DH PGI Series How to use

PGI Gripper

Short Manual

Content

Revisions...........................................................................................................................................1

1 Specifications.................................................................................................................................2

1.1 Indicator ..............................................................................................................................2

1.2 Pinout Description...............................................................................................................3

2 Modbus-RTU Control ....................................................................................................................4

2.1 Wiring .................................................................................................................................4

2.1.1 Debugging software instructions..............................................................................5

2.2 Default Communication Parameters ...................................................................................8

2.3 Modbus-RTU Description...................................................................................................9

2.3.1 RTU Framing ...........................................................................................................9

2.3.2 Supported Modbus Function Code...........................................................................9

2.3.3 Register Mapping.....................................................................................................9

2.3.4 Register Description...............................................................................................11

2.3.4.1 Initialization ................................................................................................11

2.3.4.2 Force............................................................................................................12

2.3.4.3 Position........................................................................................................12

2.3.4.4 Speed...........................................................................................................13

2.3.4.5 Initialization State .......................................................................................13

2.3.4.6 Gripper State ...............................................................................................14

2.3.4.7 Current Position ..........................................................................................14

2.3.4.8 Save Parameter............................................................................................15

2.3.4.9 Initialization Direction ................................................................................15

2.3.4.10 Slave Address............................................................................................16

2.3.4.11 Baud Rate ..................................................................................................16

2.3.4.12 Stop Bits....................................................................................................17

2.3.4.13 Parity .........................................................................................................17

2.3.4.14 Test I/O Parameters ...................................................................................18

2.3.4.15 I/O Mode Switch.......................................................................................18

2.3.4.16 I/O Parameter Configuration.....................................................................19

3 I/O Control...................................................................................................................................20

3.1 Wiring ...............................................................................................................................21

3.2 I/O Setting.........................................................................................................................21

3.2.1 Configure IO ..........................................................................................................22

3.2.2 Open IO..................................................................................................................23

3.2.3 Save Settings..........................................................................................................23

3.2.4. Restart ...................................................................................................................23

1

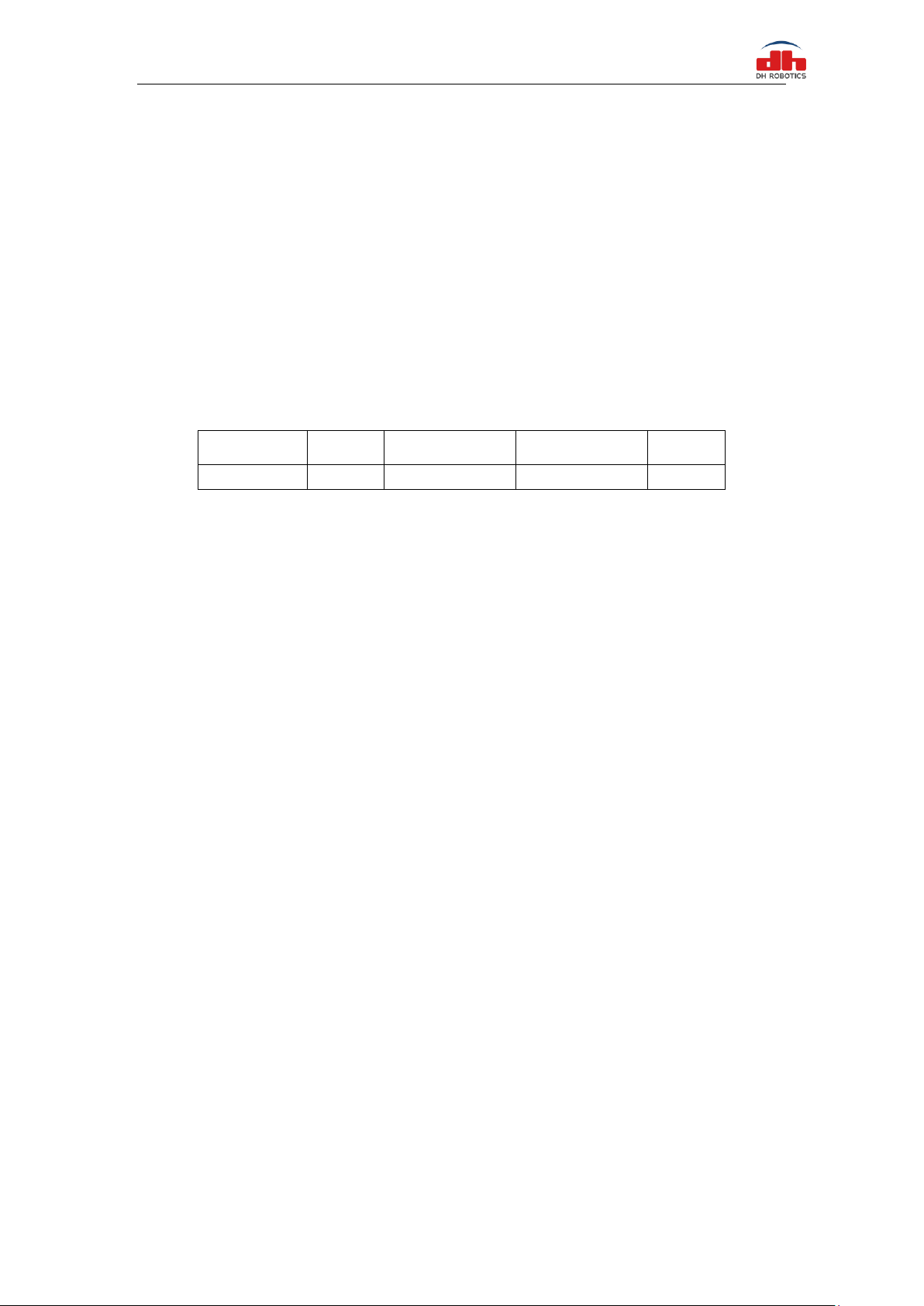

Revisions

Date

Version

Revised content

20200426

V1.0

First edition, write wiring instructions and

command instructions

20200904

V2.0

Change some instructions , Update the description

of IO mode

2

1 Specifications

PGI series are industrial electric gripper, The number(PGI-number) represents the maximum

gripping force of the gripper. The gripper is equipped with a pair of parallel fingertips, which runs

symmetrically during the movement. The main structure of the gripper is a smooth rectangular

structure. It is equipped with an 8-core communication interface, as shown in Figure 1.1. It has the

following characteristics:

Controllable force/position/speed: The gripper can program and adjust the grip position, grip

force and speed.

Multiple communication modes: The gripper supports Modbus RTU protocol and IO mode

control. Other communication protocols such as USB and ETHERNET can be transferred through

protocol converter.

Gripping Detection:The combination of force control and position control is adopted in the

gripping process.

Gripping feedback: The state of the gripper can be read by programming, and can also be judged

according to the indicator of the gripper.

Fingertips can be customized: Fingertips can be replaced according to situation, which is

suitable for precision machining, parts assembly, and other fields.

1.1 Indicator

The gripper can feed back the state of the gripper in real time. In addition to the command reading,

it can also be judged on the color of the indicator:

Color description of indicator

·Uninitialized state: Red light blinks, other lights are off.

·Initialized State: the blue light is always on, indicating that it is in the operable state.

·Received command state: the red light blink once quickly (because the blue light is

always on at this time, the gripper indicator light will looks like a purple light).

·Object Caught state: green light is always on, other lights are off.

·Object dropped state: green light blinking.

3

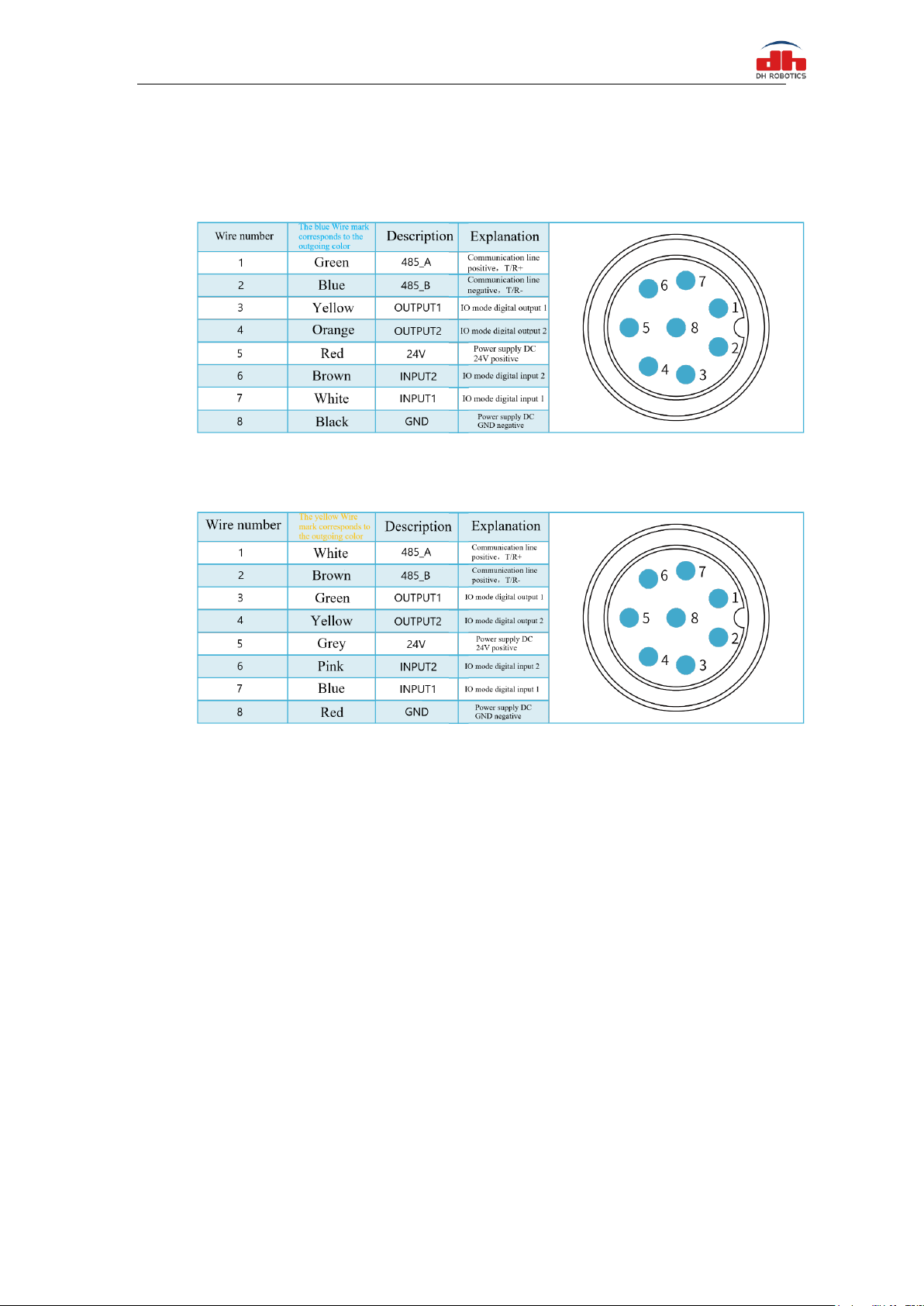

1.2 Pinout Description

The line sequence definition on the gripper body is shown in Figure 1.1(a) and 1.1(b)

Figure 1.1 (a) The blue line marked diagram

Figure 1.1 (b) The yellow line marked diagram

ote: Please distinguish the wire sequence according to the wire mark. If the wire mark is lost,

dropped, or forgotten, please contact our staff to cooperate in determining the wire

sequence. If you do not contact our staff, the clamping jaws will be damaged due to the

wrong wiring sequence, and you will be responsible for the consequences.

4

2 Modbus-RTU Control

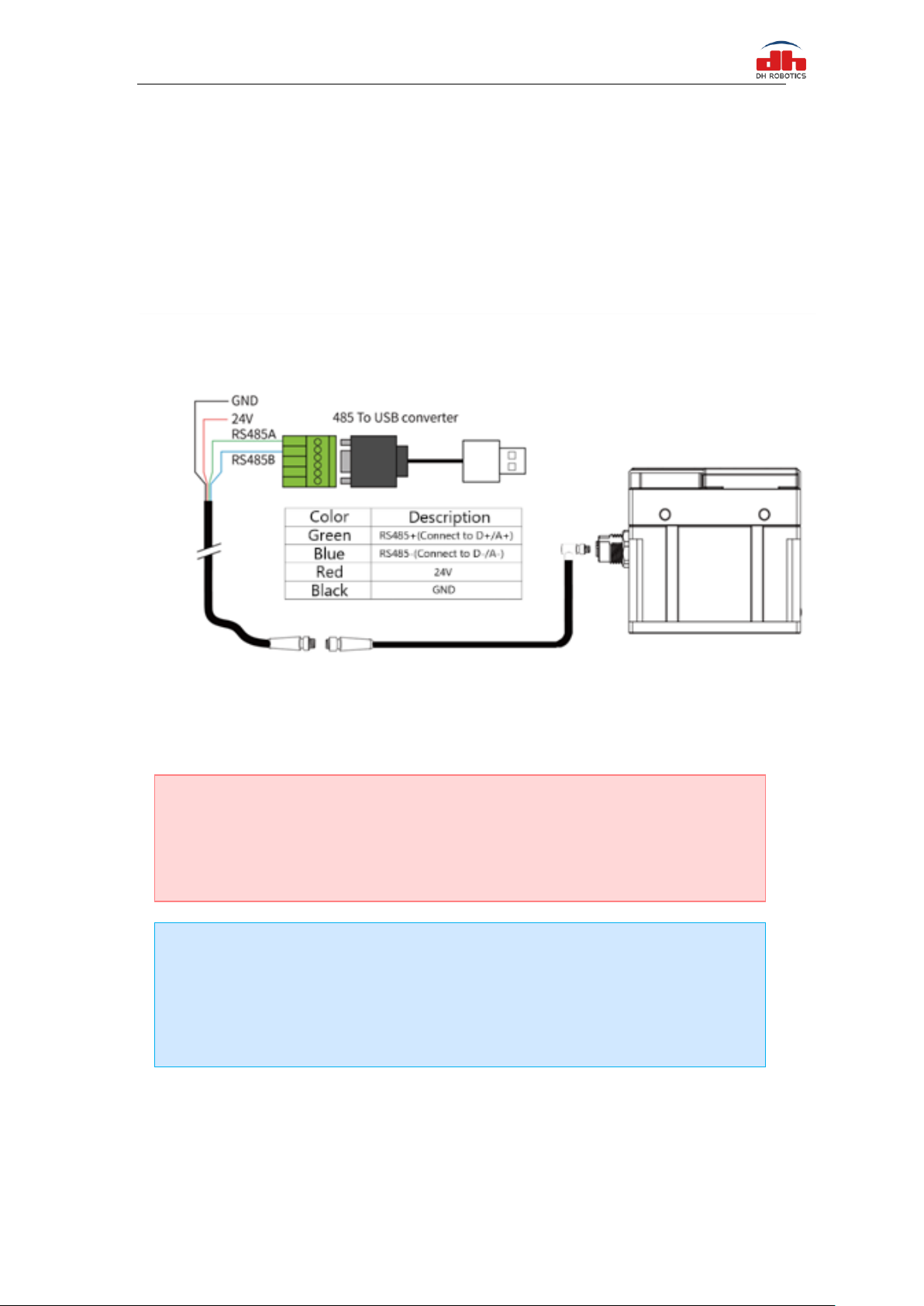

2.1 Wiring

Use the provided RS-485 to USB converter (see the schematic in Figure 1.1 below) to plug into a

PC or other Controllers.

Figure 2.1 RS485 Connection

Warning

·Please check the connector before inserting, and do not forcibly insert the plug. Even if

the cable connector has a fool-proofing design, but you can still forcibly insert it, then the

gripper would be damaged.

Wiring instructions

·① : when the device (computer) has RS485 interface, the communication can be directly

connected to RS485_A and RS485_B communication lines without transferring to 485

module through USB

·② : in this way, other serial port debugging software (such as MODBUS poll) can be

used for debugging

5

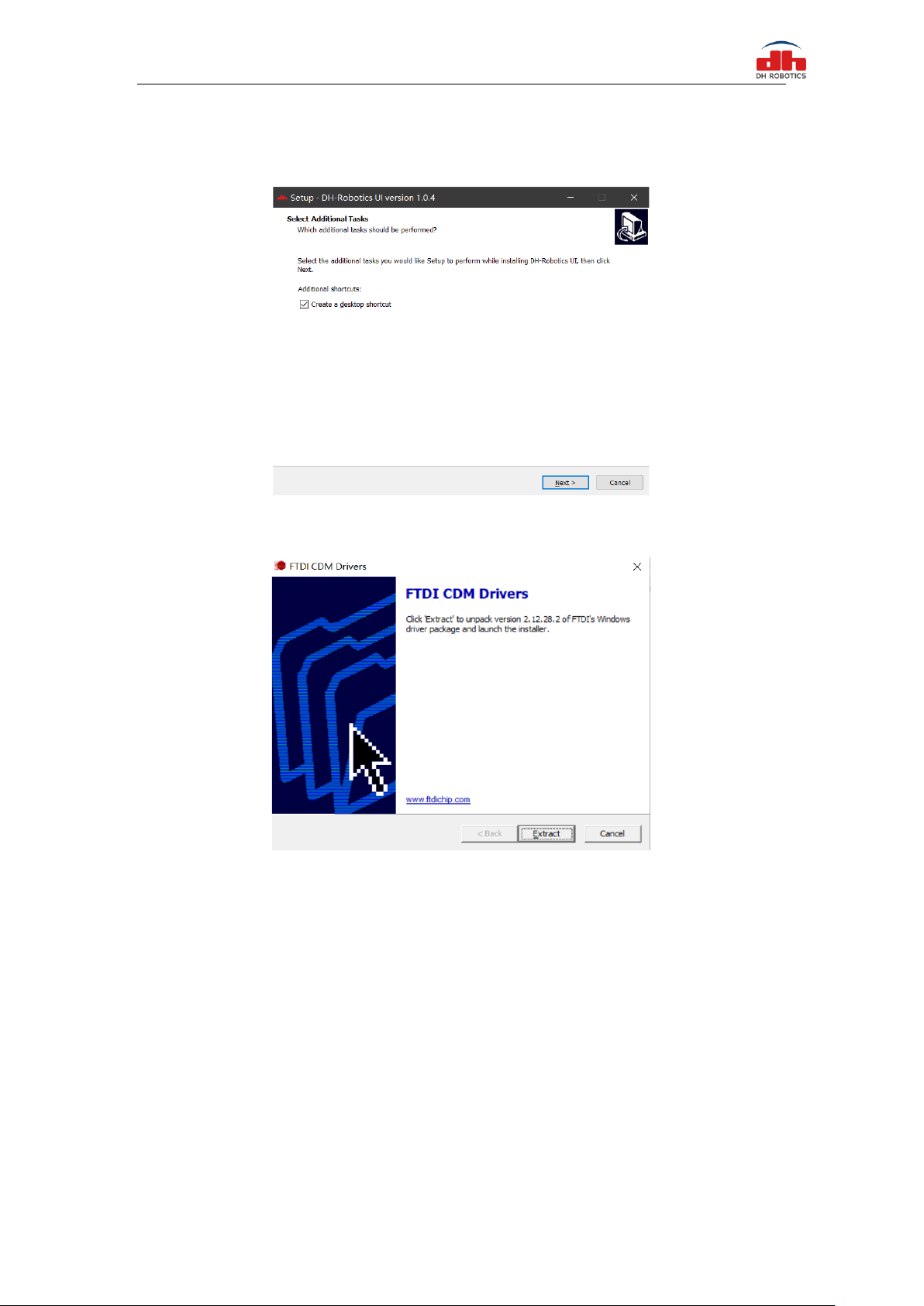

Software can be downloaded on the official website. Software and driver are integrated in the

process of software installation, and both are installed together. It is recommended to check the

create shortcut during installation.

Figure 2.2 (a) installation interface 1

Figure 2.2 (b) driver installation interface

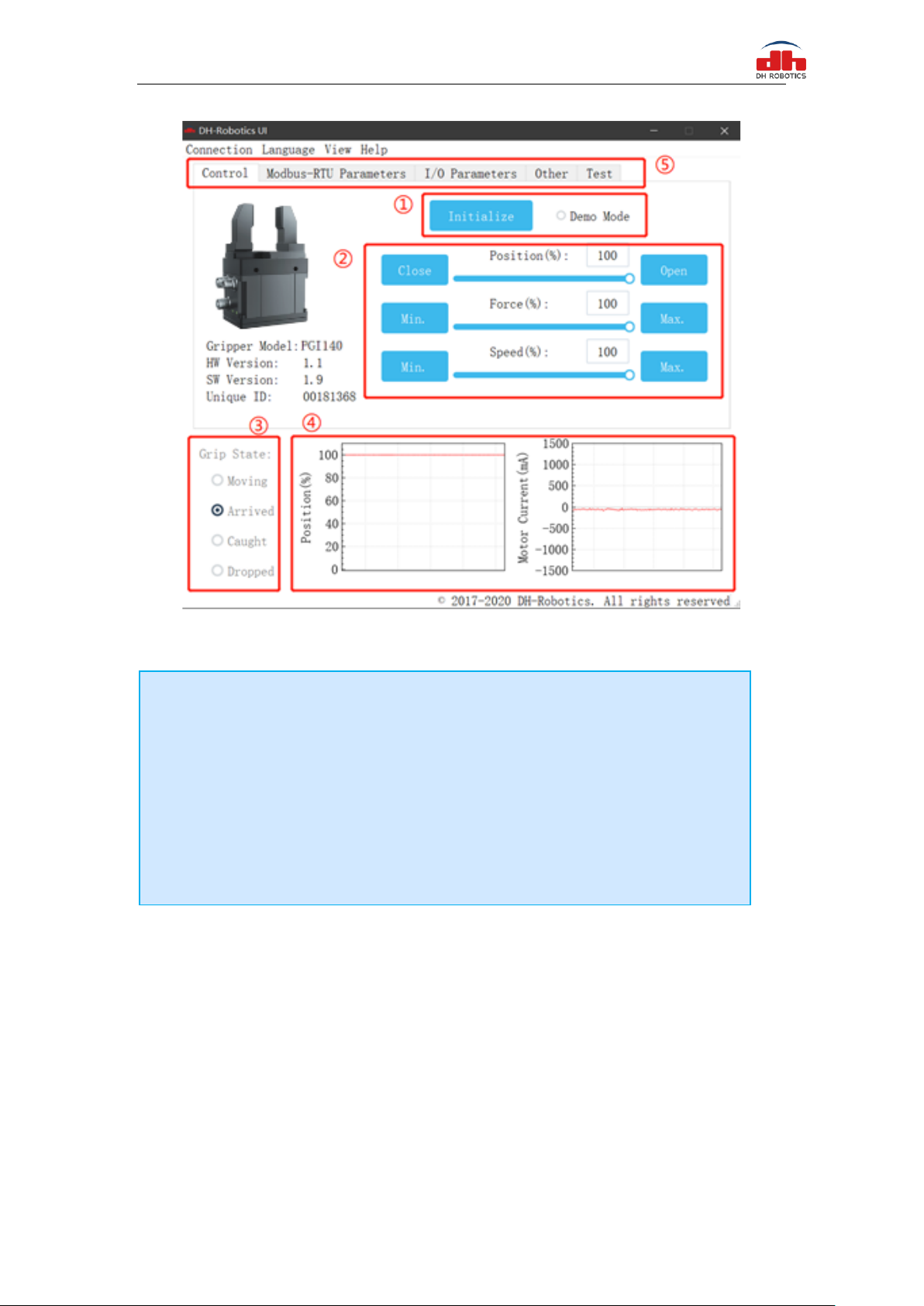

2.1.1 Debugging software instructions

Before use, it is necessary to connect the corresponding wiring according to the instructions.

Open the software, the software will automatically identify the serial port, baud rate, ID number and

other information of the gripper for automatic connection. As shown in the figure below:

6

Figure 2.3 main control interface

The specific interface description is as follows:

The gripper body uses Modbus RTU for communication, and can read and write data into the

register. The data can be read and written at the view register. The data includes control, feedback,

user parameters and I/O parameters as shown in the following figure:

Interface description

·① Initialization and demonstration mode: the gripper needs to be initialized before

operation to calibrate the zero point. The demonstration mode is a cyclic program.

·② Control interface: it can control the position, force and speed of the gripper.

·③ Clamping status: real time display of clamping status of clamping claw.

·④ Position current real time graph: real time display position and current. The

current represents the current of the internal motor, not the current actually consumed by

the gripper. The current real-time graph can reflect the stability of clamping force.

·⑤ Parameter setting: the configuration parameters of Modbus RTU, such as baud rate

and check bit, can be configured; IO mode is to configure the parameters related to IO

mode;

7

Figure 2.4 View

If there are multiple 485 devices, sometimes the baud rate and ID number of the gripper need to be

modified, the parameters can be modified in Modbus RTU parameters

Figure 2.5 Modbus RTU parameters

You can set and configure the gripper I / O parameters in [I / O parameters]. After modifying the

parameters, please click Save button to save. The following figure shows the operation of opening

IO mode:

8

Figure 2.6 Modbus RTU parameters

The steps of switching IO are as follows:

2.2 Default Communication Parameters

Slave Address :1

Baud Rate :115200

Data Bits :8 bits

Stop Bits :1 stop bit

Parity :None

Steps to switch IO mode

·① Open IO mode: open IO mode first.

·② Configure four groups of IO parameters: set the four groups of parameters of

gripper, including position, force and speed.

·③ Save: click the Save button to write the parameters to the internal register of flash,

and restart to control.

·④ Restart: after the restart, the switch to IO mode is successful. You can control the

gripper according to the input signal, and the running status will be fed back through

output.

9

2.3 Modbus-RTU Description

2.3.1 RTU Framing

This gripper uses the standard Modbus-RTU protocol.

In RTU mode, the first field is the device address. The allowable characters transmitted for all

fields are hexadecimal 0 ... 9, A ... F. Networked devices monitor the network bus continuously,

including during the silent intervals. When the first field (the address field) is received, each

device decodes it to find out if it is the addressed device.

A typical message frame is shown in Table 2.1.

Table 2.1 RTU Framing (Function Code:0x06)

Slave Address

Function

Register address

Register data

CRC

01

06

01 00

00 01

49 F6

Slave Address: The Slave address of the gripper. The default is 1, you can also modify it through

write different value to Slave Address register.

Function: The Function Code field tells the addressed slave what function to perform. Includes read

or write registers function.

Register address: Specifies which registers reference to be written.

Register data: Specifies which value to be written. Each register (word - 16 bits) of the Modbus

RTU protocol is composed of 2 bytes (8 bits) from the Gripper.

CRC: the CRC error-checking field contains a 16-bit value implemented as two eight-bit bytes. The

CRC field is appended to the message as the last field in the frame. The low-order byte of the field

is appended first, followed by the high-order byte. The CRC high-order byte is the last byte to be

sent in the message.

2.3.2 Supported Modbus Function Code

This griper uses MODBUS- RTU. The following function codes are currently supported:

03 (HEX): Read Holding Registers

06 (HEX): Write Single Register

10 (HEX): Write Multiple Registers

2.3.3 Register Mapping

The gripper’s Modbus-RTU registers consist of two types of registers: the basic control registers

and the configuration registers.

Basic control registers: initialization, force setting, reference position, speed, and some states.

10

Configuration registers: gripper’s parameter configuration. Includes Modbus communication

parameters and I/O parameters.

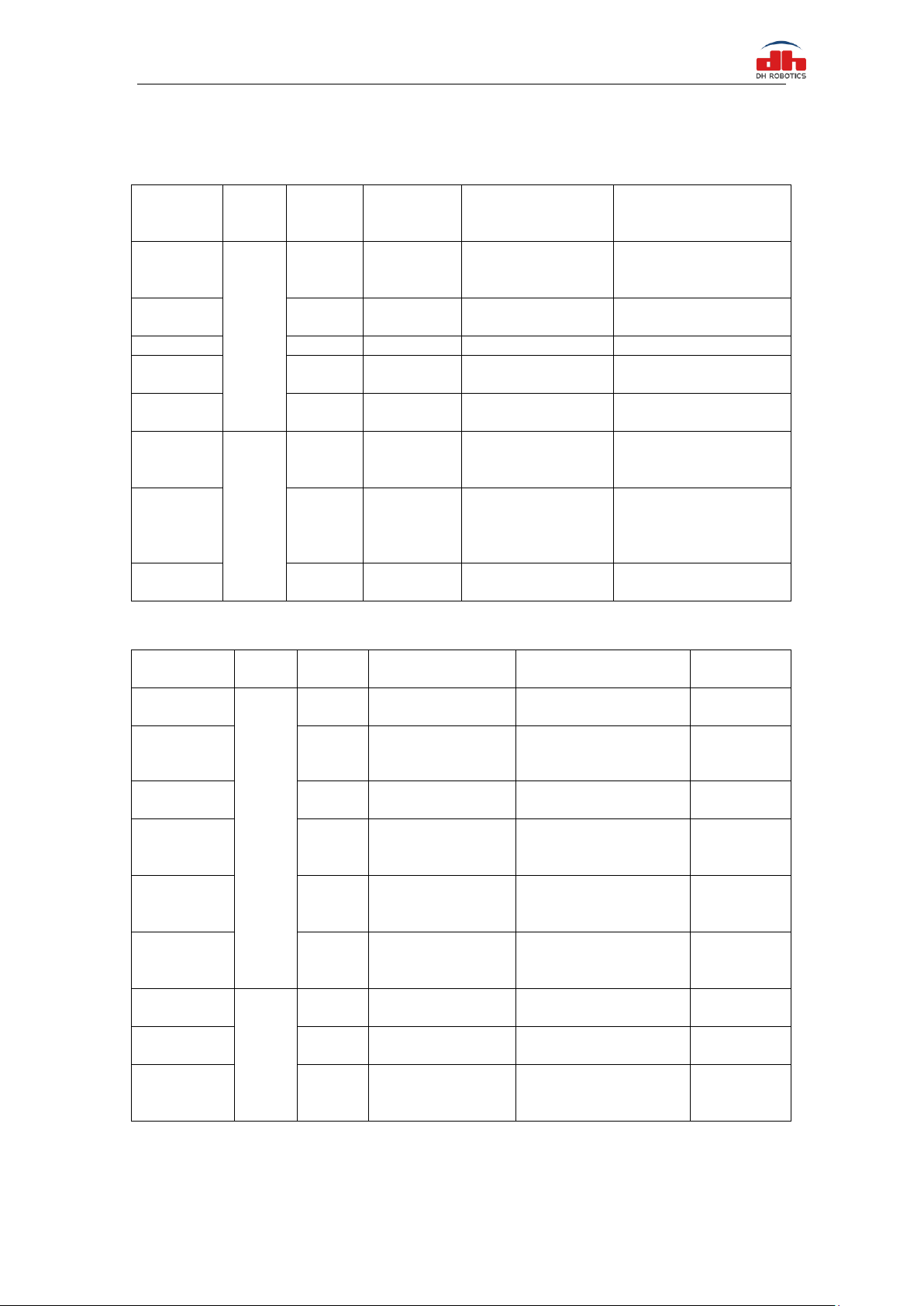

Table 2.2 Basic Control register map

Function

high-

order

byte

low-

order

byte

Description

Write

Read

Initialization

0x01

0x00

Initialize the

gripper

0x01:initialization;

0xA5: Fully

initialization

Current setting

Force

0x01

Gripper’s

force

20-100 (%)

Force

currently set

Reserve

0x02

-

-

-

Position

0x03

Position

0-1000 (‰)

Reference position currently

set

Speed

0x04

Speed

1-100 (%)

Speed

currently set

Initialization

state

0x02

0x00

Initialization

state of the

gripper

Read Only

0:Not initialized;1:

Initialized

Gripper state

0x01

Gripper state

Read Only

0:In motion;

1:Reach position;

2 Object caught;

3:Object dropped

Position

0x02

gripper

position

Read Only

Current actual position

Table 2.3 Configuration register map

Function

High

byte

Low

bytes

Description

Write

Read

Save

Parameter

0x03

0x00

Save all the parameters

0:default,1:Write all

parameters to save

0

Initialization

direction

0x01

Configure

initialization direction

0: Open,1:Close

(default: 0)

Current setting

Slave Address

0x02

Configure gripper

Modbus address

0-255 (default: 1)

Current setting

Baud Rate

0x03

Configure gripper

Modbus Baud rate

0-5:115200,57600,

38400,19200,9600,

4800(default :0)

Current setting

Stop Bits

0x04

Configure gripper

Modbus stop bits

0:1 stop bit;

1:2 stop bits

(default: 0)

Current setting

Parity

0x05

Configure gripper

Modbus Parity

0: None parity;

1: Odd parity;

2: Even parity (default: 0)

Current setting

I/O Parameters

Test

0x04

0x00

Test I/O parameters

1;2;3;4

Current setting

I/O Mode

Switch

0x02

I/O control switch

0:OFF,1:ON

Current setting

I/O Parameter

Configuration

0x05-

0x10

Four groups of I/O

parameters

position 1,force 1,speed

1 to position 4,force 4,

speed 4

Current setting

11

2.3.4 Register Description

2.3.4.1 Initialization

This register is used to initialize the gripper.

Write: If write 1 (0x01 hex) to this register, the gripper will be initialized (fingers move to the

minimal or maximum position. The initialization direction depends on the value of initialization

direction register). If write 165 (0xA5 hex) to this register will fully initialize the gripper( find the

minimal and maximum position).

Read: if gripper need to be initialized or have initialized, this register value is 0; and if gripper is in

initializing process, this register value is 1.

The register address is 0x0100. The description of this register is shown in Table 2.4.

Table 2.4 Initialization

Function

Address

Description

Write

Read

Initialization

0x0100

Initialize the

gripper

0x01:initialize;

0xA5: Fully initialize

Current setting

The gripper needs to be initialized before control.

The sample command is as follows:

Initialize (write):

Send: 01 06 01 00 01 49 F6

Receive: 01 06 01 00 01 49 F6

Reinitialize(write):

Send:01 06 01 00 00 A5 48 4D

Receive: 01 06 01 00 00 A5 48 4D

12

2.3.4.2 Force

This register is used to set Force. It defines the current for the Gripper. If the current limit is exceeded,

the fingers stop and trigger an object detection.

The address is 0x0101. The description of this register is shown in Table 2.5.

Table 2.5 Force

Function

Address

Description

Write

Read

Force

0x0101

Gripper’s

closing force

20-100 (%)

Force

currently set

The force value range is 20-100, the corresponding value is 00 14–00 64(Hexadecimal).

Example:

Set 30% closing force (write):

Send: 01 06 01 01 1E 59 FE

Return: 01 06 01 01 1E 59 FE

Read the closing force currently set (read):

Send: 01 03 01 01 00 01 D4 36

Return: 01 03 02 xx xx crc1 crc2

2.3.4.3 Position

This register is used to set the reference position of gripper's fingers, then the fingers will move to

the position immediately.

The address is 0x0103. The description of this register is shown in Table 2.6.

Table 2.6 Position

Function

Address

Description

Write

Read

Position

0x0103

Reference

Position

0-1000 (‰)

Reference position

currently set

The reference position value range is 0-1000 (‰), the corresponding value is 00 00 – 03

E8(Hexadecimal).

Example:

Set 500‰position (write):

Send: 01 06 01 03 01 F4 78 21

Return: 01 06 01 03 01 F4 78 21

Read the reference position currently set(read):

Send: 01 03 01 03 00 01 75 F6

Return: 01 03 02 xx xx crc1 crc2

13

2.3.4.4 Speed

This register is used to set the Gripper closing and opening speed.

The address is 0x0102. The description of this register is shown in Table 2.7.

Table 2.7 Speed Instructions

Function

Address

Description

Write

Read

Speed

0x0104

Speed

1-100 (%)

Speed

currently set

The speed value range is 1-100 ,The corresponding value is 00 01 – 00 64(Hexadecimal).

Example:

Set 50% speed (write):

Send: 01 06 01 04 00 32 48 22

Return: 01 06 01 04 00 32 48 22

Read the current speed (read):

Send: 01 03 01 04 00 01 C4 37

Return: 01 03 02 xx xx crc1 crc2

2.3.4.5 Initialization State

This register is used to store current initialization state of gripper, you can get the initialization state

by reading this register.

The address is 0x0200. The description of this register is shown in Table 2.8.

Table 2.8 Initialization State

Function

Address

Description

Write

Read

Initialization

State

0x0200

Initialization state

of the gripper

Read Only

0:Not initialized;

1:Initialized

Example:

Read initialization state (read):

Send: 01 03 02 00 00 01 85 B2

Return: 01 03 02 00 00 B8 44

14

2.3.4.6 Gripper State

This register is used to store the Gripper state, you can get the state of gripper by reading this register.

And the address is 0x0201. The description of this register is shown in Table 2.9.

Table 2.9 Gripper State

Function

Address

Description

Write

Read

Gripper State

0x0201

the gripper state

Read

Only

0:In motion;

1:Reached position;

2:Object caught;

3:Object dropped

Example:

Read gripper state (read):

Send: 01 03 02 01 00 01 D4 72

Return: 01 03 02 00 02 39 85(02: object caught)

2.3.4.7 Current Position

This register is used to store the Actual position of the Gripper.

The address is 0x0202. The description of this register is shown in Table 2.10.

Table 2.10 Current Position

Function

Address

Description

Write

Read

Current Position

0x0202

Gripper actual position

Read Only

Current actual

position

Example:

Read actual position (read):

Send: 01 03 02 02 00 01 24 72

Return: 01 03 02 xx xx crc1 crc2

States Description

Different values indicate different states of the gripper. The descriptions of states are as

follows:

·00: Fingers are in motion .

·01: Fingers are at reference position. No object detected or object has been dropped.

·02: Fingers have stopped due to an object detection.

·03: Fingers are at reference positon due to object has been dropped after the gripper

caught object.

15

2.3.4.8 Save Parameter

This register is used to Save Parameter.

Write 1 to this register to save all parameter, If you modified the I/O or communication parameters.

The address is 0x0300. The description of this register is shown in Table 2.11.

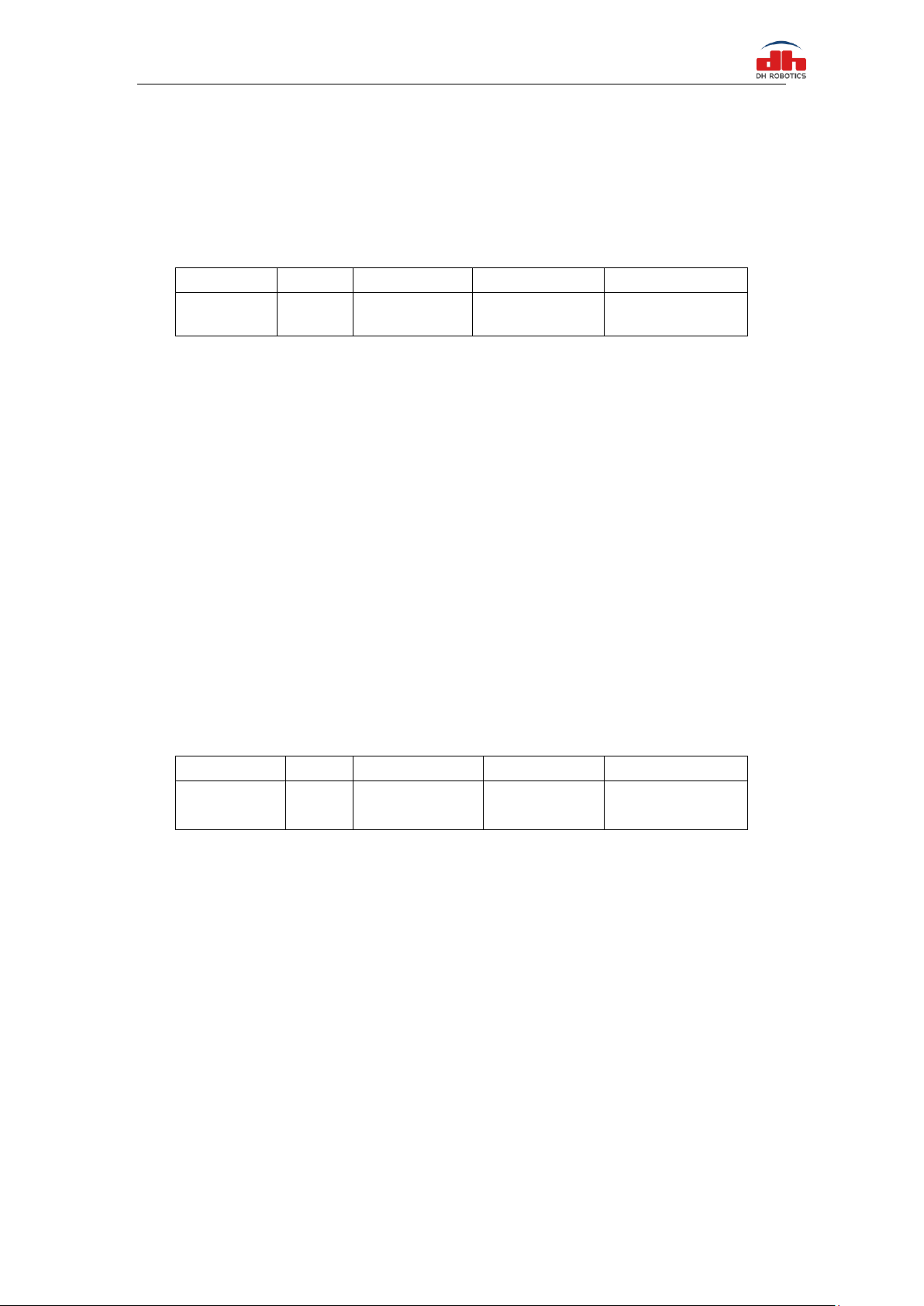

Table 2.11 Save Parameter

Function

Address

Description

Write

Read

Save

Parameter

0x0300

Save register’s

value to Flash

0:default,

1:Save all parameters

0

Example:

Save Parameter (Write):

Send: 01 06 03 00 00 01 48 4E

Return: 01 06 03 00 00 01 48 4E

2.3.4.9 Initialization Direction

This register is used to set Initialization Direction of gripper.

The address is 0x0301. The description of this register is shown in Table 2.12.

Table 2.12 Baud Rate

Function

Address

Description

Write

Read

Baud Rate

0x0301

Configure

initialization

direction

0: Open,1:Close

(default: 0)

Current setting

The value of this register is 0 by default.

If the register value is 0, when you send the initialization command, the gripper finger will open and

find the maximum position.

If the register value is 1, when you send the initialization command, the gripper finger will close

and find the minimal position.

Example:

Write 0 to initialization direction register:

Send: 01 06 03 01 00 00 D8 4E

Return: 01 06 03 01 00 00 D8 4E

NOTE

·The Saving process will take 1-2 seconds, and the gripper won’t response to other

command during this process. The gripper will response this command after saving process

finished.

16

2.3.4.10 Slave Address

This register is used to set Slave Address of gripper.

The address is 0x0302. The description of this register is shown in Table 2.13.

Table 2.13 Slave Address

Function

Address

Description

Write

Read

Slave Address

0x0302

Configure gripper

Slave Address

0-255 (default: 1)

Current setting

The value of this register is 1 by default.

Example:

Set the Slave Address to 1(write):

Send: 01 06 03 02 00 01 E9 8E

Return: 01 06 03 02 00 01 E9 8E

2.3.4.11 Baud Rate

This register is used to set Baud Rate of gripper.

The address is 0x0303. The description of this register is shown in Table 2.14.

Table 2.14 Baud Rate

Function

Address

Description

Write

Read

Baud Rate

0x0303

Configure gripper

Modbus Baud rate

0-5:115200,57600,

38400,19200,9600,

4800(default: 0)

Current setting

The value of this register is 0 by default, corresponding to a baud rate of 115200.

Example:

Set gripper baud rate to115200 (write):

Send: 01 06 03 03 00 00 79 8E

Return: 01 06 03 03 00 00 79 8E

NOTE

·Please make sure that no other networked device has the same slave address as the

gripper.

17

2.3.4.12 Stop Bits

This register is used to set Stop Bits of gripper.

The address is 0x0302. The description of this register is shown in Table 2.15.

Table 2.15 Stop bits settings

Function

Address

Description

Write

Read

Stop Bits

0x0304

Configure gripper

Modbus stop bits

0:1 stop bit

1:2 stop bits

(default: 0)

Current setting

The value of this register is 0 by default, corresponding to 1 stop bit.

Example:

Set the gripper stop bit to 1 stop bit (write):

Send: 01 06 03 04 00 00 C8 4F

Return: 01 06 03 04 00 00 C8 4F

2.3.4.13 Parity

This register is used to set Parity of gripper.

The address is 0x0305. The description of this register is shown in Table 2.16.

Table 2.16 Parity

Function

Address

Description

Write

Read

Parity

0x0305

Configure

gripper Modbus

Parity

0: None Parity

1: Odd Parity

2: Even Parity

(default : 0)

Current setting

The value of this register is 0 by default, corresponding to None Parity.

Example:

Set the gripper’s Parity to None Parity (write):

Send: 01 06 03 05 00 00 99 8F

Return: 01 06 03 05 00 00 99 8F

18

2.3.4.14 Test I/O Parameters

This register is used to test the I/O Parameters.

The address is 0x0400. The description of this register is shown in Table 2.17.

Table 2.17 I/O Control

Function

Address

Description

Write

Read

Test I/O

Parameters

0x0400

Test I/O

Parameters

1;2;3;4

Current setting

This register can be used to directly test 4 groups of I/O parameters through Modbus-RTU to ensure

that the I/Oparameters are appropriate. For example,Write 1 to this register, the gripper will execute

action with the first group of I/O parameter.

Example:

Control gripper by using first group of I/O parameter (write):

Send: 01 06 04 00 00 01 49 3A

Return: 01 06 04 00 00 01 49 3A

2.3.4.15 I/O Mode Switch

This register is used to turn I/O Control Mode ON or OFF.

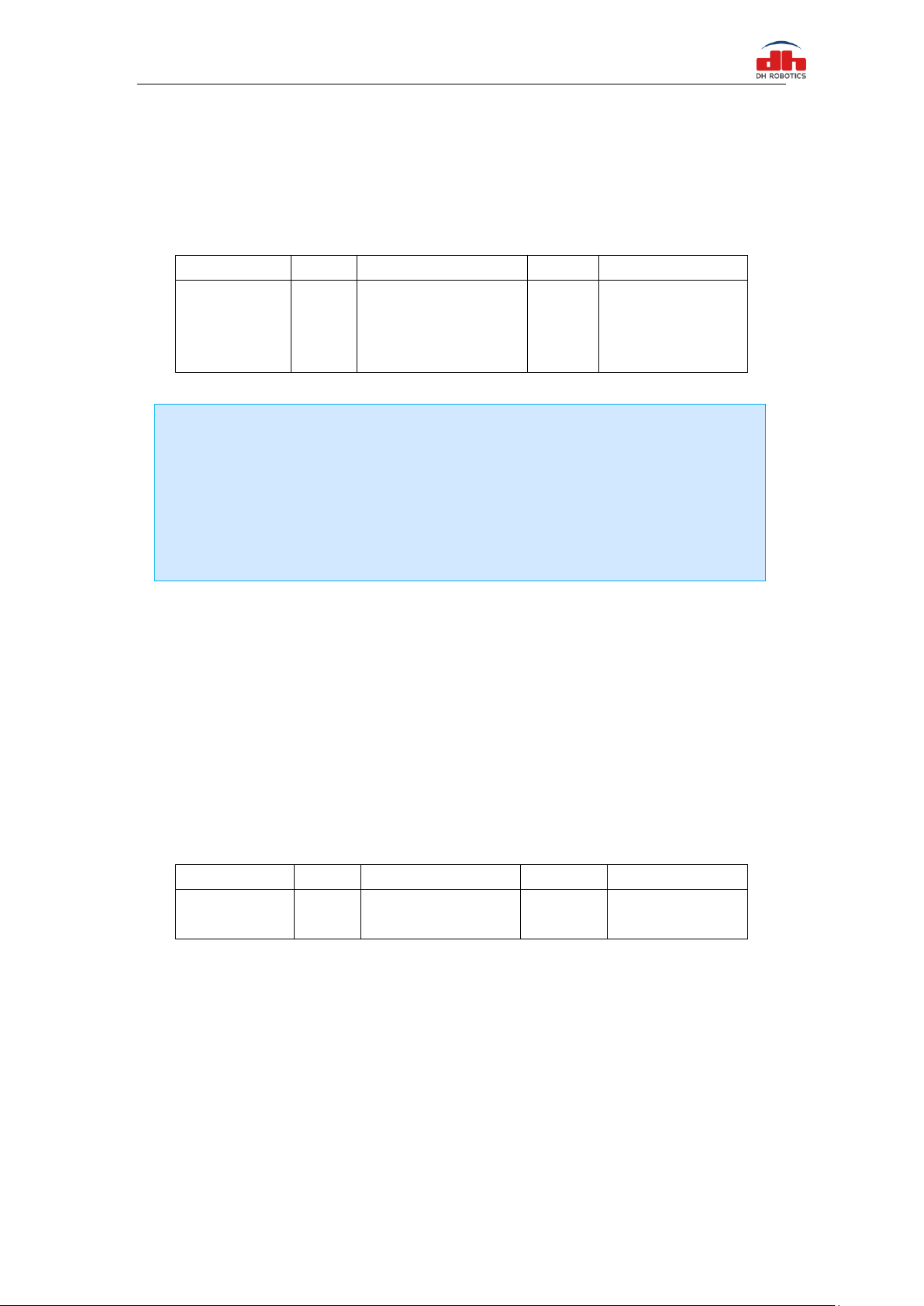

The address is 0x0402. The description of this register is shown in Table 2.18.

Table 2.18 I/O Mode Switch

Function

Address

Description

Write

Read

I/O Mode

Switch

0x0402

I/O Control

Switch

0:OFF,1:ON

Current setting

If you have written 1 to this register and have saved all parameters, the gripper will be initialized

automatically after power on.

When the I/O Control Mode is turned on, the gripper can respond to Modbus-RTU commands and

I/O, but I/O has priority.

The control method in different mode is shown in Table 2.19.

Table 2.19 Control method

Switch State

Description

Modbus-RTU

I/O

0

I/O control mode off

YES

No

1

I/O control mode on

YES

YES

Example:

Set the I/O control mode switch off (write):

Send: 01 06 04 02 00 00 29 3A

Return: 01 06 04 02 00 00 29 3A

19

2.3.4.16 I/O Parameter Configuration

Those registers are used to Set the I/O Parameters.

The address is 0x0405-0x0410. The description of this register is shown in Table 2.20.

Table 2.20 I/O Parameter Configuration

Function

High-

byte

Low

bytes

Description

Write

Read

I/O Group 1

0x04

0x05

position 1

0-1000‰

Current setting

0x06

force 1

20-100 %

0x07

speed 1

1-100 %

I/O Group 2

0x08

position 2

0-1000‰

0x09

force 2

20-100 %

0x0A

speed 2

1-100 %

I/O Group 3

0x0B

position 3

0-1000‰

0x0C

force 3

20-100 %

0x0D

speed 3

1-100 %

I/O Group 4

0x0E

position 4

0-1000‰

0x0F

force 4

20-100 %

0x10

speed 4

1-100 %

Example:

Set the first group of I/O parameter (write) :

Send: 01 06 04 05 01 2C 98 B6 (Reference position: 300‰)

Return: 01 06 04 05 01 2C 98 B6

Send: 01 06 04 06 00 1E E8 F3 (Force: 30%))

Return: 01 06 04 06 00 1E E8 F3

Send: 01 06 04 07 00 1E B9 33 (Speed: 30%)

Return: 01 06 04 07 00 1E B9 33

IO parameter address is continuous address, and four groups of IO parameters can be configured

at one time by using the function code of 0x10, as follows:

Continuous multiple address write(write)[Group 1:1000‰position;20%force;10%speed Group

2:100‰position;20%force;2%speed Group 3:0‰position;100%force;5%speed Group 4:592‰

position;100%force;10%speed]:

Send: 01 10 0405 000C 18 03e8 0014 000A 0100 0014 0002 0000 0064 0005 0250 0064

000a 9f 44

Return: 01 10 04 05 00 0C D1 3D

NOTE

·If you just need to control the gripper through Modbus RTU, you should write 0 to this

register and save all parameters to turn off the I/O control mode.

Table of contents

Other DH Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

matev

matev FPS JD-2026R operating manual

ITW Dynatec

ITW Dynatec DYNAMINI 4-HOSE Technical documentation

Festo

Festo MPS 200 operating instructions

weha

weha Transport rack for kitchen tops quick start guide

Voltaire

Voltaire 15W/F Installation, operation and maintenance manual

SAF-HOLLAND

SAF-HOLLAND Holland DB-040DQ1 owner's manual