DGH D3000M Series User manual

D3000M SERIES USERS MANUAL

REVISED: 9/15/08

DGH CORPORATION

P. O. BOX 5638

MANCHESTER, NH 03108

TELEPHONE: 603-622-0452

FAX: 603-622-0487

URL: www.dghcorp.com

The information in this publication has been carefully checked and is

believed to be accurate; however, no responsibility is assumed for possible

inaccuracies or omissions. Applications information in this manual is in-

tended as suggestions for possible use of the products and not as explicit

performance in a specific application. Specifications are subject to change

without notice.

D3000M modules are not intrinsically safe devices and should not be used

in an explosive environment unless enclosed in approved explosion-proof

housings.

2

TABLE OF CONTENTS

Warranty 3

CHAPTER 1 Getting Started

Quick Hook-Up 1-2

Module Configuration 1-5

Modbus Protocol 1-7

Modbus Exceptions (Errors) 1-12

Modbus Register Map 1-14

Modbus Enable/Disable 1-15

CHAPTER 2 Functional Description

Block Diagram 2-3

CHAPTER 3 Communications

Data Format 3-2

RS-232C 3-2

Multi-party Connection 3-3

Changing Baud Rate 3-5

RS-485 3-6

RS-485 Multidrop System 3-7

CHAPTER 4 Command Set

Table of Commands 4-6

User Commands 4-7

ASCII Error Messages 4-17

CHAPTER 5 Setup Information and Command

Command Syntax 5-2

Setup Hints 5-9

CHAPTER 6 Digital I/O Function

Manual Modes/Digital Inputs 6-1

Controller Input 6-3

Limit Switches 6-4

CHAPTER 7 Power Supply

CHAPTER 8 Troubleshooting

CHAPTER 9 Calibration

Appendix A (ASCII TABLE )

Appendix B D3000M Data Sheet

3

WARRANTY

DGH warrants each D3000M series module to be free from defects in

materials and workmanship under normal conditions of use and service and

will replace any component found to be defective, on its return to DGH,

transportation charges prepaid within one year of its original purchase. DGH

assumes no liability, expressed or implied, beyond its obligation to replace

any component involved. Such warranty is in lieu of all other warranties

expressed or implied.

WARNING

The circuits and software contained in D3000M series modules are

proprietary. Purchase of these products does not transfer any rights

or grant any license to the circuits or software used in these products.

Disassembling or decompiling of the software program is explicitly

prohibited. Reproduction of the software program by any means is

illegal.

As explained in the setup section, all setups are performed entirely

from the outside of the D3000M module. There is no need to open the

module because there are no user-serviceable parts inside. Removing

the cover or tampering with, modifying, or repairing by unauthorized

personnel will automatically void the warranty. DGH is not responsible

for any consequential damages.

RETURNS

When returning products for any reason, contact the factory and request a

Return Authorization Number and shipping instructions. Write the Return

Authorization Number on the outside of the shipping box. DGH strongly

recommends that you insure the product for value prior to shipping. Items

should not be returned collect as they will not be accepted.

Shipping Address:

DGH Corporation

146 Londonderry Turnpike

Hooksett, NH 03106

This document contains step-by-step instructions to quickly connect

and communicate with your D3000M modules. The modules require

a one-time configuration to properly operate within a data acquisi-

tion system. Parameters such as the device address, communica-

tions speed (baud rate) and communications parity type must be

determined before the configuration can begin. Each module is

shipped from the factory with the same default communications val-

ues: ASCII character address = 1 (0x31), Baud rate = 300 and Par-

ity type = None.

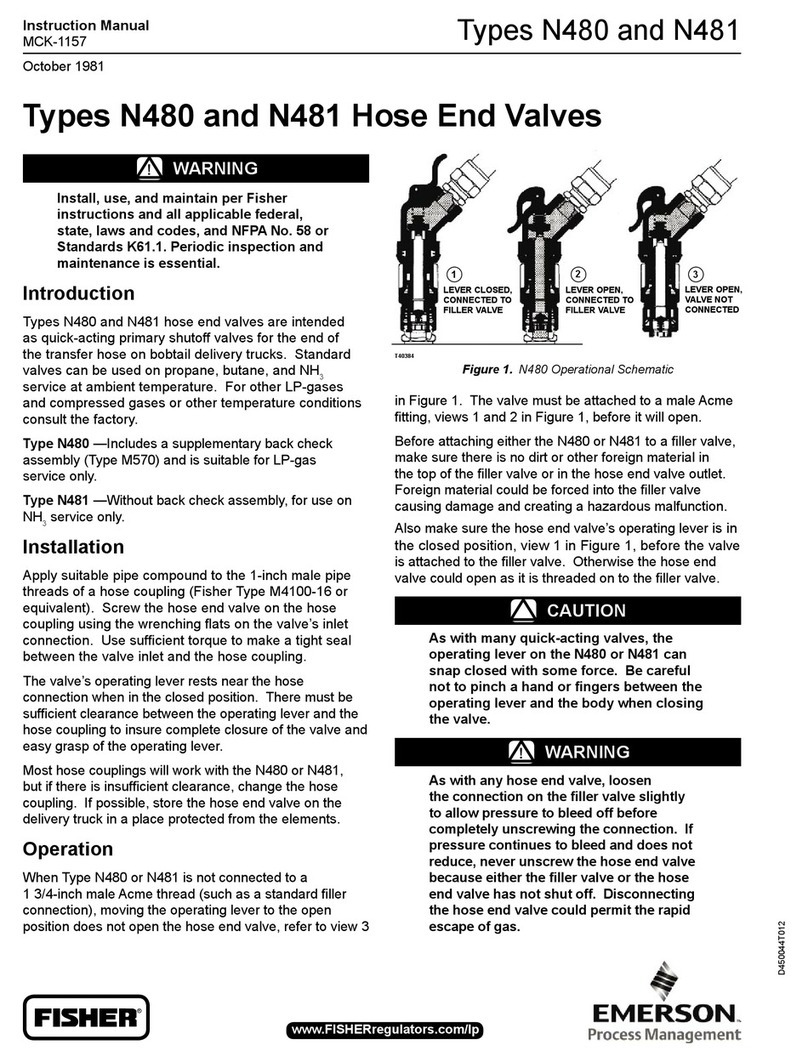

The first step is to connect the module to a host computer. Use Fig-

ure 1.0 to connect an RS-232 module to a host computer or Figure

2.0 to connect an RS-485 module to a host computer. The commu-

nications connections are the same for all models of the D3000M

series.

Configuration of each module can be performed using either the

DGH Utility Software (shipped on CD-ROM with each order) or use

Windows Hyper-terminal to manually configure a module. The DGH

Utility Software CD-ROM can be downloaded from our website

www.dghcorp.com. See the Installation Instructions below to install

the DGH Utility software on your computer.

Use the same connections and cable to pre-configure each module

before installing it into the final application system. The 10-pin screw

terminal plug on each module is removable. Therefore, make one

cable and plug each individual module onto the computer to perform

the setup and configuration.

Helpful Hints:

1. Typical Modbus slave addressing begins with address ‘0x01’. Each

following module address increments sequentially from there. If you

are installing modules into an existing Modbus application then you

must determine a free address value before setting up the module.

This will prevent communications errors due to address overlaps.

2. Before configuring the module, users must also determine the

host serial port baud rate, number of stop bits, and the parity type.

The modules must be programmed to the same communications

values as the host serial port. Otherwise, the host will not communi-

cate with the modules.

Quick Start Steps:

1. Connect the module to host computer via appropriate draw-

ing (Figure 1.0 or Figure 2.0).

2. Install the Utility Software from CD-ROM provided, using in-

structions below.

3. Start the Utility Software 2000 from Window, Start, Programs

menu selection.

4. Setup the module using ‘Software/Module Setup Instructions’

below.

Chapter 1

Getting Started

Getting Started 1-2

CD-ROM Software Installation Instructions:

1. Insert the DGH Utility Software CD-ROM into the computer

CD-ROM drive.

2. Click on the “My Computer” icon on your Windows Desktop,

a window will open that lists all the computer drives.

3. Click on the drive icon that says “Dgh”. A new window will

open.

4. Click on the file “setup.exe” and run this program.

5. Follow the installation prompts and complete the entire pro-

cess. You may close the “My Computer” and “Dgh” windows

als, and Utility Software. The software is now installed and

ready to run.

Figure 1.1, RS-232 Module Connection to Host PC:

The following connection diagrams illustrate connections between a

D3000M module and a host computer serial port. The diagrams indi-

cate connection to either a DB-9 or DB-25 pin serial port connector.

Determine your connector type and use the appropriate connection

drawing below.

Please note that these diagrams will work for any DGH RS-232 mod-

ule regardless of model number. The connections are always the

same during the configuration and setup process.

Figure 1.1a Conection to DB-9 serial port.

Getting Started 1-3

Figure 1.1b Connection to DB-25 host computer serial port.

Notes:

1. The module DEFAULT* pin is connected to GND in each of these

illustrations. Whenever, DEFAULT* is grounded, the module will only

communicate at 300 baud. The parity setting should be No parity,

eight data bits and one stop bit. Some computers may require Mark

parity and seven data bits.

Getting Started 1-4

The following connection diagrams illustrate how to connect a RS-

485 module to a host computer. Figure 1.2 illustration shows how to

connect an RS-485 module to a host PC serial port. This illustration

should be used only for configuration of modules. It is not recom-

mended, or suitable for installed applications.

Figure 1.3 illustrates connections to a RS-485 host serial port. The

RS-485 data line polarity is indicated and should be noted when

making the connect

Figure 1.2 RS-485 Module to RS-232 Serial Port.

Figure 1.3 RS-485 Module to Host RS-485 Serial Port:

Getting Started 1-5

The polarity of the DGH RS-485 lines is indicated above. It should

be noted that ‘(Y) Data’ is the Positive (+) line. The ‘(G) Data*’ line is

the Minus (-) line.

Note: The module DEFAULT* pin is connected to GND in each of

these illustrations. Whenever, DEFAULT* is grounded, the module

will only communicate at 300 baud. The parity setting should be No

parity, eight data bits and one stop bit. Some computers may require

Mark parity and seven data bits.

Setup Overview:

The D3000M contains two different protocol sets: the Modbus RTU

protocol and the D3000 ASCII protocol. The D3000M ships from the

factory in the D3000 ASCII protocol mode. Users configure the mod-

ule in the ASCII protocol before installation in a Modbus application.

The D3000 ASCII protocol makes configuring the module easier with

programs such as Hyper-Terminal or the Utility Software. Further,

configuration should always be performed with the DEFAULT* line

connected to ground as shown in Figures 1 and 2.

While the DEFAULT* line is connected to ground the module will

only communicate in the D3000 ASCII protocol mode at 300 baud,

mark parity, seven data bits, and one stop bit. This mode provides a

known set of communications parameters and the module will an-

swer to any ASCII character address. Thus, allowing easy access to

setup information. Setup values such as the Modbus Slave Address,

application Baud Rate and Parity Type must be determined written

into the module. In addition writing the new setup values, the Modbus

RTU protocol must be ‘enabled’ in the module before installing the

module into the application.

Utility Software Setup Instructions:

1. To run the software, click on the Windows “Start” button in lower

left corner of the screen.

2. Select “Programs” and select “Dgh Data Acquisition”

3. Select “Utility Software” and select “Utility Software 2000” to run

this program.

4. From the software main menu select “Edit” and “Serial Ports”

5. Select the correct COM Port, COM1:..COM32: and press “Open”

button. All other port parameters are configured for a module in

DEFAULT mode.

6. Plug the cable into the host computer serial port.

7. Connect the module to host computer using cable illustrations in

this document.

8. Turn the power on and at the software main menu select “Setup”

and “Modules”.

9. Ensure that the proper COM Port is displayed.

10. The program default address of ‘1’ is usable when the Default*

pin is connected to Ground.

Getting Started 1-6

11. Select the four-digit model number from the “Model” drop-down

list box.

12. Press the ‘Read Setup’ button.

13. A progress bar will appear while the program is reading the mod-

ule parameters. If no communications errors are displayed then

the module is communicating properly with the host computer.

14. Make the required setup adjustments to the ‘on-screen’ values

and ‘APPLY’ the changes.

After the new settings have been ‘APPLY’d then you can disconnect

the module from the 10-pin connector, insert the next module, and

repeat this same process for the remaining modules. Once all the

modules have been configured then they can be installed into the

system application.

Manual Setup Instructions

The D3000M can be configured manually using a terminal emulation

program such as Windows Hyper-Terminal. This configuration method

will require an understanding of the binary and hexadecimal num-

bering systems to interpret the setup configuration tables in the

D3000M Users Manual. The setup configuration tables illustrate the

user-selectable bits that control features such as the module Baud

Rate, Parity Type, and number of stop bits. Once the new bit values

are determined then use the SetUp (SU) command to send the new

value.

The Modbus Protocol mode can be manually enabled using the MBR

command. All of this information can be found in the D3000M Users

Manual. The MBR and MBD commands are described further down

in this document.

Overview

Once the configuration process is completed then the D3000M mod-

ules can be installed into the system application. The D3000M mod-

ules will use the Modbus RTU protocol mode to communicate with

the host Programmable Logic Controller (PLC) or PC based com-

puter. The Modbus RTU protocol is widely used in data acquisition

and control applications that utilize either a PLC or a PC based com-

puter and data acquisition software program.

Data acquisition software programs and OPC servers are commonly

used in process control applications today to read and write values

to control modules. All commercial data acquisition software programs

in the market today include a Modbus RTU protocol driver, providing

instant connectivity to your D3000M module. The D3000M analog

output module can be used to control devices such as valves, actua-

tors, annunciators and more. Consult the factory if you need further

assistance with compatibility questions about a specific program.

The Modbus RTU protocol handles data values in registers and dis-

crete I/O bits as numbers. A complete register map of locations, func-

tions and data values can be found at the end of this document.

Getting Started 1-7

The D3000M Modbus RTU protocol mode supports six functions that

are part of the Modbus RTU protocol specification. The function num-

bers and their descriptions have been detailed below. If you need

more information about the Modbus RTU protocol then you can find

it on the internet at www,modbus.org

D3000M Modbus RTU Protocol

The D3000M series modules support several of the Modbus RTU

protocol functions. These functions read and write values to register

locations within the D3000M. The values and register locations con-

trol features such as the Analog Output value, the Slope control value,

and the Watchdog Timer value. Table 1.0 below contains a list of the

supported Modbus functions and their descriptions.

Function Description

01 Read Coil Status

02 Read Input Status

03 Read Holding Registers

04 Read Input Registers

06 Preset Single Register

10 Preset Multiple Registers

Table 1.0. D3000M Modbus Functions.

Modbus RTU Command Structure

The Modbus RTU serial protocol operates using a command and

response protocol. The command structure begins an address, com-

monly referred to as the Modbus Slave Address. The address is fol-

lowed by the command value or the Modbus function number. The

function number indicates what action the device should perform.

The required data values for the command function will follow and

the message is terminated by a cyclical redundancy check (CRC)

value.

The response message contains the same address and function val-

ues along with the requested data. Each response is terminated by a

CRC checksum of the response bytes.

The Modbus protocol contains provisions for error checking. The

Modbus standard contains a standardized set of values that can be

returned from a Modbus Slave device when a problem or error is

detected. These error values are referred to as “exception codes”

and the DGH implementation of the Modbus RTU protocol utilizes

these exception codes when applicable. See Table 3.0 for a com-

plete list of supported exception codes.

A typical Modbus RTU command to read the analog output value

from a D3000M module whose slave address is 0x01 would be:

Command: 03 03 00 00 00 01 85 E8

Getting Started 1-8

Response: 03 03 02 00 7D 01 A5

In the event that an error is detected, an error response would be

generated and return one of the standardized error codes. The most

significant bit (MSB) of the function number will always be set in any

exception response. Therefore, an error response message that was

generated from a function ‘03’ command would return the function

value of 0x83. The value is followed by the standardized error code

(02) and the two-byte CRC checksum. A typical exception response

would be:

Command: 03 03 00 0A 00 01 A5 EA

Response: 03 83 02 61 31

Modbus RTU Functions

Function (01) Read Coil Status

Modbus function (01) Read Coil Status will read the status of dis-

crete digital inputs. Modbus relay input coils are considered the digi-

tal input bits on the D3000M series modules. This function can be

used to read status of the digital input bits. The D3000M digital input

bits DI0 to DI2 correspond to Modbus coils 0x00001 to 0x00003.

Exception error messages will be generated when attempting to read

the more than three digital inputs. The following example can be

used to read the digital input status (3 bits):

Command: 03 01 00 00 00 03 7D E9

Response: 03 01 01 07 11 F2

In the command string:

03 is the slave address

01 is the Read Coil Status command

00 00 is the starting coil number

00 03 is the number of bits to read

7D E9 is the CRC to this message

In the response string:

03 is the slave address

01 is the Read Coil Status command

01 is the number of data bytes returned

07 is the status of DI0, DI1, and DI2 bits, set High, Logic

“1”

11 F2 is the CRC for this message

Getting Started 1-9

Function (02) Read Input Status

Modbus function (02) Read Input Status will read the status of the

D3000M digital inputs. Modbus inputs are the digital inputs on the

D3000M series modules. This function can be used to read the sta-

tus of digital input bits DI0, DI1 and DI2. These bits correspond to

Modbus coils 0x10001 to 0x10003.

Exception error messages will be generated when attempting to read

the more than three digital inputs. The following example can be

used to read the digital input status (3 bits):

Command: 03 02 00 00 00 03 39 E9

Response: 03 02 07 E1 F2

In the command string:

03 is the slave address

02 is the Read Coil Status command

00 00 is the starting coil number

00 03 is the number of bits to read, DI0, DI1, DI2

39 E9 is the CRC to this message

In the response string:

03 is the slave address

02 is the Read Coil Status command

07 is the status of DI0, DI1 and DI2 bits, set High, Logic

“1”

E1 F2 is the CRC for this message

Function (03) - Read Holding Registers (Analog Output Value)

Read Holding Register function (03) can be used to read data val-

ues from registers within the D3000M module. These data values

represent features such as the present analog output value, the

watchdog timer value, or the slope value. This function supports

reading of up to six registers starting from Modbus slave register

40001 through 40006.

Some data acquisition and monitoring programs and some program-

mable logic controllers (PLC) may use zero based register address-

ing. In that case, the registers are addressed starting from zero mean-

ing registers 40001-40006 are addressed as 0-5. Consult your soft-

ware or PLC manual for the proper addressing mode.

The data for each register is returned as two bytes that represent a

16-bit binary value. The binary values can range from 0000-FFFF

(hexadecimal). Consult the register map in Table 4.0 to determine

the exact meaning of the response value in each register.

Getting Started 1-10

A typical command and response to read the analog output value

from a D3000M whose slave address is ‘01’ would be:

Command: 03 03 00 00 00 01 85 E8

Response: 03 03 02 00 7D 01 A5

In the command string:

03 is the slave address

03 is the Read Input Registers command

00 00 is the starting register to be read (Register 40001)

00 01 the number of registers to be read

85 E8 is the CRC for this message

In the response string:

03 is the slave address

03 is the command

02 indicated the number of data bytes in the message

00 7D is the analog data

01 A5 is the CRC for this message

Function (04) - Read Input Registers (Analog Output Value)

Read Input Register function (04) can be used to read data values

from registers within the D3000M module. These data values repre-

sent features such as the present analog output value, the watchdog

timer value, or the slope value. This function supports reading of up

to six registers starting from Modbus slave register 30001 through

30006.

Some data acquisition and monitoring programs and some program-

mable logic controllers (PLC) may use zero based register address-

ing. In that case, the registers are addressed starting from zero mean-

ing registers 30001-30006 are addressed as 0-5. Consult your soft-

ware or PLC manual for the proper addressing mode.

The data for each register is returned as two bytes that represent a

16-bit binary value. The binary values can range from 0000-FFFF

(hexadecimal). Consult the register map in Table 4.0 to determine

the exact meaning of the response value in each register.

A typical command and response to read the analog output value

from a D3000M whose slave address is ‘01’ would be:

Command: 03 04 00 00 00 01 30 28

Response: 03 04 02 00 7D 00 D1

In the command string:

03 is the slave address

04 is the Read Input Registers command

00 00 is the starting register to be read (Register 30001)

00 01 the number of registers to be read

30 28 is the CRC for this message

Getting Started 1-11

In the response string:

03 is the slave address

04 is the command

02 indicated the number of data bytes in the message

00 7D is the analog data

00 D1 is the CRC for this message

Function (06) - Preset Single Register

The Preset Single Register function (06) can be used to write values

to a single register. The D3000M contains several registers that sup-

port this command. The register locations begin at 40001 and there

are five registers that accept values from this command. Primary uses

for this command are writing a new analog output value to the D3000M

module or updating values such as the Watchdog Timer and Slope

control values.

This command can also be used to suspend the Modbus RTU proto-

col mode and return the D3000M back to the DGH ASCII protocol

mode. Write a value of 0000 to Modbus register 40003 to temporarily

suspend the Modbus RTU protocol mode. The module will then com-

municate using the D3000M ASCII protocol command set.

The D3000M ASCII protocol command set can be used to verify or

alter setup data or for troubleshooting purposes. The module will

continue to communicate using the ASCII protocol until either a Re-

mote Reset (RR) command (RR) is received or the power is cycled.

At which time, the module will return to the Modbus RTU protocol

mode. Refer to the D3000M ASCII Modbus Disable command (MBD)

for more information on permanently disabling the Modbus RTU pro-

tocol mode.

The following command will write a value of zero to the Analog Out-

put register, causing the D3000M analog output to move down to the

minus full scale value.

Command: 03 06 00 00 00 00 88 28

Response: 03 06 00 00 00 00 88 28

In the command string:

03 is the slave address

06 is the Preset Single Register command

00 00 is the starting register to be read (Register 40001)

00 00 specifies the data value written.

88 28 is the CRC for this message

In the response string:

03 is the slave address

06 is the command

00 00 is the starting register to be read (Register 40001)

00 00 specifies the data value written.

Getting Started 1-12

88 28 is the CRC for this message

Function (10) - Preset Multiple Registers

The Preset Multiple Registers function (10) can be used to write val-

ues to multiple registers. The D3000M contains several registers that

support this command. The register locations begin at 40001 and

there are five registers that accept values from this command. Pri-

mary uses for this command are writing more than one register value

to the D3000M in one command and response sequence. For ex-

ample, new Watchdog Timer and Slope control values could be writ-

ten simultaneously with one command.

The following command will write a single value into register 40005,

setting the Watchdog Timer to the maximum value.

Command: 03 10 00 04 00 01 02 FF FF BF 04

Response: 03 10 00 04 00 01 41 EA

In the command string:

03 is the slave address

10 is the Preset Multiple Registers command

00 04 is the starting register to be read (Register 40005)

00 01 specifies the quantity of registers written.

02 is the data byte count

FF FF is the data value written into 40005

BF 04 is the CRC for this message

In the response string:

03 is the slave address

10 is the command

00 04 is the starting register to be read (Register 40005)

00 01 specifies the quantity of registers written.

41 EA is the CRC for this message

Note: This function has been implemented to comply with the Modbus

Standard and many commercial programs in the data acquisition

market today. However, it only supports a one-register write at this

time.

Modbus Exception Codes

The Modbus protocol contains provisions for error checking. The

Modbus standard contains a standardized set of values that can be

returned from a Modbus Slave device when a problem or error is

detected. These error values are referred to as “exception codes”

and the DGH implementation of the Modbus RTU protocol utilizes

these exception codes when applicable. See Table 3.0 below for a

complete list of supported exception codes.

In the event that an error is detected, an error response would be

generated and return one of the standardized error codes. The most

Getting Started 1-13

significant bit (MSB) of the function number will always be set in any

exception response. Therefore, an error response message that was

generated from a function ‘03’ command would return the function

value of 0x83. A typical exception response would be:

Command: 03 03 00 0A 00 01 A5 EA

Response: 03 83 02 61 31

The following error codes may be returned from a DGH D3000M

Modbus RTU compatible module.

Table 3.0. DGH Modbus Exception Codes.

Exception Name Description

01 Illegal This exception code is generated

Function when the module does not recognize

the function code.

02 Illegal Data This exception code is generated

Address when the module does not support the

specified data address in the command.

03 Illegal Data This exception code is generated if the

Value command data is out of range for the

function.

06 Slave Busy This exception code is generated dur

ing the 3 seconds after the module is

reset or powered up.

Getting Started 1-14

Table 4.0. D3000M Modbus Register Map

Function Register Direction Value Description

03 40001 Read 0.FFFF Analog Output Value

03 40002 Read 0..7 Digital Input Status

03 40003 Read 0 Control Register

03 40004 Read 0.FFF RAW DAC Output

03 40005 Read 10.FFFF EEPROM Slope Value

03 40006 Read 45.FFFF Watchdog Timer Value

04 30001 Read 0.FFFF Analog Output Value

04 30002 Read 0..7 Digital Input Status

04 30003 Read 0 Control Register

04 30004 Read 0.FFF RAW DAC Output

04 30005 Read 10.FFFF EEPROM Slope Value

04 30006 Read 45.FFFF Watchdog Timer Value

01 00001 Read 0,1 Digital Input 0

01 00002 Read 0,1 Digital Input 1

01 00003 Read 0,1 Digital Input 2

02 00001 Read 0,1 Digital Input 0

02 00002 Read 0,1 Digital Input 1

02 00003 Read 0,1 Digital Input 2

06 40001 Write 0.FFFF Analog Output Value

06 40003 Write 0 Temporarily suspend

Modbus RTU and

return back to DGH

ASCII protocol.

06 40003 Write 2 Reset Module

06 40004 Write 0.FFF RAW DAC Output

06 40005 Write 10.FFFF EEPROM Slope

06 40006 Write 45.FFFF Watchdog Timer, write

FFFF to disable.

10 40001 Write 0.FFFF Analog Output Value

40002 Read 0..7 Digital Input Status

10 40003 Write 0 Control Register

10 40004 Write 0.FFF RAW DAC Output

10 40005 Write 10.FFFF EEPROM Slope Value

10 40006 Write 45.FFFF Watchdog Timer Value

Getting Started 1-15

Modbus RTU Enable (MBR)

To place any D3000M module in Modbus protocol mode use the

Modbus RTU (MBR) command. The MBR command must be used

to specify the Modbus device address and enable the Modbus pro-

tocol mode. The device address consists of a two character hexa-

decimal value and is stored in EEPROM. The two-byte address speci-

fied is translated to a one byte, 8 bit address required by the Modbus

protocol. The example below can be used to specify a Modbus slave

address of “01”.

Command: $1MBR01

Response: *

Command: #1MBR01

Response: *1MBR019D

Note: This address value is different and separate from the address

value specified in the Setup (SU) message of the module. After the

Modbus address is specified, a reset is necessary to activate the

Modbus protocol mode. The reset may be accomplished in one of

three ways:

1) Removing power for about 10 seconds to perform a power-up

reset.

2) Momentarily grounding the Default* pin.

3) Issue a Write Enable (WE) command followed by a Remote Re-

set (RR) command.

After a reset is performed, the module is in Modbus protocol mode.

Modbus Disable (MBD)

The Modbus Disable (MBD) command is used to disable the Modbus

RTU protocol. Any D3000M series module in Modbus mode can be

returned to D3000 ASCII protocol mode by connecting a jumper wire

between module pins GND and Default* pin. This places the mod-

ule in Default Mode, where the module will only communicate at 300

baud, no parity, D3000 ASCII protocol, and answer to any address.

While in Default mode, transmit an MBD command to internally dis-

able the Modbus protocol.

Following the MBD command a device reset must occur. The reset

is necessary to activate the D3000M ASCII protocol. A reset can

occur by removing the Default* jumper, performing a power-up reset

or by transmitting a Write Enable (WE) and Remote Reset (RR) com-

mand sequence. After a reset is performed, the module is in D3000M

ASCII protocol mode.

Command: $1MBD

Response: *

Command: #1MBD

Getting Started 1-16

Response: *1MBD2E

Testing and Troubleshooting:

1. The RS-485 type D3000M modules “cannot” be tested in

the Modbus RTU protocol mode using the DB-9 connection

in Figure 2.0. The RS-485 Quick Hook-up Diagram to an RS-

232 serial port causes the command to be read back into the

computer before the response from the module. This causes

parsing problems with Modbus drivers. The diagram in Fig-

ure 2.0 is only for setup and configuration of the module.

2. Communications with USB converters can sometimes lead

to Modbus Timeout Errors. Meaning, that it appears as though

the D3000M does not respond in Modbus RTU protocol mode.

This is sometimes caused by converters that place gaps in

between the data characters in the transmitted command. If

a converter places gaps in between the characters, and the

gap is more than 3.5 character times at the specified baud

rate then the module will consider the message ended. There-

fore, it will not receive a complete message and will never

respond. This problem usually appears at the higher baud

rates where the character times are much quicker.

Chapter 2

Functional Description

The D3000M Computer to Analog Output interfaces provide accurate

analog process control signals in response to simple digital commands from

a host computer. The D3000M units are completely self-contained and are

designed to be operated remotely from the host. Digital commands are

transmitted to the D3000M units using standard RS-232 or RS-485 commu-

nications links. Commands and responses are in the form of simple English

ASCII character strings for ease of use. The ASCII protocol allows the units

to be interfaced with dumb terminals and modems as well as intelligent

controllers and computers.

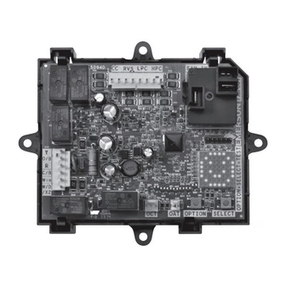

Figure 2.1 shows a functional block diagram of the D3000M. The key block

is the 12-bit Digital to Analog Converter (DAC). The DAC converts digital

data derived from host commands into the desired analog output. All of the

other components provide a supporting role for proper operation of the DAC.

An 8-bit CMOS microprocessor is used to provide an intelligent interface

between the host and the DAC. The microprocessor receives commands

and data from the host computer through a serial communications port.

Specialized communications components are used to interface the micro-

processor to either RS-232 or RS-485 communications standards. Com-

mands received by the microprocessor are thoroughly checked for syntax

and data errors. Valid commands are then processed to complete the

desired function. A wide variety of commands are available to control the

DAC, read status information, and to configure the module to fit the user’s

requirements. Responses to the host commands are then produced by the

microprocessor and transmitted back to the host over the RS-232/RS-485

serial link.

An Electrically Erasable Programmable Read-Only Memory (EEPROM) is

used to retain important data even if the module is powered down. The

EEPROM contains setup information such as the address, baud rate, and

parity as well as calibration data.

In response to host commands, the microprocessor produces the appropri-

ate digital data necessary to control the DAC. Digital data is transmitted to

the DAC through opto-isolators which provide electrical isolation. The DAC

produces a precise analog current that is directly proportional to the

magnitude of the digital data. The DAC output current is then processed and

amplified by signal conditioning circuits to produce the desired output

voltage or current. Output protection circuits are included to protect the

module from potentially damaging output faults.

Table of contents

Other DGH Control Unit manuals

Popular Control Unit manuals by other brands

Emerson

Emerson Fisher Types N480 instruction manual

Thermon

Thermon Terminator ECM-P-XP Installation procedures

Kentec Electronics

Kentec Electronics Syncro Si product manual

Sun Microsystems

Sun Microsystems Ultra 2 UltraSPARC-II Upgrade

Emerson

Emerson 47D01U-843 installation instructions

Torqeedo

Torqeedo TORQ TRAC operating manual