Dialight SafeSite DHZCPSD4C8 User manual

Document No.

9100-127-2044-99 Rev C

Release Date: August 2020

Dialight Corporation 1501 Route 34 South Farmingdale NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 1 of 21

Introduction

This manual is for orientation and function of the Power Supply only. Individual manuals

are supplied for each component of Dialight’s Safesite® Medium Intensity L864/L865

Dual Strobe System.

NOTE: For Controller connections and wiring refer to its manual.

NOTE: For Flash Head connections refer to its manual.

NOTE: For Photocell connections refer to its manual.

Included in this manual

•WARNINGS

•Classifications for use

•System overview

•Installation Tips and requirements

•System Installation Requirements for EMC and Lightning Immunity

•Power Supply Specifications & Electrical Parameters

•Mechanical Dimensions of Power Supply Enclosure

•Replacement Part Numbers

•Refer to product labelling for applicable

installation locations

•DO NOT let any supply cords touch hot

surfaces higher than cord or fixture ratings.

•DO NOT mount near gas or electric heaters

•Equipment should be mounted in locations

and at heights where it will not be subjected to

tampering by unauthorized personnel.

•The use of accessory equipment not

recommended by the manufacturer may cause

unsafe conditions.

•DO NOT use this equipment for other than

intended use.

•Pictures of the install are required for

warranty purposes

SAVE THESE INSTRUCTIONS!!

•The operation and maintenance must be carried

out by authorized personnel.

•Repairs and Installation must only be carried

out by a qualified electrician.

•Only genuine Dialight replacement parts must

be used when unforeseen repairs are required.

•Observe the national safety rules and

regulations during installation!

•Earth Grounding is required throughout the

install process. Failure to do so could void all

warranties!

•No alterations are allowed without the

agreement from Dialight Corp. Alterations other

than written in this manual will void all

warranties.

•Ensure that all conduit or external cable feeds

have been installed so water or condensation

cannot enter the enclosures.

Hazardous Location Medium Intensity Power Supply Manual

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

Document No.

9100-127-2044-99 Rev C

Release Date: August 2020

Dialight Corporation 1501 Route 34 South Farmingdale NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 2 of 21

WARNINGS

Warning

To avoid the risk of fire, explosion, or electric shock, this product should be installed,

inspected, and maintained by a qualified electrician only, in accordance with all

applicable National electrical codes.

Warning

To avoid electric shock:

•Be certain electrical power is OFF before and during installation and maintenance.

•The Power Supply must only be connected to Dialight Corp approved products.

Warning

To avoid explosion:

•Do not connect to equipment that the Controller is not intended for.

•Ensure the marked T Rating is less than the ignition temperature of the Hazardous

Atmosphere.

•Do not operate in ambient temperatures above those indicated on the Products label.

•Do not operate if the fasteners are not properly tightened.

•Do not operate in Hazardous locations with the Enclosure cover open.

Warning

To avoid explosion (Continued):

•EXPLOSION HAZARD- DO NOT DISCONNECT EQUIPMENT UNLESS POWER

HAS BEEN SWITCHED OFF OR THE AREA IS KNOWN TO BE NON-

HAZARDOUS.

•AVERTISSEMENT –RISQUE D’EXPLOSION –AVANT DE DECONNECTER

L’EQUIPEMENT, COUPER LE COURANT OU S’ASSURER QUE

L’EMPLACEMENT EST DESIGNE NON DANGEREUX.

•DO NOT REMOVE OR REPLACE WHILE CIRCUIT IS LIVE UNLESS THE AREA IS

KNOWN TO BE FREE OF IGNITIBLE CONCENTRATIONS.

•THIS EQUIPMENT IS SUITABLE FOR USE IN HAZARDOUS OR NON-

HAZARDOUS LOCATIONS ONLY. REFER TO PRODUCT FOR RATINGS

•EXPLOSIONS HAZARD –DO NOT DISCONNECT WHILE THE CIRCUIT IS LIVE OR

UNLESS THE AREA IS KNOWN TO BE FREE OF IGNITABLE

CONCENTRAITIONS.

Document No.

9100-127-2044-99 Rev C

Release Date: August 2020

Dialight Corporation 1501 Route 34 South Farmingdale NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 3 of 21

•WARNING –EXPLOSION HAZARD –DO NOT REPLACE ANY COMPONENTS

UNLESS POWER HAS BEEN SWITCHED OFF OR THE AREA KNOWN TO BE

NON-HAZARDOUS.

•AVERTISSEMENT –RISQUE D’EXPLOSION – NE PAS REMPLACER LES

COMPOSANTES QUE L’ALIMENTATION EST COUPEE OU QUE LA ZONE

EST CONNUE POUR ETRE NON DANGEREUX.

•WARNING –EXPLOSION HAZARD –SUBSTITUTION OF COMPONENTS MAY

IMPAIR SUITABILITY FOR CLASS I, DIVISION 1.

•AVERTISSEMENT –RISQUE D’EXPLOSION –LA SUBSTITUTIOND E

COMPOSANTSP EUTR ENDRE CE MATERIEL INACCEPTABLE POUR LES

EMPLACEMENTS DE CLASSE I, DIVISION 1.

Warning

•DO NOT mount near gas or electric heaters.

•Equipment should be mounted in locations and at heights where it will not be

subjected to tampering by unauthorized personnel.

•The use of accessory equipment not recommend by the manufacture may cause an

unsafe condition.

•DO NOT use this equipment for other than intended use.

Warning:

The technical data indicated on the product label is to be observed.

•Changes to the design and modifications of the Controller are not permitted.

•Only genuine Dialight replacement parts are to be used when unforeseen

maintenance is required. Consult factory at www.Dialight.com or authorized

representative as required.

Document No.

9100-127-2044-99 Rev C

Release Date: August 2020

Dialight Corporation 1501 Route 34 South Farmingdale NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 4 of 21

System Overview

Document No.

9100-127-2044-99 Rev C

Release Date: August 2020

Dialight Corporation 1501 Route 34 South Farmingdale NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 5 of 21

E2 SYSTEM OVERVIEW

Note - this is a typical installation example. It is possible to feed the input voltage

in and out of the controller box to the additional power supply boxes, i.e. “daisy-

chaining” is acceptable.

Installation Tips and Requirements

Cable Requirements

The power supply only requires 3 wiring connections:

WARNING: Failure to use specified cable will VOID all warranties and could cause

premature failures.

1) Mains connection using a 3 conductor Power Cable (14AWG minimum to 10AWG

maximum).

2) An RS485 communications cable. This is required to be a 3 conductor cable

(18AWG minimum) with a shield or braid as well as a drain wire.

3) The connection between the Flash Head and the Power supply. This is required to

be 8 conductors of 18AWG minimum or 4 conductors of 14AWG minimum, with a

shield or braid as well as a drain. Maximum run distance is 550 feet.

4) Common Ratings for the above cables:

-40ºC to 90ºC temperature rating minimum (stationary use)

Outdoor rated/ wet location

UV resistant

Minimum of 300V rating (if 277Vac is used then a 600V cable is required)

UL, CSA and RoHS complaint

Flame retardant

Document No.

9100-127-2044-99 Rev C

Release Date: August 2020

Dialight Corporation 1501 Route 34 South Farmingdale NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 6 of 21

Maximum cable diameter is .47 inches

NOTE: Liquid tight, Conduit and TECK (armored) cable are acceptable to be used in the

installation, with properly sized conductors.

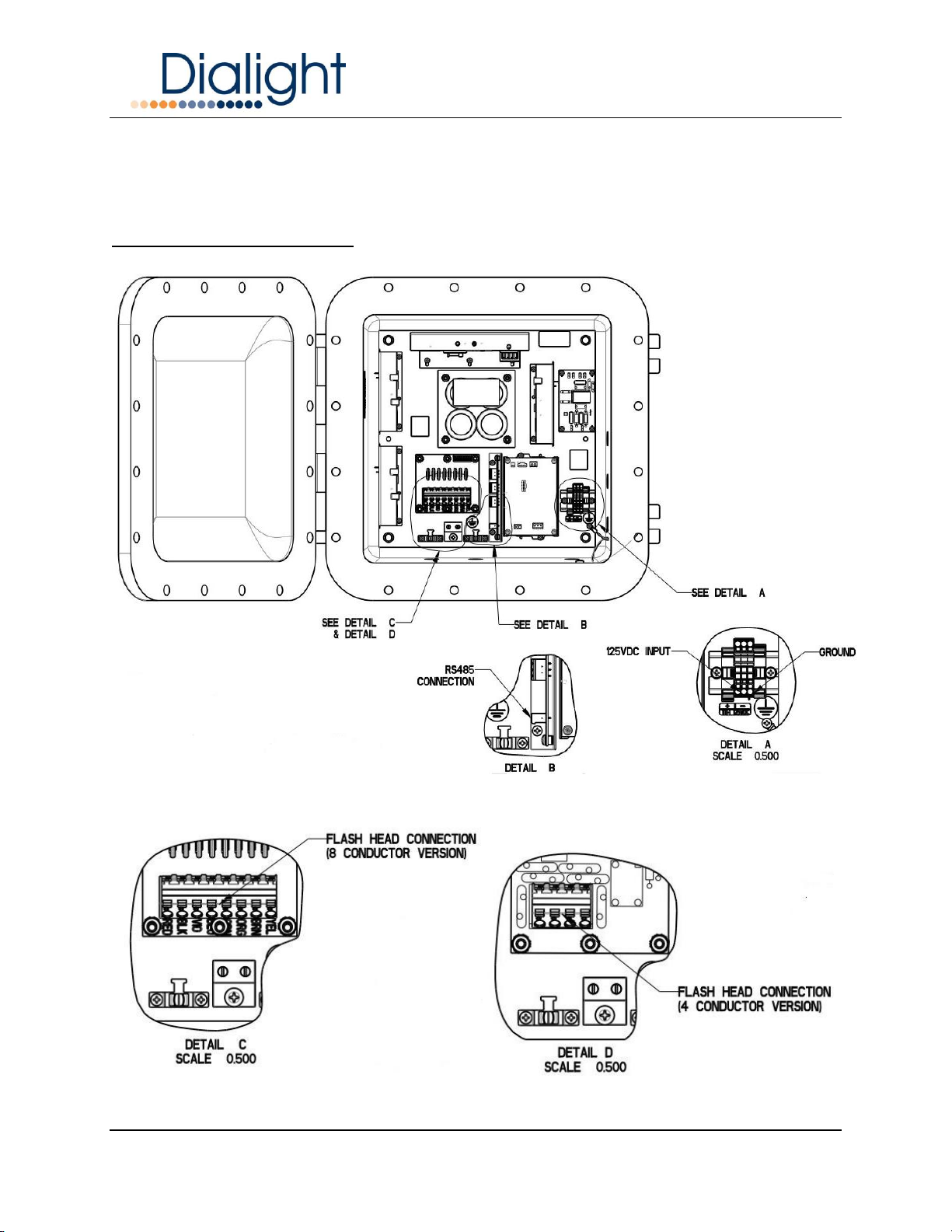

Power Supply Connections

Document No.

9100-127-2044-99 Rev C

Release Date: August 2020

Dialight Corporation 1501 Route 34 South Farmingdale NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 7 of 21

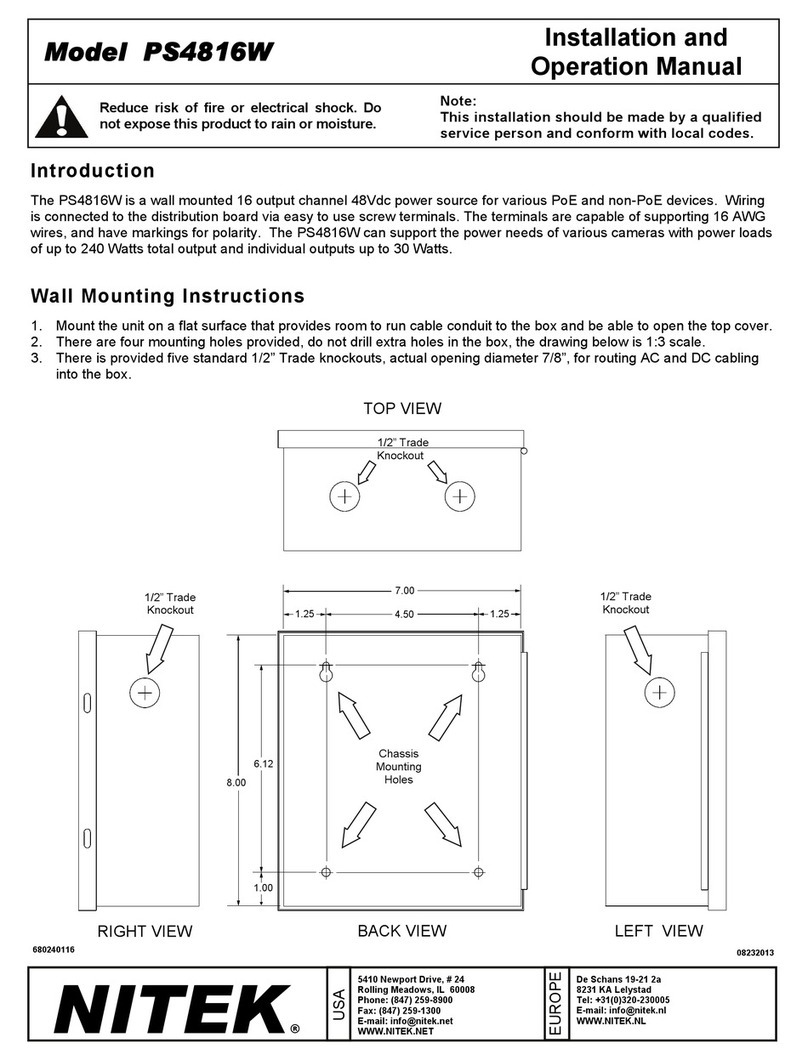

POWER SUPPLY CONNECTIONS

The Enclosure has holes drilled and tapped for all wiring connections.

WARNING: No additional holes can be added to the enclosure.

NOTE: Multiple grounding points are provided in the enclosure for protective and

functional Earth/Ground connections.

FRONT VIEW OF THE POWER SUPPLY ENCLOSURE

Entry Number

Size

For

1

3/4 NPT

Flash Head Connection

2

3/4 NPT

RS485

3

3/4 NPT

AC or DC Input and, if

needed, output*

*A conduit “T” can be used at entry 3, for additional mains output or input

Document No.

9100-127-2044-99 Rev C

Release Date: August 2020

Dialight Corporation 1501 Route 34 South Farmingdale NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 8 of 21

SIDE VIEW OF THE POWER SUPPLY ENCLOSURE

Installation and Wiring

WARNING: Before any service or wiring is conducted ensure the DC at the breaker is

off!!!

SYSTEM BLOCK DIAGRAM

A Com B + - GND

Multi-way connection cable (up

to 550ft) See pg. 4 for

conductor sizing

Flash

Head

AC or DC

Power In

Power Supply

Enclosure

RS485

Control

Signal

Document No.

9100-127-2044-99 Rev C

Release Date: August 2020

Dialight Corporation 1501 Route 34 South Farmingdale NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 9 of 21

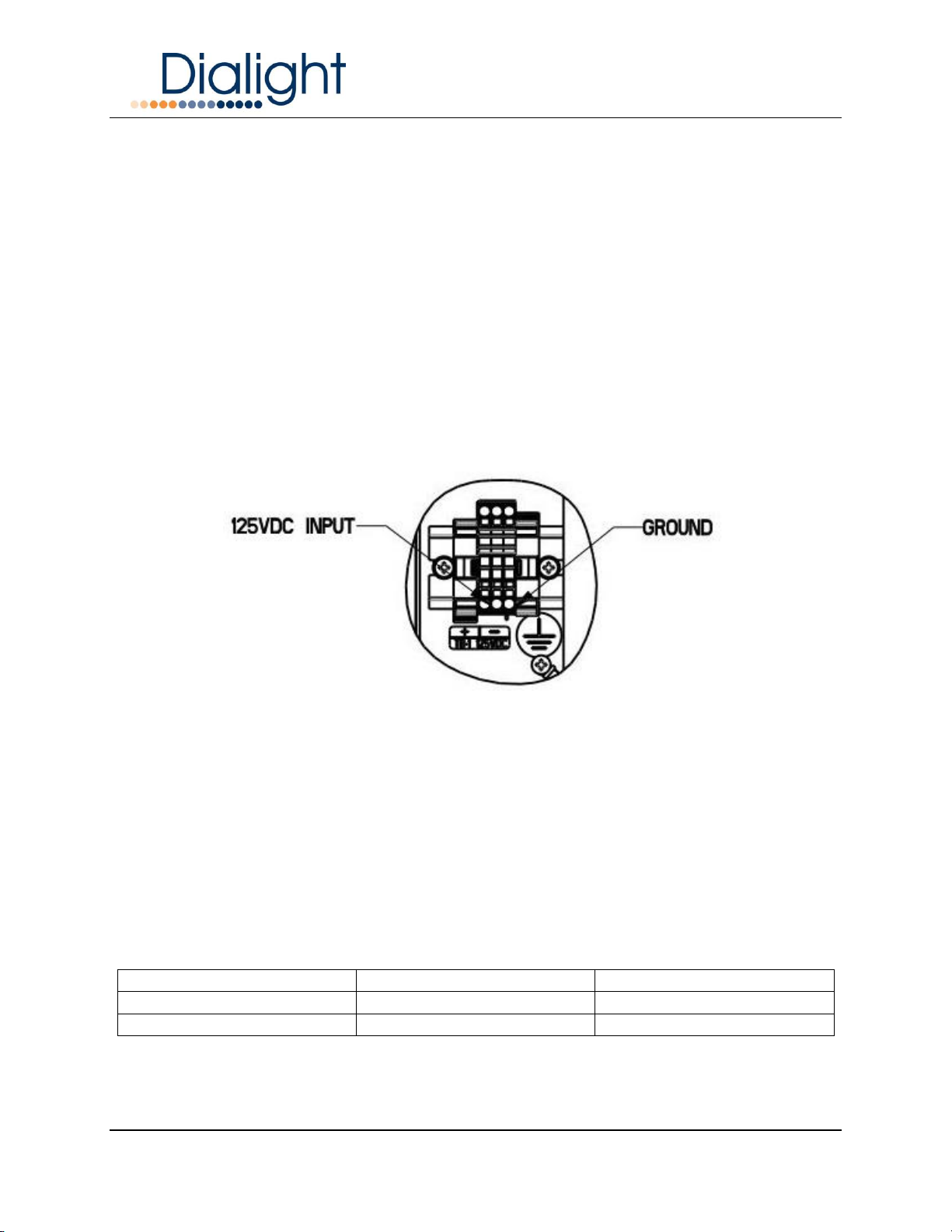

Power Supply Terminal Connection

Located at the bottom right hand side of the enclosure is the terminal block required for

connecting the Positive, Negative and Earth Ground to the power supply.

WARNING: Floating Neutrals are not permissible within the wiring of the system and the

installer must verify the connections. This will “Void” all warranties.

WARNING: Ground connection is required to provide safety and proper operation of the

system.

WARNING: There can be no more than 305Vac measured from Live to Earth ground on

TB1

NOTE: The load and voltage loss of the cable must be quantified before selecting the

cable size requirements.

DC TERMINAL BLOCK

RS485 Communication Connection

The connection of the RS485 cable is vitally important to the operation of the system.

This connection provides all the events and alarms to the Master controller that is being

used with the installation.

Factory connected wiring color code:

The RS485 consists of 3 conductors

Boards are Labeled Description Color Code

Label “A”

Communications “A”

Gray or White

Common

Common for RS485

Yellow

Label “B”

Communications “B”

Blue

Document No.

9100-127-2044-99 Rev C

Release Date: August 2020

Dialight Corporation 1501 Route 34 South Farmingdale NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 10 of 21

Option 1:

The RS485 consists of 3 conductors, a drain wire and either a shield or braid.

Install Cable Connected to Description Color Code

Conductor 1

Label “A”

Communications “A”

Gray or White

Conductor 2

Common

Common for RS485

Yellow

Conductor 3

Label “B”

Communications “B”

Blue

Drain wire

Ground stud

Ground

Bare wire

Shield or Braid

Clamping terminal

Ground

Connected when

cable enters the

enclosure and must

be connected to

plate

Option 1 above is applicable with RS-485 communication cable as purchased from

Dialight, part number CAB---183BFD. Where --- represents the cable length in feet.

Option 2:

When 2 Conductors, a drain wire and either a shield or braid is used.

Install Cable Connected to Description Color Code

Conductor 1

Label “A”

Communications “A”

TBD by installer

Drain Wire

Common

Common for RS485

Bare Wire

Conductor 2

Label “B”

Communications “B”

TBD by installer

Shield or Braid

Clamping Terminal

Ground

Connected when

cable enters the

enclosure and must

be connected to

plate

WARNING: For Color Codes labeled TBD the installer must take note of the colors

used for these connections since it is required that all A, Common and B terminals be

connected the same throughout the system.

Located inside the Power Enclosure to the left of the DC terminal block is the

connection point for the RS485 cable.

Document No.

9100-127-2044-99 Rev C

Release Date: August 2020

Dialight Corporation 1501 Route 34 South Farmingdale NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 11 of 21

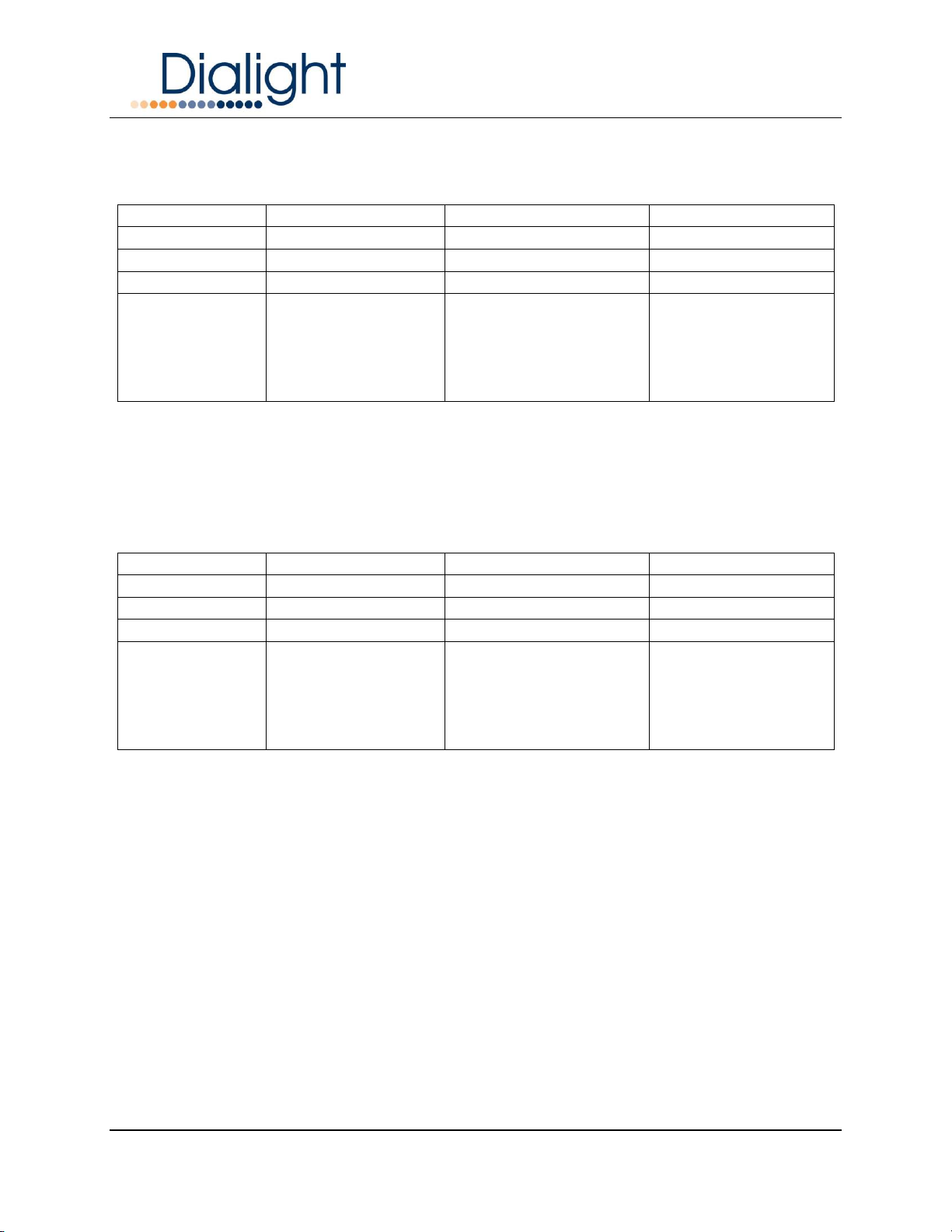

TRANSLATOR & RS485 JUNCTION BOARD

NOTE: Rotary switch SW1 on the Translator must be set to a unique address for each

Power Supply connected to the Controller.

NOTE: If ordered as a system, typically SW1 will be factory set per this table (i.e. JB4-

xxxxxxxxxx would have SW1 set to Position 3). This should be confirmed by the

installer. Replacement plates will typically have SW1 set to 0; the switch must be set by

the installer to match the address that is being replaced.

SW1 Position

MIOL No.

0

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

Document No.

9100-127-2044-99 Rev C

Release Date: August 2020

Dialight Corporation 1501 Route 34 South Farmingdale NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 12 of 21

RS485 shall be connected throughout the system per the simplified diagram below.

Both the Controller and Power Supply enclosures house the same RS485 junction

board. Beginning at the Controller; it is always connected from the Output (J5) to the

Input (J1) of the next enclosure.

RS485 SYSTEM DIAGRAM

Flash Head Connection

The connection between the Flash Head and the Power Supply requires an 8 conductor

cable.

NOTE: This is the only connection to the Flash Head that is required.

WARNING: If the cable is not color coded or numbered the instructions state the

installer must take notes of wiring to ensure that both the Flash Head and Power supply

get wired the same. If for example wire 1 is inserted in to location 4 by mistake severe

damage could result to the LED’s in the flash head. This will VOID all warranties.

Pin 1 or RED in the flash head must go to Pin1 RED in the power supply and so

on.

NOTE: The installer should provide this information to the site manager upon

completion for future reference when required

Controller

P/S 1

P/S 2

P/S 3

Document No.

9100-127-2044-99 Rev C

Release Date: August 2020

Dialight Corporation 1501 Route 34 South Farmingdale NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 13 of 21

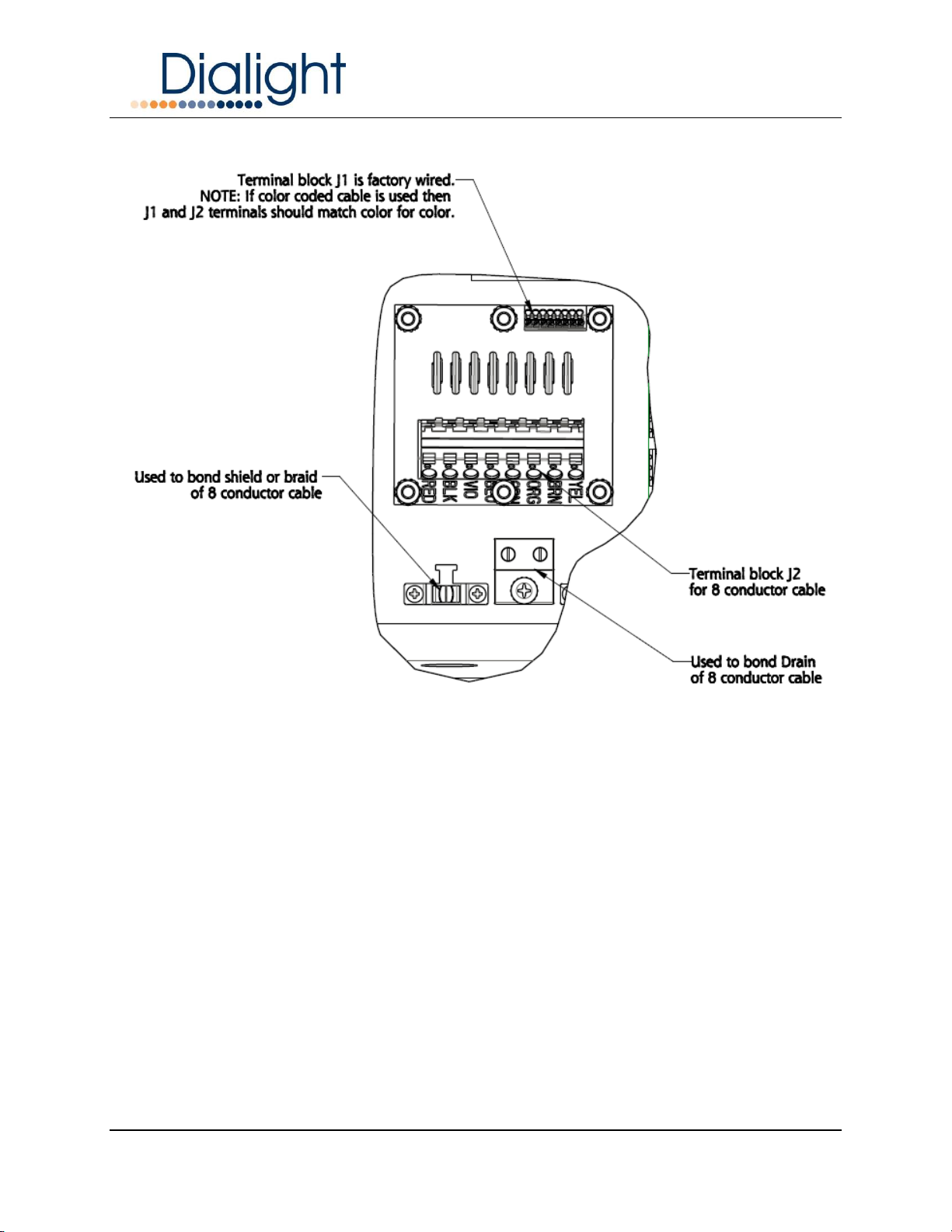

8 CONDUCTOR VERSION

FLASH HEAD CONNECTION, 8 CONDUCTOR

J2 Terminal block definitions:

NOTE: The Flash head and Power supply have the same protection board.

Two conductors are required for the Red Beacon and six for the White Strobe.

Red L864 Connections: Terminal block J2 pins 1 and 2

White L865 Connections: Terminal Block J2 pins 3 thru 8

RED (Pin1) = + (positive) for Red L864

BLK (Pin 2) = - (return) for Red L864

VIO (Pin 3) = + (positive) for White L865

BLU (Pin 4) = - (return) for White L865

GRN (Pin 5) = - (return) for White L865

ORG (Pin 6) = + (positive) for White L865

BRN (Pin 7) = - (return) for White L865

YEL (Pin 8) = - (return) for White L865

Document No.

9100-127-2044-99 Rev C

Release Date: August 2020

Dialight Corporation 1501 Route 34 South Farmingdale NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 14 of 21

4 CONDUCTOR VERSION

FLASH HEAD CONNECTION, 8 CONDUCTOR

J2 Terminal block definitions:

NOTE: The Flash head and Power supply have the same protection board.

Two conductors are required for the Red Beacon and two for the White Strobe.

Red L864 Connections: Terminal block J2 pins 1 and 2

White L865 Connections: Terminal Block J2 pins 3 and 4

RED/BLACK (Pin1) = - (NEGATIVE) for Red L864

RED (Pin 2) = + (POSITIVE) for Red L864

WHITE/BLACK (Pin 3) = - (NEGATIVE) for White L865

WHITE (Pin 4) = + (POSITIVE) for White L865

WARNING: Take care to connect correctly, as incorrect operation can cause

damage to the driver modules.

Document No.

9100-127-2044-99 Rev C

Release Date: August 2020

Dialight Corporation 1501 Route 34 South Farmingdale NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 15 of 21

System Installation Requirements for EMC and Lightning Immunity:

1: Ensure the shield of the cable that connects the Flash head to the power supply is

grounded at both ends. Make 360-degree ground connections around the braid or foil

(avoid pigtails).

2: For increased lightning protection adding a lightning rod that extends up 3 feet above

the fixture and 18 inches away from the light is recommended.

3: The drain-wire in the Flash Head cable must be connected to ground at both ends.

Ensure that the wire is short as possible and avoid loops.

4: Ensure the Flash Head is electrically bonded to the tower. Scrape away access paint/

powder coating as necessary.

5: Minimize loop areas by tying all cables against the tower or passing through conduit.

6: Ensure the Power Supply enclosure is electrically bonded to the tower. Scrape away

access paint/ powder coating as necessary.

7: Ground any spare/unused conductors in the Flash Head connection cable at both

ends.

8: It is recommended that a minimum of ¾” conduit is used for all wiring ways.

9: RS485 connections must be secure and shield or braiding must be grounded

securely.

Power Supply Specifications & Electrical Parameters:

Flash Rate for L864/L865

The Red Beacon factory setting is 30FPM (Flash per minute).

The White Strobe factory setting is 40 FPM (Flash per minute).

Fault / Alarm Connections

There are NO additional fault connections required in the Power Supply enclosure. All

faults are sent to the Base controller via the RS485 communications.

NOTE: It is vitally important that the RS485 connections are checked and secured.

Document No.

9100-127-2044-99 Rev C

Release Date: August 2020

Dialight Corporation 1501 Route 34 South Farmingdale NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 16 of 21

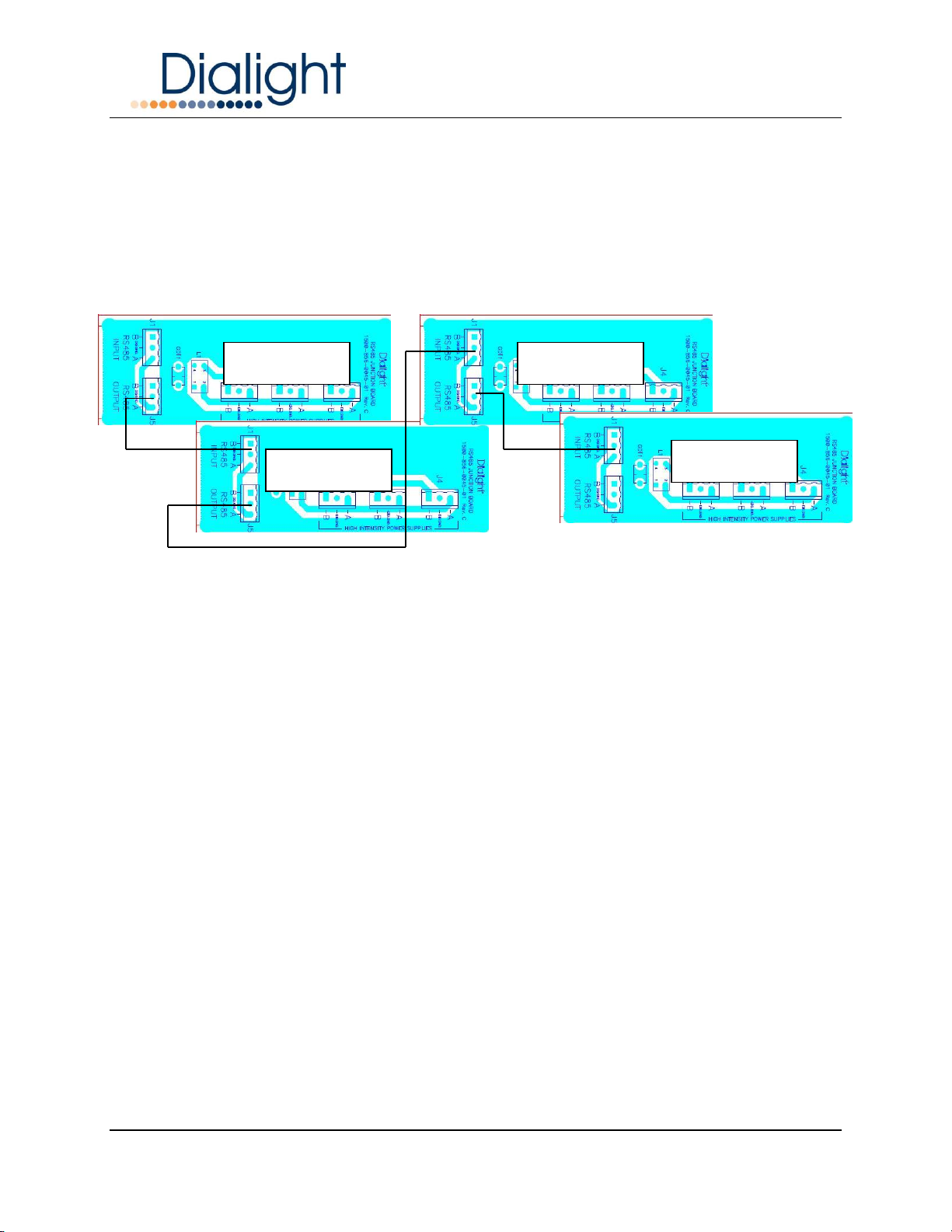

Configuration Option Switches

NOTE: In previous versions of the Dialight D1RW there were settings required for the

dip switches on the micro board.

This version only requires position 1 of SW1 to be used.

If being used as a Dual red and white beacon the micro board switches SW1 must be

set to the off position.

If being used as a White only system then SW1 position 1 should be set to the on

position.

NOTE: The switches are factory set to the off position and positions 2, 3, & 4 should be

checked that they are set in the off position.

Micro / Filter Assembly Image

Capacitor Voltage Indication

Safety Warning

This unit holds a number of large capacitors for storage of the energy required

during the Strobe’s flash duration. These capacitors may be charged with

voltages up to 185Vdc. Associated with each capacitor is a red indicator LED.

When lit, this indicates the capacitor voltage is 50V or higher. When power is

removed from the module the capacitors automatically discharge to 50V within 30

seconds.

Do not attempt any maintenance or wiring until the capacitors have been allowed

time to discharge to a safe level and all red indicator LED’s have gone out.

SW1

Up is on towards

Black connectors

Down is off

Position 1

Position 4

Document No.

9100-127-2044-99 Rev C

Release Date: August 2020

Dialight Corporation 1501 Route 34 South Farmingdale NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 17 of 21

Strobe White Driver Diagnostic LED’s

The two Strobe White Driver modules each have three indicator LED’s.

LED 2 and 3: Each is driven from one of the driver’s three outputs. Therefore normally

each one should blink at the same rate as the Strobe output. These indicate the driver

module is operating. If for some reason some of the White LED’s in the Flash Head do

not operate yet these diagnostic LED’s do blink, this would indicate the fault is not with

the Driver module. Should one or more of these LED’s be stuck on or not flash at all,

this may indicate a fault with the driver module.

LED 4: Lights continuously when the Strobe is energized to show that an excess of 50V

is present at its output. If this does not light it might indicate either the Driver module is

faulty or not receiving any power.

Red Beacon Driver Diagnostic LED

LED 1: Indicates more than 50V is present on the output and gives a good indication

that the Beacon Driver module is working.

Microcontroller Board Diagnostic LED’s

LED 1 (Red) on the Microcontroller board shows the status of the Flash Head. In white

mode, it will flash the driver number of any white drivers that currently have faulty

strings. In red mode, it will flash once every two seconds if the red current is low and

twice if the current is too high. It will not flash at all when all drivers are operating

properly.

LED 2 (Green) on the Microcontroller board pulses once every time a flash is initiated in

the Flash Head.

NOTE: Verification of the above may only be required if a communications Alarm is sent

to the Master Controller

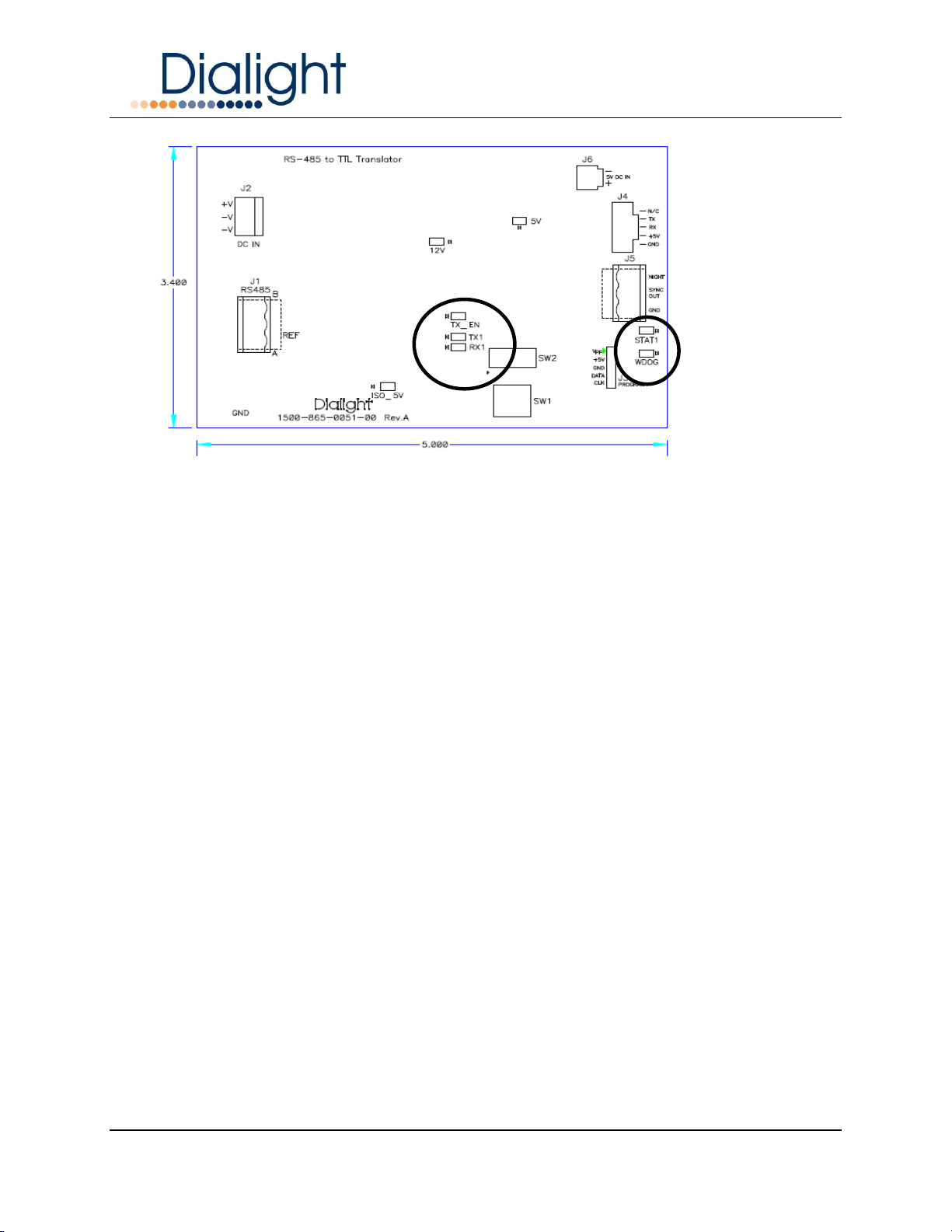

Translator Board Diagnostic LED’s

When power is applied to the Power Supply there are 3 LED’s labeled ISO 5V, 12V and

5V that must be solidly lit. The LED labeled Watchdog must be blinking.

Once communications from the Master controller has been established there 3 LED’s

that will Blink in unison.

These are TX_EN, TX 1 and RX 1

NOTE: If these are not blinking then there are no Communications.

NOTE: SW1 must be to set to position 0 when used as an AOL

Document No.

9100-127-2044-99 Rev C

Release Date: August 2020

Dialight Corporation 1501 Route 34 South Farmingdale NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 18 of 21

J1 is the connection point for the incoming RS485 cable, ports B (Pin1) and A (Pin3)

can be seen. The Common connection point is the center pin 2.

Translator Indicators

Translator Communications LED’s:

Once communication has begun LED’s labeled TX_EN, TX1 and RX1 will begin to

flash.

LED marked “watchdog” will also blink approx. every half second.

STAT1 LED will be solidly lit.

Pin3 (+)

Pin 2 (-)

Pin 1 (-)

Square on bottom of

board is always pin1

LED

indicators

Must be

steady on

Document No.

9100-127-2044-99 Rev C

Release Date: August 2020

Dialight Corporation 1501 Route 34 South Farmingdale NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 19 of 21

Translator Indicators

Document No.

9100-127-2044-99 Rev C

Release Date: August 2020

Dialight Corporation 1501 Route 34 South Farmingdale NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 20 of 21

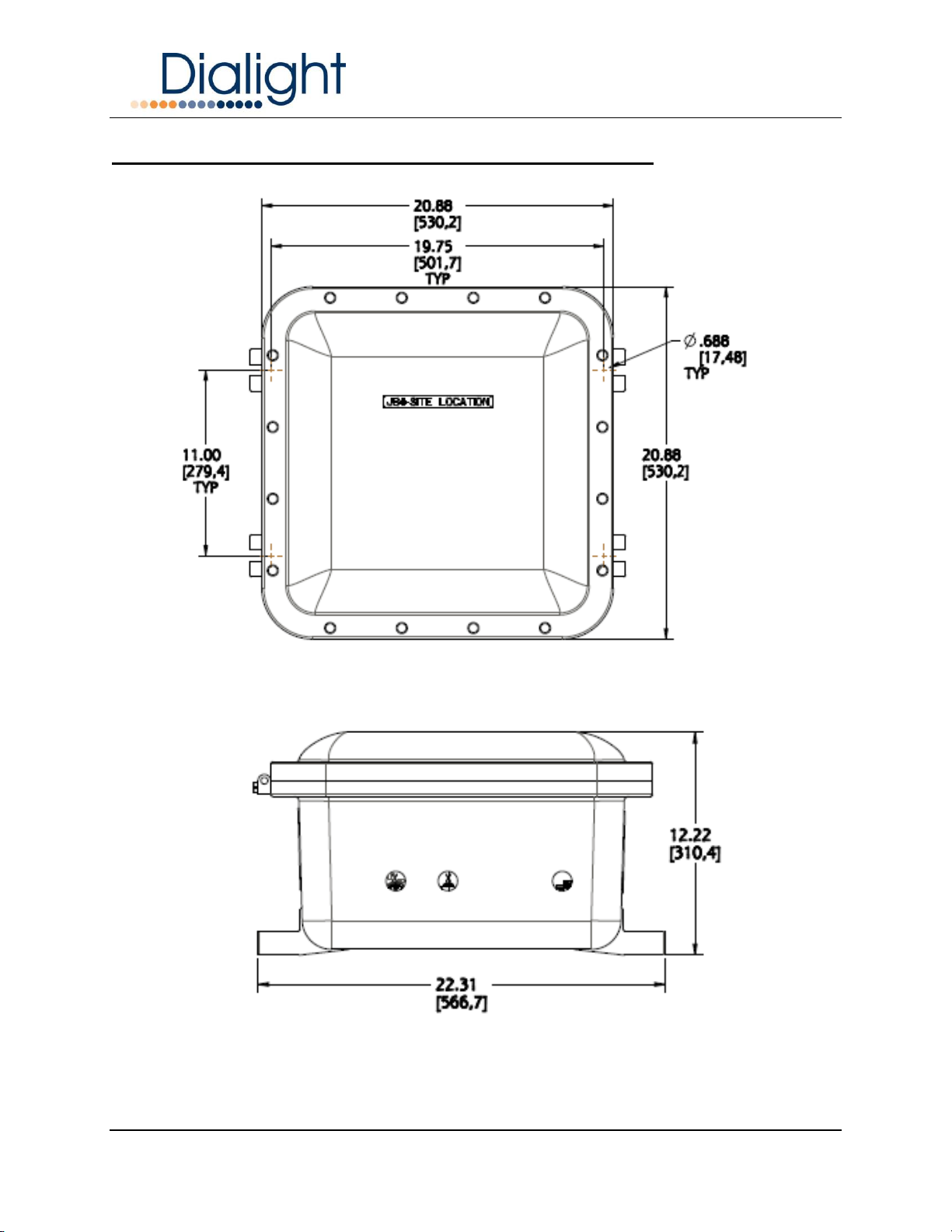

Mechanical Dimensions of Power Supply Enclosure:

Enclosure dimensions

This manual suits for next models

5

Table of contents

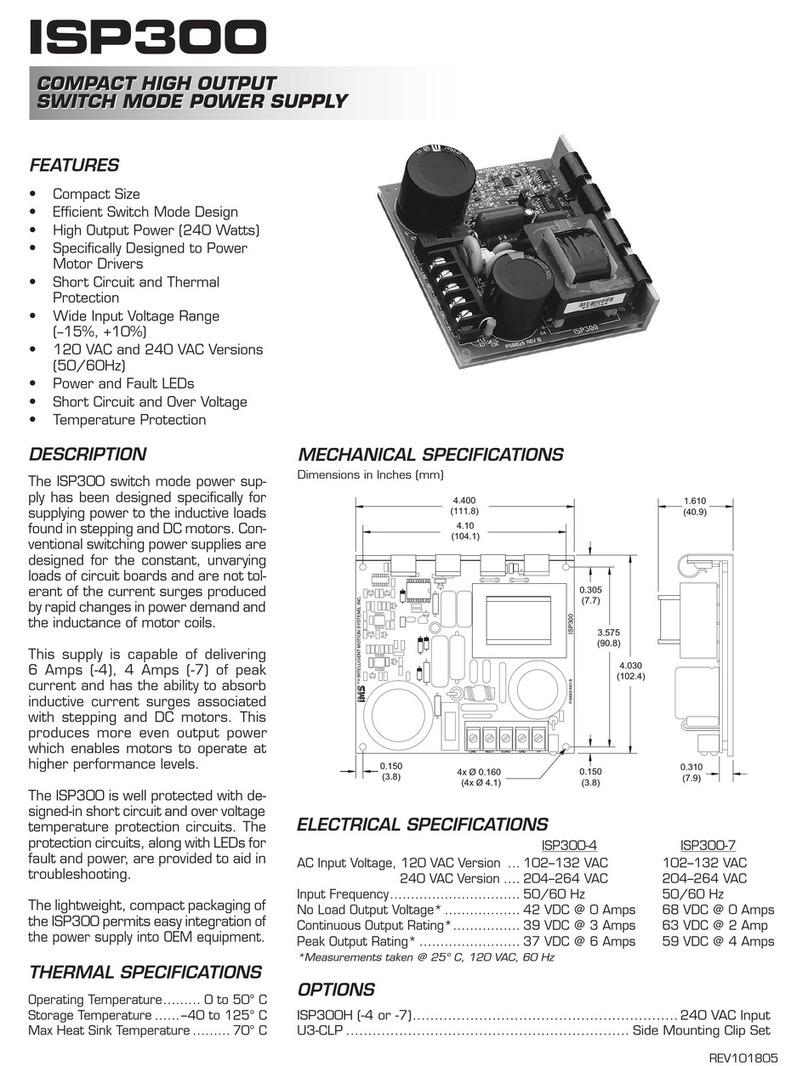

Popular Power Supply manuals by other brands

Intelligent Motion Systems

Intelligent Motion Systems ISP300 datasheet

KTI Networks

KTI Networks KPW-1012-D user manual

Allen-Bradley

Allen-Bradley 1606-XLE480EP installation instructions

Scientific

Scientific PSD7303A user manual

Matsusada Precision

Matsusada Precision DOPF Series instruction manual

Cooper Wheelock

Cooper Wheelock POWERPATH PS-24-8MC installation instructions