Table of Contents

1. Product Description ................................................................................................................... 6

1.1. Related documentation....................................................................................................... 7

1.1.1. GEW Product manuals................................................................................................ 7

1.1.2. European (EN) Standards ........................................................................................... 7

1.1.3. British Standards ......................................................................................................... 7

1.1.4. Guidance notes ........................................................................................................... 7

1.1.5. North American & Canadian Standards ...................................................................... 7

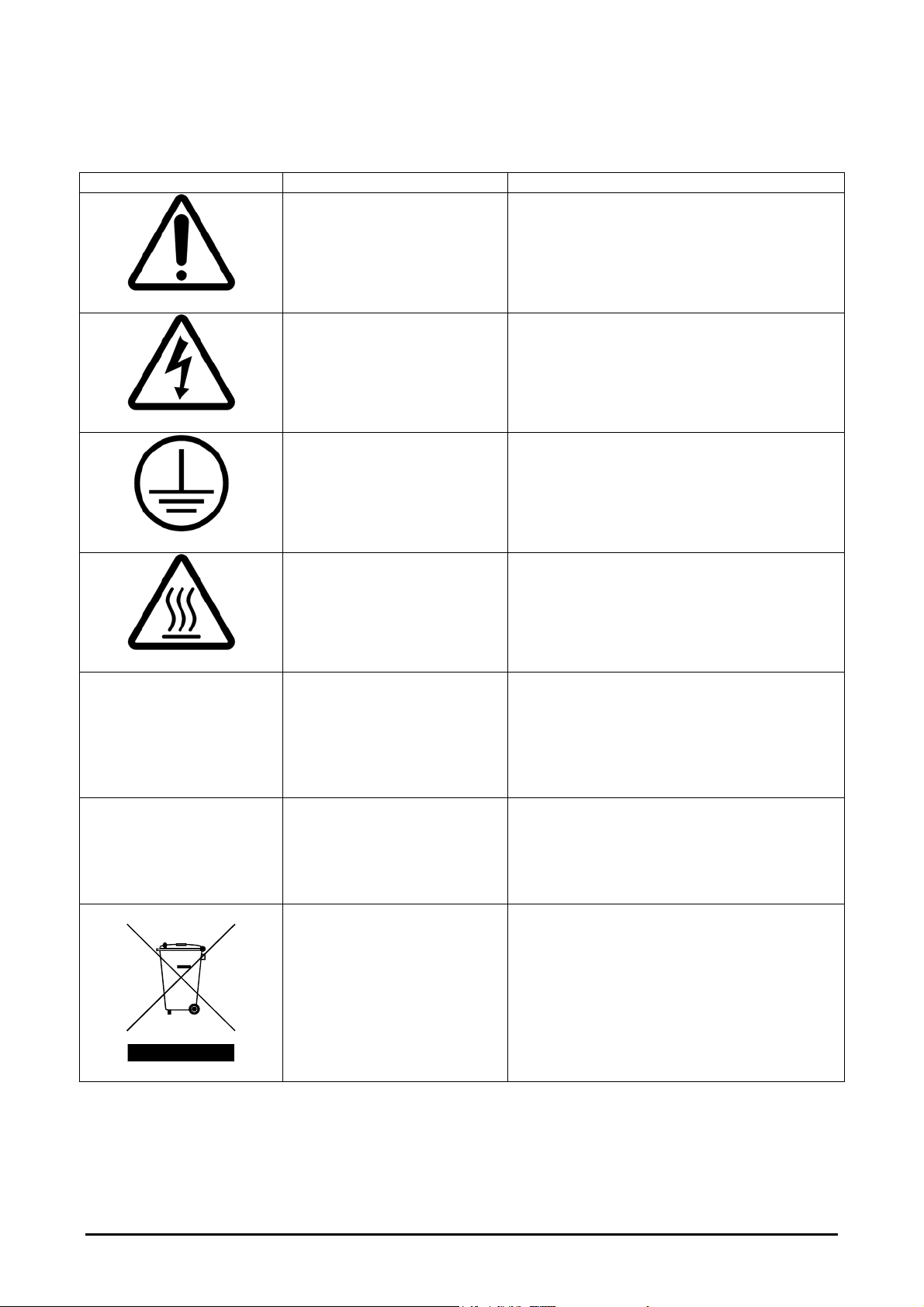

1.1.6. Symbols used.............................................................................................................. 8

2. Transport, Handling, Storage..................................................................................................... 9

2.1. Storage ............................................................................................................................... 9

2.2. Dimensions......................................................................................................................... 9

2.3. Handling ........................................................................................................................... 10

3. Installation & Commissioning................................................................................................... 11

3.1. Fixing / anchoring ............................................................................................................. 11

3.1.1. Freestanding applications ......................................................................................... 11

3.1.2. Fitment of optional feet.............................................................................................. 12

3.1.3. Permanent Mounting ................................................................................................. 13

3.2. Space needed for use and maintenance.......................................................................... 14

3.3. Environmental conditions ................................................................................................. 15

3.3.1. Temperature.............................................................................................................. 15

3.3.2. Humidity .................................................................................................................... 15

3.3.3. Altitude ...................................................................................................................... 15

3.3.4. Contaminants ............................................................................................................ 15

3.3.5. Vibration, shock and bump........................................................................................ 15

3.3.6. Electromagnetic compatibility.................................................................................... 15

3.4. Connection to power supply ............................................................................................. 16

3.4.1. Essential electrical installation data........................................................................... 16

3.4.2. Residual current devices ........................................................................................... 16

3.5. General recommendations ............................................................................................... 17

3.5.1. Installation ................................................................................................................. 17

3.5.2. Modifications ............................................................................................................. 17

3.5.3. Markings and tamper evident seals........................................................................... 17

3.5.4. Location of equipment ............................................................................................... 17

3.6. Waste removal & disposal ................................................................................................ 18

4. Product information.................................................................................................................. 19

4.1. Description of the

e

-Brick ............................................................................................... 19

4.2. Applications ...................................................................................................................... 19

4.3. Prohibited usages............................................................................................................. 19

4.4. Safety features .................................................................................................................19

4.4.1. Internal fuses............................................................................................................. 19

4.4.2. Indicators................................................................................................................... 20

4.4.3. System Emergency stop ........................................................................................... 20

4.4.4. Contactor................................................................................................................... 20

4.4.5. Temperature & cooling .............................................................................................. 20

4.4.6. Output protection....................................................................................................... 20

4.5. General Data ....................................................................................................................21

4.5.1. Electrical supply ........................................................................................................ 21

4.5.2. Performance Ratings................................................................................................. 21

4.5.3. Noise & Vibration....................................................................................................... 21

4.5.4. Radiation ................................................................................................................... 22

4.5.5. Gases, Vapours, Dust ............................................................................................... 22

4.6. Electrical Data .................................................................................................................. 22

4.6.1. Block diagram............................................................................................................ 22

4.6.2. Interface details ......................................................................................................... 23

4.6.3. SELV ports ................................................................................................................ 25

GEW UV

e

-Brick installation and operating manual 2 of 49