Diamond Dust CW Kit User manual

Diamond Dust CW Kit

_________________ ASSEMBLY MANUAL ________________

Specifications

Wingspan: ……………… 29.75 in (755.65mm)

Length: .…………………. 24.50 in (622.30mm)

Wing A ea: ……….……. 468 sq in (30.19 sq dm)

Weight: ………………… 2.25 – 3.0lbs (1020g–1360g)

Engine size: ………………… .25 - .40 2 cycle

Wing Loading …………………… 12oz/SF

Radio: ………………… 4-channel w/3 se vos

2

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents of Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Radio and Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Additional Required Tools and Adhesives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 1: Framing of the Airframe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 2: Elevon Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 3: Vertical Fin Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 4: Installing the Control Horns and Elevon Linkage. . . . . . . . . . . . . . . . . . . . . .

Section 5: Equipment Placement and Pre-Balancing. . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 6: Covering the Aircraft. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 7: Fuel Tank Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 8: Final Equipment Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 9: Final Inspection / Control Throws. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 10: Balancing the Diamond Dust. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 11: Pre-Flight & At the Flying Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

4

5

6

7

8

33

37

40

44

45

50

51

54

55

56

3

Introduction

Thank you for purchasing the Diamond Dust Clipped Wing Kit high performance delta wing

aircraft. Backed by Diamond Dust’s high quality reputation, the Diamond Dust CW will

provide you with the superior performance and features you are looking for in a high speed

high performance aircraft. The Diamond Dust CW features lightweight balsa, composite

tubes, and light-ply construction. This lightly loaded delta wing design makes it ideal for

extremely aggressive maneuvers as well as excellent low speed maneuverability.

Before Starting Assembly

Before beginning the assembly of your Diamond Dust CW, remove each part from the box

and the parts bag for inspection. Closely inspect the wood pieces and parts bag for damage.

If you find any damaged or missing parts, contact the place of purchase.

Using the Manual

This manual is divided into sections to help make assembly easier to understand and to

provide breaks between each major section. Remember to take your time, and follow the

directions closely. You can also check on the Diamond Dust RC website for any updates to

this manual at www.diamonddustrc.com.

Also there are a number of steps in the assembly of the Diamond Dust and Diamond Dust

Clipped Wing version that are identical. For practicality and efficiency reasons, some pictures

in this manual may show the Stock Diamond Dust in the illustrations. This should not be a

problem since the majority of the steps are identical for both aircraft. If you have any

questions, please don’t hesitate to contact our tech support line at (352-871-7301)

Monday through Friday, between the hours of 8am to 6pm EST.

4

Warranty Information

Tetracam, Inc. and Diamond Dust RC, guarantees this kit to be free from defects in both

material and workmanship at the date of purchase. This warranty does not cover any

component parts damaged by use or modification. In no case shall the liability to Tetracam,

Inc. exceed the original cost of the purchased kit. Further, Tetracam, Inc. reserves the right

to change or modify this warranty without notice.

In that Tetracam, Inc. and Diamond Dust RC have no control over the final assembly or

materials used for the final assembly, no liability shall be assumed nor accepted for any

damage resulting from the

use of the final assembled product . By the act of using the assembled product, the user

accepts all resulting liability. Please note that once assembly of the model has been

started, you must contact Tetracam, Inc. directly regarding any warranty questions. Please

do not contact your local hobby shop regarding warranty issues, even if that is where you

purchased it. This will enable Tetracam, Inc. to better answer your questions and service you

in the event that you may need any assistance. If the buyer is not prepared to accept the

liability associated with the use of this product, the buyer is advised to return this

kit immediately in new and unused condition to the place of purchase.

Warning

An RC aircraft is not a toy! If misused, it can cause serious bodily harm and damage to

property. Fly only in open areas, perferably at AMA (Academy of Model Aeronautics)

approved flying sites, following all instructions included with your radio and equipment.

Tetracam, Inc

Devonshire St.

Suite 310

Chatsworth, CA 91311

Sales - (818) 718 -2119

Tech Support – (352) 871-7301

www.tetracam.com

5

Contents of Kit – Diamond Dust CW

Main Box

Qty Description

1 Assembly manual

1 Blueprint / Plan

2 14 ¼” Main wing spars (Front &

Rear)

2 Rear main spar extenders Tubes

(.300” x 6-3/4)

2 Approximately 23” Leading Edge

tubes (.300” O.D.)

2 Root ribs (#1 Ribs)

2 Mid wing ribs (#2 Ribs)

2 Tip ribs (#3 Ribs)

1 1/16” Balsa partial rib

1 1/8” Plywood engine mount

1 1/8” Plywood engine mount doubler

1 1/8” x 3-7/8” x 1-3/4” Plywood switch

plate

2 Balsa Wing tips (Precut 1/4”x1-1/2”

elevon stock)

2 Elevon stock (1 ½” x 3/8” )

6 ½” x 1/16” x 36” Balsa cap strips

8 4” x 4-5/8” x 1/16” Balsa sheets

1 4/ x 4-5/8” x 1/16” Balsa sheet with

precut slots.

2 1/8” precut vertical fin (front half)

2 1/8” precut vertical fin (rear half)

1 ¼” x 3/8” Balsa trailing edge

stock

3 ¼” x ¼” x 36” Balsa triangle stock

1 1/16” x 1-3/4” x 4” Balsa fuel tank

compartment rear bulkhead

1 3/16” Antenna tube 36”

1 1/32” antenna pull tube 36”

1 Diamond Dust CW decal

2 4-40 Pushrods

1 2-56 Pushrod

2 Composite pushrod stiffener tubes

Qty Description

2 1/8” x 1/8” Bass wood coving stock

(For Leading Edge)

1 6oz Fuel tank with hardware

2 .005” Carbon fiber Strip (1/4”x34”)

Hardware Bag

Qty Description

1 1/8” x ¾” x 3-7/8” Plywood firewall

2 ¼” x ¼” x 4-3/8” Hardwood servo rails

2 ¼” x ¼” x 7/8” Hardwood servo rails

4 1/8” x 1/8” x 4” balsa fin offset spacer/

Fin cap strip.

4 1/8” x ¼” x ½” Plywood spar end / rib

locking tabs

4 1/8”thick 1 ¼” x 1 ¼” Triangle gusset

1 Spool Kevlar thread

10 CA Hinges

11 #19 Rubber bands

2 HD Control horns with base plate

2 4-40 Ball links

2 #4 Ball Link bushing

1 2-56 Nylon clevis

1 1” wide x 15’ roll of Solartex

8 4-40 x 1” Socket head cap screw

2 4-40 x 5/8” Socket head cap screw

2 4-40 Nylon insert locknut

1 Velcro strip

6

equired adio and Engine

Radio Equipment

•4-channel radio system (minimum)

•2 High torque digital servos (JR9411

recommended or equivalent)

•1 HS 85MG or equivalent mini servo

Engine / Power System

Any .25 to .40 two stroke RC engine

(Recommended Items)

SERVOS

Throttle:

JR: 331Micro or 3121 Mini

Hitec: HS-85MG Mini servo

Elevon .28 and under:

JR: DS537

Hitec: HS475

Elevon .30and above:

JR: DS9411 or DS8611A

Hitec:

HS-7985MG

NOTE: Since there are so many servo choices

available, please compare and match as

closely as possible, the specifications of the

above mentioned servos with the servos you

intend to use

7

Additional equired Tools and Adhesives

Tools

•Drill

•Drill bits: 1/16”,3/32”, 7/64”, 1/8”

•Hobby Knife

•Razor saw or hacksaw

•#2 Phillips Screwdriver

•120 or 240 grit sandpaper

•Sanding Block or Permagrit File

•Scissors

•3/32” hex driver or Allen wrench

•Pliers

•Ruler or measuring tape

•Speed square or small square

•Soldering Iron

•Heat Gun

•Covering Iron

•Pencil

Adhesives

•Thin CA Glue (Cyanoacrylate)

•Thick CA Glue (Cyanoacrylate)

•CA Accelerator

•CA Remover / Debonder

•Stix-It Covering Adhesive

Other Required Items

•Wax paper or Parchment paper

•Foam pad or rubber pad for fuel tank

•Epoxy Brushes

8

Section 1: Framing of the Airframe

Step 1

Locate all parts listed in materials list, and

take inventory of all parts. This will help you

familiarize yourself with the various

components.

Lay your print out on large flat surface ( the

larger and flatter the better). Cover your

plans with either parchment paper or wax

paper and tape them down to secure to your

work surface.

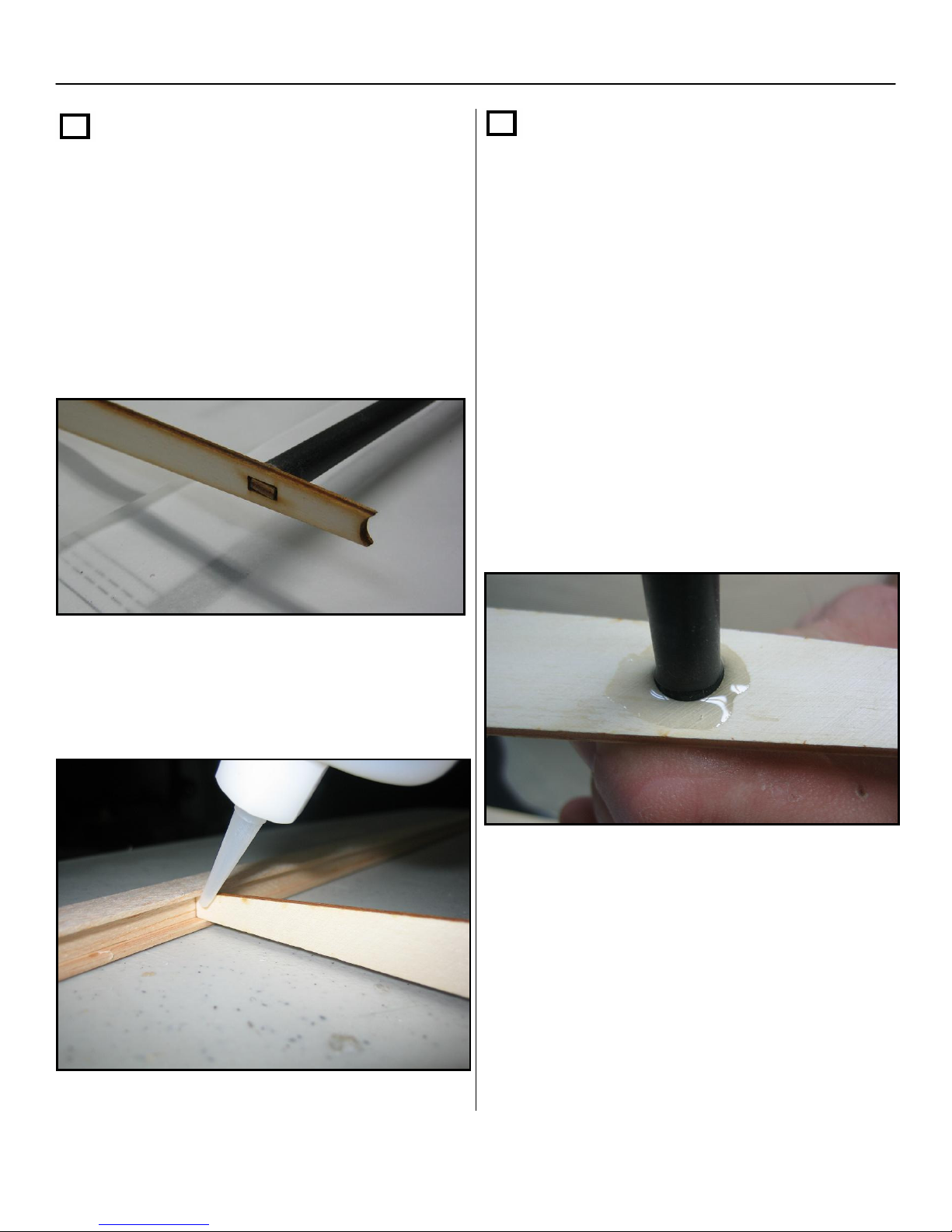

Step 2

Assemble the rear spar by locating the tubes

labeled “Rear Spar” and “Spar extenders”.

Insert the spar extenders into each end of the

rear spar. You may have to lightly sand the

spar extenders so that they go into the rear

spar with a moderate amount of force, but

first try the opposite end of the spar extender

tube to see which end fits the best.

9

Section 1: Framing of the Airframe – Cont.

Step 3

Lay the assembled spar on the print to see

how far the tubes should fit into one another.

Adjust both sides so the center main spar is

centered on the print and the end tubes

extend to the correct length shown on the

print (be as precise as possible when

matching the print through all the steps).

When the rear spar matches the print (tube

engagement and overall length), apply a drop

of thin C.A. on each joint.

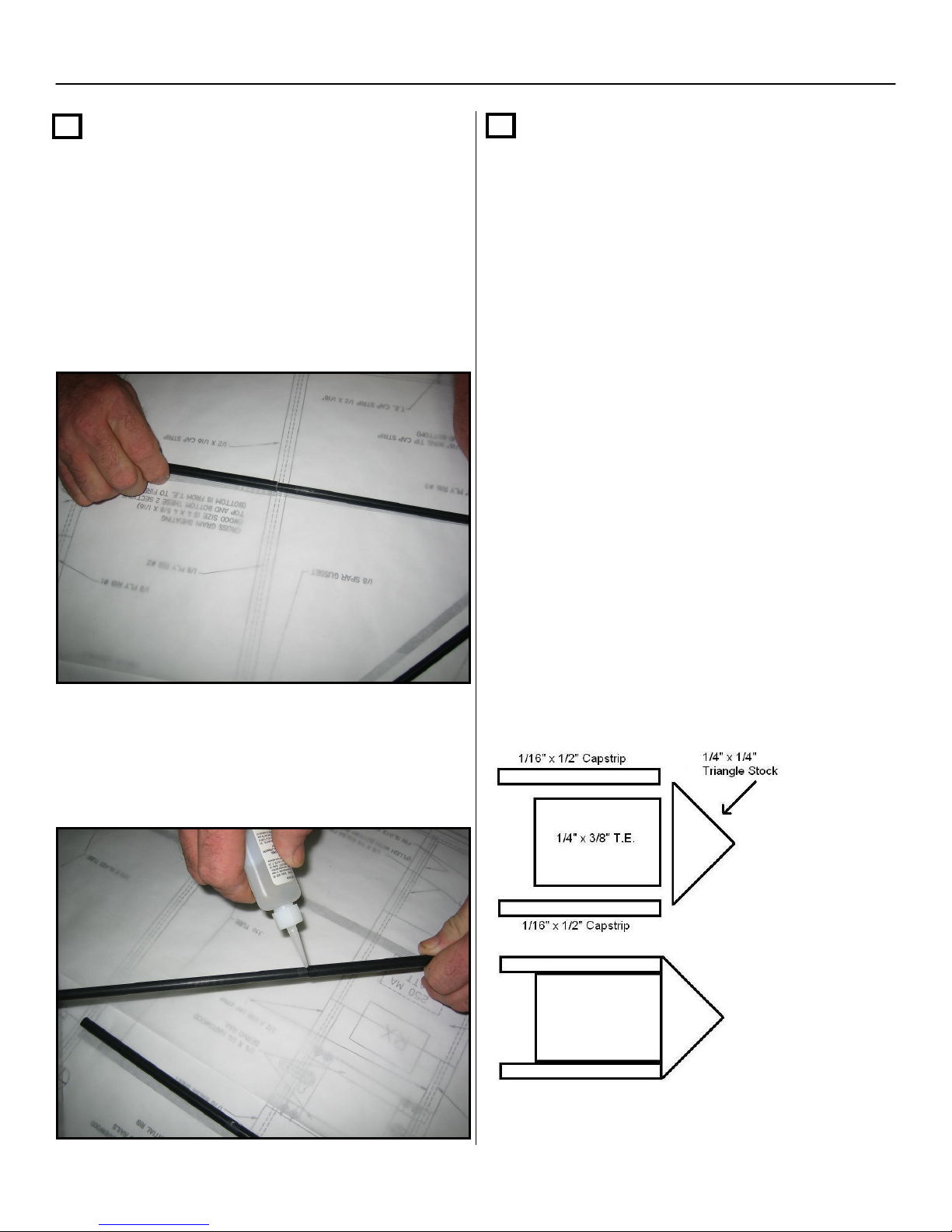

Step 4

Find the ¼” x 3/8” x 36” balsa stick trailing

edge (T.E) and cut it the same length as

shown on the plan.

Find one of the ¼” x ¼” x 36” triangle stock,

and also cut it to match the trailing edge you

just cut. Center the triangle stock on the ¼”

side of the ¼” x 3/8” T.E. Glue the triangle

stock to the ¼” side with thick CA.

Next, find two 1/16” x ½” cap strips that seem

to be the stiffest from the wood supplied with

the kit. Cut them to match the length shown

on the plans.

NOTE: Do not glue the T.E. cap strips

beyond the #2 ribs until the wing tips are

installed in step #16.

Examine the drawing below to ensure proper

assembly of the T.E assembly.

When you are done assembling the T.E.,

set it aside until step 10.

10

Section 1: Framing of the Airframe – Cont.

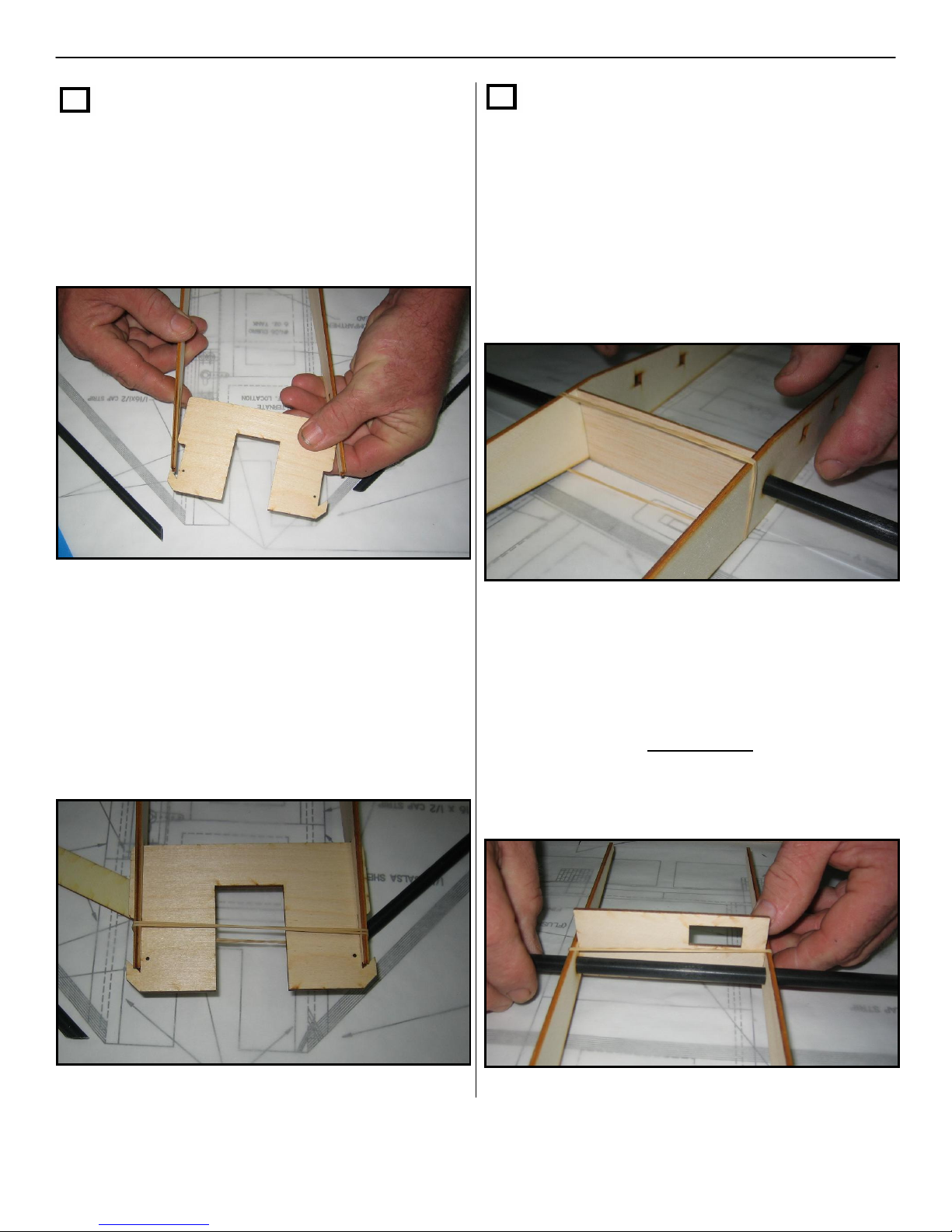

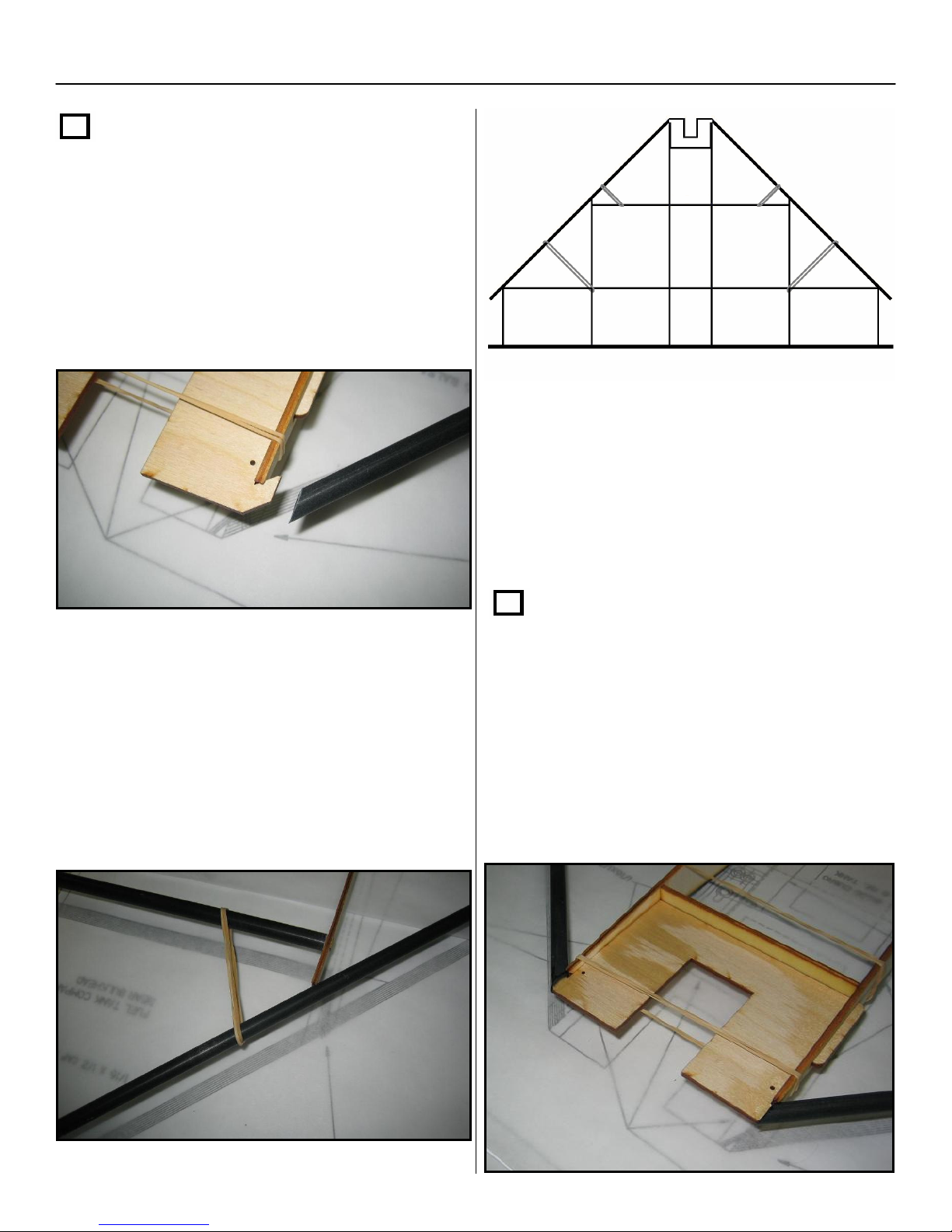

Step 5

Take the two center ribs (rib #1) and locate

the square 1/4 x 1/4 servo rail holes. Note:

the square holes are closest to the top

side of the airfoil.

Next, hand slide the front and rear spars

onto the center ribs (#1 ribs). Align the ribs

and position them as shown on the print.

Do not glue anything yet!!!

Step 6

Install one #19 rubber band (included) over

each rear spar half and one rubber band

over each forward spar half, as shown

below. Note: you will need to double turn

the rubber bands that go over the forward

spar halves.

Next, slide the #2 ribs over the rear spar.

Add one more rubber band to each side of

the rear spar and one diagonally around the

rear spar and rib #2, as shown below.

Section 1: Framing of the Airframe – Cont.

11

Step 7

Place the engine mount in between the two

#1 ribs. You will first have to insert the front

part of the #1 ribs into the front part of the

mount in order to clear the leading edge

locking tabs.

Next, temporarily secure the mount into

position by using one #19 rubber band

around it and the #1 ribs

.

You will have to

double the turns on the rubber band in order

to achieve a strong hold

Step 8

Take the 1/16” x 1-3/4” x 4” balsa fuel tank

c

ompartment rear bulkhead

and lay it

vertically against the front of the front spar

between the #1 ribs. Place a #19 rubber

band around the ribs to secure the bulkhead

as a spacer. You may have to double the

turns on the rubber band in order to achieve

a strong hold. Do not glue yet!!!

Next take the 1/8” x 3-7/8” x 1-3/4” plywood

switch plate and place it vertically on the

rear spar between the #1 ribs. Place a large

rubber band around the ribs to secure the

switch plate as a temporary spacer.

NOTE: Do not glue this plate to the ribs

or rear spar !!!

12

Section 1: Framing of the Airframe – Cont.

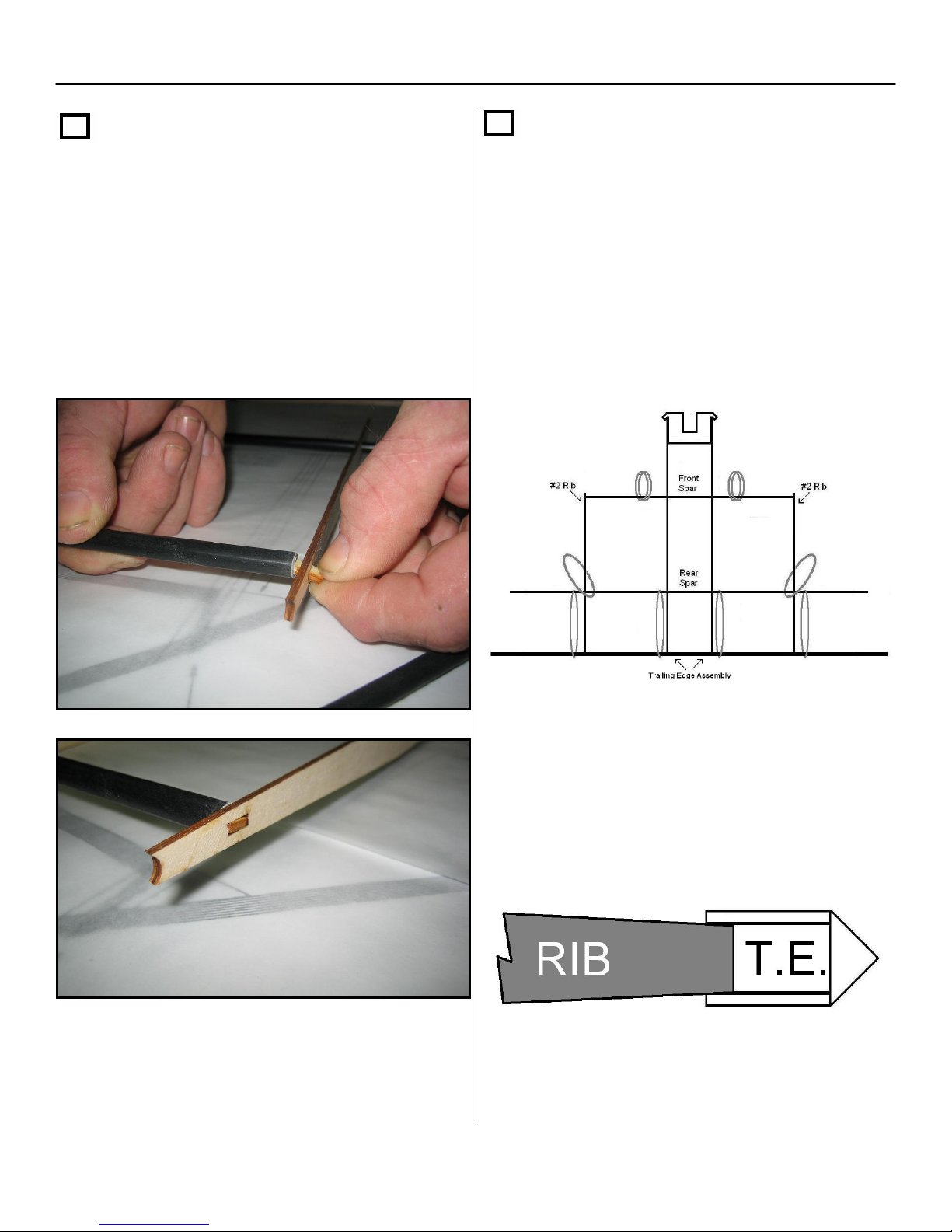

Step 9

Center the forward spar with the alignment

hole in the #2 rib (centered top and bottom),

and insert one of the 1/8” x ¼” x ½”

plywood spar end / rib locking tabs through

the rib and into the spar. Put a few drops of

thin CA where it is connected. Repeat on

the opposite side.

Step 10

Take the trailing edge assembly from step 4

of this section and slide it through the four

#19 rubber bands that are on the rear spar.

Place the rubber bands so they are

alongside the #1 ribs and on both sides of

the #2 ribs, as shown below. Line up all

spars and ribs to match the print as

precisely as possible.

When in place, put a drop of thin CA at

each rib to tack in place.

Note: the trailing edge of the ribs should

self center in between the 1/16” cap strips

on the T.E assembly.

13

Section 1: Framing of the Airframe – Cont.

Step 11

Square up and center the #3 rib on the T.E

and the rear spar extender. Next, insert the

wood tab through the #3 rib into the rear

spar extender. When everything is aligned

and square, first glue with thin CA and then

with thick CA. Repeat this step for the

opposite side.

Make sure that everything lines up on the

print and finish gluing all ribs to the trailing

edge.

Step 12

NOTE: be careful not to glue the

temporary spacers at the spars or the

rubber bands.

Make sure the fuel tank compartment rear

bulkhead is square and then first glue with

thin CA then with thick CA.

Next, glue the main ribs to both the forward

and rear spars first using thin CA, then fill in

around the spars with thick CA.

You can now cut the four rubber bands that

hold the T.E. assembly. Keep the remaining

rubber bands on the airframe, since you will

need these to install the leading edges of the

aircraft.

14

Section 1: Framing of the Airframe – Cont.

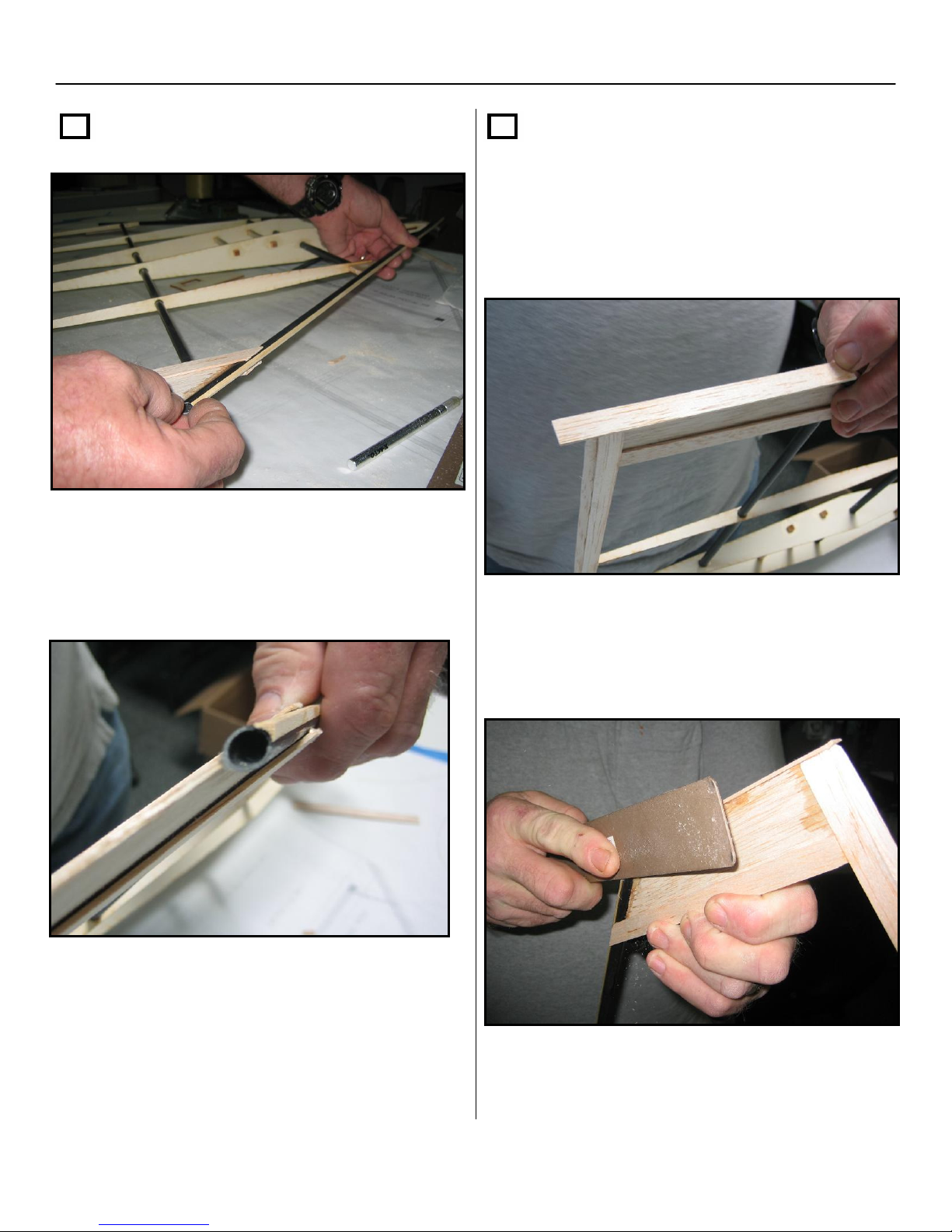

Step 13

Next you will be installing the leading edges

on the airframe. Find the two tubes labeled

“L.E. Tubes” and slide each one through the

double rubber bands attached to the forward

spar halves. Make sure the 45 degree cuts

are facing the motor mount.

Insert the L.E. tube into the angled motor

mount tabs and rest the tube on both the #2

and #3 ribs.

Note you may have to slide the rubber band

back in order to increase the tension

between the L.E. and the front spar.

Once you have both leading edges aligned

and sitting on both the #2 and #3 ribs, place

a drop of thick CA on both sides of the #2

and #3 ribs at the leading edge. The square

end of the L.E. tube will extend beyond the

wing tips. Leave this extra length for now.

Step 14

Next, Locate the

1/8” x ¾” x 3-7/8”

plywood firewall and center it between the

#1 ribs and the motor mount plate. Apply

glue

on both sides, where the firewall

intersects the #1 ribs and where it touches

the motor mount, with both thin and then

thick CA. Then, cut the rubber bands holding

the motor mount.

15

Section 1: Framing of the Airframe – Cont.

Step 15

Locate the triangle gussets from the parts

bag. The first ones are installed behind the

leading edge at the motor mount. Glue

them in with thick CA in the location shown

on the plans.

Note: the forward gusset should be

installed underneath the protruding tab from

the motor mount while the airframe is in the

upright position.

Next glue the triangle gussets, that are

positioned behind the L.E. and on the outside

of the #2 ribs, with thick CA.

NOTE: make sure you glue both the top

and bottom sides of gussets where they

connect to the leading edge and ribs.

Now add the motor mount doubler plate to

the bottom of the motor mount. Glue in using

thick CA all around the bottom of the motor

mount and clamp tight until the glue dries.

16

Section 1: Framing of the Airframe – Cont.

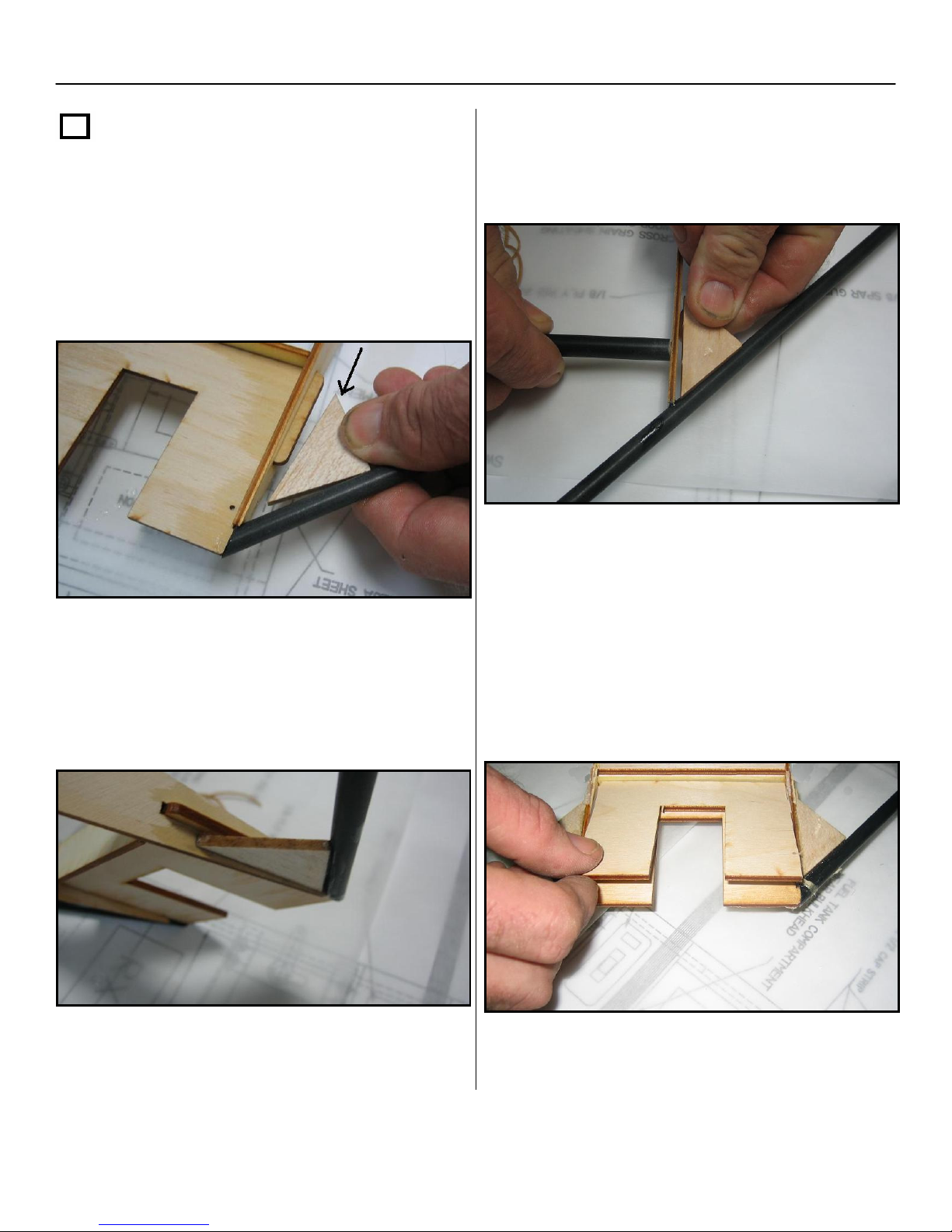

Step 16

Locate the two p

recut 1/4”x1-

1/2” elevon

stock / balsa wing tips, with

the 38 degree

angle on one end, and place the square end

between the TE cap strips with the 38

degree angle cupped into the rear side of

the leading edge on the outside of rib #3.

Glue in place first with thin CA and then add

thick CA where the balsa meets the

backside of the L.E. Repeat this step for

both sides. NOTE: Do not glue the 1/16 x

½ “cap strips on the trailing edge

assembly yet!

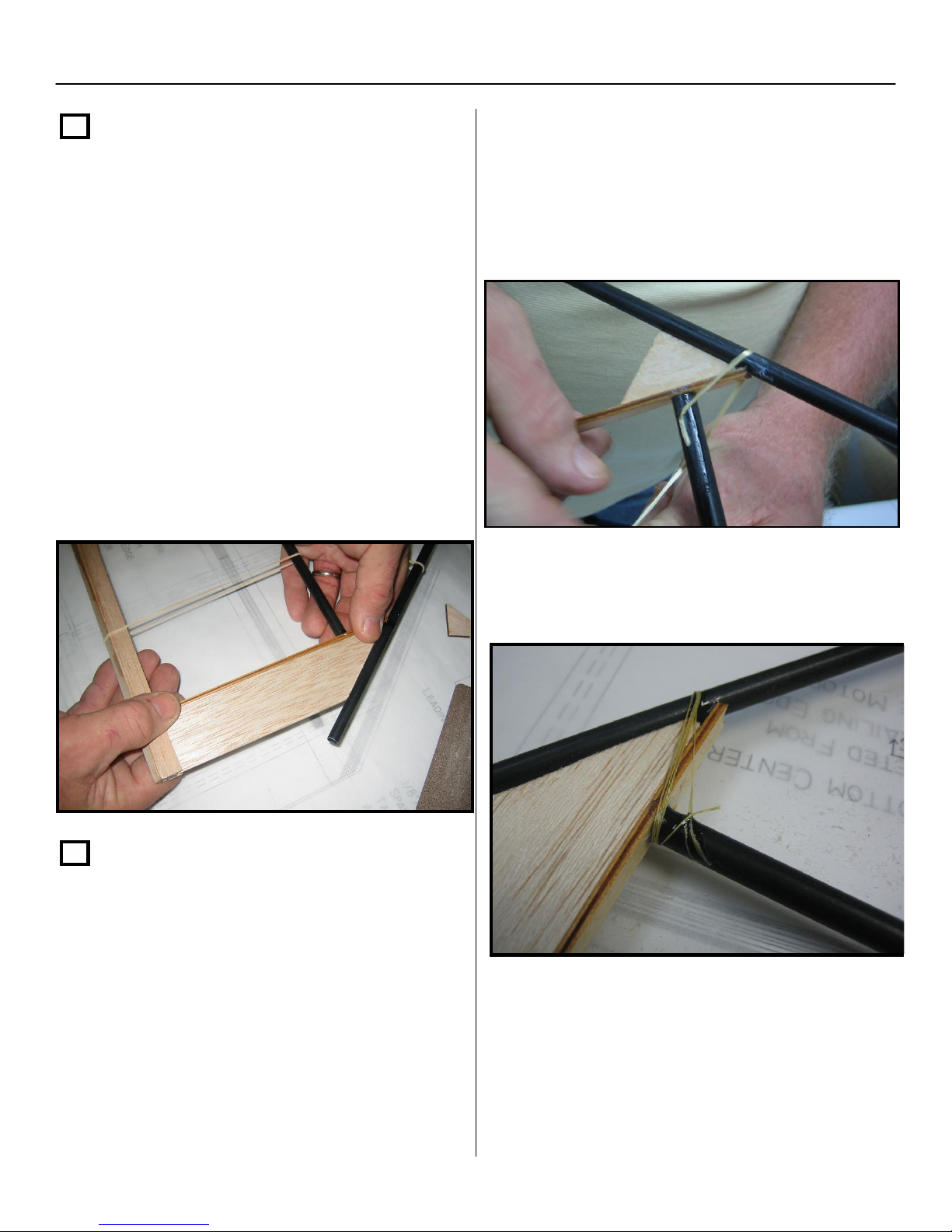

Step 17

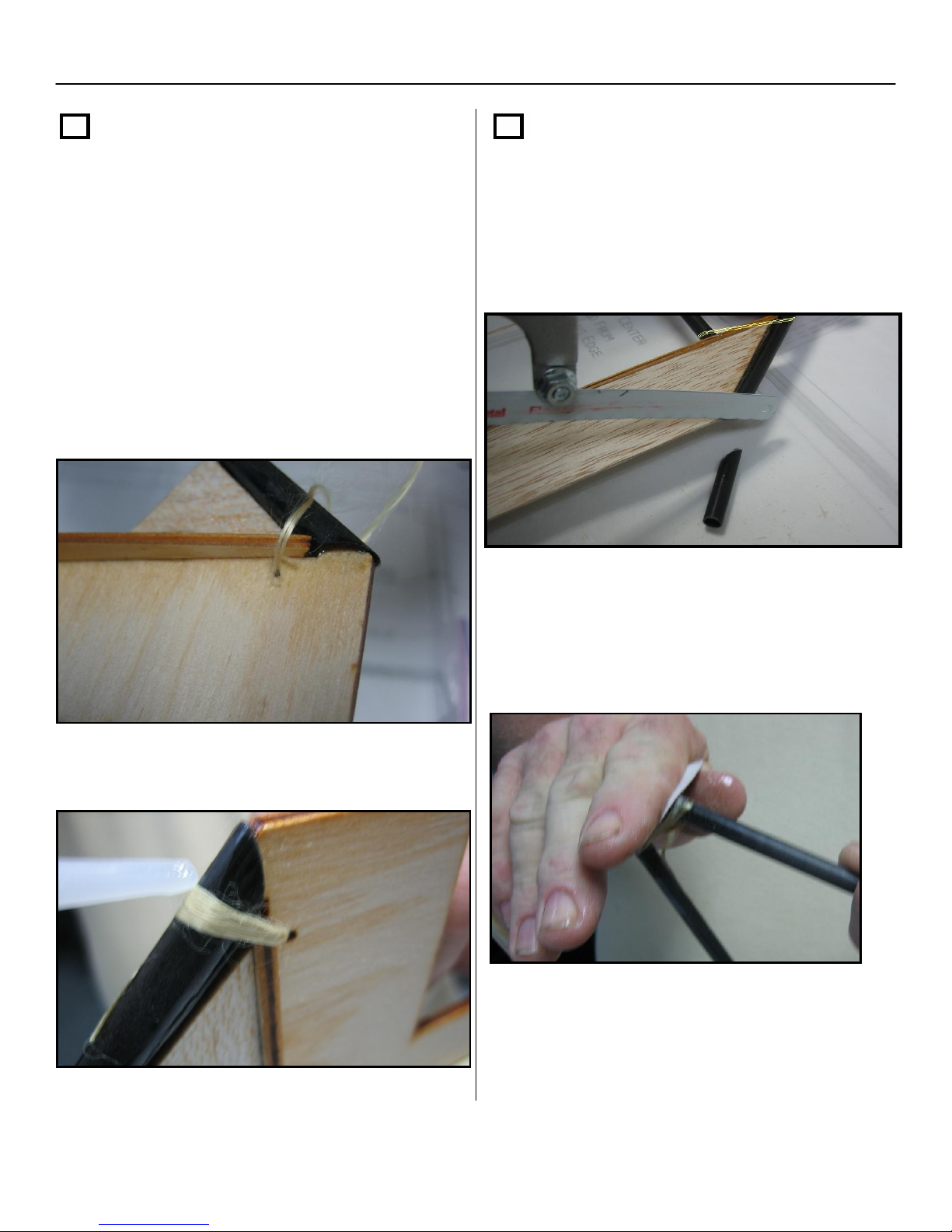

Locate the Kevlar thread in the parts bag.

Following the illustrations on the print, first

wrap the #2 and # 3 ribs where they

intersect the L.E. Make sure you reference

the print first before starting, to ensure that

you will be installing the Kevlar at the proper

angles.

Place a drop of thin CA on the spar tube and

lay the tip of the Kevlar thread in the glue

drop and allow it to dry. This will hold the

Kevlar in place while you wrap the thread

around the ribs and L.E. and spar.

Next, wrap 5 to 6 turns around the rib, L.E.

and spar, while holding the Kevlar thread

tight.

Once wrapped, soak the entire Kevlar thread

with thin CA. Repeat this step for all four

points where the ribs and L.E. intersect, as

shown on the print. NOTE: You can now

cut the four rubber bands that hold the

leading edge tubes.

17

Section 1: Framing of the Airframe – Cont.

Step 17 – Cont.

Next, thread the Kevlar through one of the

small laser cut holes found on the motor

mount and wrap it around the leading edge

and motor mount 5 or 6 times while

reinserting it through the laser cut hole. Glue

it in with thin CA.

NOTE: you may have to re-drill the holes

since the laser cut hole may have been filled

in with glue from step 15

Repeat this for both sides of the motor

mount.

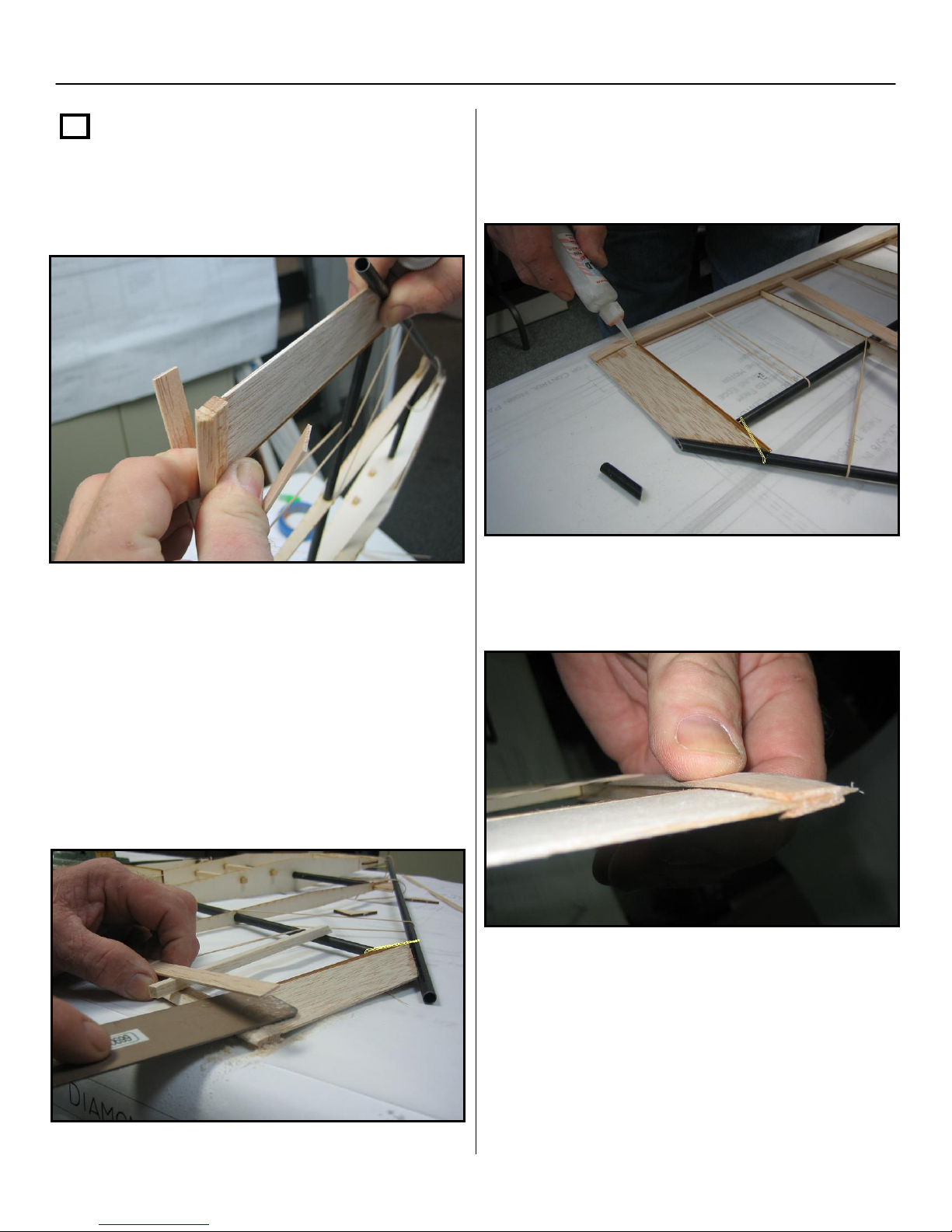

Step 18

Trim the .300 E glass tube flush with the

wing tip (Hack saw, razor saw,9+ or band

saw works well for this; a fine file will also do

the job).

After cutting off the extra tubing from both

L.E. tubes, sand the ends down flush to the

1/4”x1-1/2” elevon stock / balsa wing

tips.

18

Section 1: Framing of the Airframe – Cont.

Step 19

Now separate the unglued portions of the

cap strips at the ends of the T.E. assembly.

Next, place a small piece of balsa stock or a

pencil in between the cap strip and the ¼” x

3/8” T.E. stock to keep the cap strip

elevated. Sand the trailing edge to match

the taper of the wing tip balsa stock. Repeat

the sanding and shaping of the T.E. for both

top and bottom of the T.E assembly on both

sides of the airframe.

When you have finished shaping both sides

of the T.E., glue the cap strips down to the

tapered T.E assembly on both sides of the

airframe.

Your cap strips and trailing edge should look

like the photo below when completed.

19

Section 1: Framing of the Airframe – Cont.

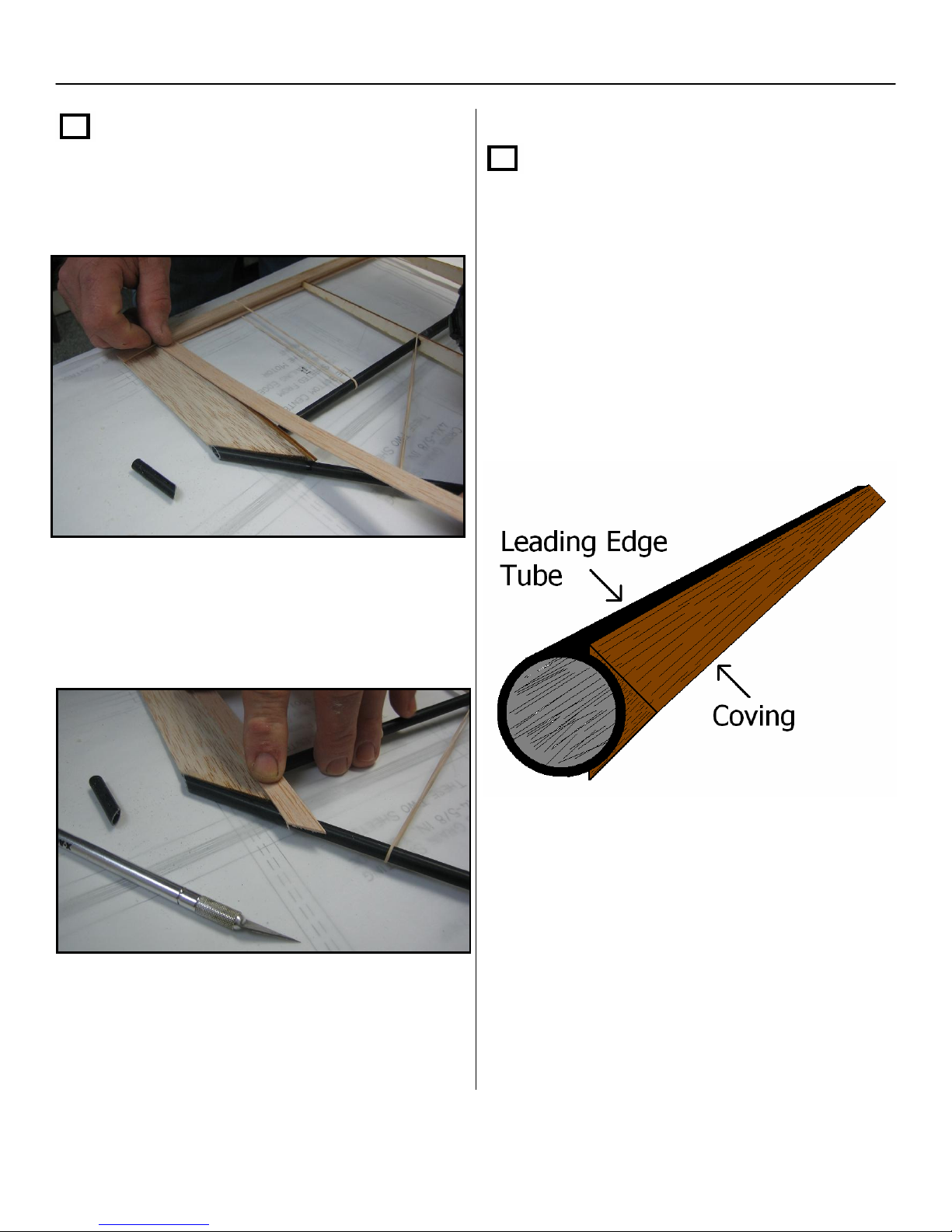

Step 20

Apply cap strips to both top and bottom of the

#3 ribs on both sides of the airframe.

Trim the cap strip with a hobby knife or

scissors to match the angle of the L.E. tube.

Step 21

Next, locate the leading edge hardwood

coving stock and apply one piece to each of

leading edge tubes with thick CA. Start at

the motor mount and apply rearward. Make

sure to leave a little at the motor mount so

you can cut and sand to shape later.

Note: Take care to apply the coving as strait

as you can on the L.E. tubes.

20

Section 1: Framing of the Airframe – Cont.

Step 21 – Cont.

Cut each piece of coving stock flush with the

tip of the L.E. tubes and the motor mount,

then sand lightly.

Step 22

Now cap strip the outer edge of both the

balsa wing tips from the L.E tubes back to

the T.E. Leave a little extra at both ends

for shaping.

When dry, sand down the end cap strip so it

tapers from the L.E. tube back to the T.E

assembly.

This manual suits for next models

1

Table of contents