Di-soric SB-RGB User manual

IO-LINK SIGNAL LIGHTING &

SIGNAL LIGHTS

SB-RGB, SBT-RGB & SBP-RGB

OPERATING INSTRUCTIONS

600017-0000EN · Rev 1 · 2023/01

IOL SIGNAL LIGHTING & SIGNAL LIGHTS IOL SIGNAL LIGHTING & SIGNAL LIGHTS2

600017-0000EN · Rev 1 · 2023/01

TABLE OF CONTENTS

1 PRELIMINARY NOTE 3

2 OVERVIEW 4

3 GENERAL DESCRIPTION 5

4 NORMAL OPERATION AND APPLICATION AREAS 5

4.1 Reliably signaling various statuses .................................................................................................................................. 5

4.2 Signal lighting: suitable for a variety of uses .................................................................................................................... 5

4.3 Ambient conditions [IP protection classes]...................................................................................................................... 5

5 OPERATING MODES 6

5.1 External Trigger mode..................................................................................................................................................... 6

5.2 Operation via IO-Link [Segment mode, Level mode, Demo mode] ................................................................................... 6

5.2.1 Communication via IO-Link.................................................................................................................................... 6

5.2.2 Segment mode ..................................................................................................................................................... 6

5.2.3 Level mode ........................................................................................................................................................... 6

5.2.4 Demo mode .......................................................................................................................................................... 6

6 COMMISSIONING 7

6.1 Operation without IO-Link in External Trigger mode......................................................................................................... 7

6.2 Operation with di-soric IO-Link master............................................................................................................................ 7

6.3 Operation with other PLC online tools: e.g. Siemens master............................................................................................ 8

7 PARAMETERIZATION AND CONFIGURATION 9

7.1 Basic functions .............................................................................................................................................................. 9

7.1.1 Color configuration and designation....................................................................................................................... 9

7.1.2 Standard commands........................................................................................................................................... 10

8 OPERATING MODES 10

8.1 External Trigger mode [standard mode]......................................................................................................................... 11

8.1.1 Parameterization [parameter data]........................................................................................................................ 11

8.1.2 Application example ........................................................................................................................................... 12

8.2 Segment mode ............................................................................................................................................................ 13

8.2.1 Parameterization [parameter data]........................................................................................................................ 13

8.2.2 Process data and application example................................................................................................................. 14

8.3 Level mode .................................................................................................................................................................. 15

8.3.1 Parameterization [parameter data]........................................................................................................................ 15

8.3.2 Process data and application example................................................................................................................. 16

9 TROUBLESHOOTING 17

9.1 Error display................................................................................................................................................................. 17

IOL SIGNAL LIGHTING & SIGNAL LIGHTS2 3

600017-0000EN · Rev 1 · 2023/01

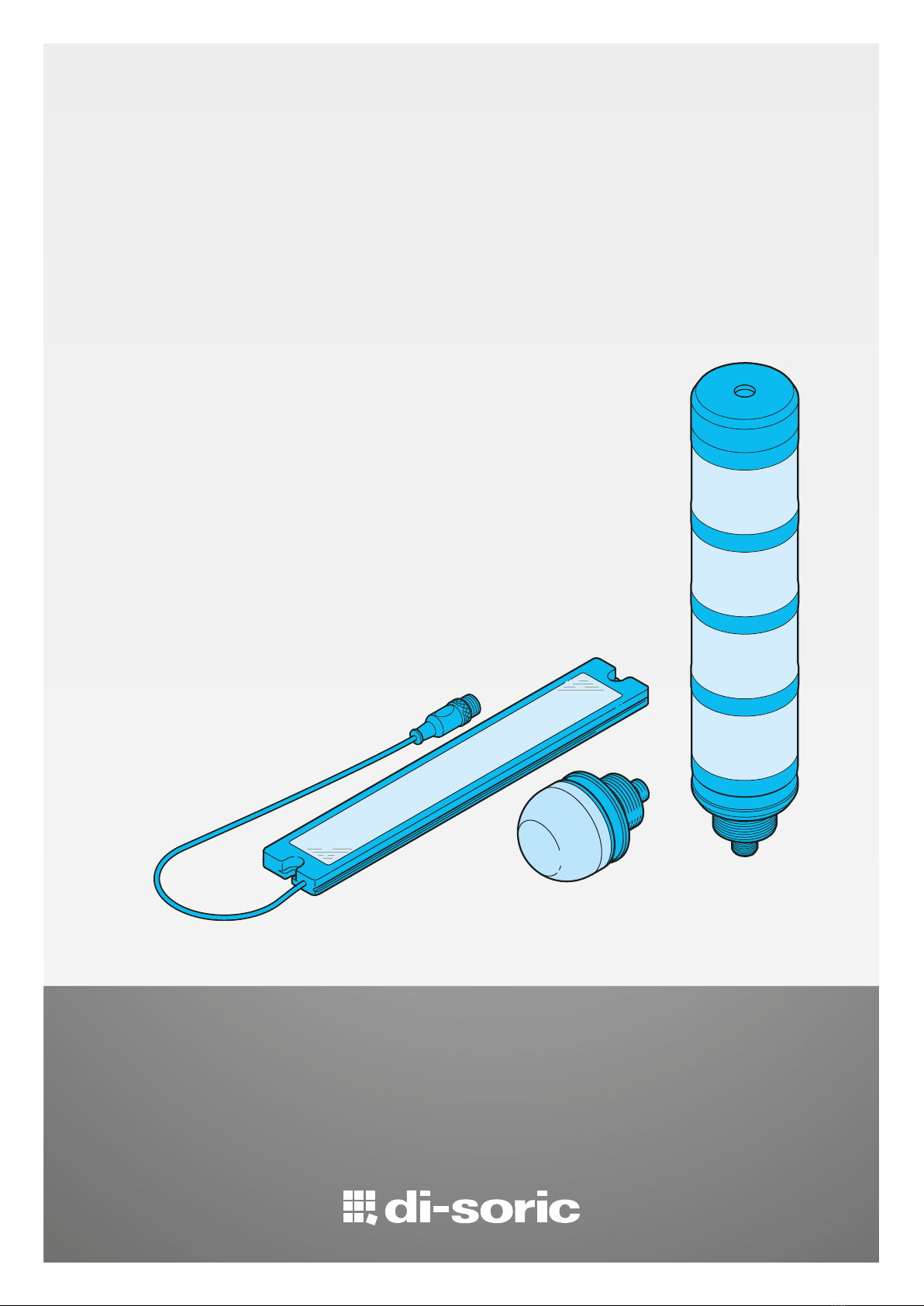

SBT-RGB

SBP-RGB

SB-RGB

1 PRELIMINARY NOTE

Foreword | Purpose

This quick guide helps you with the initial commissioning process for di-soric SBx-RGB signal lighting and with using the

USB IO-Link master to configure parameters. The quick guide is a supplementary document for the existing product

documentation.

For more information, see: http://www.di-soric.com

IOL SIGNAL LIGHTING & SIGNAL LIGHTS IOL SIGNAL LIGHTING & SIGNAL LIGHTS4

600017-0000EN · Rev 1 · 2023/01

2 OVERVIEW

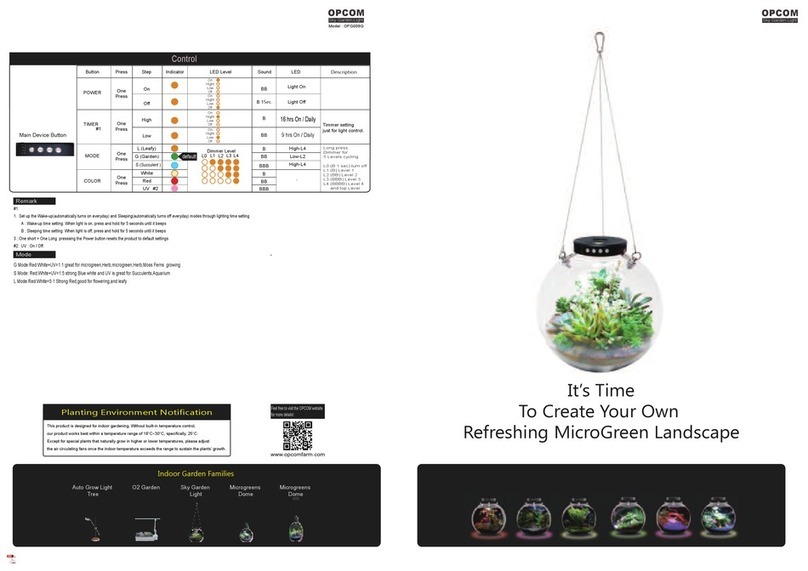

Product overview: IOL signal lighting & signal lights

SBP-RGB 1-segment IOL

signal lights SBP-RGB-R50D-B5

Segments 1

Operating mode Trigger mode, Segment mode, Demo mode

Color Red, green, yellow, blue, white, orange, pink, user-defined (IO-Link), RGB color spectrum

Brightness / intensity 10 to100%, can be freely customized via IO-Link

Frequency / mode Constant light, flashing light, blinking light

SB-RGB multi-segment IOL

signal lighting SB-RGB-126-K-B5 SB-RGB-251-K-B5 SB-RGB-481-K-B5 SB-RGB-701-K-B5 SB-RGB-911-K-B5

Segments 2 3 6 9 12

Operating mode Trigger mode, Segment mode, Level mode, Demo mode

Color Red, green, yellow, blue, white, orange, pink, user-defined (IO-Link), RGB color spectrum

Brightness / intensity 10to 100%, can be freely customized via IO-Link

Frequency / mode Constant light, flashing light, blinking light

SBT-RGB multi-segment IOL

signal columns with/without

buzzer

SBT-RGB-R50-

3S-B5

SBT-RGB-R50-

3B-B5

SBT-RGB-R50-

4S-B5

SBT-RGB-R50-

4B-B5

SBT-RGB-R50-

5S-B5

SBT-RGB-R50-

5B-B5

Segments 3 3 4 4 5 5

Buzzer Without With Without With Without With

Operating mode Trigger mode, Segment mode, Level mode, Demo mode

Color Red, green, yellow, blue, white, orange, pink, user-defined (IO-Link), RGB color spectrum

Brightness / intensity 10to 100%, can be freely customized via IO-Link

Frequency / mode Constant light, flashing light, blinking light

IOL SIGNAL LIGHTING & SIGNAL LIGHTS4 5

600017-0000EN · Rev 1 · 2023/01

3 GENERAL DESCRIPTION

Signal lighting is indispensable for safety in the industry or in the public sphere because it reliably provides a visual warning to

and protects not only the workers, but also passersby. Particularly in the industry at indoor and outdoor facilities, for example,

signal lighting supports workplace safety by indicating various operating states of machines and systems. Signal columns, for

example, can of course be used in other situations, too. The optical signal transducers help you monitor machines and complex

manufacturing processes, identify emergency or hazardous situations so that action can be taken in good time if the safety of

the environment, people or products is in jeopardy. di-soric signal lights and signal lighting have the advantage that they can be

configured to suit your individual needs via IO-Link. The signal lights can be integrated into any machine and system with practical

accessories for signal lighting.

4 NORMAL OPERATION AND APPLICATION AREAS

The di-soric signal lighting and signal lights are operated with a service voltage of 18 to 30 V.

On machines and systems with IO-Link, the device is connected to a class A port of the IO-Link master with a 3 to 5-pin M12

connecting line.

On machines and systems without IO-Link, the device is connected to a 5-pin cable, with the presets being activated via

the 3 digital inputs.

Even from a great distance, the signal lighting indicates the status of machines or machine segments in a clearly visible way

with vibrant colors.

4.1 RELIABLY SIGNALING VARIOUS STATUSES

By using professional signaling, you ensure more safety in your applications and considerably reduce response and waiting times.

Due to the dierent signaling stages, employees can promptly react to faults and more quickly fix any existing problems.

Attention is additionally drawn by the loud buzzer integrated into the cover of the SBT signal towers.

4.2 SIGNAL LIGHTING: SUITABLE FOR A VARIETY OF USES

It is impossible to imagine mechanical engineering and plant construction without signal columns But signal lighting is also found

in many other areas, such as intralogistics and building services engineering.

4.3 AMBIENT CONDITIONS [IP PROTECTION CLASSES]

The di-soric SBx-RGB lighting is typically suited for industrial applications; depending on the variants, they have the following IP

protection types: IP20, IP 65 and IP 67.

IOL SIGNAL LIGHTING & SIGNAL LIGHTS IOL SIGNAL LIGHTING & SIGNAL LIGHTS6

600017-0000EN · Rev 1 · 2023/01

5 OPERATING MODES

The di-soric LED signal lighting (SBx-RGB) can be operated via IO-Link as well as via the integrated digital inputs. In total,

4 operating modes are available: External Trigger mode, Segment mode, Level mode, Demo mode:

It is important to mention that the SBP-RGB is only operated with 3 operating modes, namely, External Trigger mode, Segment

mode and Demo mode. Level mode is not possible for the SBP-RGB series because the SBP-RGB has only one segment.

5.1 EXTERNAL TRIGGER MODE

In External Trigger mode (factory setting), 8 predefined color and lighting configurations can be activated through the 3 digital

trigger inputs, even without IO-Link.

5.2 OPERATION VIA IO-LINK [SEGMENT MODE, LEVEL MODE, DEMO MODE]

5.2.1 COMMUNICATION VIA IO-LINK

IO-Link is a globally standardized I/O technology (IEC61131-9) for communication

between control system and sensor/actuator below the fieldbus level.

The well-known connection technology is used with unshielded M12 cables. Here,

the 3-wire connection of a digital switching signal is enhanced by the bidirectional

communication.

5.2.2 SEGMENT MODE

In Segment mode, individual segments can be activated via IO-Link process data,

which enables countless color configurations. IO-Link can be used on the fly to set

the colors of each segment, the intensity from 10 to 100% and blinking or flashing

behavior.

5.2.3 LEVEL MODE

Level mode is for displaying fill levels and process progress. In Level mode, the signal

light requires an input value from the control system between 0 and 100 percent.

Furthermore, there is the option of using IO-Link process data to define a background

color (inactive segment) and a color of the active segment.

5.2.4 DEMO MODE

In Demo mode, the device demonstrates the dierent operating functions: dierent

colors, Level mode, Segment mode, blinking, flashing and, if present, an acoustic

signal.

Fieldbus

PLC

Industrial

Ethernet

IOL MASTER

SIO

Possible system architecture

IOL SIGNAL LIGHTING & SIGNAL LIGHTS6 7

600017-0000EN · Rev 1 · 2023/01

6 COMMISSIONING

For initial commissioning of our signal lighting, you need either a control system with 3 free digital outputs and a 5-wire

connecting cable with M12 socket or, if you want to connect the lighting to IO-Link, then you need a compatible IO-Link

master and a 5-wire connecting cable with M12 socket.

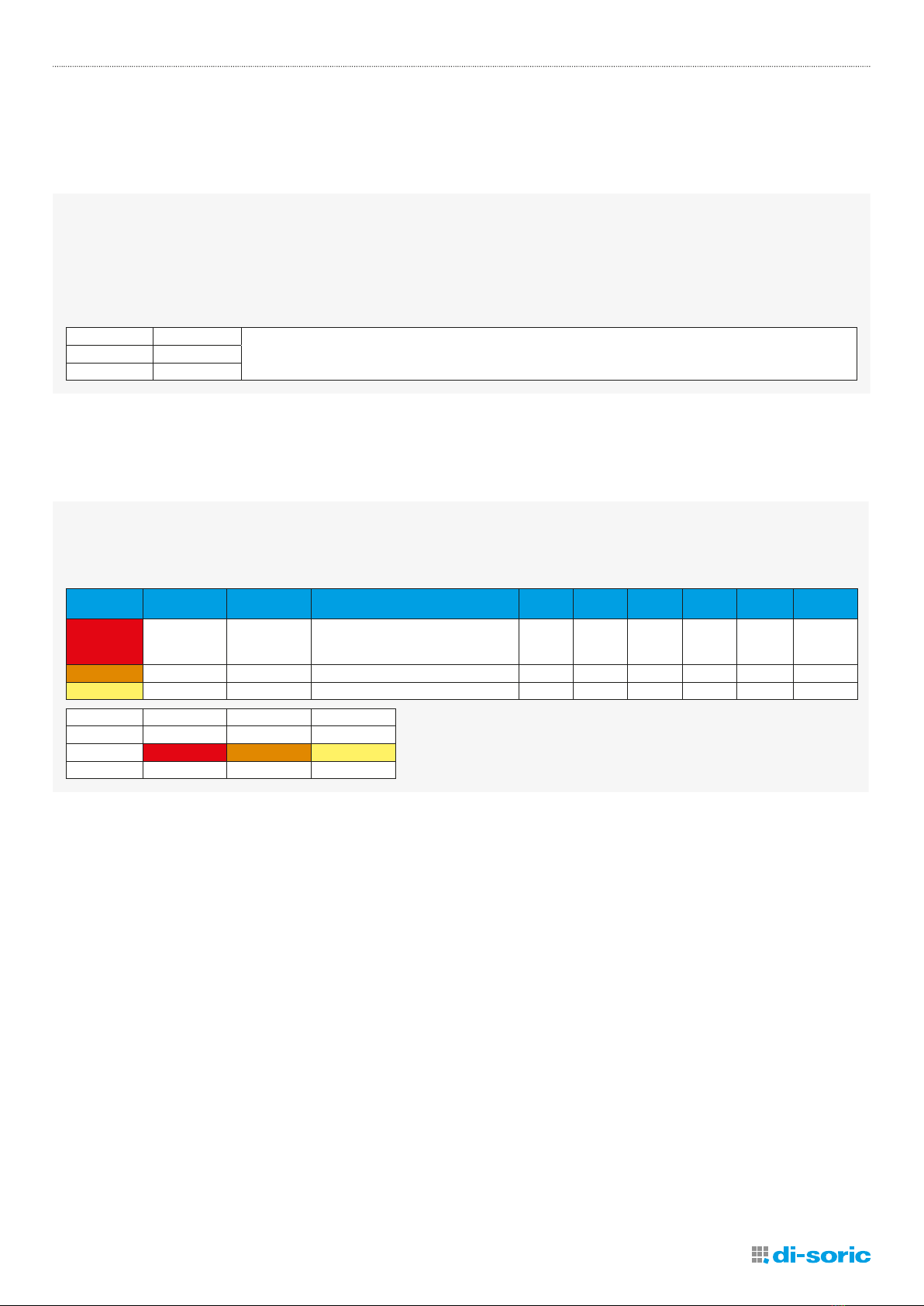

6.1 OPERATION WITHOUT IO-LINK IN EXTERNAL TRIGGER MODE

The lighting and/or products arrive from the factory in External Trigger mode. The 3 digital inputs can be used to activate the

predefined presets for the lights. The statuses that are displayed when the respective preset is activated depend on the product

and are described in the data sheet for the respective product. As an example, here is an excerpt from a data sheet from the

SBP-RGB series:

Operating mode: External trigger

BN 1

2WH

BU 3

5GY

BK 4

Trigger 1

Trigger 2

Trigger 3

TRIG 1 TRIG 2 TRIG 3 Pre-Set Factory setting

0001O

1002Red

0103Green

1104Yellow

0015Blue

1016Red blinking

0117Green blinking

1118Yellow blinking

All Trigger Inputs have a delay ~50 ms.

Pre-sets can be defined via IO-Link.

Operating mode: External Trigger

Trig 1 Trig 2 Trig 3 Preset Factory setting

0 0 0 1 O

1 0 0 2 Red

0 1 0 3 Green

1 1 0 4 Yellow

0 0 1 5 Blue

1 0 1 6 Red blinking

0 1 1 7 Green blinking

1 1 1 8 Yellow blinking

All trigger inputs have a delay ~50 ms. Presets can be defined via IO-Link.

6.2 OPERATION WITH DI-SORIC IO-LINK MASTER

Our signal lighting and signal lights from the SBx-RGB series can be configured directly with a computer running Windows 7 or

later, in combination with the di-soric USB IO-LINK MASTER and the associated “IOL Device Tool” software.

IOL MASTER:

Operation on PC via USB

The IO-Link devices are described by means of XML device descriptions, so they can be quickly

and easily observed and configured. The tool is designed for presetting, testing and

demonstrating IO-Link devices. The tool is not intended for ongoing operation in production

systems.

In addition to the computer and IO-Link master with software, you also need the IODDs of the

respective signal lights. You will find these in our product selector under the respective product on

the Downloads tab.

The IODD is a ZIP file in which the actual IODD is compressed with the associated graphics files.

After the files are imported into your engineering tool, the lighting functions can be visualized and

programmed.

You can also find the IODDs in the IODDfinder portal of the IO-Link Consortium: ioddfinder.io-link.com

For details about the functions and additional information for integrating IO-Link devices with the di-soric USB IO-Link master,

please see the user manual for the IOL master: www.di-soric.com/210075

IOL SIGNAL LIGHTING & SIGNAL LIGHTS IOL SIGNAL LIGHTING & SIGNAL LIGHTS8

600017-0000EN · Rev 1 · 2023/01

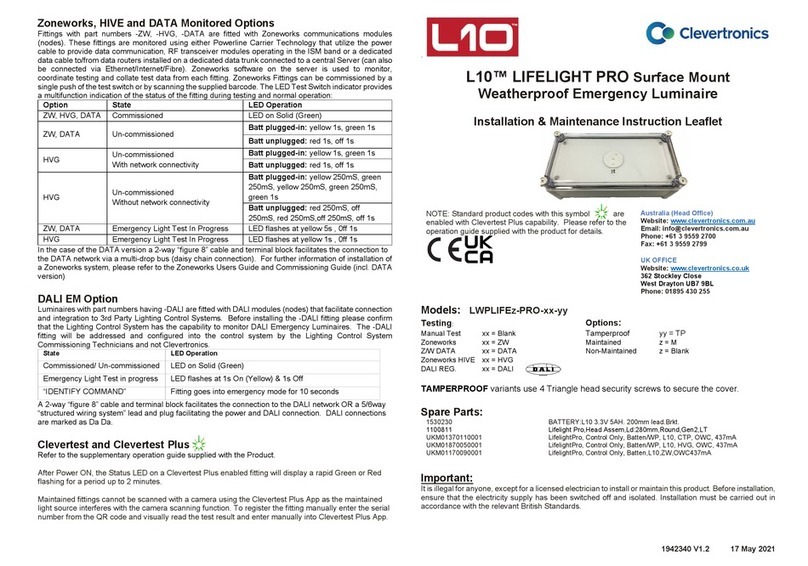

6.3 OPERATION WITH OTHER PLC ONLINE TOOLS: E.G. SIEMENS MASTER

Figure 1 – External Trigger mode (factory configuration)

Figure 2 – Segment mode (bytes for the process data are assigned)

S7-PCT with IODD of a device and the contained device information

Important note: Before operation with IO-Link, the IO-Link

devices should be switched from External Trigger mode

(factory configuration) to Segment mode or Level mode.

(see Figures 1 and 2)

It is entirely possible to use other engineering tools

for planning and parameterization of IO-Link devices:

Example: Siemens master with Port Configuration Tool

(“PCT”).

The Port Configuration Tool (“PCT”) is PC-based software

for parameterization of Siemens IO-Link master modules

and IO-Link devices from any manufacturer. The IO-

Link devices are integrated through the standardized

“IODD” device description, which can be obtained from

the respective device manufacturer or at the IODDfinder

portal (ioddfinder.io-link.com).

With the Siemens IO-Link master, it is necessary to make

sure that the latest IODD file revised for this is used. This

can be identified by the time code (Release Date: 2022-

04-25). For example, for the SB-RGB-126-K-B5 signal

lighting it looks like this: di-soric-SB-RGB-126-K-B5-

20220425-IODD1.1-de.html.

If a previous version of the IODD is installed, then this

must first be completely removed from the Siemens

master. Then the PCT tool must be restarted; after that,

the new version can be used.

IOL SIGNAL LIGHTING & SIGNAL LIGHTS8 9

600017-0000EN · Rev 1 · 2023/01

7 PARAMETERIZATION AND CONFIGURATION

7.1 BASIC FUNCTIONS

Among other things, di-soric signal lighting has 3 basic functions: color configuration, locator function and reset to factory

settings. The colors are configured to indexes [650to 657] by the “Color content” variable and to indexes [620 to 627] by the

“Designation” variable.

The “Locator function” at index [126=Locator Start, 127=Locator Stop] and the Reset to the factory setting

with the values [200 to207] are at subindexes 16 and are located under the “Standard command” standard variable

index=2 id=V_SystemCommand.

The Locator function is at 126 for Locator Start and 127 for Locator Stop; it enables the integrated product to be quickly found

in the system.

The factory settings are restored through the allowed value 130 as the subindex.

7.1.1 COLOR CONFIGURATION AND DESIGNATION

In the color configuration it is possible to configure 8 dierent colors; the “Color content” variables lie at the

indexes=650 to 657 and have the id=V_ColorRGB0 to V_ColorRGB7. The colors red, green and blue lie at the

subindexes=1,2,3 and are indicated with values 0 to 100.

The “Designation” variables lie at the indexes=620 to 627 and have the id=V_ColorDesignation0 to

V_Color Designation7. The color designations can be freely changed and have a data type of 32-octet string UTF-8.

Configuration color 000

“Color content” variable index=600 id=V_ColorRGB0

description: Color content

data type: 24-bit record

access rights: rw

dynamic

subindex bit oset data type allowed values default value acc. restr. mod. other var. excl. from DS name description

1 16 8-bit Ulnteger 0 to 100 0 Red Red part

2 8 8-bit Ulnteger 0 to 100 0 Green Green part

3 0 8-bit Ulnteger 0 to 100 0 Blue Blue part

octet 0 1 2

bit oset 23-16 15-8 7-0

subindex 1 2 3

element bit 7-0 7-0 7-0

Trigger preset 1 (TRIG1=0, TRIG2=0, TRIG3=0)

“Designation” variable index=620 id=V_ColorDesignation0

description: Designation can be freely selected

data type: 32-octet string UTF-8

default value: “O (factory setting)”

access rights: rw

dynamic

octet 0 1 2 3 4 5 6 7

bit oset 255–248 247-240 239-232 231-224 223-216 215-208 207-200 199-192

octet 8 9 10 11 12 13 14 15

bit oset 191-184 183-176 175-168 167-160 159-152 151-144 143-136 135 128

octet 16 17 18 19 20 21 22 23

bit oset 127-120 119-112 11-104 103-96 95-88 87-80 79-72 71-64

octet 24 25 26 27 28 29 30 31

bit oset 63-56 55-48 47-40 39-32 31-24 23-16 15-8 7-0

For example, for ColorDesignation0 the index lies at the value 620. At index=620 the color is o or dark by default (factory

setting).

IOL SIGNAL LIGHTING & SIGNAL LIGHTS IOL SIGNAL LIGHTING & SIGNAL LIGHTS10

600017-0000EN · Rev 1 · 2023/01

7.1.2 STANDARD COMMANDS

For the Locator function and factory setting, the “Standard command” standard variable lies at index=2 with the

id=V_SystemCommand. Restore the allowed values 126 for Locator Start and 127 for Locator Stop, as well as 130

for restoring to factory settings. For Reset to factory settings for ColorDesignation0to7, the allowed values lie between

[200 to 207].

“Standard command” standard variable index=2 id=V_SystemCommand

data type: 32-octet string UTF-8

allowed value: 126=Locator start, 127=Locator Stop, 130=Restore factory settings, 161=Function test, 162= Function test stop, 200=Reset to

factory settings, 201=Reset to factory settings, 202=Reset to factory settings, 203=Reset to factory settings,

204=Reset to factory settings, 205=Reset to factory settings, 206=Reset to factory settings, 207=Reset to factory settings,

240=IO-Link 1.1 system test command 240, Event 8DFF appears, 243=IO-Link 1.1 system test command 243, Event 8DFF appears

access rights: wo

modifies other variables

octet 0

bit oset 7-0

element bit 7-0

The Locator function enables the integrated product to be quickly found in the system.

The factory settings are restored through the allowed value 130 as the subindex.

8 OPERATING MODES

The signal lighting of the SB- and SBT-RGB series have four operating modes, which can be set by means of the “device control”

parameter:

• External Trigger mode (factory configuration)

• Segment mode (PD)

• Level mode (PD) [not available for the SBP lighting series]

• Demo mode

The operating modes can only be selected individually and cannot be combined. The operating mode is set by means of the

“device control” parameter.

“Device control” variable index=602 id=V_DeviceControl

description: Device control

data type: 8-bit Ulnteger

allowed value: 1=External Trigger mode, 2=Segment mode (PD), 3=Level mode (PD), 4=Demo mode

default value: 1

access rights: rw

octet 0

bit oset 7-0

element bit 7-0

The device control has index=602, the allowed values are 1=External Trigger mode, 2=Segment mode (PD),

3=Level mode (PD), and 4=Demo mode. The default value or standard value is typically 1 (external trigger).

IOL SIGNAL LIGHTING & SIGNAL LIGHTS10 11

600017-0000EN · Rev 1 · 2023/01

8.1 EXTERNAL TRIGGER MODE [STANDARD MODE]

The signal lighting of the SB-, SBP- and SBT-RGB series is delivered in Trigger mode. (factory configuration). This is the standard

operating mode at delivery. In this operating mode, each color of each segment is represented as a separate switching signal.

Important note: Complete integration into IO-Link is possible only with the new Gen. 2 devices possible, and these are stipulated

in this manual.

The delivery of Generation 2 lighting in Trigger mode enables backward compatibility with the devices of Generation 1.

Furthermore, Generation 1 devices dier from Generation 2 devices in terms of voltage range (Gen. 1: 24 V DC +-5%,

Gen. 2: 18 to30 V DC).

Preset color for each segment simulation

“Preset selection” variable index=604 id=V_TriggerSimulation

description: Simulation of all eight selectable presets in External Trigger mode in parallel with an IO-Link connection

data type: 8-bit Ulnteger

allowed value: 0=0 (simulation o), 1=preset 1, 2=preset 2, 3=preset 3, 4=preset 4, 5=preset 5, 6=preset 6, 7=preset 7, 8=preset 8

default value: 0

access rights: rw

excluded from data storage

octet 0

bit oset 7-0

element bit 7-0

For simulation of all eight selectable presets in Trigger mode, the index has the value 604 and the allowed base values for the

presets are [ 0- 8 ]: 0=(simulation o), 1=preset 1, 2=preset 2, 3=preset 3, 4=preset 4, 5=preset 5, 6=preset 6, 7=preset 7,

8=preset 8.

The default value or base value is typically 0.

8.1.1 PARAMETERIZATION [PARAMETER DATA]

Trigger mode means that customers can use digital inputs to switch predefined colors directly. Due to the 3 trigger inputs of the

lighting, the 8 predefined trigger presets can be selected.

For a trigger preset selection [preset 0to7], the following light functions (light color, intensity and mode) and buzzer function are

preset at the factory for each segment [1to 12] (depending on the variant). However, there is the option of simply using IO-Link to

freely and individually parameterize the trigger presets.

Recommended procedure for commissioning:

1.Configure colors

2.Configure presets

3.Simulate presets

IOL SIGNAL LIGHTING & SIGNAL LIGHTS IOL SIGNAL LIGHTING & SIGNAL LIGHTS12

600017-0000EN · Rev 1 · 2023/01

Buzzer function

For the variants that have a buzzer, a buzzer can also be configured in addition to the color configurations. Here, you can decide

whether the buzzer should emit a continuous tone or a slow or fast intermittent tone.

“Buzzer” variable index=700 id=V_SegmentPre-Set1_Buzzer

description: slow intermittent (1 Hz) / fast intermittent (2.5 Hz)

data type: 8-bit Ulnteger

allowed value: 0=o, 1=on (continuous), 2=slow intermittent, 3=fast intermittent

default value: 0

access rights: rw

octet 0

bit oset 7-0

element bit 7-0

Preset for each segment

In the preset segment configuration, the previously configured colors can be assigned to the individual presets or segments.

In addition, you can configure the light intensity as well as have the active segment be lit continuously, blink or flash.

“Seg 1” variable index=701 id=V_SegmentPre-Set1_1

description: Segment preset

data type: 24-bit record

access rights: rw

subindex bit oset data type allowed values default

value acc. restr. mod. other

var.

excl. from

DS name description

1 16 8-bit Ulnteger

0=color 001, 2=color 010, 3=color 011,

4=color 100, 5=color 101, 6=color 110,

7=color 111

0 Color Color

2 8 8-bit Ulnteger 0 to 100 100 Intensity Intensity

3 0 8-bit Ulnteger 0=static, 1=blinking, 2=flashing 0 Color Mode

octet 0 1 2

bit oset 23-16 15-8 7-0

subindex 1 2 3

element bit 7-0 7-0 7-0

8.1.2 APPLICATION EXAMPLE

To activate the color red in Trigger mode, the following pin assignment is connected:

Pin 2 (TRIG 1)=VDD, High level > 8.0 V

Pin 5 (TRIG 2)=GND, Low level < 5.0 V

Pin 4 (TRIG 3)=GND, Low level < 5.0 V

For the color green, the following pin assignment is required:

Pin 2 (TRIG 1)=GND, Low level < 5.0 V

Pin 5 (TRIG 2)=VDD, High level > 8.0 V

Pin 4 (TRIG 3)=GND, Low level < 5.0 V

IOL SIGNAL LIGHTING & SIGNAL LIGHTS12 13

600017-0000EN · Rev 1 · 2023/01

8.2 SEGMENT MODE

If the signal lighting or signal lights are completely integrated into the IO-Link communication, then it is advisable to operate the

product in Segment mode.

In Segment mode, individual segments can be activated via IO-Link process data, which enables countless color configurations.

IO-Link can be used on the fly to assign the previously configured colors and static, blinking or flashing lighting behavior to the

segments.

8.2.1 PARAMETERIZATION [PARAMETER DATA]

Depending on the selected number of segments, the various color combinations can be displayed. The intensity [10 to100] and

Dynamic mode [blinking or flashing] can also be set up freely.

The “Number of segments selection 1=1” setting applies the selected color to all the lighting. Important note: The index 610 is

not available for the SBP-RGB lighting.

Number of segments selection

“Number of segments selection” variable index=610 id=V_SelectionSegmentNumber

description: Selection of the number of segments in Segment mode (PD)

data type: 8-bit Ulnteger

allowed value: 1=1, 5=5

default value: 5

access rights: rw

Dynamic mode for each segment

In Segment mode, for example, for segment 1 the result is index=681 and for the intensity the result is subindex=1 and

the values are [10to100]. The factory setting is usually 100.

For Dynamic mode, the subindex=2 and the possible values are 1=blinking and 2=flashing. For the factory setting,

the value=1 is usually set.

“Seg 1” variable index=681 id=V_SegmentModus1

description: Segment

data type: 16-bit record

access rights: rw

subindex bit oset data type allowed values default

value acc. restr. mod. other

var.

excl. from

DS name description

1 8 8-bit Ulnteger 10 to 100 100 Intensity Intensity

2 0 8-bit Ulnteger 1=blinking, 2=flashing 1 Dynamic

mode

Dynamic

mode

octet 0 1

bit oset 15-8 7-0

subindex 1 2

element bit 7-0 7-0

IOL SIGNAL LIGHTING & SIGNAL LIGHTS IOL SIGNAL LIGHTING & SIGNAL LIGHTS14

600017-0000EN · Rev 1 · 2023/01

8.2.2 PROCESS DATA AND APPLICATION EXAMPLE

The process data of the devices is transmitted cyclically in a data telegram; the device defines the process data size. For each

device it is possible to have process data from 0 to 32 bytes (for both the input and output). In Segment mode, the process data

can be used to assign the 8 preconfigured colors to the individual segments or activate them. Furthermore, the (static or dynamic)

lighting mode can be selected for each segment. In addition, if products have a buzzer, this can be activated.

The ProcessDataOut “PD for Segment mode” is under the id=PDOUT_Segment at V_DeviceControl == 2. For example, the color

setting for Seg 3 is at subindex 6 and the buzzer is at subindex 7.

ProcessData id=PD_Segment (condition V_DeviceControl ==2)

ProcessDataOut “PD for Segment mode” id=PDOUT_Segment

bit length: 64

data type: 64-bit record (subindex access not supported)

subindex bit oset data type allowed values default

value acc. restr. mod.

other var.

excl. from

DS name description

1 63 Boolean false=static, true=dynamic Seg 1 mode

2 60 3-bit Ulnteger

0=color 000, 1=color 001, 2=color 010,

3=color 011, 4=color 100, 5=color 101,

6=color 110, 7=color 111

Seg 1 color

3 59 Boolean false=static, true=dynamic Seg 2 mode

4 56 3-bit Ulnteger

0=color 000, 1=color 001, 2=color 010,

3=color 011, 4=color 100, 5=color 101,

6=color 110, 7=color 111

Seg 2 color

5 55 Boolean false=static, true=dynamic Seg 3 mode

6 52 3-bit Ulnteger

0=color 000, 1=color 001, 2=color 010,

3=color 011, 4=color 100, 5=color 101,

6=color 110, 7=color 111

Seg 3 color

7 51 Boolean false=static, true=dynamic Seg 4 mode

8 48 3-bit Ulnteger

0=color 000, 1=color 001, 2=color 010,

3=color 011, 4=color 100, 5=color 101,

6=color 110, 7=color 111

Seg 4 color

9 47 Boolean false=static, true=dynamic Seg 5 mode

10 44 3-bit Ulnteger

0=color 000, 1=color 001, 2=color 010,

3=color 011, 4=color 100, 5=color 101,

6=color 110, 7=color 111

Seg 5 color

11 0 2-bit Ulnteger 0=o, 1=on (continuous), 2=slow intermittent,

3=fast intermittent Buzzer

In Segment mode, the number of segments [1 to12] of lighting (depending on variant) can be easily displayed and the

preconfigured colors [000to 111] selected for each segment can be optically visualized.

A variety of information can be clearly and optically displayed with the segments. The Segment mode setting causes the lighting

to accept only the commands for color changes, activation via the I/O-Link connection.

In Segment mode, the signal lighting can be used to display process progress. Thus the machine operator can immediately

determine the current status of manufacturing processes and act accordingly in case of error messages.

IOL SIGNAL LIGHTING & SIGNAL LIGHTS14 15

600017-0000EN · Rev 1 · 2023/01

8.3 LEVEL MODE

In Level mode, it is possible to use IO-Link process data to define a background color [inactive segment], which can be used,

for example, as a corporate identity color. In addition, the fill levels and machine status can be displayed with the active segments

[foreground color] with a predefined color selection.

8.3.1 PARAMETERIZATION [PARAMETER DATA]

Important note: Level mode is not available for SBP-RGB lighting because it has only one segment.

Segment behavior

“Mode” variable index=616 id=V_LevelMode

description: Mode

data type: 8-bit Ulnteger

allowed value: 0=segments increasing, 1=segment migrating

default value: 0

access rights: rw

octet 0

bit oset 7-0

element bit 7-0

For example, for Level mode the index=616 and the allowed values are 0=segments increasing, 1=segment migrating.

Level display direction

With the signal lighting Level mode, the display direction [Bottom>Top or Top>Bottom] can also be selected and optically

displayed.

“Display direction” variable index=615 id=V_LevelDisplayDirection

description: Display direction

data type: 8-bit Ulnteger

allowed value: 0=Bottom > Top, 1=Top > Bottom

default value: 0

access rights: rw

octet 0

bit oset 7-0

element bit 7-0

Dynamic mode for each segment

Furthermore, it is possible to define a foreground color with the index=617 [active segment level] and a background color

with the index 618 [inactive segment level]. For example, the background color can be set as a corporate identity color.

“Active segment dynamic mode” variable index=617 id=V_LevelActiveSegment

description: Active segment dynamic mode (foreground color)

data type: 8-bit Ulnteger

allowed value: 1=blinking, 2=flashing

default value: 1

access rights: rw

octet 0

bit oset 7-0

element bit 7-0

IOL SIGNAL LIGHTING & SIGNAL LIGHTS IOL SIGNAL LIGHTING & SIGNAL LIGHTS16

600017-0000EN · Rev 1 · 2023/01

“Inactive segment dynamic mode” variable index=618 id=V_LevelInactiveSegment

description: Inactive segment dynamic mode (background color)

data type: 8-bit Ulnteger

allowed value: 1=blinking, 2=flashing

default value: 1

access rights: rw

octet 0

bit oset 7-0

element bit 7-0

8.3.2 PROCESS DATA AND APPLICATION EXAMPLE

Process data (e.g. analog values) are transmitted cyclically. In Level mode, the process data transmits the analog value [0to100]

as an input, for example, so that fill levels and process progress can be displayed. The 8 preconfigured colors can be freely set

for the active segments as well as for the inactive segments. Furthermore, the (static or dynamic) lighting mode can be selected.

In addition, the buzzer can be activated. The buzzer's tone mode [slow or fast intermittent] can also be freely selected.

ProcessData id=PD_Level (condition V_DeviceControl ==3)

ProcessDataOut “PD for Level mode” id=PDOUT_Level

bit length: 64

data type: 64-bit record (subindex access not supported)

subindex bit oset data type allowed values default

value acc. restr. mod.

other var.

excl. from

DS name description

1 56 8-bit Ulnteger 0 to 100 Analog value

2 51 Boolean false=static, true=dynamic

Active

segments

mode

3 48 3-bit Ulnteger

0=color 000, 1=color 001, 2=color 010,

3=color 011, 4=color 100, 5=color 101,

6=color 110, 7=color 111

Active

segments

color

4 40 7-bit Ulnteger 10 to 100

Active

segments

intensity

5 35 Boolean false=static, true=dynamic

Inactive

segments

mode

6 32 3-bit Ulnteger

0=color 000, 1=color 001, 2=color 010,

3=color 011, 4=color 100, 5=color 101,

6=color 110, 7=color 111

Inactive

segments

color

7 24 7-bit Ulnteger 10 to 100

Inactive

segments

intensity

8 0 2-bit Ulnteger 0=o, 1=on (continuous), 2=slow intermittent,

3=fast intermittent Buzzer

The ProcessDataOut “PD for Level mode” is under the id=PDOUT_Level at V_DeviceControl == 3. As an example, the “intensity

of active segments” is at subindex 4 with the allowed values [10to100].

The fill levels and/or machine status are displayed with the active segments [foreground color] with preconfigured color

selection for the respective process. In accordance with the color selection predefined by the user, fill levels in the process can

be displayed more eciently with lit LED segments. The allocation of the analog value depends on the available number of

segments.

IOL SIGNAL LIGHTING & SIGNAL LIGHTS16 17

600017-0000EN · Rev 1 · 2023/01

9 TROUBLESHOOTING

9.1 ERROR DISPLAY

Error types for the signal lighting of the SBx-RGB series

Code Additional code Name Description

128 (0x80) 0 (0x00) Application error in device – no details Access was denied by device. No detailed information available

128 (0x80) 17 (0x11) Index not available Access to a nonexistent index

128 (0x80) 18 (0x12) Subindex not available Access to a nonexistent subindex

128 (0x80) 32 (0x20) Service currently unavailable Currently the parameter cannot be accessed. The device does not allow this in the

current status.

128 (0x80) 35 (0x23) Access denied Write access to a write-protected parameter

128 (0x80) 48 (0x30) Parameter value outside the valid range Written parameter value lies outside the allowed value range.

128 (0x80) 49 (0x31) Parameter value above the allowed limit Written parameter value lies above the allowed value range.

128 (0x80) 50 (0x32) Parameter value below the allowed limit Written parameter value lies below the allowed value range.

128 (0x80) 51 (0x33) Parameter length too large Written parameter value is larger than allowed.

128 (0x80) 52 (0x34) Parameter length too small Written parameter value is smaller than allowed.

128 (0x80) 53 (0x35) Function not available Written command is not supported by the device.

128 (0x80) 54 (0x36) Function currently unavailable Written command is not supported by the device in the current status.

128 (0x80) 64 (0x40) Invalid parameter set Written individual parameter value collides with the other parameter settings.

128 (0x80) 65 (0x41) Inconsistent parameter set Inconsistencies were detected at the end of the block parameter transfer.

The device plausibility check failed.

128 (0x80) 130 (0x82) Application not ready Access was denied because the device is not ready currently.

© di-soric | All information is subject to change. Contents may contain mistakes or print errors and are subject to technical changes. | (Document number) · (revision number, date)

SOLUTIONS. CLEVER. PRACTICAL.

© di-soric | All information is subject to change. Contents may contain mistakes or print errors and are subject to technical changes. | 600017-0000EN· Rev 1 · 202301

SOLUTIONS. CLEVER. PRACTICAL.

di-soric GmbH & Co. KG | Steinbeisstrasse 6 | 73660 Urbach | Germany

Phone +49 71 81 98 79-0 | Fax +49 71 81 98 79-179 | info@di-soric.com

www.di-soric.com

This manual suits for next models

24

Table of contents

Popular Light Fixture manuals by other brands

V-TAC

V-TAC VT-8315 Installation instruction

ProLights

ProLights LUMA1500SP user manual

Clevertronics

Clevertronics L10 LIFELIGHT PRO LWPLIFEz-PRO Series Instruction leaflet

Cooper Lighting

Cooper Lighting Metalux WB SERIES Specifications

Blizzard Lighting

Blizzard Lighting Stiletto Z3 user manual

Lightolier

Lightolier 1102P1 Installation