DGFLOW PRESFLO MULTI User manual

10194507A _rev.03

PRESFLO

MULTI

CODE:

V / Hz:

I max: B

V00103101

~230 / 50-60

16 A

SN 1506003

RUEN FRIT ES

ELECTRONIC PUMP CONTROLLER

PRESFLO®is a device that

starts and stops the pump to

which it is tted, thus replacing

traditional pressure switch /

surge tank systems.

The pump is started when, as

a tap is turned on, the pressure

within the system drops below

the “start-up pressure” (Pm),

and is stopped when the ow

USER’S MANUAL

rate required is zero or less

than the “shut-off ow rate”

(Qa).

The electronics of PRESFLO®

protects the pump against

abnormal running conditions

such as dry running, repeated

start-ups due to leaks in the

system or overcurrents.

Technical specications

Losses

- Voltage: ~ 230 V / ~ 115 V - Frequency: 50-60 Hz

- Current: 12A, max 16A for 3 sec.

- Protection grade: IP 65

- Start-up pressure ( Pm ): 1÷5 Bar (15-70 psi)

- Shut-off ow rate ( Qa ): 2 litres/min (0,5 gpm)

- Connections: 1”M BSP / 1”M NPT

- Operating pressure: 8 bar (120 psi)

- Bursting pressure: 24 bar (350 psi)

- Weight: 1600 g

- Protection against: dry running

( automatic restart),

repeated start-ups,

overcurrents

Before installing, the product, check

that the RATINGS correspond with those

required.

Operating conditions

A. Compatible/non compa-

tible uids

PRESFLO®is suitable for use

with clean water and chemical-

ly non-aggressive liquids. If the

uid contains impurities, a lter

should be tted upstream.

B. Environmental conditions

PRESFLO®should not be used

where there is the risk of an

explosion. The temperature

of the location should range

between 0°C and 40°C, and

the humidity should not exceed

90%.

C. Power supply

Make sure that the variation

in the power supply is never

more or less than 10 % of the

RATING value.

Higher values may cause

damage to the electronic

components.

PRESFLO®can only be used

with single-phase pumps.

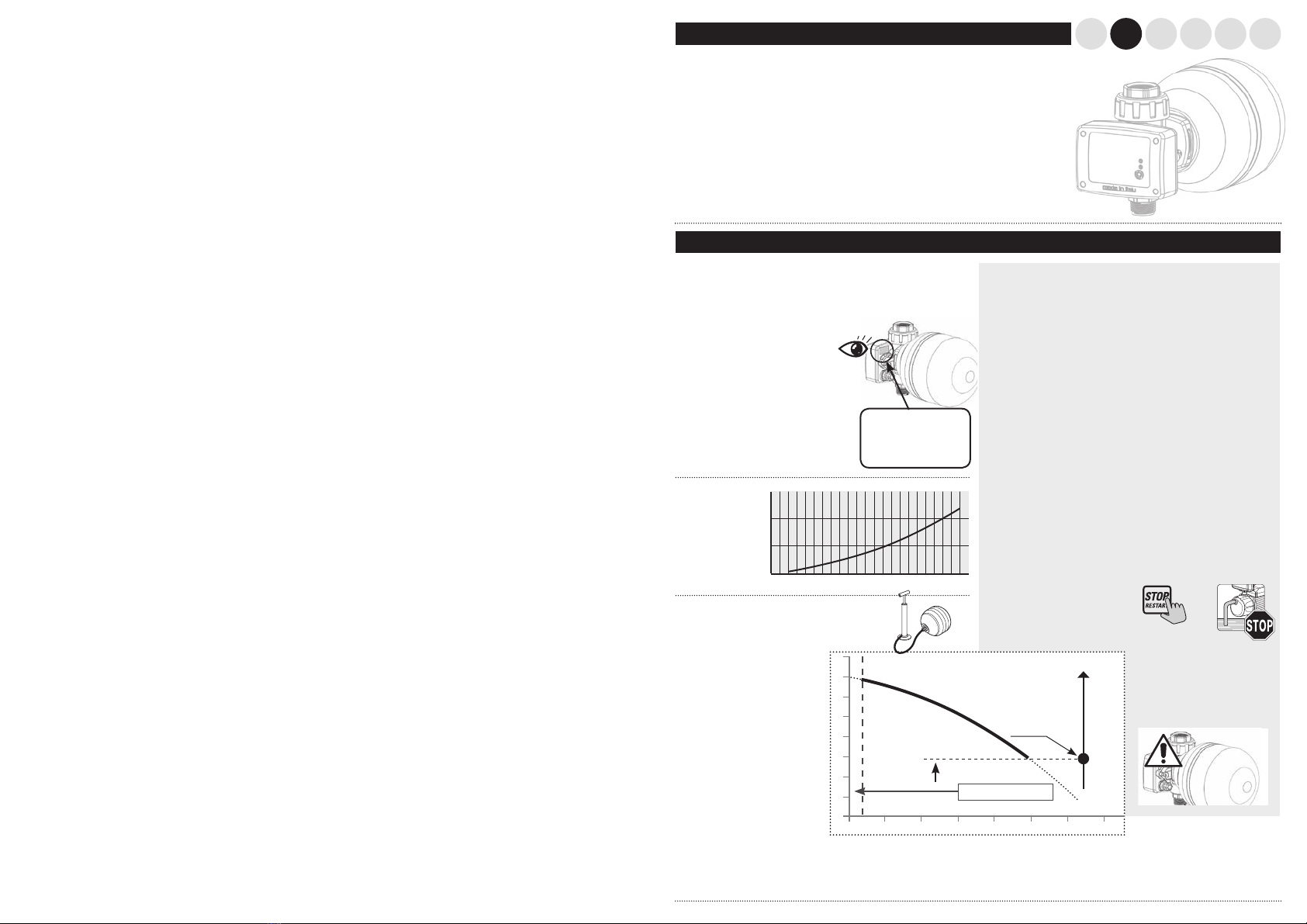

Working area

Flow rate

Pressure

Shut-off ow rate

Start-up pressure

Qa

Pm

Safety regulations

Before installing or using

PRESFLO®, read this manual

carefully and thoroughly.

The pump should be installed

and serviced by qualied per-

sonnel, responsible for making

the hydraulic and electrical

connections in compliance with

the relevant regulations.

DGFLOW®shall not be held lia-

ble for any damage relating to,

or resulting from, an improper

use of the product, or for any

damage relating to, or resulting

from, servicing or repairs carri-

ed out by unqualied personnel

and/or with non-OEM spare

parts.

The warranty, which is valid

for 24 months from the date

of purchase, will no longer be

applicable should the product

suffer damage as a conse-

quence of the use of non-OEM

spare parts, tampering or

improper use.

When starting the installation,

check the following:

- the power supply is switched

off.

- the power lines can withstand

the maximum current.

- the cable bushings and circuit

board cover have been properly

assembled and secured ( see

Electrical Connections ).

- the power supply is tted with

regulation earthing and safety

devices.

When servicing the product,

check the following:

- the system is not pressurised

(turn a tap on)

- the power supply is switched

off.

Emergency Stop

When in use, the pump can

be stopped in the event of an

emergency:

press

STOP/RESTART

.

PRESFLO®is put OUT OF

SERVICE.

For no reason, disassemble

the water accumulator with the

system pressurized.

Cover

Water accumulator

To set the running pres-

sure (Pm) and the max.

motor current (I max.), see

Conguration paragraph.

Water accumulator pressure.

Should be inated to a value 0,5 bar lower than

the running pressure.

0 50 100 150 200 l/min

0 5 10 15

m H2O

Manufacturer’s

settings

Other selectable settings

RUEN FR DEIT ES

2l/min (0,5 gpm)

5,0 bar

(75 psi)

2,0 bar

(30 psi)

1,0 bar

(15 psi)

max = 48 m (160 ft)

Preliminary checks

Take the PRESFLO®out of

the packaging and check the

following:

- check for damage,

- check the RATINGS correspond

with those required,

- that the cable bushings and

screws are in place,

- that PRESFLO®’s inlets and

outlets are clean and free of any

packaging materials,

- that the check valve moves

smoothly.

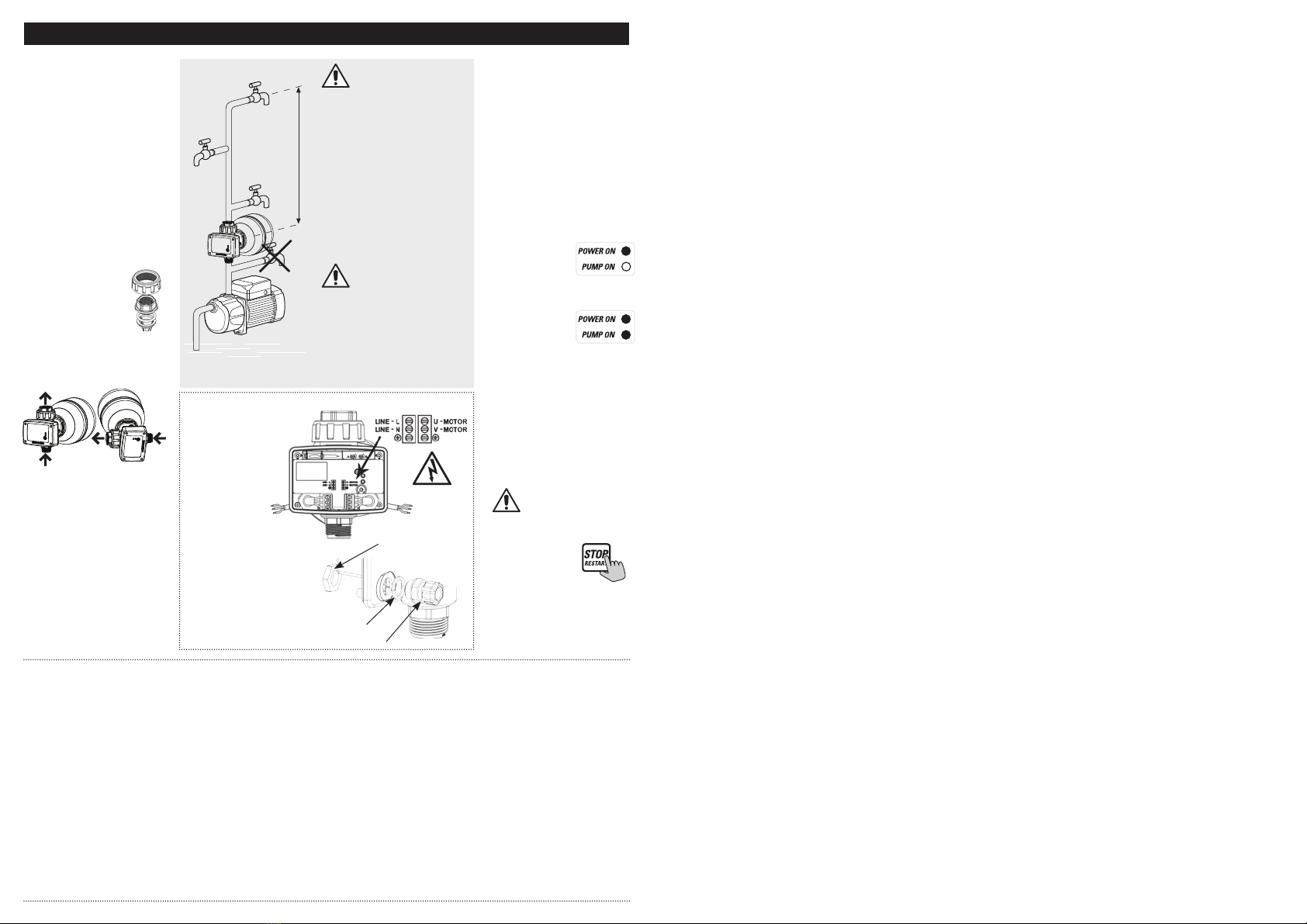

Hydraulic connections

the joint in two pieces allows ra-

pid connection to the sy-

stem.

DO NOT apply se-

alant inside the 2-piece

joint because it already

has an internal o-ring.

Orientation

PRESFLO®can be installed at

any angle depending on the ow

direction, as indicated in the

diagrams.

Position

PRESFLO®can either be tted

directly to the pump outlet or

anywhere along the delivery

line. Never install taps between

the pump and PRESFLO®. Do

not install a non-return valve

between PRESFLO®and the taps,

meanwhile it is possible, although

not necessary, to install a non-

return valve on the suction piping

of the pump.

Installation

Attention

The pressure applied

by the water column above

PRESFLO®must not exceed that

of the pump start-up pressure

(Pm). If, for example, PRESFLO®

is installed at a height 20 metres

(65 ft) below that of the highest

tap in the system, the pressure

detected by PRESFLO®will be

approximately 2 bar (30 psi).

A model with Pm = 2.5 – 35 psi

bar should, therefore, be installed

in order to guarantee that the

pump is started when a tap is

turned on.

Attention

The maximum pressure

produced by the pump

must be at least 0.5 bar (7 psi)

higher than the start-up pressure

(Pm). If the pressure produced by

the pump is too low, PRESFLO®

will stop the pump and indicate a

‘dry running’ error message.

First start-up

Priming the pump

For instructions on how to

prime (ll) the pump, see the

pump manual.

Attention

PRESFLO®is tted with a

check valve: do not use the

PRESFLO®’s outlet to ll the

pump for priming.

Switching the pump on

The red (Power On) LED lights

up; PRESFLO®

instantly detects

that there is no

pressure within the system and

starts the pump

(the green ‘Pump

On’ LED lights up).

If, within 15 secon-

ds of starting up,

PRESFLO®does not detect the

correct priming of

the pump, it stops the pump

and indicates a ‘dry running’

error message.

Attention

When the pump is started for

the rst time, it may have to

be run for longer in order to

complete the priming

procedure.

Press the STOP/RE-

START button

to restart the

pump and

complete the

priming procedure.

NOTE 1 - DRY RUNNING = there is no ow and the pressure is lower

than that of the pump start-up pressure (Pm). It occurs when there is no

water. After 15 seconds PRESFLO®stops the pump and indicates an ERROR

message. PRESFLO®AUTOMATICALLY tries to resume NORMAL SERVICE

at intervals of increasing time (1, 15, 30, 60 minutes and successively once

every hour - 24 H for AU/NZ - ). If PRESFLO®detects any pressure and/or

ow, NORMAL SERVICE is resumed, otherwise, the pump is stopped again

until the next attempt is made. A MANUAL attempt to resume NORMAL

SERVICE can be made at any time.

NOTE 2 - FREQUENT START-UP = the repeated stopping and starting of

the pump at intervals of less than 1 minute from each other. This occurs

when the ow rate is less than 2 litres/min. This may cause damage to the

pump. In event of small leaks (dripping), PRESFLO®’s water accumulator

guarantees that the pump starts/stops at time intervals of over 1 minute

(less than 60 starts/hour) and that FREQUENT START-UP errors do not occur.

In the event of a major leak or extended use at excessively low ow rates

(less than 2 litres/min), the pump may be started/stopped as often as once

every few seconds, putting the pump at risk of damage. In this case, after

about 40 minutes, PRESFLO®stops the pump for the following 30 minutes

(in order to let it cool down) and indicates an ERROR message. If the time

interval between the starts-stops is more than 10 seconds (and therefore

poses less of a risk to the pump), PRESFLO®will allow the pump to be

used for more than 30 minutes. Once that enough time has passed to allow

the pump to cool down it is restarted AUTOMATICALLY. The pump may be

restarted MANUALLY any time.

NOTE 3 - OVERCURRENT = electric absorption of the pump (in Ampere)

exceeding the max. allowed (I max). By means of the conguration, it is

possible to set the max. current allowed (I max). During the start-up phase

of the pump PRESFLO®allows for a few seconds the current to exceed the

Imax value. If the absorptions remain above the set Imax value, PRESFLO®

stops the pump to avoid damaging the motor and signals an anomaly.

PRESFLO®will not automatically restart the pump. The pump may be

MANUALLY restarted at any moment. Should the problem persist an anomaly

will again be signalled. The manual restart can be repeated several times

since PRESFLO®does not limit the number of attempts.

NOTE 4 - SHUT-OFF FLOW RATE = Flow rate (Qa) of around 2 litres/min

(0,5 gpm) below which PRESFLO®stops the pump.

MotorLine

Nut

Seal

Cable bushing

Attention! The cable

bushings and circuit board

cover must be properly

assembled and secured

in order to guarantee IP

65 grade protection of the

electrical components.

Electrical con-

nections

The electrical

connections

should be made

as indicated in the

diagram which

can also be found

on the inside of

the circuit cover.

1

2a

2b

2c

3

4a

4b

4c

Operation

PRESFLO®is switched off.

Press briey or hold down =

nothing happens

Power is restored =

PRESFLO®resumes NORMAL

SERVICE and starts the pump (if

necessary).

No power supply

The system is pressurised.

All taps are turned off. There is no

demand for water. PRESFLO® detects an

assembly pressure higher than that of

the start-up pressure (Pm) and no ow.

Press briey = the pump is

started manually and runs for

a few seconds before stopping

again.

Hold down = lthe pump is put OUT OF

SERVICE.

For instructions on how to reactivate the

pump, see point 3.

A tap is turned on = as soon as the

pressure falls below the start-up pressu-

re (Pm), the pump is started.

NORMAL SERVICE: the pump is inactive.

The pump has been

stopped manually.

The pump will remain inactive until a new

command is given.

Press briey

= nothing happens.

Hold down

= the pump resumes NORMAL

SERVICE. See points 2a - 2b.

OUT OF SERVICE

PRESFLO®has

detected that the

pump is dry running and has therefore

stopped it TEMPORARILY.

Press briey = the pump is started

and manually and resumes

NORMAL SERVICE. See points

2a - 2b.

Hold down = the pump is put

OUT OF SERVICE. For instructions on

how to reactivate the pump, see point 3.

ERROR: stopped temporarily due to DRY RUNNING

The assembly requires water.

One or more taps are turned on.

PRESFLO®detects a ow; the assembly

pressure is normally higher than the

START-UP pressure, but it may also be

lower.

Press briey or hold down

= the pump is stopped and put

OUT OF SERVICE. For instruc-

tions on how to reactivate the

pump, see point 3.

The taps are turned off = Sif there is

no ow for a few seconds, the pump is

stopped.

NORMAL SERVICE: the pump is running PRESFLO®has

detected that the

pump starting-up too often and has there-

fore stopped it TEMPORARILY.

Press briey = the pump

is started and manually and

resumes NORMAL SERVICE. See

points 2a - 2b.

Hold down = the pump will

not restart and goes OUT OF ORDER.

The pump is put OUT OF SERVICE. For

instructions on how to reactivate the pump,

see point 3.

ERROR: temporary shut down due to FREQUENT START UP

ERROR: stop due to overload.

PRESFLO®has

detected a current

exceeding the max. allowed and has the

pump stopped.

Press briey = the pump is started

and manually and resumes

NORMAL SERVICE. See points

2a - 2b.

Hold down = the pump is put

OUT OF SERVICE. For instructions on

how to reactivate the pump, see point 3.

The system has just ceased to require

water. All taps are closed. The pump

is still in operation. The system is

pressurized.

PRESFLO®

detects a system

pressure higher than the start-up

pressure (Pm) and no ow.

Press briey or hold down =

the pump is stopped and put in

STAND-BY. To reset see point 3.

If the absence of ow lasts for a

few seconds the pump is stopped.

NORMAL SERVICE: pump during shutdown

= Off = On = Flashing

Made in Italy by

DGFLOW srl Via Emilia, 5

46030 Bigarello (Mantova) Italy

tel. +39 0376 340922

fax. +39 0376 249525

info@dgow.it - www.dgow.it

Disposal

When disposing of any

PRESFLO®parts, adhere

to the relevant laws and

regulations in force in

the country in which the

equipment is being used.

Do not dispose of any

polluting parts in

the environment.

Conguration

Settable parameters:

- Running pressure.

When the pressure in the

system falls below the Pm,

PRESFLO®starts-up the pump.

The Pm should always be

higher by at least 0.2 – 0.3

bar of the pressure genera-

ted by the column of water

overlooking PRESFLO®.

The Pm value can be carried

in the eld between 1 bar and

5 bar.

- Maximum current

allowed.

PRESFLO®is tted with a cur-

rent sensor, which continually

detects the absorption of the

pump. If the current remains

above the set Imax value for

a signicant period of time,

PRESFLO®stops the pump to

protect it from damages (LOCK

condition for OVERCURRENT).

PRESFLO®nevertheless allows

the Imax to be exceeded for

short periods during the pump

start-up phase.

For correct functioning,

the Imax should be set at

a value higher by approx.

10 – 20% to the maximum

absorption of the pump

(normally indicated on the

rating plate of the motor).

If this rating value is not known,

it s better to leave the standard

Imax value (16A) to avoid that

the pump stops also in normal

absorption conditions.

The Imax value may be varied

in the eld between 4A and

16A.

Manufacturer’s setting:

PRESFLO®is supplied with the

following STANDARD CONFIGU-

RATION:

- Running pressure

Pm = 2 ( bar )

- Max. current allowed

I max = 16 ( A )

Statement of Compliance: we declare, under our own respon-

sibility, that the product in question is in compliance with the fol-

lowing European Directives and national implementation provisions

2006/95/CEE Low Voltage Directive

2002/95/CEE (RoHS)

2002/96/CEE - 2003/108/CEE (WEEE)

2004/108/CE Electromagnetic Compa-

tibility Directive (EMC)

EN 60730-2-6

EN 61000 6-3

Bigarello 27.05.15

DGFLOW S.r.l.

President

Stefano Concini

Conguration

The adjustment of the starting

pressure (Pm) and the ma-

ximum permissible current (I

max) is done by means of two

trimmers shown in FIG.

1. Remove the small screwdri-

ver and adjust the trimmer on

the desired limits, according to

the values shown on the plate

located under the screwdriver.

2. The start-up pressure can

be adjusted continuously from

1 to 5 bar (trimmer A)

3. The maximum permissible

current can be adjusted

continuously from 4 to 12 A

(trimmer B)

4. When you nish adjustment

close the cover

CODE:

V / Hz:

I max: B

V00103101

~230 / 50-60

16 A

SN 1506003

1

2

3

6

5

4

8 7

Exploded view of

spare parts

Attention: when orde-

ring spare parts, always

state the position n°

from the diagram below

and the product code

number found in the

pressure-ow regulator

technical data table.

Article

Version

Dimensions

= Off = Flashing

= On

1 - Circuit board cover

2 - Sensor kit

3 - Circuit board

4 - Valve kit

5 - Two-pieces joint with OR

6 - Cable bushings

7 - Accumulator adapter

8 - Water accumulator

Problems Signals Possible causes Solutions

PRESFLO®

will not turn on No power Check the electrical connections

The pump will

not start when

a tap is turned on

PRESFLO®model with an inadequate

start-up pressure (Pm) for the chosen

application.

Relocate PRESFLO®to another position

Install a model with a higher start-up pressure (Pm)

Faulty electrical connections or

pump out of service

Check the electrical connections and that the pump

is working

PRESFLO®“STAND-BY” Reset PRESFLO®(See Operation, point 3).

PRESFLO®in temporary shut down

due to “DRY RUNNING” due to lack

of water

Wait for the automatic restart or press START to

restart manually (See Operation, point 4a)

Maximum pump pressure is

insufcient

Replace the pump with one with more suitable

characteristics

Install a model with a lower start-up pressure (Pm)

PRESFLO®in temporary shut down

due to “FREQUENT START-UP”

Wait for the automatic restart or press START to

restart manually (See Operation, point 4b). Remove

any cause of leakage from system or install an

expansion tank

PRESFLO®stops due to “OVERCUR-

RENT”

Check if the setting of the maximum current (Imax)

is congruent with the data of the pumps’ rating

plate. If after manually restarting the pump after

correctly setting PRESFLO®, it again signals an

anomaly, check that the motor has no mechanical

or electrical problems.

The pump

delivers no or low

pressure

Filters or pipes may be partly blocked Check the water pipes

PRESFLO®’s valve will not open

completely

Check that the valve is not blocked by any foreign

objects and clean if necessary

The pump stops

and starts

repeatedly

Leaks within the system (less than

the shut-off ow rate Qa)

Check the hydraulic connections and repair any

leaks. If a leak cannot be repaired, install an

expansion tank

The pump will

not stop

The ow rate is higher than the

shut-off ow rate (Qa)

Make sure that all taps are turned off and that

there are no leaks within the system

PRESFLO®’s check valve will not

close or is damaged

Check that the valve is not blocked by any foreign

objects and clean if necessary

Popular Water Pump manuals by other brands

SHURflo

SHURflo 200 Series installation manual

ULTIMATE SPEED

ULTIMATE SPEED UOP 12 A1 translation of original operation manual

Lutz

Lutz B70V-HD-D operating instructions

Franklin Electric

Franklin Electric NCX Series owner's manual

coolado

coolado E-PUMP X user manual

Kärcher

Kärcher 3.532-777.0 Service handbook

Allfett

Allfett ALL-6 Instruction and user's manual

moyno

moyno 300 Series Service manual

Gormann-Rupp Pumps

Gormann-Rupp Pumps 82D1 GX160 Installation, operation, and maintenance manual with parts list

Viking pump

Viking pump SG-04 SERIES Technical & service manual

Lincoln industrial

Lincoln industrial CENTRO-MATIC 85430 manual

Becker

Becker DXLF 200 operating instructions