DGS 101 Instruction Manual

TECHNOLOGIES

Technical Sheet

ref C1540 J

GDS 101

SINGLE POINT GAS ALARM

Operation

A fixed single point alarm unit that meets the requirements for continuous economic and reliable monitoring of gas levels in a

wide range of environments from commercial premises through to heavy industrial applications that may require hazardous

area sensing. The GDS101 may be utilised as a standalone unit or as an addressable sensor forming part of the GDS Combi

CANbus addressable network system and therefore offering the features of our most advanced system.

Typical monitor locations are – public buildings, boiler plant rooms, swimming pools, water treatment works, H&V control

systems, manufacturing and process plants.

Installation

CONTROL UNIT: The control unit should be mounted in a position which is

accessible and in the field of vision.

Mains should be from a fused supply.

SENSORS: The positioning of sensors depends upon the type of gas to be

monitored and its density with respect to air.

HEAVY GASES (LPG, Propane, Butane, Refrigerant Gases) – locate at 15

to 20 cm from the floor.

LIGHTER GASES (Methane, Natural Gas, Town Gas) –

locate at 5 to 10cm from the ceiling.

CARBON MONOXIDE – locate at 1.5 metres above floor level.

All equipment should be mounted away from direct heat and in

accordance with its IP rating.

Initial Set–up Procedure

Having terminated all cables switch on the power and wait for the 1 minute

stabilisation period to complete, this is indicated by the power and inhibit

indicator changing from flashing to a steady state, a reduced power mode

feature is activated one hour following any operator activity, this state is

indicated by a screen power reduction of approximately 50%, pressing

any button will return the screen to full display.

The alarm panel may have been supplied without a sensor and a customer

supplied device is to be used, in this case the following adjustments should

be carried out. Adjust jumpers as follows:

For 24DC (+ sig –) 4~20mA sensor devices connect jumpers

J5/11 Position A, J12 Off, J14 link B.

For catalytic sensors (W Y P) J5/11 Position B, J12 On, J14 Link A.

(Caution reset link J14 to position A before connecting the sensor

as damage will occur requiring sensor replacement).

Sensor supply may be measured between the two sensor voltage test pins,

adjust as required using the sensor supply adjustment potentiometer. See

sensor cell supply table.

Test pins TP6/TP7 may be used to check 4~20mA sensor input signals 4mV

= 4mA.

Measuring across TP8/TP9 will allow the 4~20mA output signal to be

checked 4mV = 4mA. Output for pellistor (flammable) can be adjusted

using 4+20mA pots.

Changes to gas type and range can be made by connecting GDS RS232

pod to J3 and using a PC running hyper terminal at 4800 baud.

The Hyper Terminal output screen shows continuous data output/

commands and allows input from the PC keyboard pressing ‘C’ enters

calibration mode, press ‘G’ to change the gas type to match the cell being

used. Note – the range of the new gas has a default value but can be

adjusted by pressing ‘R’.

For catalytic sensors course zero adjustment is achieved by turning the zero

potentiometer (10 turn) until the zero LED just turns off.

Access to the Menu

The GDS101 is supplied with factory set default settings which may be

re-adjusted from the front screen and push buttons:

Press 2 to access the menu followed by 231, menu entry will be at level 5

(Exit), pressing 1 or 3 will enable travel through the sub menus 1–9 and

adjustment of settings, pressing 2 enables access into each sub menu and

on completion pressing 2 will confirm your selection and move to the next

setting.

1. Zero/Span – In clean air Zero display – apply test gas at the peak

reading and adjust the span.

2. Alarm Levels – 3 alarm levels. Pressing 1+3 together will cycle through

rising and falling alarms and latched (L) or unlatched (U) (auto reset)

relays in following order

() L, ( ) U, ( ) U, ( ) L. Default setting latched.

3. Alarm Delay – Time to alarm in seconds

(default setting 2 seconds) maximum 255 seconds.

4. Inhibit Alarm – Isolate alarm functions – maintenance and test periods.

Second part of this menu allows YES/NO selection of sounder alert for

alarm A1.

5. Exit Press 2 – Entry and Exit point of menu.

6. L.C.D Brightness – Adjustment of display brightness.

7. L.E.D/Relay Test – Turns indicators and relays ON.

8. Auto Zero – Use only when very low alarm levels are required

(<10% of scale).

9. Sensor Address – Used when connecting to a GDS

Combi system.

A. 4~20mA output adjust (Tox/O2only). Pressing 1 or 3 will allow for

output to be adjusted to 4mA and 20mA as measured on test pins 8+9.

B. To set A1 alarm relay to become a global sounder relay with a 10min

time delay after alarm condition ends. Press 1 to active or press 3 to

deactivate.

C. To delay relay deactivation after alarm condition has ceased, press

2 to cycle through alarms A1,A2 and A3. when the required alarm is

displayed press 1 to increase the delay and 3 to decrease the delay.

D. Allows relay A3 to change from alarm relay to valve timer central relay

E. Relay on time, minimum 2 minutes maximum 200 mins.

F. Relay off time, minimum 2 minutes maximum 200 mins.

GDS TECHNOLOGIES LTD |FUSION POINT |ASH LANE |GARFORTH |LEEDS |LS25 2GA |UK www.gds-technologies.co.uk

TECHNOLOGIES

GDS TECHNOLOGIES LTD |FUSION POINT |ASH LANE |GARFORTH |LEEDS |LS25 2GA |UK www.gds-technologies.co.uk

This document is not contractual and the equipment specification may be modified at any time without prior notice.

Technical Sheet

ref C1540 J

Mains Version

230/115v AC 50/60 Hz

DC Version 24v DC ± 15%

Power 4w

Outputs

Alarms 1, 2, 3 relays – S.P.C.O. ND (NE option)

Fault Relay – S.P.C.O. ND (NE option)

normaly latched (unlatched option)

Relay contacts rated 3A/230v AC

CANbus – see Combi alarm system

4~20mA analogue output

Sensor Cell Supply Table

Indicators

Power Green L.E.D

Alarms 1, 2, 3 Red L.E.D’s

Fault Amber L.E.D

Display 2 line alpha–numeric

Audible Alarm

Gas/Fault mutable: 85dB@10cm

Environmental

Operating temperature: 15 to +50°C

Storage temperature: 5 to +55°C

Humidity 5–95% RH non condensing

Protection IP65

Sensor Cable

3 core 1.5mm screened →1.5km

SPECIFICATION

4–20

OV

Lo

Hi

24V

NO C

AL3

NC NO C

NCNO C

AL2

NCNO C

AL1

NC

W

+

Y

sig

P

–

SENSOR FAULT

+ –

4–20mA

Output

PC comms via

hyperterminal

Sensor

Voltage

test pins

Zero LED

4mA

J28

20mA

Zero

Gain

J3

J29

J 11

J18 J17 J16

J15

J19

J1

TP3

A B

A

B

A

B

TP11

TP12

TP6TP7

TP13

TP8 TP9 TP2

TP4

TP1

Contrast

J6

J20

J5

J4 J7

J 12

J 13 J 14

J8

J9

x fault

Inhibit Ov 24v J1 CANbus – EOL – see Combi

J4/7 For Semiconductor sensors

J5/11 Sensor (B–catalytic A–4~20mA)

J6/20 Sink/Source 4~20mA output

J8 Gain – factory set

J9 Normally fitted 4~20mA out

J12 Bridge fault enable fit for catalytic sensor

J13 See J8

J14 Sensor supply selector

A for catalytic sensor

B for 4~20mA sensor

J15 Sounder mute

J16 N/E – A3 relay link on

J17 N/E – A2 relay link on

J18 N/E – A1 relay link on

J19 N/E – fault relay link on

J28 Reset processor

J29 Address change enable – see Combi

C1529

A

B

4~20mA In

Sensor

supply

adjust

4~20mA

Output

CAT300A 2v/300mA

CAT170A 2v/175mA

SEM–1 5v/170mA

SEM–1 4v/170mA Ammonia

GDS PRIME 4v/70mA

F6–170 2v/175mA

CAT335C 2.5v/335mA

THE300A 2v/300mA

SS10 2v/175mA

CAT335A 2.5v/335mA

CAT335B 2.5v/335mA

CAT100A 2v/100mA

3 wire

GDS 101 Sensor

+24

0v

4~20mA

+ s

Y PW

–

+24

Hi

Lo

0v

4~20mA

2 wire

GDS 101 Sensor

+24

0v

4~20mA

+ s

Y PW

–

Popular Security System manuals by other brands

Concoa

Concoa Advantium 1 Plus Installation and operating instructions

Avitech

Avitech Rainier-4a user manual

Concept Smoke Screen

Concept Smoke Screen TITANIUM Ti70 Installation and operation manual

Radio Shack

Radio Shack Self-Stick Door/Window Alarm owner's manual

Paso

Paso PAW5500-VES Series quick start guide

Vestil

Vestil BOL-G-24-3.5 Use and maintenance instructions

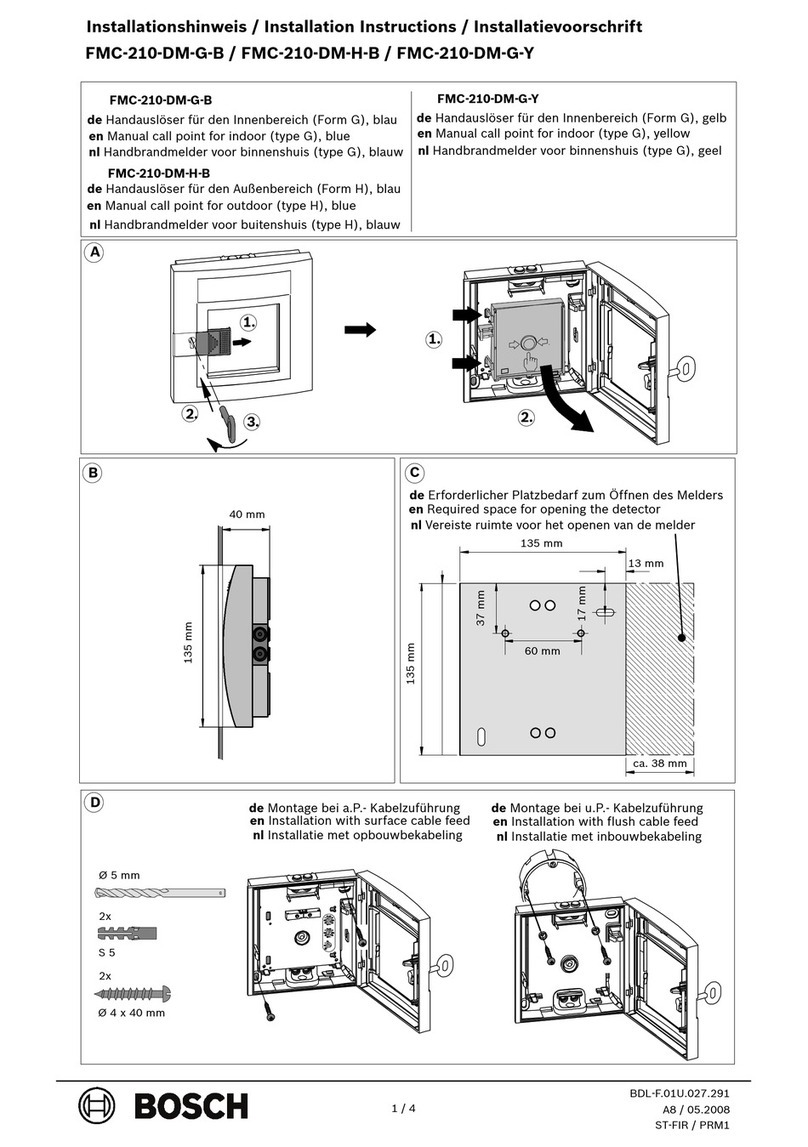

Bosch

Bosch FMC-210-DM-G-B installation instructions

Alderon Industries

Alderon Industries Versa'larm VA02A Operation, maintenance and installation manual

Trigon

Trigon 301A operating instructions

Imrita

Imrita IMT-P-ZL6 installation instructions

Viper

Viper 3606V owner's guide

PNI

PNI SafeHouse HS650 user manual