Arion KRF110-01 User manual

Spec.No.KRF110-01E

Orion Trade NameDRYPUMP

Orion ModelKRF110-01

Date March.4.2008

APPD CKD DWN

K.

Tagawa

y.

Takahashi

T.

Hasebe

ORION MACHINERY CO., LTD.

Spec.No.KRF110-01E

−1−

1. Warranty

1-1. Warranty period

The product shall be warranted for a period of one year from the date of purchase, or for

3000 hours of operation, whichever comes first.

1-2. Items exempted from warranty

① Consumable parts and periodic replacement parts.

② Fault caused by careless handling or improper use and maintenance. (Operation not

following the specifications and the instruction manual. Operation under abnormal

environmental conditions.)

③ Fault caused by fire, flood, lightning stoke, abnormal voltage or unforeseen disasters.

④ Fault caused by repair or modification not performed by ORION or ORION authorized

service contractors.

⑤Change of appearance, such as damage or deterioration caused in general use.

⑥Secondary damages caused by the fault (Incidental damages such as loss, inconvenience,

and commercial loss resulting from the failed product).

(Note) In case of a fault or an accident, contact the dealer with the model name and

serial number.

Spec.No.KRF110-01E

−2−

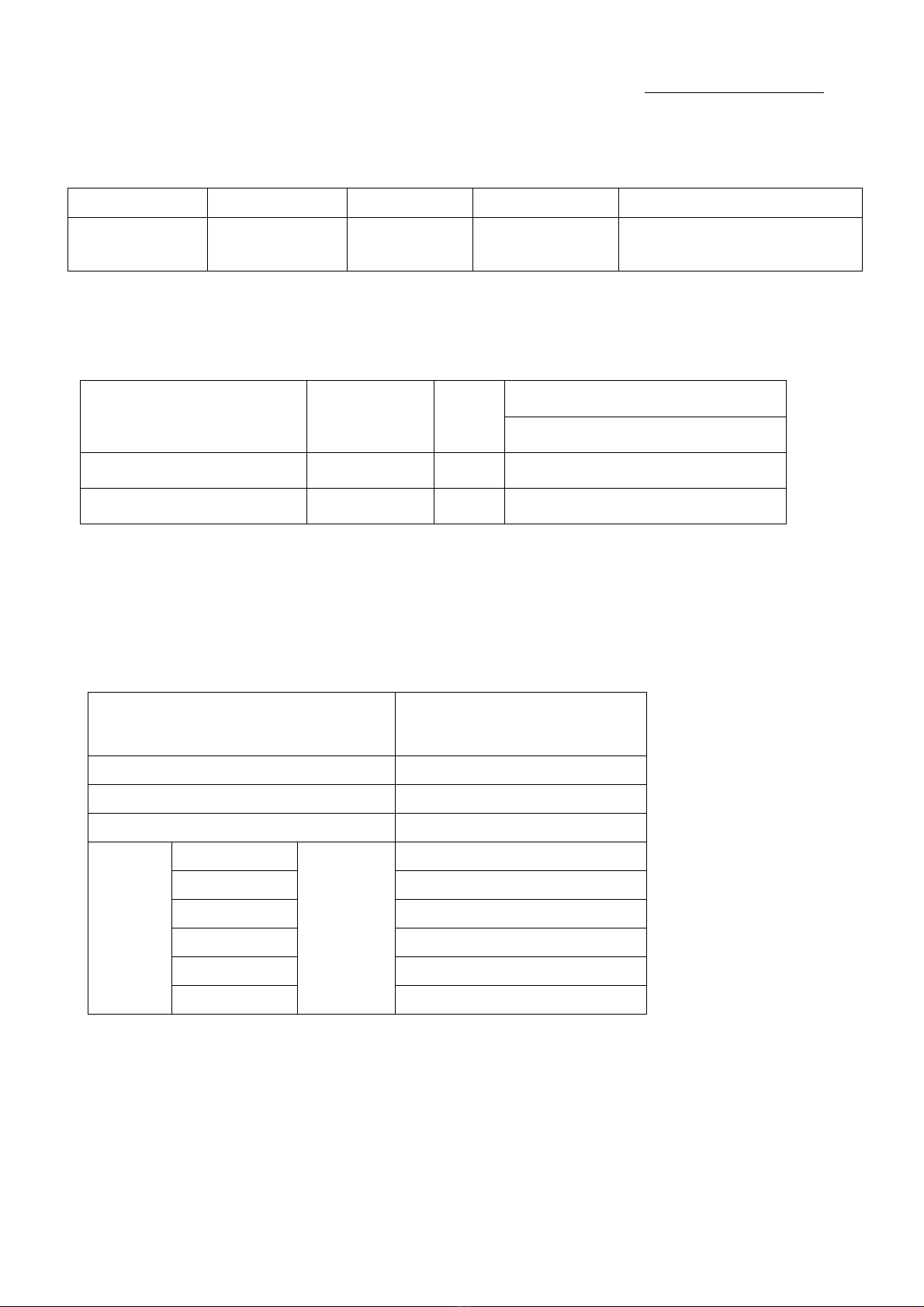

2.Consumable parts / Periodic replacement parts

(1) Consumable parts (Parts to be replaced depending on the state at the time of inspection)

* The second digit from the right is subject to thickness.

0.2t(white)→1, 0.1t(black)→2, 0.05t(yellow)→3,0.03t(red)→4

(2) Replacement parts (Parts to be replaced at regular time intervals)

Exchange time

Name of Parts Parts Number Qty /

unit Operation under normal pressure.

Vane 04100653010 6 5,500

Bearing 0A000333000 2 5,500

* When vanes are replaced, replace bearing at the same time. Use ORION specified bearings

that are lubricated with special grease.

* The exchange time is a recommended value in the rotational speed 940/1140 rpm(50/60Hz)

and vacuum 60kPa driving.

* Use the maintenance kit for replacement parts.

Name of Parts Maintenance kit 110 Assembly

Model KRF110

Parts number 04101348010

Kit / unit 1

Vane 6

Bearing 2

Liner (white) 2

Liner (black) 2

Liner (yellow) 4

Items

Liner (red)

Pcs / kit

6

Name of Parts Parts Number Qty/ unit Inspection period Replacement criterion

Liner * 040028390□0 Tobedecidedby

actualpositioning Replacement of

vane Whendamaged.

Spec.No.KRF110-01E

−3−

3. Specifications

Model KRF110-01

Frequency Hz 50 60

Designed capacity *1L/min 1850 2200

Continuous operative

pressure *2kPa Vacuum and pressure in total: 60 or less

Ultimate vacuum *3kPa 90or more

Necessary power Phase・output・pole Three-phase・3.7 kW・6P

Setting for thermal

protection *4ARated current shown in the name plate of motor

Mass kg 54

Painting color Gray (Except some parts)

Installation site Indoor

Permissible

ambient

temperature 0to40℃

Permissible

ambient humidity 65±20%(JIS Z8703)

Installation condition

(Suction air)

Conditions

Conditions where there is no corrosive and

explosive gas exist.

Clean air without vapor and dew condensation,

and less dirt and dust.

*1 Designed capacity: It is the theoretical value calculated from capacity. Please use the

pressure-flow rate diagram for the actual flow rate. It is a designed capacity at rotational

speed 940/1140 rpm(50/60Hz).

*2 Continuous operative pressure: Operative range of pressure. Install the gauge and controller

to the pump or the piping, and use the Dry Pump at the continuous operative pressure or

less.

*3 Ultimate vacuum: Continuous operation is not possible at maximum ultimate vacuum of the

pump. It is used as model selection calculation.

*4 Use the thermal set value as a target since the apparatus and acceptable motor are different

individually.

Spec.No.KRF110-01E

−4−

4. Precautions

(1) Observe precautions, and operate the product within specifications.

(2) Read the instruction manual prior to installation, operation, maintenance and inspection

of the product. Especially pay attention to safety.

(3) The vanes may get damaged if the residual pressure reverses the rotation when the pump

stops. A check valve must be installed within 50 cm from the inlet port or exhaust port for

protection.

(4) Be sure to install the product horizontally on the flat surface.

(5) Operating the product in an enclosed space may cause malfunction due to heat generated

from the pump. Provide good ventilation around the product, so the ambient temperature

does not exceed the permissible level.

(6) Be sure to clean the filters periodically. Failure to do so may cause clogging and result in

trouble due to overload.

(7) Wiring work has to be performed by qualified personnel according to applicable laws and

in-house regulations.

(8) Be sure to install an overload protection such as a thermal relay in the electric circuit.

(9) Be sure to use the product 1,000m or below above sea level.

(10) Adjust Alignment (less than 0.3 mm) correctly when install the motor onto the Pump.

Under the miss-alignment operation, it may cause abnormal noise with vibration then

damaged.

(11) The permitted rotational speed is 750〜1140 rpm. Please use it in this range.

5. Accessories

There is no accessory.

Spec.No.KRF110-01E

−5−

6. Pressure-Flow rate diagram

KRF110-01

Vacuum Specification

0

500

1000

1500

2000

0102030405060 Vacuum(kPa)

Flowrate(L/min)

Pressure Specification

0

500

1000

1500

2000

0 102030405060

Exhaust(kPa)

Flowrate(L/min)

Conditions: 1 atmospheric pressure

20℃

60Hz

50Hz

60Hz

50Hz

(Note)Incasevacuumis0kPa

(Note)Incaseexhaustpressureis0kPa

−6−

27.5

0

-0.2

8

10

φ32

-0.025

-0.050

56

467

246

7070

250

Rc1

OUTLET Rc1

INLET

13.4

(247)

A

120

4-φ11

216

15051

132

A

7 Outline Dimensions

Detail of shaft shape

Spec.No. KRF110-01E

Table of contents

Popular Water Pump manuals by other brands

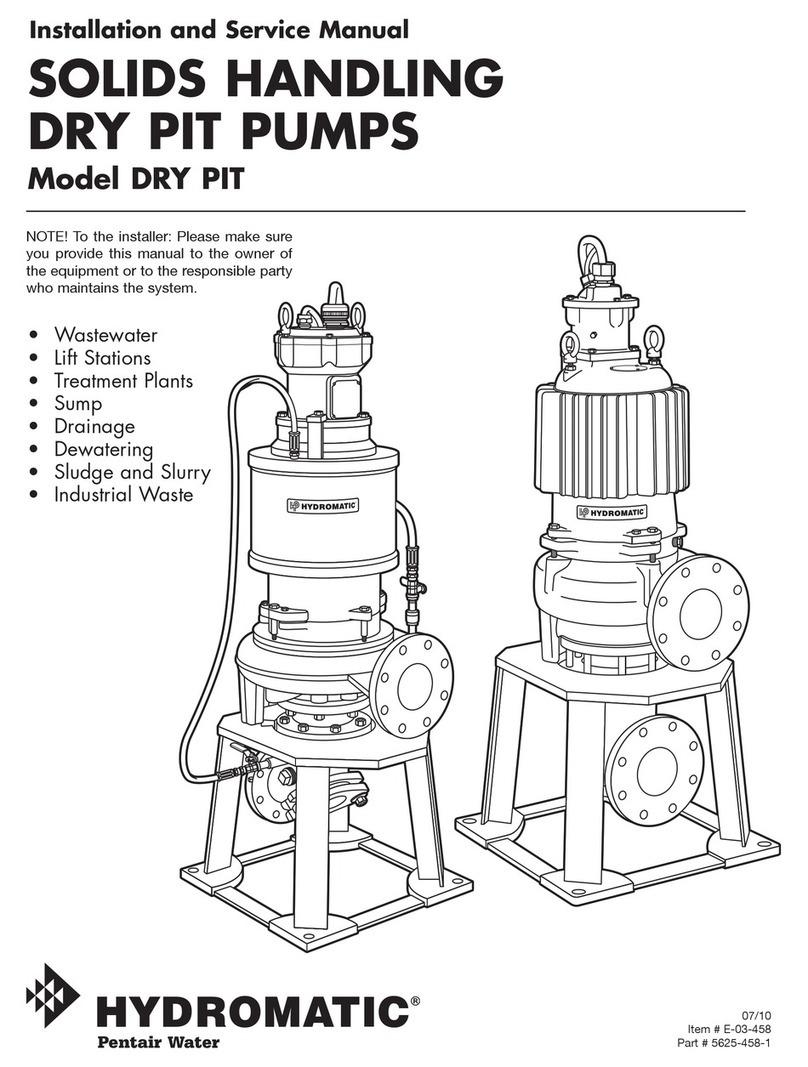

Hydromatic

Hydromatic DRY PIT Installation and service manual

CTX

CTX MyPOOL Series Operating instructions and maintenance

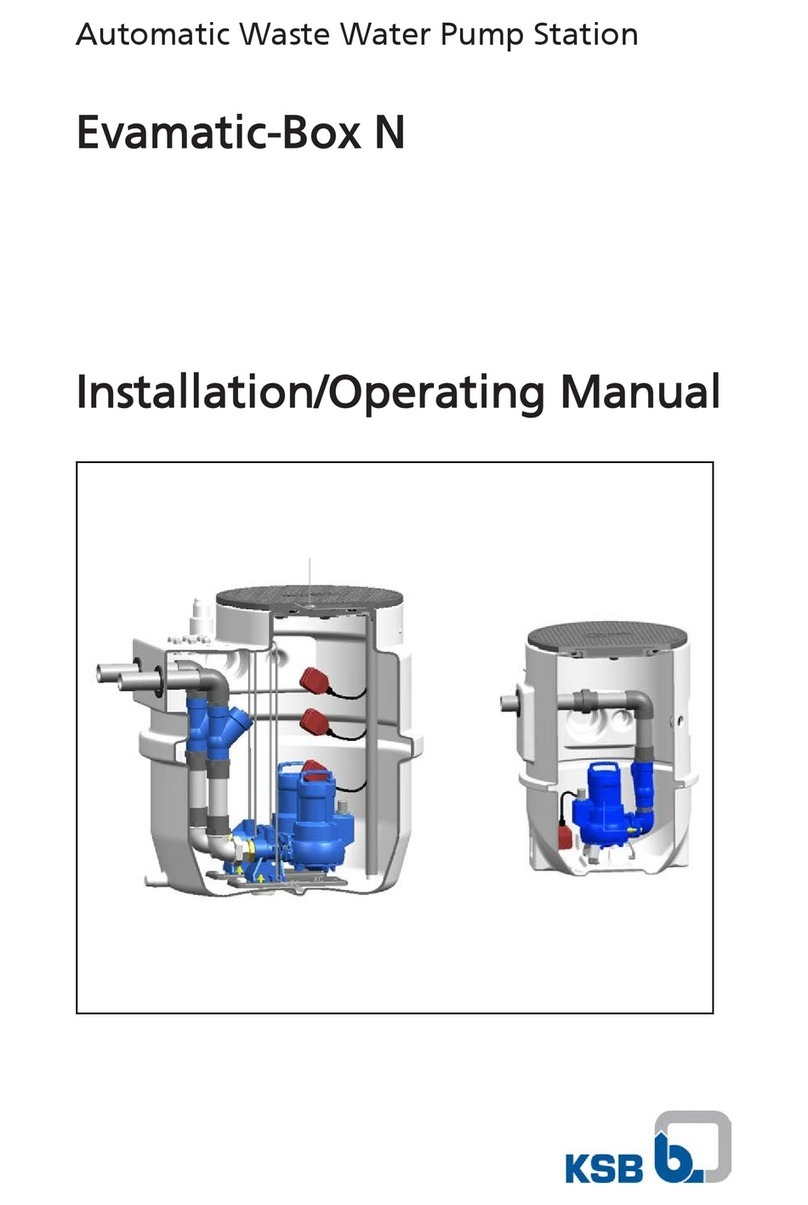

KSB

KSB Evamatic-Box N 200 l Installation & operating manual

Enerpac

Enerpac PTA-1404 instruction sheet

IWAKI AMERICA

IWAKI AMERICA EH Series instruction manual

Marco

Marco 164 404 15 Instructions for use