperatures.

60

50

40

30

20

10

0

-10

-20

t oC

24,2 МPа

23,1 МPа

21,0 МPа

19,0 МPа

22,0 МPа

20,0 МPа

17,9 МPа

16,9 МPа

15,8 МPа

The deviation of pressure from the specified values by no more than 1.0 MPa is permitted

Gas temperature in the cylinder is considered as an equal to the ambient temperature if the

cylinder has been kept at such a temperature for at least 5 hours.

The filling of the cylinder must be carried out with intermediate time lag in two or three stages,

each time the temperature inside the cylinder should equalize with the environment.

NOTE!

For easy and convenient filling of oxygen cylinders,it is recommended to use DEZEGA Oxygen gas

booster system HIHPG2.

CAUTION!

Thread on the P-70i shut-o cylinder valve is M22х1,5. Prior to filling the oxygen cylinder check the

correspondance of the thread of the shut-o valve, connector (if used) and booster pump’s thread to

avoid a high pressure oxygen leak.

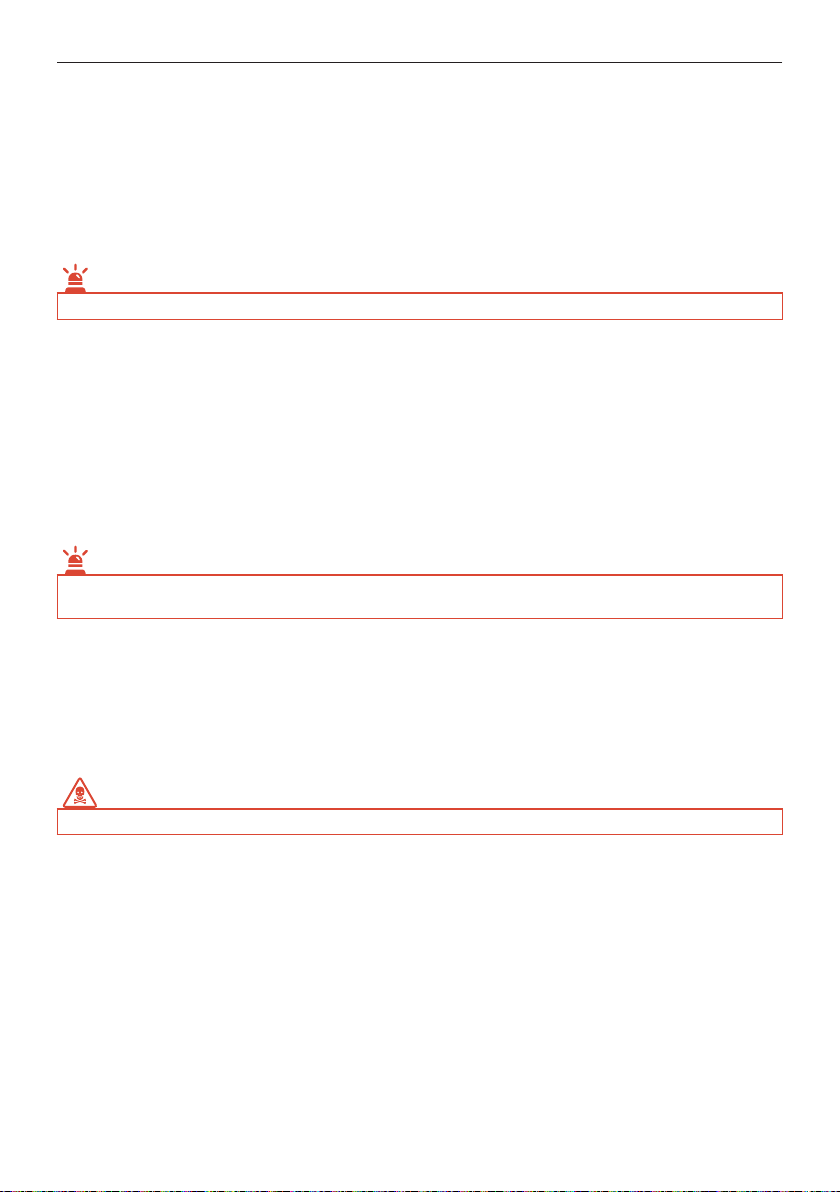

Preparation of cooling elements

Use special forms for water ice with lids to freeze water ice cubes.

DEZEGA Р-70i

17

Before use, fill the cooling briquette with water, preferably distilled. To do so, unscrew the cap and

fill it with water up to the level of the lower edge of the upper part of the element. Filling with water

must be carried out by placing the briquette in a container for freezing. Remove the briquette and,

by squeezing the elastic walls, minimize the air space between the water and the cap. Screw the lid

tightly. When freezing, the volume of ice is approximately 10% larger than the volume of water, so

when it freezes, the ice will occupy the entire volume defined for it.

Place the forms into the freezer of an industrial, commercial, or household refrigerator until they are

completely frozen.

CAUTION!

The temperature in the freezing chamber must be below -5 °C.

After complete freezing, keep at least one set of cooling elements in the freezer compartment and

one in a thermos, which should be continuously kept in a refrigerator.

Place the cooling element into the cooler of the breathing apparatus before work if the path to the

high temperature zone takes no more than 30 min. Otherwise, it is recommended to carry the ice

cubes in a thermos bag.

The eective time of water ice elements depends upon environmental conditions and the intensity

of the user’s work in a breathing apparatus, so the required amount of ice cubes may be determined

on the basis of the expected duration of work and physical activity. Fully frozen ice cubes reduce the

temperature of inhaled air by 4-7 °C.

CAUTION!

The eective time of the cooling element may vary significantly depending on the load and the ambient

temperature.

9. BREATHING APPARATUS ASSEMBLY

Before assembly, make sure that all its parts do not have deformations, cracks, or other damages.

Before assembly, all parts and components of the breathing apparatus must be cleaned, disinfected,

and dried. Ensure that all sealing elements are in place and tight, and connections are not

contaminated with oil or grease.

DANGER!

Upon contact with oil, lubricant, or similar pollutants, compressed oxygen may cause a fire or explosion.

Р-70i DEZEGA

18

Harness system

If the harness system of the breathing apparatus is dismounted during maintenance, then:

• Pass the upper strap loops on shoulder belts through the holes located on the body of the

breathing apparatus at the top. Fix the loops with fixing plates.

• Insert the lower ends of the shoulder straps into the hinged metal loops in the lower part of the

breathing apparatus body.

• Fasten the straps to the tension buckles located at the bottom of

belt pads. Mount the waist plate on the waist belt. Attach buckles on the ends of the straps.

• Fill in the swivel tab on the waist plate into the hole on the body. The choice of the desired hole

on the case is determined by the anthropometric parameters of the user. To do this, insert the

tab into the hole and push it into the body until it stops. Without releasing it, turn it a quarter

of a turn so that the spring tab on the plate fits into the corresponding slot on the casing

of the breathing apparatus.

Oxygen distribution unit

If the oxygen distribution unit is dismounted during breathing apparatus disassembly:

• Install the unit into the protective case of the breathing apparatus.

• Tighten in the captive screw.

• Connect the high-pressure sensor connector with an internal electronic module of the

communication device.

Electronic measuring device (EMD)

If EMD is dismounted during breathing apparatus disassembly:

• Install sensor unit in the breathing apparatus case.

• Connect HP sensor to sensor unit.

DEZEGA Р-70i

19

• Connect LP sensor to sensor unit.

• Connect control unit to sensor unit using SU-CU cable.

• Install a new battery in the sensor unit, observing the polarity.

• Install the RFID tag in the control unit slot.

Breathing hoses

• Thread the breathing hose fittings through the holes in the upper part of the breathing

apparatus case.

• Insert them until stop in corresponding grooves on the frame.

Device for pressurization in a breathing circuit

• Hook the frame with the lower part for the corresponding projections, and snap it onto the

body with the help of spring clips.

• Connect the exhalation valve to the pressure relief valve; connect the low-pressure sensor to

the exhalation valve. Position them appropriately and mount them on the frame. In this case,

the valve fitting must enter coaxially into the exhalation hose fitting, and the body of the relief

valve with its side walls should pass between the frame protrusions until it stops. Next, fix them

in this position by turning the appropriate bracket. During installation, in order to avoid damage,

exclude the possibility of pressing on the valve seat located under the petal.

• Lay the cable going from the low pressure sensor to EMD along the left side of the housing,

fixing it in the spring elements. Connect the connector to the electronic unit.

• Connect the inhalation valve to the lung demand valve. Position them appropriately and mount

them on the frame. In this case, the valve fitting must enter coaxially into the inhalation hose

fitting, and the lung demand valve`s body with side walls should pass between the frame

protrusions until it stops. Next, turn the locking bracket to fix them.

• Lay the hose coming from the lung demand valve and the constant supply hose along the

right side of the body and fix it in the respective spring elements. Connect the hoses to the

appropriate connectors on the oxygen distribution unit.

Absorption cartridge, Cooler

• Connect the absorption cartridge to the cooler, fixing the connection with the appropriate

fasteners.

• Mount the separator on the assembled block, observing the requirements for its correct location.

• Insert the absorption cartridge together with the cooler and the separator into the body of the

breathing apparatus.

• Secure the cooler with a spring stop and the absorber with a suitable lock.

Breathing bags

• Attach bags to the exhalation and inhalation valves.

• Attach the breathing bags to the cooler and regenerative cartridge flanges.

• Make sure that the spring clips hold the flanges securely on the nozzles and that the flanges are

installed so that they do not create deformation of the walls of the breathing bags.

• Connect the сrosstop’s lever to the frame by sliding on the corresponding tabs on the axle.

Secure the lever with a lock.

Р-70i DEZEGA

20

Oxygen cylinder

• Carefully inspect the prepared cylinder for mechanical damage and organic contamination.

Insert the cylinder in the body of the breathing apparatus.

• Align the cylinder valve with the leg of the oxygen distribution unit. Tighten the union nut by

hand, without using a wrench. Fasten additionally the cylinder in the body with an elastic strap.

• Close the breathing apparatus protective case.

• Align the guides on the top of the body with the hooks on the cover. Pulling the cover down, put

it on the body until the two side locks operate.

Battery insert in EMD

• Insert the battery from outside the breathing apparatus into the sensor unit, following the

instructions and labels on the box.

10. CHECKING THE BREATHING APPARATUS

Carry out the complete check of the breathing apparatus and adjust it using Breathing apparatus

test set DEZEGA CheckUp. When adjusting the breathing apparatus, it is recommended to set the

average values for each parameter and to set the tightness parameter close to zero.

A detailed description of the breathing apparatus check method is provided in the documentation for

the respective control device.

It is recommended to check individual parameters in the sequence shown below. Place the

breathing apparatus on the table right upon the harness system, remove the cover and attach

it to the control unit.

NOTE!

The pressure in the cylinder at the beginning of the inspection and adjustment must be (20,0±1,0) MPa.

Checking the oxygen distribution unit

Check the oxygen distribution unit together with all the components of the breathing apparatus

assembled.

Open the cylinder valve and check if there is no oxygen leakage (in the cylinder valve, at the cylinder

and the oxygen distribution unit connection, in an emergency valve, a high pressure sensor and the

external connections of the unit with a demand valve) using the soap solution bubble test.

Other manuals for P-70i

1

Table of contents

Other DEZEGA Diving Instrument manuals