Di-soric VS-05 User manual

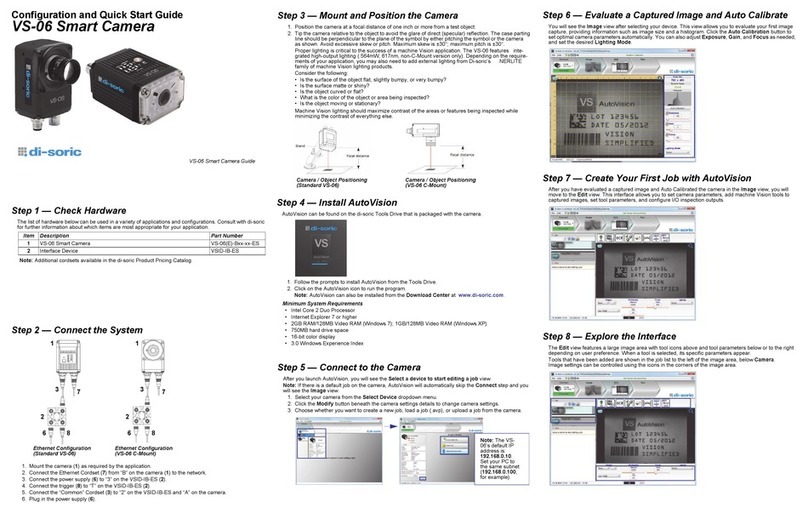

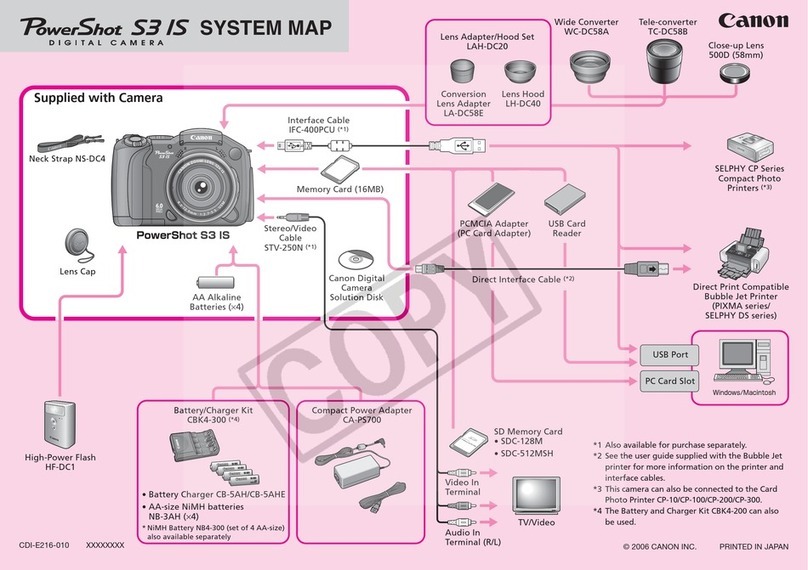

Step 2 — Connect the System

1. Mount the camera (1) as required by the application.

2. Connect the USB side of the camera cable to the USB host cable (4).

3. Connect the VSID-A-24/5V-S (2) to the VSID-IB-S (3).

4. Connect the D-sub side of the camera cable to the VSID-A-24/5V-S (2).

5. Connect the trigger (6, 7, or 8) to the VSID-IB-S (3).

6. Connect the power supply (9 or 10) to the VSID-IB-S (3).

7. Plug in the power supply (9or 10).

Hardware Configuration

14

2

3

6,7,or 8

9 or 10

Step 3 — Mount and Position the Camera

1. Place the camera and object in a location with as little ambient light as possible.

2. Position the camera at a focal distance between 2” and 6” from the object.

3. Tip the camera relative to the object to avoid glare from specular reflection. Avoid excessive skew

or pitch. Maximum skew is ±30°; maximum pitch is ±30°.

Proper lighting is critical to the success of a machine vision application. The VS-05 features inte-

grated lighting (SXGA: built-in red LEDs @ 617nm; QXGA: built-in white LEDs). Depending on the

requirements of your application, you may also need to add external lighting from di-soric’s NERLITE

family of machine vision lighting products.

Consider the following:

• Is the surface of the object flat, slightly bumpy, or very bumpy?

• Is the surface matte or shiny?

• Is the object curved or flat?

• What is the color of the object or area being inspected?

• Is the object moving or stationary?

Machine vision lighting should maximize contrast of the areas or features being inspected while

minimizing the contrast of everything else.

Camera / Object Positioning

Step 5 — Connect to the Camera

After you launch VS AutoVision, you will see the Select a device to start editing a job view.

Note: If there is a default job on the camera, VS AutoVision will automatically skip the Connect step and

you will see the Image view.

1. Select your camera from the Select Device dropdown menu.

2. Click the Modify button beneath the camera settings details to change camera settings.

3. Choose whether you want to create a new job, load a job (.avp) from your PC, or upload a job from

the camera.

Configuration and Quick Start Guide

VS-05 Smart Camera

Step 1 — Check Hardware

The list of hardware below can be used in a variety of applications and configurations. Consult with di-soric

for further information about which items are most appropriate for your application.

Item Description Part Number

1VS-05 Smart Camera VS-05-BM3-X-US

2Voltage Converter (to 10-28V) VSID-A-24/5V-S

3VSID-IB-S Interface Box VSID-IB-S

5Communication Cable (VSID-IB-S to Host, 6’) VSID-K-25S/9K-2

9Power Supply (90-264 VAC, 24VDC, USA/Euro plug) VSID-PS-IB

Step 6 — Evaluate a Captured Image and Auto Calibrate

You will see the Image view after selecting your device. This view allows you to evaluate your first image

capture, providing information such as image size and a histogram. Click the Auto Calibration button to

set optimal camera parameters automatically. You can also adjust Exposure, Gain, and Focus as needed,

and set the desired Lighting Mode.

Step 7 — Create Your First Job with VS AutoVision

After you have evaluated a captured image and Auto Calibrated the camera in the Image view, you will

move to the Create view. This interface allows you to set camera parameters, add machine vision tools to

captured images, set tool parameters, and configure I/O inspection outputs.

Step 8 — Explore the Interface

The Create view features a large image area with tool icons above and tool parameters below. When a tool

is selected, its parameters appear below the image area.

Tools that have been added are shown in the job list to the left of the image area, below the Camera box.

Image settings can be controlled using the icons in the corners of the image area.

Step 4 — Install di-soric AutoVision

AutoVision can be found on the di-soric Tools Drive that is packaged with the camera.

1. Follow the prompts to install VS AutoVision from the Tools Drive.

2. Click on the VS AutoVision icon to run the program.

Note: VS AutoVision can also be installed from the Download Center at www.di-soric.com.

Minimum System Requirements

• Core2Duo processor

• Windows 7 32-bit or XP operating system

• Internet Explorer 7 or higher

• 2GB RAM/128MB Video RAM (Windows 7); 1GB/128MB Video RAM (XP)

• 750MB to 1GB hard drive space

• 16-bit color display

• 3.0 Windows Experience Index (4.0 preferred)

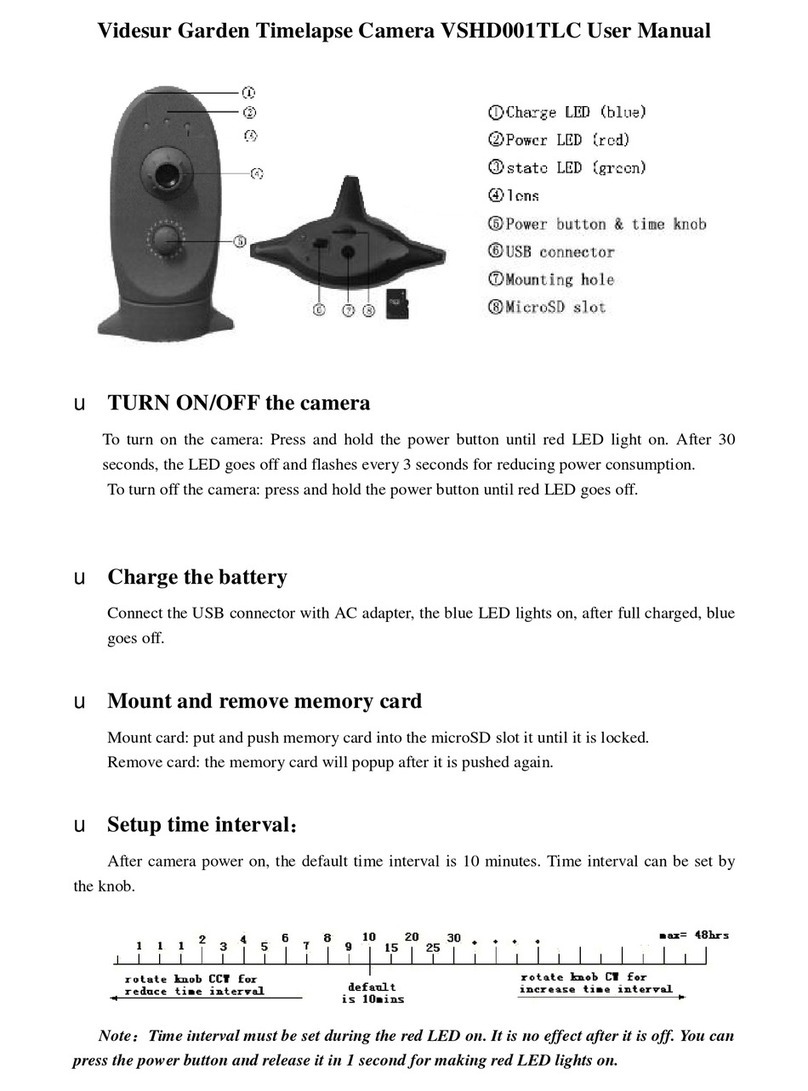

Power Requirements and Pin Assignments

SXGA Power Requirements: 5VDC +/– 5%, 200 mV p-p max. ripple, 465 mA @ 5VDC (typ.), 4.5 watts (max.)

VS-05 USB and I/O connectors

USB Type B

Connector

D-sub I/O

Connector

D-sub I/O Connector

Pin Host RS-232 In/Out

1 Power +5VDC In

2 TxD Out

3 RxD In

4 Power/Signal Ground

5NC

6 NC Out

7 Output 1 TTL (Can sink 10mA and souce 10mA) Out

8 Default configuration (activated by connecting pin 8

to ground pin 4)

In

9 Trigger In

10 NC In

11 Output 3 TTL (Can sink 10mA and souce 10mA) Out

12 Input 1 (NPN) In

13 Chassis ground (Connects chassis body to earth ground

only. Do not use as power or signal return.)

14 Output 2 TTL (Can sink 10mA and souce 10mA) Out

15 NC

USB Type B Connector

Pin Function

1 Vbus (5V)

2D–

3D+

4 Ground

VS-05 Smart Camera Accessories

Communication and I/O Devices and Cables

VSID-A-24/5V-S Adapter VSID-A-24/5V-S Connects the camera to an VSID-IB-S interface device.

Provides 5VDC power and optoisolation for the camera.

Interface VSID-IB-S Allows cameras to be connected easily to power, trigger,

and standard serial connections.

Communication Cable VSID-K-25S/9K-2 DB25 Plug to DB9 Socket, 6’ (1829 mm)

Power Supply

Power Supply VSID-PS-IB 90-264 VAC, 24VDC, USA/Euro plug

Mounting Options

Side Mount Bracket VSID-BW-001 Allows the camera to be mounted at a 90° angle.

Right-Angle Mirror Kit VSID-R90-001 Changes field of view direction by 90°.

Note: Additional accessories are available in the di-soric Product Pricing Catalog.

Step 12 — Run the Job

When all job parameters are set, click on the Run step at the top of the interface. The software will download the

vision job just created to the camera and will begin the inspection

. Inspection results and the list of active tools

are shown at the right of the image view. That information can also be moved below the image area by

clicking the orientation buttons above the inspection results area.

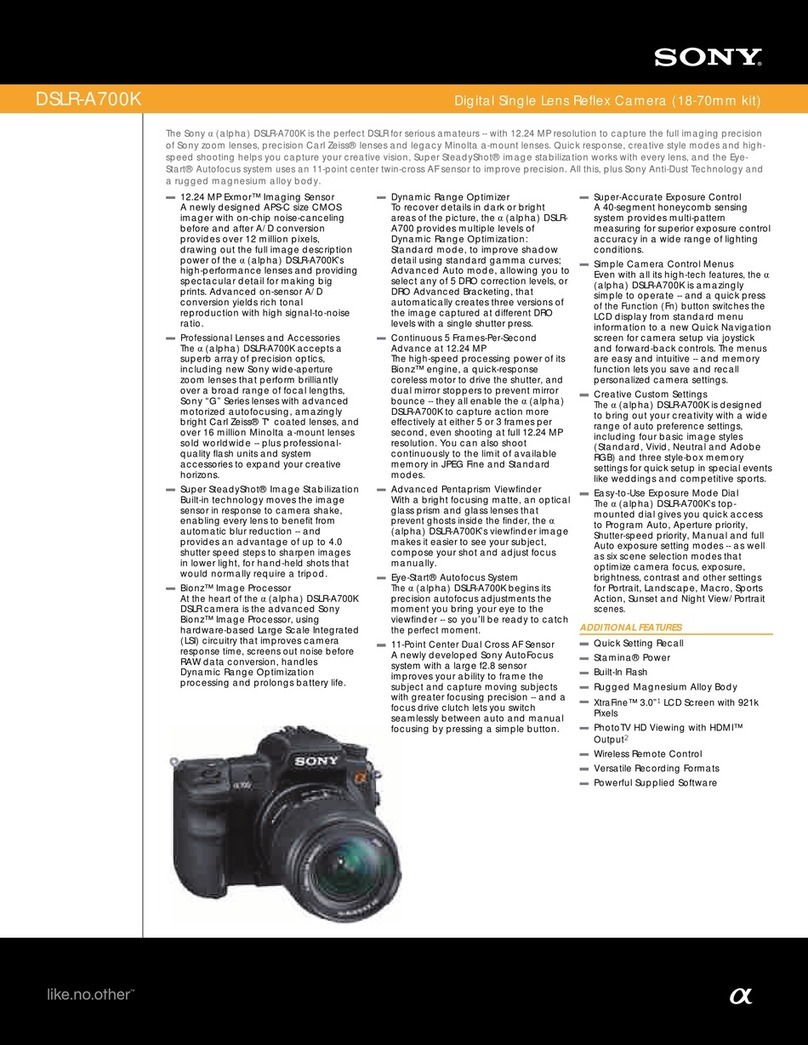

Test Jobs

Note: For descriptions of more advanced functionality, such as setting Inspection Outputs or using the

Locate Tool and Decode Tool’s Dynamic Locate functionality to track multiple tools from image to image,

see the help documentation in AutoVision software.

Decode Tool, OCR Tool, Match Strings Tool,

String Format Tool

Measure Tool,

Count Tool

LOT 123456

DATE 05/2012

VISION

SIMPLIFIED

Measure:

Measure the distance between

the jaws of the caliper gauges at left.

Count:

Count the circles on the dice shown

at right.

Step 9 — Set Camera Parameters

1. Click on the Camera box to the left of the image area.

2. In the camera parameters below the image area, select the desired type of Trigger, Trigger Polarity,

Photometry (Exposure and Gain), Focus, and Lighting.

Step 10 — Add Tools to the Job

1. Click on the Decode Tool or drag it onto the image area.

2. Use the anchor points at the corners of the region of interest to form a box around the Data Matrix

symbol. Leave plenty of space on each side of the symbol.

3. Now add a second Decode Tool and do the same for the 1D symbol below the Data Matrix symbol.

4. Finally, add an OCR Tool and drag the region of interest around the area of the image where “123456”

is printed.

Step 11 — Try Out the Job

Once you have configured the tools as desired, use the arrow icons in the Job area to try the job you have

just created.

Note: Most jobs will inspect multiple captured images. If only one image is being inspected, the effect of the

arrow icons will not be evident.

Try Out Job

Once

Try Out Job

in Loop

Other manuals for VS-05

1

Other Di-soric Digital Camera manuals