DHV RISING STEM User manual

Installation, Operation and Maintenance Manual

Rising Stem Ball Valve

Document #: DHV-IOM-RSBV-19

Published: October 2019

Revision: 0

Page 1 of 28

INSTALLATION, OPERATION

AND MAINTENANCE

MANUAL

RISING STEM

BALL VALVE

Installation, Operation and Maintenance Manual

Rising Stem Ball Valve

Document #: DHV-IOM-RSBV-19

Published: October 2019

Revision: 0

Page 2 of 28

TABLE OF CONTENTS

TYPICAL CONFIGURATION ..................................................................................................................3

FOREWORD.........................................................................................................................................6

1. ENDUSER INSTRUCTION .................................................................................................................6

2. VALVE TRANSPORTATION AND STORAGE .......................................................................................7

2.1 TRANSPORTATION.........................................................................................................................7

2.2 STORAGE .......................................................................................................................................7

3. VALVE INSTALLATION ...................................................................................................................... 8

3.1 INSPECTION BEFORE INSTALLATION .............................................................................................8

3.2 INSTALLATION ...............................................................................................................................9

4. VALVE OPERATION ........................................................................................................................14

5. VALVE MAINTENANCE ..................................................................................................................18

6. DETAILED DISASSEMBLY AND ASSEMBLY......................................................................................22

6.1 VALVE DISASSEMBLY ...................................................................................................................22

6.2 VALVE ASSEMBLY ........................................................................................................................22

7. TROUBLESHOOTING......................................................................................................................25

8. WARRANTY AND SERVICE.............................................................................................................26

8.1 VALVE WARRANTY PERIOD .........................................................................................................26

8.2 SERVICE.......................................................................................................................................26

APPENDIX I –INSTALLATION REQUIREMENTS..................................................................................27

Installation, Operation and Maintenance Manual

Rising Stem Ball Valve

Document #: DHV-IOM-RSBV-19

Published: October 2019

Revision: 0

Page 3 of 28

TYPICAL CONFIGURATION

VALVE DETAILS –RISING STEM BALL VALVE –SOFT SEAT

Installation, Operation and Maintenance Manual

Rising Stem Ball Valve

Document #: DHV-IOM-RSBV-19

Published: October 2019

Revision: 0

Page 4 of 28

VALVE DETAILS –RISING STEM BALL VALVE –METAL SEAT

Installation, Operation and Maintenance Manual

Rising Stem Ball Valve

Document #: DHV-IOM-RSBV-19

Published: October 2019

Revision: 0

Page 5 of 28

VALVE DETAILS –RISING STEM BALL VALVE –METAL SEAT –PISTON ACTUATOR

Installation, Operation and Maintenance Manual

Rising Stem Ball Valve

Document #: DHV-IOM-RSBV-19

Published: October 2019

Revision: 0

Page 6 of 28

FOREWORD

Personal safety and Long Term Ownership of your DHV Rising Stem Ball Valve is the most important

matter in reviewing our Installation, Operation & Maintenance Manual. This manual will provide all

the necessary safety guidelines for our valve including information for the valve transportation,

storage, installation, operation and maintenance. Please read carefully before installing or servicing

the valve.

DHV provides general guidelines in this manual, and cannot provide specific data and warnings for all

possible applications. The purchaser/end user must therefore assume responsibility for proper valve

selection, sizing, installation, operation, and maintenance of DHV valve products. The purchaser/end

user should read and understand this document and any instructions provided with the product, and

conduct training with its employees and contractors to ensure they are aware of the proper and safe

use of DHV valve products in connection with the specific application.

1. ENDUSER INSTRUCTION

Personnel safety is always the most important factor in the transportation, storage, installation,

operation and maintenance of any valve. DHV valves are designed to meet the customer’s order

requirements and specifications. DHV disclaims all responsibility for problems that may be caused by

applications other than the specified use. Valve service pressure/temperature information is detailed

on the valve name plate. When selecting a valve, always consider the application, service and

temperature for the intended service. Select the applicable valve material for anti-corrosion and anti-

abrasive service. For safety of personnel and plant/environment: Prior to conducting any service to

the valve, ensure the valve is not under pressure, properly vented, and drained before servicing. For

all electric, hydraulic or pneumatic actuated valves, all power connections to the valve/actuator must

be turned off before performing any maintenance and service. When performing any operation,

maintenance or service, personal protective equipment should be used, such as protective clothing,

oxygen masks, safety glasses, work gloves, etc. DHV will not be responsible for any loss or expense

resulting from the failure of equipment, damage to any property, or death or injury to any person

resulting in whole or in part from repairs or modification performed by other than authorized DHV

personnel. Such unauthorized repairs shall also serve to terminate any contractual or other warranty,

if any, on the equipment and may result in equipment no longer meeting applicable requirements.

Installation, Operation and Maintenance Manual

Rising Stem Ball Valve

Document #: DHV-IOM-RSBV-19

Published: October 2019

Revision: 0

Page 7 of 28

2. VALVE TRANSPORTATION AND STORAGE

2.1 TRANSPORTATION

1. Valves should remain in the closed position during shipping and handling. Each valve should be

securely packaged either on a pallet or in a crate to avoid any damage during shipping.

2. Use the proper hoisting equipment to transport the valve, especially during lifting or lowering the

valve. Special attention to personnel safety and the care of the valve should be made when

transporting the valve. Avoid impacting or striking the valve during transportation. Lay the valve on a

clean flat surface; make sure to avoid laying the valve on the flange face. Ensure there is adequate

clearance around the valve for proper operation and maintenance.

3. During transportation, ensure the valve paint, name plate and flange sealing surfaces are fully

protected. Do not drag the valve on the floor, nor put the valve flange sealing face on the floor.

4. For those valves not required to be immediately installed, do not open the end flange protective

covers. Ensure the valves are stored in a safe clean environment and are protected from rain and dust.

2.2 STORAGE

1. Valves should be stored in the closed position. Valve ports and flange serration surfaces should be kept

sealed with protective flange covers.

2. Valves should be stored in a dust free, low humidity and well ventilated room, not in direct contact to

the floor. If possible, the valves shall be kept in the original packing box. If valves have to be stored

outdoors, keep the valve in the original crate or shipping container. Ensure the valve packaging is stored

on raised blocking to avoid moisture damage. Protective covering should be used for protection against

dust and rain.

3. Valves should never be stacked on top of each other, to avoid any valve distortion which may affect

valve performance and cause personnel injury.

4. Valves that have been stored for an extended period of time should be cleaned and inspected prior to

installation. Inspect the sealing surface to ensure it is clean and free of any debris or damage.

5. Do not expose the valve to any corrosive environment as this may cause damage to the valve

components.

Installation, Operation and Maintenance Manual

Rising Stem Ball Valve

Document #: DHV-IOM-RSBV-19

Published: October 2019

Revision: 0

Page 8 of 28

3. VALVE INSTALLATION

Review all documentation to fully understand the valve and related information that will provide safe

installation and a long service life for your valve.

Valve information can be found on the valve body, and the name plate. Fig 1 is a typical nameplate.

Reference the information on our nameplate for ordering replacement parts, or when making inquiries

about your valve’s operation or maintenance needs.

Valve ends should have a protective cover to protect the valve port from any foreign particles and dust

which will damage the ball and seat sealing surfaces.

Figure 1 Typical Valve Nameplate Information

3.1 INSPECTION BEFORE INSTALLATION

3.1.1 Before installation, check the valve nameplate and valve body information to ensure the valve is

suitable for the intended service.

3.1.2 Before installation, remove the flange cover and the protective film on the flange sealing face, inspect

the ports and the flange sealing surface, remove any dirt with a clean soft cloth, use an anti-corrosive

cleaning liquid to clean if necessary, and never use any other chemical products.

3.1.3 Inspect the flange gasket (including ring gasket) sealing surface and ensure it is in acceptable

condition for installation.

3.1.4 After cleaning the valve and before installation, open and close the valve one time. Ensure the valve

cycles smoothly. If abnormal operation is experienced, stop the operation and inspect the valve internals

for any obstructions that may be preventing normal operation.

3.1.5 After successfully cycling and assuring the proper operation of the valve, return the valve to the open

position and ensure the valve sealing surfaces are protected until installation is complete.

SIZE BODY

CLASS STEM

FIG NO. BALL

S/N NO. SEAT

DATE

API 607 NACE MR0175/ISO15156

750 psi at -50 ℉705 psi at 400 ℉

RISING STEM BALL VALVE

ASME B16.34

DHV INDUSTRIES,INC

10(DN250)

300(PN50)

BD30XF52

WCC

A182 F51

A182 F51

A182 F51+R-PTFE

LOW EMISSION

Installation, Operation and Maintenance Manual

Rising Stem Ball Valve

Document #: DHV-IOM-RSBV-19

Published: October 2019

Revision: 0

Page 9 of 28

3.2 INSTALLATION

Position the valve into the pipe or the flange connection; ensure that any stresses caused by improper pipe

alignment are relieved. Valves are not intended to be a means of aligning improperly fitted pipe.

3.2.1 MANUAL VALVES

Install the valve using qualified piping standards and practices. Valves marked with flow direction

must be installed in line with the piping flow.

The recommended orientation for rising stem ball valves is upright with the valve in a horizontal

line. The valve may be installed in other orientations; however, any deviation from recommended

horizontal position may compromise proper valve operation and void the warranty.

3.2.2 ACTUATED VALVES

All DHV pneumatic actuated valves are equipped with

lifting lugs on the valve, use these lifting lugs to lift the

valve to avoid any damage to the valve or injury to the

operator. Never use the lifting lugs on the actuator to lift

the entire valve assembly.

During installation, follow the valve body flow arrow

direction, connecting the valve upstream side to the

pipeline high pressure side.

Correct valve installation is very important, if valve is

installed backwards, the valve parts may not be able to

hold the pressure as original designed. If possible, install

the actuated valve vertically.

If actuated valve is installed in other than vertical

position, according to the arrangement of the

valve/actuator, additional support for the actuator may

be required.

Installation, Operation and Maintenance Manual

Rising Stem Ball Valve

Document #: DHV-IOM-RSBV-19

Published: October 2019

Revision: 0

Page 10 of 28

Once the pneumatic actuator position limiting screw has been set,

the end user can not adjust the screw by themselves, otherwise

equipment damage, personnel safety or financial loss may occur,

end user shall take full responsibility.

After valve and actuator have been

installed on the pipe line, connecting

the power and pressure source to the

actuator.

WARNING: Pneumatic actuator air/gas pressure shall be adjusted

to the value listed on the name plate; otherwise this may damage

the actuator.

Cycle the valve to full close and full open

position to verify the valve operation is

normal. Check the valve position

indicator has indicated correct valve

position, check the valve control system

is correctly installed and calibrated.

Installation, Operation and Maintenance Manual

Rising Stem Ball Valve

Document #: DHV-IOM-RSBV-19

Published: October 2019

Revision: 0

Page 11 of 28

FLANGE ENDS:

Select the proper gasket (including ring gasket) to install, line up the bolt holes between the valve flange

and pipeline flange, then install the bolts and nuts and tighten to the accepted piping and bolting

standards. The bolt threads should be lubricated first for ease of bolting.

Use an appropriate sized torque wrench when tightening the bolt/nut, to avoid flange deformation.

Please follow Fig 2 and Table 1 for bolting sequence and bolting torque. If the bolting quantity is

different from the chart shown, please follow the same principle to get a new sequence to follow.

For large diameter valves, the valve must be properly and safely supported during installation. After

installation is completed, valve supports should be moved to the bottom of the valve flanges.

After valve installation is complete, recheck and tighten the bolts including the gland bolts as necessary

to the values provided in Table 1 & Figure 2.

It is recommended that the tightness of the joint bolt tension and gland bolts be inspected at least

yearly. Refer to Table 1 & Figure 2.

DURING INSTALLATION, IF VALVE IS NOT IN LINE WITH THE PIPELINE, FLANGE FACES ARE NOT

PARALLEL TO EACH OTHER, OR BOLTING TORQUEIS NOT UNIFORM, VALVE LEAKAGE MAY BE

EXPERIENCED.

Installation, Operation and Maintenance Manual

Rising Stem Ball Valve

Document #: DHV-IOM-RSBV-19

Published: October 2019

Revision: 0

Page 12 of 28

Table 1 Bolting Tightening Torque Chart

Stud Size

(Inch)

Measurement: Newton-meters N·m Tolerance: +/- 10%

(Conversion: 1 ft⋅lb= 1.36 N·m 1 N·m = .74 ft⋅lb)

B7M/L7M

B7/L7

B8 (I)/

B8M(I)

B8M (II)

B8 (II)

B8MLCuN

B16

5/16-18UNC

21

27

8

25

26

9

28

3/8-16UNC

36

47

13

43

45

16

48

1/2-13UNC

85

111

32

101

107

37

112

9/16-12UNC

121

158

45

144

152

53

160

5/8-11UNC

165

217

62

197

208

72

218

3/4-10UNC

289

378

108

344

362

126

380

7/8-9UNC

459

601

171

459

-

200

605

1-8UNC

683

894

255

683

-

298

901

1-1/8-8UN

992

1298

370

811

-

433

1308

1-1/4-8UN

1381

1807

515

1130

-

602

1820

1-3/8-8UN

1860

2435

693

1167

-

812

2452

1-1/2-8UN

2438

3192

909

1530

-

1064

3214

1-5/8-8UN

3126

4092

1165

-

-

1364

4120

1-3/4-8UN

3931

5146

1465

-

-

1715

5182

1-7/8-8UN

4863

6367

1813

-

-

2122

6411

2-8UN

5933

7767

2211

-

-

2589

7820

2-1/4-8UN

8519

11152

3175

-

-

3717

11229

2-1/2-8UN

11764

15400

4385

-

-

5133

15507

2-3/4-8UN

15742

18747

5867

-

-

6869

18747

3-8UN

20528

24447

7651

-

-

8958

24447

Installation, Operation and Maintenance Manual

Rising Stem Ball Valve

Document #: DHV-IOM-RSBV-19

Published: October 2019

Revision: 0

Page 13 of 28

Table 1 Bolting Tightening Torque Chart (cont.)

Stud Size

(Metric)

Measurement: Newton-meters N·m Tolerance: +/- 10%

(Conversion: 1 ft⋅lb= 1.36 N·m 1 N·m = .74 ft⋅lb)

B7M/L7M

B7/L7

B8 (I)/

B8M(I)

B8M (II)

B8 (II)

B8MLCuN

B16

M10

43

56

16

51

54

19

56

M12

73

96

27

87

92

32

96

M16

175

230

66

209

221

77

232

M20

338

443

126

338

424

148

446

M24

578

757

215

578

-

252

762

M30

1134

1484

422

928

-

495

1495

M36

1964

2572

732

1232

-

857

2589

M42

3125

4091

1165

1960

-

1364

4119

Figure 2 Bolt Tightening Sequence

Installation, Operation and Maintenance Manual

Rising Stem Ball Valve

Document #: DHV-IOM-RSBV-19

Published: October 2019

Revision: 0

Page 14 of 28

WELD ENDS:

Weld ends must be kept clean with no burrs, oil, dirt or foreign objects.

The valve end and pipe end must be in proper alignment for effective welding.

Follow the approved WPS to perform the welding. Ensure that the temperature of the body/seats area

does not exceed 200°F, verify this temperature with a Tempil stick; welding too close to the

seat/sealing area will cause area distortion. Protect the valve port area to prevent welding slag and

foreign matter from entering the valve.

After welding, use approved and proper Non-Destructive Testing (NDT) method to check the welds;

clean the welds thoroughly, and then perform local heat treatment if required.

When installation is complete, prior to system testing and start-up, clean the valve by flushing the line

of debris and other materials that may have accumulated inside the valve and in the valve seating area

and surfaces during construction. When flushing the valve, open the valve fully, flush for a determined

time based on line size. Close the valve to allow the fluid to fill the line; operate the valve to the half

open and half closed position repeatedly, this action allows the fluid to build up within the valve

assisting in flushing heavier debris from the valve. Fully close the valve, if seat leakage is noted after

flushing, repeat flushing procedure. If leakage from the seat is still evident, the seating surface maybe

damaged and need repair. If the valve is equipped with seat injection, the seats should be charged with

a valve lubricant to displace any residual fluids or moisture in the seal areas of the valve.

DURING WELDING, THE TEMPERATURE NEAR THE VALVE SEAT INSERT AND ANY O-RING AREAS

SHOULD NEVER EXCEED 94°C/200°F. A TEMPERATURE INDICATING DEVICE SHOULD BE USED TO

MONITOR THE TEMPERATURE DURING THE WELDING. THIS ALSO APPLIES TO POST WELD HEAT

TREATMENT.

4. VALVE OPERATION

To assure maximum valve performance, only use a valve that is suitable for the rated

pressure/temperature and corrosive environment.

For your safety and normal operation, please read the following valve operation procedures:

4.1 The valve must be kept either in the fully open or fully closed position. Never throttle or leave the

valve at the half-open position as erosion of the ball and seating surface may occur and damage will

result.

4.2 Valve open and closed positions are indicated on the valve stem travel indicator. Rotating the valve

hand wheel clockwise will close the valve; counter-clockwise operation will open the valve, this is also

applicable to gear or motor actuated operation.

4.3 Install the pneumatic actuated valve, according to the instrument air/gas pressure rating listed on

Installation, Operation and Maintenance Manual

Rising Stem Ball Valve

Document #: DHV-IOM-RSBV-19

Published: October 2019

Revision: 0

Page 15 of 28

the name plate, regulate the instrument pneumatic line to move the valve stem, watch the travel

indicator on the actuator, when pointer to CLOSE position and cannot move further, this indicates valve is

at closed position, when pointer to OPEN position and cannot move further, this is at full open position.

4.4 Don’t use oversized torque to operate the valve when valve is jammed, because this may damage

the actuator parts to make the valve not operable. Handwheel operated valves are in the open position

when the stem travel indicator reads open. Conversely when the valve stem travel indicator reads closed

the valve is fully closed. Gear operated valves will have a position indicator on the gear.

4.5 Never operate the valve without authorization and a full understanding of the safe operation

procedures, inspections and proper handling instructions.

4.6 Before operating the valve in the piping system, ensure you have the related operation instructions,

never operate the valve without authorization.

4.7 Do not remove the valve stem guiding pins on the yoke when valve is under pressure.

4.8 Do not open the drain valve at the bottom of the valve body unless it is to check the seat leakage,

when the valve drain is open, make sure the valve body is not under any pressure.

4.9 Rising stem ball valve operation are as follows:

4.10 Opening process:

1. At close position, valve core is tightly pressed against the valve seat through stem mechanical

force.

2. When the stem is turned counter-clockwise through either the hand wheel or actuator, the stem

will move upward, this will cause the valve core to move away from the valve seat.

3. Valve stem continues to rise, due to the curved shape at end of the stem, this will make the valve

core rotate without any friction.

4. At full open position, valve stem has reached its highest location; valve core is at full open

position.

4.11 Closing process:

1. When closing, turn the hand wheel or the pneumatic actuator clockwise to make the stem move

downward.

2. Through the curved slot in the side of the stem, the guiding pins will force the stem downward

and rotating at the same time, valve core is also rotating with the stem rotation.

3. When near the closing position, the core/stem has rotated 90 degrees.

4. Stem continues to go downward, through the stem end curved shape, this will force the valve

core to mechanically press against the valve seat.

4.12 Pneumatic actuator operation is as follows:

4.13 Equipped with hydraulic damping oil tank, hand wheel plus hand pump to re-position the

pneumatic actuator operation, see following steps and figures:

Installation, Operation and Maintenance Manual

Rising Stem Ball Valve

Document #: DHV-IOM-RSBV-19

Published: October 2019

Revision: 0

Page 16 of 28

4.14 During normal pneumatic operation, counter-clockwise (according to open mark on the hand wheel)

rotate the hand wheel to full open position (until the hand wheel is not able to turn), close the air/gas tank

globe valve, then lock the hand wheel.

4.15 Need to close the valve if there is a loss of the instrument air/gas, first open the tank globe valve,

then unlock the hand wheel, clockwise (follow arrow close mark on the hand wheel) to close the valve

(until the hand wheel is not able to turn) to full close position. When instrument air pressure back to normal.

Follow the above step 1 to normal automatic operation mode and close the air/gas tank globe valve.

4.16 Need to open the valve if there is a loss of the instrument air/gas, first open the air/gas tank globe

valve, and then close the ball valve A underneath the tank, open ball valve B and ball valve C, then operate

the hand pump to pressurize the air tank (inlet pressure at the bottom of the tank, the maximum hydraulic

pressure is 1 MPa (145 psi), until valve is fully open. When the instrument air/gas is back to normal, then

close the globe valve, also close ball valves B and C, but open ball valve A.

4.17 Equipped with hand wheel re-positioned pneumatic actuator operation:

4.18 Change to manual operation when loss of instrument air pressure: During normal pneumatic

actuation process, the valve position will remain at the last position between the full close and full open

when the valve control lost either the instrument air or electric power, in order to manually operate the

valve to the process required position, this hand wheel can operate the valve to either open or close

position, follow the marking on the hand wheel, clockwise rotation to close the valve, and counter-

Installation, Operation and Maintenance Manual

Rising Stem Ball Valve

Document #: DHV-IOM-RSBV-19

Published: October 2019

Revision: 0

Page 17 of 28

clockwise to open the valve. At beginning of the hand wheel operation, there is a short rotation without

any engagement (stem is not moving, stem nut is turning and going upward or downward), until the stem

nut is touching the upper shaft step or lower thrust bearing, the stem nut can only rotate and no vertical

movement, this will drive the stem going either upward or downward to the desired position.

4.19 After the instrument air pressure gauge is back to normal, change back to automatic operation status:

4.20 Manual operation (rotate the hand wheel clockwise) to move the valve to the closed position, stem

is touching the upper shaft step, then counter-clockwise rotate the hand wheel, the stem nut will turn until

it contacts the lower thrust bearing surface (resistance force will increase rapidly), then turn the hand

wheel clockwise 4 turns or gear box hand wheel (4 x gear box ratio) turns to form the stem coasting amount

during automatic operation. The hand wheel locking hole should be in line with the locking hole on the

bracket, put the lock through the hand wheel, the valve is back to automatic control operation.

4.21 Manually operate (turn the wheel counter-clockwise) the valve will rotate to the open position, the

stem nut is touch the lower thrust bearing surface, then turn the hand wheel clockwise until the stem nut

contacts the upper shaft step (resistance force will increase immediately), at this time, turn the hand wheel

counter-clockwise 2 turns or gear box hand wheel (2 x gear ratio) turns to form the stem coasting amount

during automatic operation. The hand wheel locking hole should in line the locking hole on the bracket,

put the lock through the hand wheel, the valve is back to automatic control operation.

Installation, Operation and Maintenance Manual

Rising Stem Ball Valve

Document #: DHV-IOM-RSBV-19

Published: October 2019

Revision: 0

Page 18 of 28

5. VALVE MAINTENANCE

Valves should be inspected regularly during operation and any findings should receive immediate attention

in order to avoid any further damage to the valve or the system. Regular inspection and maintenance

should be scheduled at a minimum of twice per year, or more often if required.

5.1 In less corrosive environments, it is suggested to check the valve body thickness every six months. In

more corrosive environments, it should be checked every three months. If the measured wall thickness is

less than specified in ASME B16.34, the valve should be replaced immediately.

5.2 Lubrication

5.2.1 Rising stem ball valve lubrication is not for valve sealing purposes, it is to reduce the friction

and wear between the moving parts.

5.2.2 Lubrication schedule and selection

Valve lubrication shall be based on end user’s experience; the following are the minimum lubrication

requirements which are not included in normal operation experience and other applicable

standards.

a) Minimum once a year.

b) Lubrication when stem shows leakage.

c) If valve is operated more than once a day, suggest to lubricate once every 3 months.

d) If valve is operated more than 10 times a day, suggest lubricating every 1000 cycles.

e) If valve is under corrosive or other special occasion also operated more than 10 times a day,

suggest lubrication every 500 cycles.

5.2.3 For Rising stem ball valve, we recommend to use a high quality lithium based lubricant, for

service temperature lower than -20℉(-29℃), we recommend to use low temperature lubricant,

For automatic valves with a gas-liquid linkage system, we recommend the use of Mobil ATF220

Installation, Operation and Maintenance Manual

Rising Stem Ball Valve

Document #: DHV-IOM-RSBV-19

Published: October 2019

Revision: 0

Page 19 of 28

hydraulic transmission fluid or equivalent.

5.2.4 Lubrication points are showing on the following pictures:

5.2.5 All DHV Rising stem ball valve lubrication joints are

equipped with a zerk fitting, this fitting is at top of the stem

and bearing, do not remove under pressure. Pump the

grease gun 2 to 10 times to provide sufficient lubrication.

WARNING: do not remove the injection fitting from

the valve, otherwise it may cause an accident or personnel

injury.

5.2.6 When inspecting the oil level of the pneumatic

actuator tank, ensure the valve is closed so that the oil is

returned from the actuator to the tank, and the screw plug

at the oil level sight is unscrewed. When the valve is closed,

the tank is closed. The oil level should be at the oil level

sight.

WARNING: If the valve is in the open position and the

valve is under pressure, removal of the screw plug at the oil

level sight port may cause an accident or personal injury.

Installation, Operation and Maintenance Manual

Rising Stem Ball Valve

Document #: DHV-IOM-RSBV-19

Published: October 2019

Revision: 0

Page 20 of 28

5.3 Valve stem packing adjustment

5.3.1 All Rising stem ball valve soft seat (not including metal

seat design), has the injectable type of packing design, this

can effectively stop the stem packing leakage.

5.3.2 After injecting the packing material to the packing

box compartment, this will increase the pressure inside the

packing box, to spread the V-ring lips to seal the leakage,

generally turn the packing screw 5-10 turns to stop the

stem leakage.

5.3.3 If injected packing is empty, the packing screw can

be removed to add new injectable packing. (be careful,

make sure the ball check valve underneath has no

leakage)

5.3.4 DHV high temperature Rising stem ball valve design

is using an adjustable gland packing type design, it

consists of the packing ring, packing gland, packing flange

and eyebolt/nuts.

Table of contents

Popular Control Unit manuals by other brands

Harvia

Harvia XENIO CX45J Instructions for installation and use

HighLine

HighLine CCU2 Installation & user manual

Generac Power Systems

Generac Power Systems SMM Owners & installation manual

Cisco

Cisco LightStream 1010 Configuration note

GUNPOWER

GUNPOWER GPR-WIFI-001 manual

Wirepath

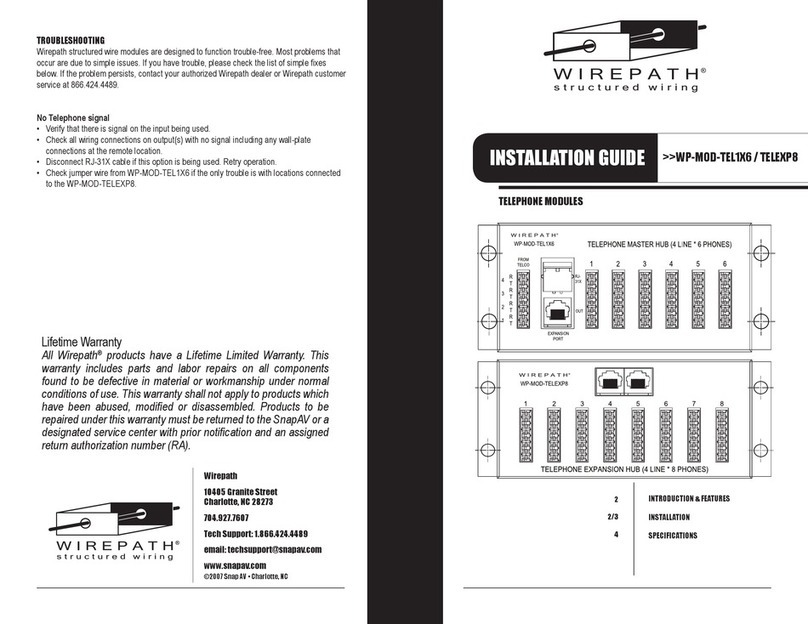

Wirepath WP-MOD-TEL1x6 installation guide