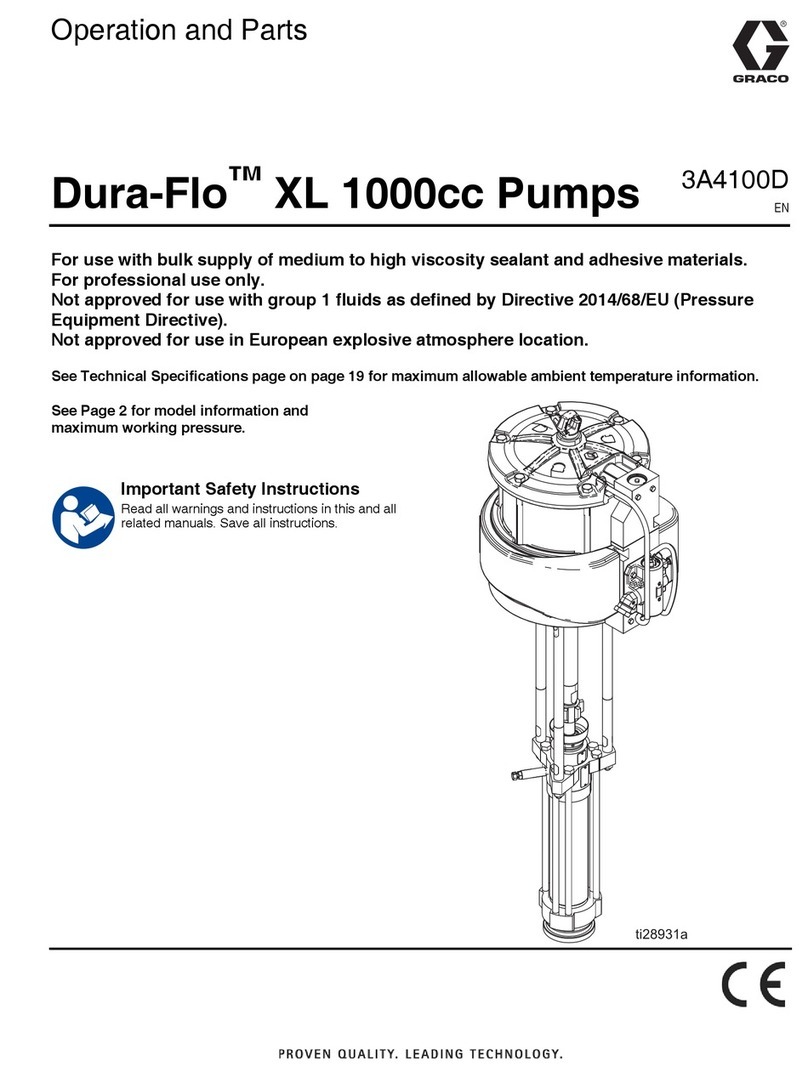

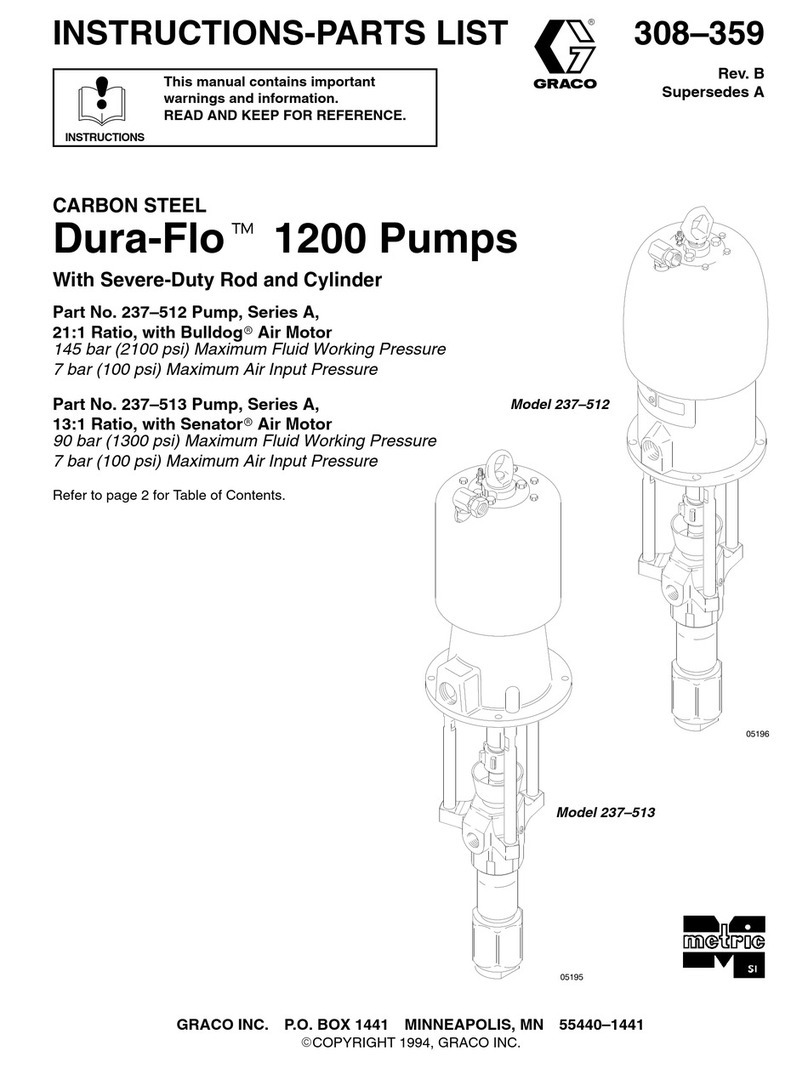

DiamaPro Systems DP-PUMP10GAL User manual

OWNER’S MANUAL

DUAL PUMP

DUAL COMPONENT POLYMER PUMP

INSTRUCTION MANUAL

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE

INTRODUCTION

This manual outlines the maintenance and

operation of the Dual Component Polymer

Pump.

This is a professional tool and is intended

for use by trained and experienced opera-

tors.

To get maximum benefi t from your tool and

to ensure maximum safety, be sure to read

this manualthoroughly. You should also

periodically review safety instructions.

Operators and maintenance personnel

must always comply with the following

safety precautions. These precautions are

given here for your safety. Review them

carefully before operating the tool and

before performing general maintenance

repairs on the tool. Supervising personnel

should develop additional precautions

relating to the specifi c work area and local

safety regulations.

SAFETY PRECAUTIONS

• Read, understand, and follow all safety,

transportation, and storage recom-

mendations on the Material Safety and

Data Sheets of the material that will be

dispensed.

• Keep hands, fi ngers, and clothing free

from all moving parts including gears,

chains, and other moving parts while

operating the pump.

• Never run the pump without the gear/

chain guard in place.

• Disconnect power supply before servicing

the gear/chain or changing gears.

• Disconnect power supply before opening

or servicing the electrical components.

• Make sure there is adequate ventilation if

a gas powered generator is being used

to supply power.

• Secure the pump before transporting.

• Always use the same tanks (A or B) for

the same material to minimize risk of ma-

terial hardening inside of the tank, pump,

hoses, and other parts.

Key Elements:

1. Clean tanks, pumps, lines, and manifold

2. No cross contamination

3. Proper mixing ratio = proper material

cure

Prior to use:

1. Inspect tanks for evidence of loose parti-

cles or debris.

2. Inspect manifold (located at the end of

the dispensing wand where both hoses

attach. The static mixing element attach-

es to the manifold with a 7/8” static mixer

nut) - Inspection should be performed at

the start of each day’s work and consists

of the following:

a. Remove hoses connected to manifold

and remove 90 degree fi tting.

b. Inspect for and remove any debris or

contamination that might clog the exit

hole. A 1/4” drill bit can generally be used

to clean the exit hole.

c. Reconnect lines to manifold.

3. If hydraulic fl uid remains in the tank

(used for fl ushing and pump storage and

should be left at least a couple inches

deep in the tanks when not in use) plug

in power supply and trigger applicator

gun to dispense fl uid.

a. Watch fl uid fl ow out of manifold and

inspect for clog or uneven fl ow.

b. Using graduated measuring cups, dis-

pense fl uid into containers to check for

proper ratio.

4. After confi rming ratio is correct and that

no contamination remains in the lines

or in the manifold, dispense remaining

hydraulic fl uid to empty the tanks.

5. The unit is now ready for use.

Dispensing Filler:

1. Prior to fi ling tanks, premix the Part A

Polyol (gray component).

2. Ensure that Part A material is placed in

Part A tank and Part B material is placed

in Part B tank. DO NOT CROSS CON-

TAMINATE. It is advised to keep the lid

on the tank that is not being fi lled.

3. After fi lling tanks, dispense polyurea

through manifold assembly watching

fl ow. An errant stream out of one or

both sides of the manifold will generally

indicate that there is a restriction in the

manifold and disassembly and cleaning

should be performed.

4. If fl ow is even and equal, attach static

mixing tip to end of manifold.

5. Dispense a small amount of material

through the tip into waste container to

ensure thorough mixing in the tip. Then

dispense small amount of material onto

cardboard or other disposable sheet

to monitor cure. Allow to set for 10-15

minutes or until signifi cant cure has been

achieved prior to commencing. This will

ensure proper ratio and cure of future

material.

6. While waiting on test material to cure,

remove static mixing tip and discard.

7. Pump grease (white lithium supplied with

pump) into fi ttings on manifold to prevent

cross contamination.

8. Upon confi rmation of test sample cure,

install new static mixing tip.

9. Install fi ller into joint of crack per product

installation guidelines.

Work Interruption:

1. If work is stopped for short term (5 min-

utes or so, to move pump, etc.) periodi-

cally trigger applicator wand to dispense

material every 30-45 seconds to ensure

material in static mixing tip does not set.

2. If dispensing is stopped for longer term

(lunch break, etc.) remove static mixing

tip and discard. Pump Grease into fi ttings

on the manifold as described above.

Upon commencement, re-install a new

static mixing tip.

End of Day:

1. If possible, stop material placement

when tanks are “nearly” empty (material

is down to within a couple of inches of

the tank bottom). DO NOT RUN tanks

dry of polyurea or improper ratio and

cure may result if one tank empties

slightly ahead of the other.

2. In case material is run to the bottom of

the tank, remove static mixing tip and

dispense remaining material into a waste

container until tanks are empty and line

sputters at the static tip.

a. Fill both tanks with hydraulic fl uid to ap-

proximately 3 inches from the bottom.

b. Dispense hydraulic fl uid to purge the

pumps and lines. Ensure some fl uid

remains in the tanks once complete.

c. Grease the fi ttings on the manifold and

secure for next use.

3. In case several inches of polyurea

remains in the tank at day’s end AND,

pump will be used to place additional

joint fi ller the following day, it can be pos-

sible to leave the material in the machine

overnight using the following procedure.

NOTE: Do not leave polyurea in the

tanks or within the system (tanks, pumps,

lines, manifold) if material placement will

not be performed the following day.

SET-UP AND OPERATION

SPECIFICATIONS

SAFETY

Part No. DP-PUMP10GAL

Capacity: 2-6.5 Gallon Tanks

Electrical Requirements: 120V

Motor: 1/2 HP

Weight: 220 lbs

SET-UP (cont.)

a. Remove static mixing tip.

b. Grease the fi ttings on the manifold and-

secure for next use.

c. Fill Iso side tank (Part B for Metzger/

McGuire joint fi llers, amber colored side)

with Iso product to within a couple inches

of the top of the tank.

d. Press a new clean plastic bag, or similar

plastic sheeting, over tank and into top

of product lapping excess plastic over

the top sides of the tank. By doing this,

excess air potentially containing moisture

or humidity is forced away from the top of

the polyurea Iso component.

e. Place tank lid over plastic sheeting and

secure.

f. At next use, a thorough evaluation must

be done as indicated in the “Prior to Use”

section to ensure no cross contamination

exists in the manifold.

Next Day Use:

1. It is always advisable to re-check the

manifold fi rst by removing the check ball

assembly and inspecting for clogs and

also re-checking ratio by dispensing a

small amount of material into graduated

plastic containers.

2. Before use, cure test should be per-

formed by dispensing through the static

mixer onto a cardboard or plastic sheet

and monitored for 10-15 minutes to con-

fi rm cure prior to commencement of fi ller

placement.

3. Follow instructions outlined above under

“Prior to Use” and “Dispensing Filler”.

End of Project:

1. Dispense all remaining polyurea into

waste container.

2. Once polyurea has been dispensed,

partially fi ll each tank with hydraulic fl uid

and run through the machine to ensure

pumps and lines have been purged.

3. Grease fi ttings on the manifold.

4. Wrap mixing manifold with plastic or

shrink wrap tightly sealing end and pre-

venting moisture exposure and absorp-

tion into manifold.

5. Package up for storage.

Problems During Dispensing

Polyurea Joint Filler:

1. Material fl owing slowly:

A. May occur when material temperature

is cool and in the case of cooler/freezer

environments. Preheat material and/

or store outside of cooler/freezer area.

For freezer installations, tank heaters

should be used to maintain a “pump-

able” viscosity.

B. May occur if static mixing manifold has

buildup or restriction in the outlet orifi ce.

Remove pump lines from the manifold,

remove fi ttings,

plastic washer, check ball, and spring

and ensure no buildup or restriction is

present. Inspect outlet orifi ce for restric-

tion and drill out if buildup is present.

C. May occur if mixed material begins to

“gel” inside of the static mixing element

(tip). This typically will occur when

jumping from joint to joint allowing

mixed product to set inside the plastic

mixer without purging. Purging the

static mixing element should be done

approximately every 45 seconds with

most M/M products.

2. Material STOPS fl owing:

A. Check main power supply to ensure

voltage is entering the speed con-

trol unit. Inside the control box cover

located on the face of the circuit board

a GREEN LED light should be illumi-

nated when proper voltage is present. If

indicator light is off (switch is on), check

main power supply cord to ensure

power is being supplied to the control

box. Correct if necessary. If control box

is receiving power and the light on the

front is OFF, check 12A ceramic fuse

behind the control box cover (left side of

electrical panel). Replace if necessary.

B. If control box is receiving power and the

LED light on the circuit board is ON,

check 8A MDL (slow burn) fuse behind

the control box cover (right side of

electrical panel). DISCONNECT POW-

ER before removing or testing fuses!

Replace if necessary. Burnt 8A MDL

fuses will be the primary cause for NO

FLOW situations and will typically occur

when the motor is being placed under

excess strain. Most common to occur

when dispensing in cold environments

or freezer/cooler installations.

C. If control box fuses are not “blown”,

check trigger switch mechanism on dis-

pensing wand. A trigger switch malfunc-

tion is not common, but does occur from

time to time. In this instance, the green

LED light will be illuminated indicating

the circuit board is receiving power.

3. Material does not cure or cures “soft”:

A. Always test cure of previously placed

materials as you move from section to

section. Most M/M polyurea products,

even in freezer environments, should

reach signifi cant cure within 1 hour.

B. ALWAYS confi rm that the proper pump

pulleys or sprockets are being used.

Equal sized pulleys/sprockets for 1:1

ratio.

C. If uncured or soft cure is found, an off

ratio mixture is most always caused

by a restriction or buildup inside of

the mixing manifold. Disconnect lines,

inspect and clean mixing manifold. Prior

to reassembly, test material fl ow and

ratio check directly from the pump lines.

After confi rming proper ratio from the

lines, connect mixing manifold, attach

static mixing element and dispense test

material to monitor for full cure.

D. If OFF ratio dispensing is found when

testing directly from the pump lines

(without the manifold attached), check

each hose line for contamination or

restriction. Ultimately, it will be VERY

diffi cult to visually fi nd a restriction

inside the hose line. Generally, hose

lines should be replaced before starting

a project.

E. If hose lines are clear, buildup or re-

striction will likely be within one or both

pump units. Disassemble, clean thor-

oughly, and reassemble. Attach hose

lines and test fl ow ratio.

TROUBLESHOOTING

SET-UP (cont.)

www.diamaprosystems.com | (404) 834-1162

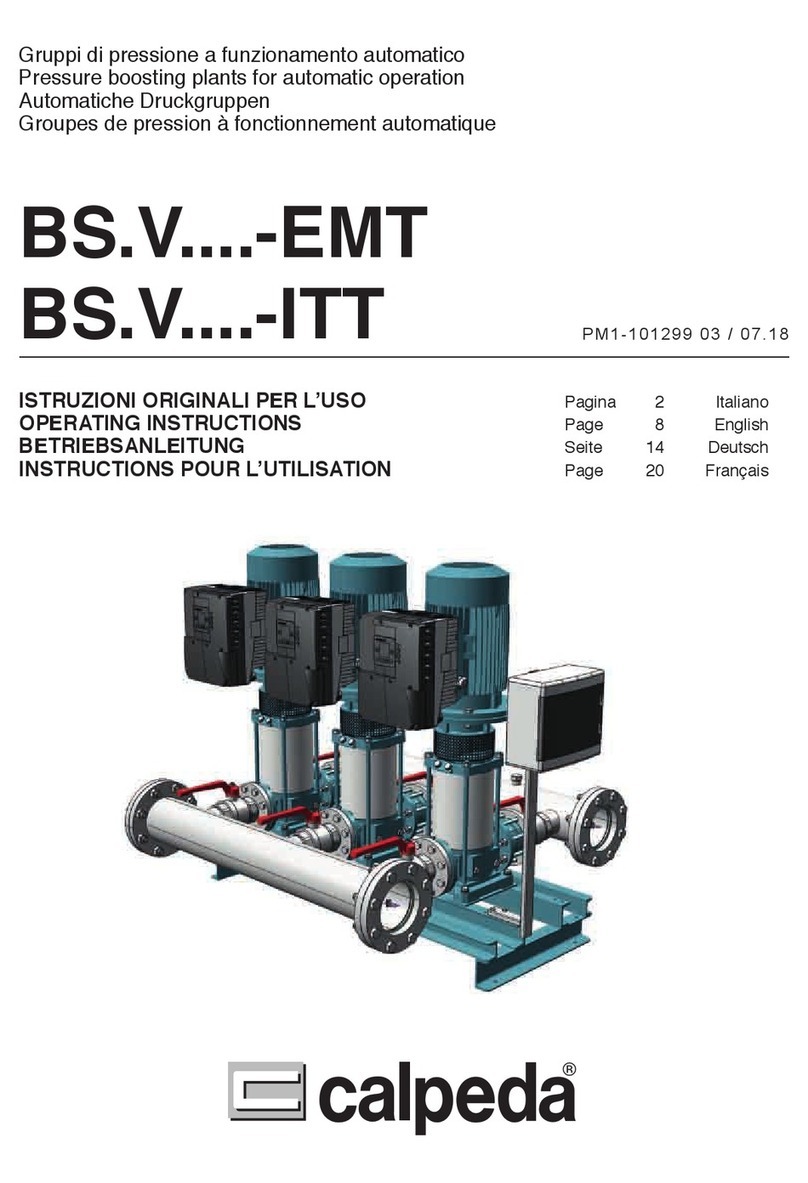

Popular Water Pump manuals by other brands

Lincoln industrial

Lincoln industrial 84960 owner's manual

DigiCare

DigiCare IP41 Series Operator's manual

TOHATSU

TOHATSU VE 1500 owner's manual

Xylem

Xylem GOULDS NPO instruction manual

Gude

Gude GS 4002 P Translation of the original instructions

Grundfos

Grundfos SmartFlo Installation and operating instructions