DIAMOND PACIFIC Genie User manual

Genie

Manual

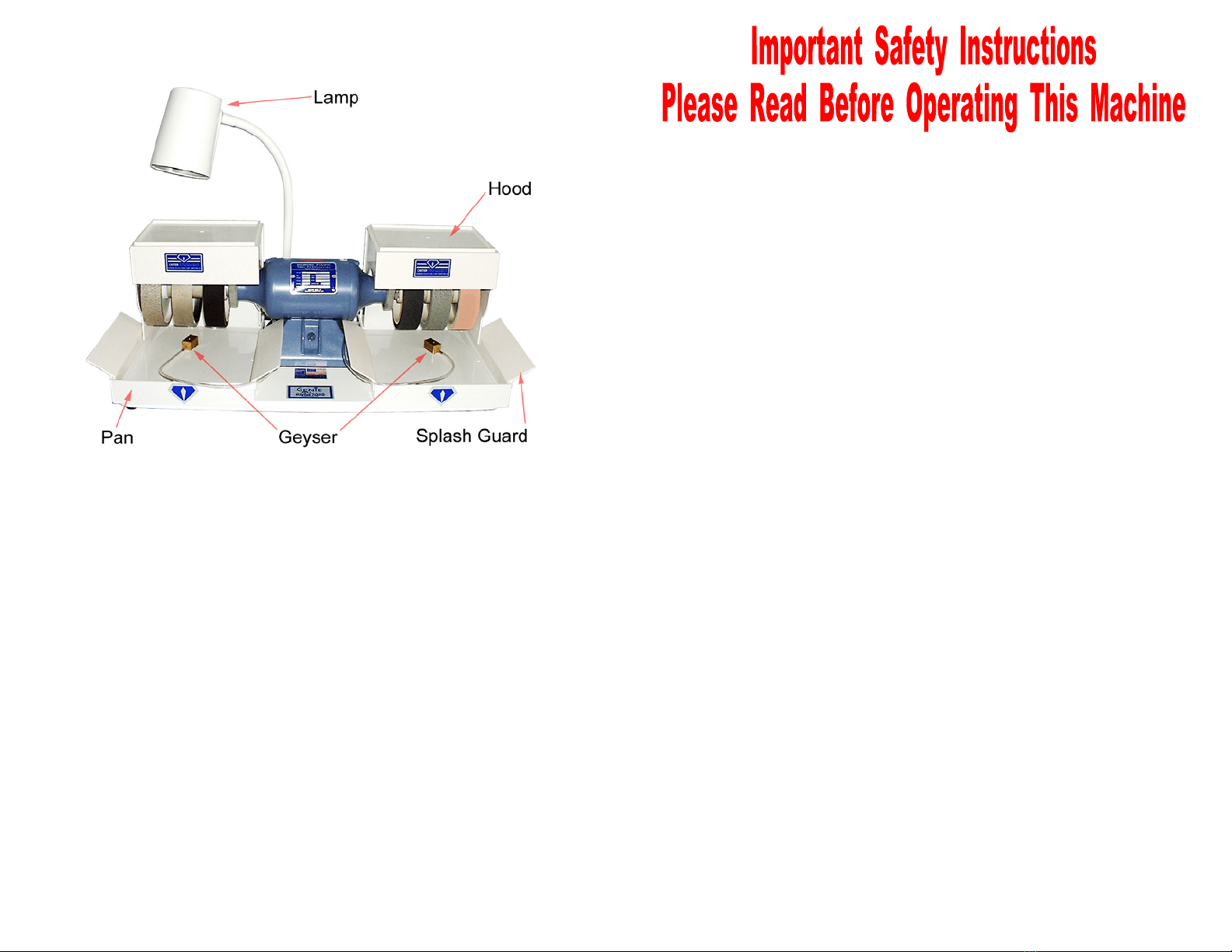

Assembly Instructions for the Genie

1. Remove strapping from around motor. Remove wooden board

under machine baseboard. (Do not leave this board underneath

your baseboard as it can cause machine to be unlevel.)

2. Set pans in place. Ease each hood over its aluminum bracket.

It will fit snug. Make certain back edge of hood is inside pan to

prevent water from running outside pan.

3. Two sets of splash guards are included. They slip down over the

outside and inside edges of each pan. They fit tight, and you

may have to trim inside groove of guard with a sharp knife if it is

too snug for you.

4. Lamp can fit on either button screwed onto the rear of the

baseboard. Pull up the quick-connect fitting on stem of lamp and

it will slip over the base button and attach.

5. Please read safety instructions and entire operating instructions

in the manual before using machine.

1

Before plugging in this machine, make certain the electrical

outlet is properly grounded and of the proper voltage. Since

the Genie uses water as a coolant your electrical circuit

should also be protected by a Ground Fault Circuit

Interrupter (GFCI) to prevent the possibility of electrical

shock. If a GFCI protected circuit is not available you may

purchase a portable unit from Diamond Pacific or your local

hardware store. Also make certain that the machine switch

is off and that your hands and the electrical connections are

dry.

Do not use silicon carbide or aluminum oxide wheels on this

unit. Such wheels require metal guards as they may break

and fly apart while in use. The hood and pan on this unit are

designed for use with diamond grinding wheels only, and

should not be used with silicon carbide or aluminum oxide

wheels.

Rock dust can be hazardous to one’s health. Use sufficient

water at all times while grinding and polishing stones so that

rock dust does not form.

Before grinding and polishing any material, make certain that

it will not produce toxic fumes or dust. Sea shells are one of

the known hazardous materials of this type. If you should

ever have occasion to grind metallic ores or other mineral

specimens, be aware of the possibility that they may contain

toxic quantities of such substances as uranium, lead,

mercury, arsenic, asbestos, copper sulfate, etc.

Use safety glasses to protect your eyes from flakes of stone

or other objects that might be thrown by the wheels.

It is possible for a stone to become wedged between

adjacent wheels or between wheels and the pan which could

result in injury to yourself and/or damage to the machine,

such as a bent shaft. Be alert while working to prevent this

from occurring.

The motor of this unit is sealed to prevent grit contamination

and normally runs hot to the touch. Avoid contact with the

motor while in use to prevent possible burns.

2

Introduction

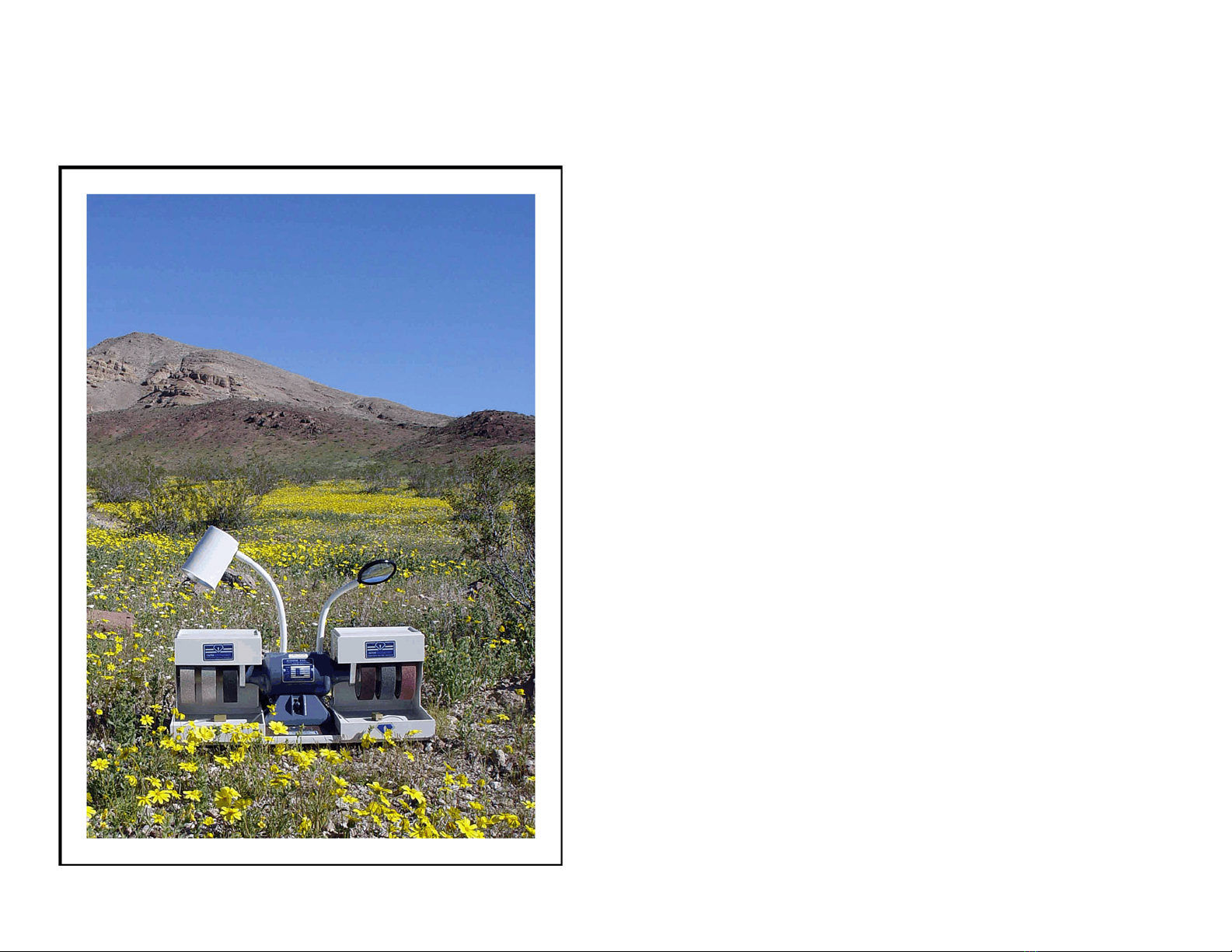

The Genie is a compact cabochon grinding and polishing unit

complete with motor, diamond wheels, and coolant system. It requires

no attachment or hookups other than a standard 115 volt electrical

outlet, (230 volt for export model) making it portable and light weight.

Since the grinding and polishing wheels do not require large amounts

of water, the Genie is also a clean operating unit, and can be used in

any convenient place such as the kitchen.

The Genie comes with two Galaxy metal-bond diamond grinding

wheels: one 80 grit for coarse grinding, and one 220 grit for fine

grinding. The set of four Nova resin-bond diamond sanding and

polishing wheels (grit sizes 280, 600, 1200, and 3000) is an excellent

all-around combination that will produce a high polish on most stones.

For those stones that may benefit from an additional polishing step, a

14000 grit Nova Disc is included and can be attached to the right hand

shaft. With the six wheels mounted at once, the lapidary can quickly and

efficiently grind and polish most stones in a matter of minutes, without

having to stop to change or charge attachments and wheels.

Flex Stem Lamp and Magnifier

The lamp has a flexible stem for easy adjustability, and a quick-

coupler at the base for easy detachment. The extra coupler base on the

unit may be used for an extra lamp or optional magnifier (see page 24).

When adjusting the lamp or magnifier, use both hands so you can

grasp the base of the flexible stem and bend it from there in order to

prevent excessive strain on the base attachment, use care not to cause

excessive strain on the lamp shade or magnifier lens rim.

The lamp and magnifier are interchangeable on the metal buttons.

To remove either one, raise the plastic ring near the base of the flexible

stem, and the unit will lift off. Use maximum 100 watt bulb.

Motor

The Genie motor is a heavy-duty, industrially rated, sealed, capacitor

start motor made especially for Diamond Pacific Tool Corp. by the

Baldor Electric Company. It is unconditionally guaranteed by the

manufacturer against defects in workmanship or components for one

year from date of purchase.

3

The domestic motor is 1/4 HP, single phase, 1800 RPM operating

on 115 volt, 60 cycle (Hz) AC current.

The export motor is 1/4 HP, single phase, 1450 RPM operating on

230 volt, 50 cycle (Hz) AC current.

Since the motor is totally enclosed to prevent grit contamination of

the bearings, it has high temperature insulation which allows it to

operate at higher temperatures than fan cooled motors. The motor

never needs oiling.

The Genie can be operated with any small generator producing a

minimum of 400 watts power. With a generator, you can use your Genie

out in the field as well as in your home or shop.

USE CAUTION:

The motor normally runs very hot to the touch. Care should be taken to

avoid touching the motor while it is in use in order to avoid possible

burns.

Hoods and Pans

The Genie comes equipped with a hood and pan for each side of the

unit. Both hood and pan are molded of rigid plastic that is durable,

lightweight and easy to clean. A ridge around the top edge of the hood

makes it a convenient tray for stones.

To remove either hood from its bracket, grasp it with both hands and

rotate it towards you (in same direction that wheels rotate) rather than

attempting to lift it straight up and off the bracket. Once the hood has

been removed, the pan can be slipped out for cleaning.

To use flat laps on either end of the motor shaft, first remove the

hood from its bracket, then unscrew the end plate from the hood. Turn

the pan 90 degrees and parallel lengthwise to the shaft. Replace the

hood. This arrangement allows easy access to the lap or pad and

provides ample drip pan space.

Some flat laps may require more room on the left end of the Genie. This

additional room may be acquired by cutting out the special thin section

on the right side of the left hood as follows:

1. Use a strong, sharp knife, and be careful not to cut yourself.

4

2. Cut down each side of the section, then score across the bottom of

the inside. Work the piece back and forth to break it across the

bottom.

3. You may want to dress the new edges with the knife, and the plastic

cuts easily for this.

4. Once this portion has been removed, the hood will slide further from

the motor, allowing more room for laps on the end of the motor shaft.

CAUTION: The plastic hoods and pans are designed for use ONLY with

diamond grinding wheels. Do not ever use silicon carbide or aluminum

oxide wheels on the Genie.

Cab Rest

The odd shaped plastic cab rest has two main purposes, to act as

a steady rest for the hands while grinding and polishing a stone, and to

provide an easy, accurate way to grind the bezel on cabochons.

The cab rest can be set in the pan in any position that enables you

to steady your hands while grinding and polishing. Usually it will be laid

flat in the pan.

To grind a uniform bezel on your stones, set the cab rest upright,

with the down slope towards you and the upper end close to the

grinding wheel. Turn your cab topside down, place on top of cab rest,

and proceed to grind the edge. The slope of the cab rest is at an angle

that will give you a uniform 12-½degree bezel.

Spra-Mist Cooling System

Description:

The Spra-Mist coolant system utilizes a piston type air pump to

operate two geysers that provide a fine mist to the underside of the

grinding and polishing wheels. The pump is located on the left hand

side of the machine, under the hood. Air from the pump is supplied

through plastic tubing to the two geysers.

The Spra-Mist pump is relatively trouble free because of its unique

design. No water flows through the pump itself, so it cannot be

damaged or clogged by rock dust or grit. Regular oiling of the leathers

and bearings will generally keep the pump operating at maximum

5

efficiency.

Operation:

1. The pump automatically begins to operate when the motor is turned

on. It will not operate if the left hand wheel adaptor is not mounted

on the shaft as the wheel adaptor holds the motor shaft pulley in

place

2. The geysers should be placed in the water pan with the large hole

down, and set towards the rear of the wheels to avoid excess water

splash. Remember to move the geyser from wheel to wheel as you

work.

3. About two cupfuls of water should be placed in each pan, or

enough to reach approximately one third the way up the side of the

geyser.

4. By attaching the white plastic base to the brass geyser, the geyser

sits at an angle that will provide a spray of water to either “No-Hole”

metal laps or Nova discs attached to the right hand side of your

Genie, or laps having a ½" center hole attached to the left hand

side of your Genie. The plastic base should be removed after the

lapping process is complete. If left on, it may not properly spray the

underside of the wheels. The outside plate of the hood, on the side

to be used, must be removed by unscrewing the attaching screws.

Turn the water pan 90 degrees so that its long dimension is parallel

to the shaft so that the geyser with base can be set to provide water

to the lap or Nova Disc. (The geyser spray should not be used on

canvas polishing pads with diamond compound as it will wash away

the compound. Use a silicon lubricant such as Gem-Lube instead.)

5. Occasionally a geyser will become plugged from the mineral

content in the water. This usually can be corrected by boiling the

geyser in a solution of vinegar and water. Or if plugged by a small

piece of grit, use a needle or paper clip to remove the obstruction.

6. A few drops of Water Aid in the pan will improve the cutting ability

of the Galaxy metal-bond diamond grinding wheels. Avoid excess

Water Aid as it can cause excessive foam in the pan.

Galaxy Metal Bond Diamond

Grinding Wheels

6

Description:

Galaxy metal-bond diamond grinding wheels are designed to

provide the gem-cutter with a smooth, fast cutting, true-running grinding

surface ideal for working stones. The diamonds in a Galaxy Wheel are

held on a heavy steel ring by an extremely hard nickel alloy plating. The

ring is mounted on a tough, glass-filled polyester core, making a

smooth, quiet running wheel.

Use and Maintenance:

Galaxy Wheels never need dressing. Do not attempt to do so as

you may damage or ruin the wheel.

For longer wheel life and to prevent wheel damage, the following

practices should be followed when using your Galaxy Wheels:

1. Use a light to medium pressure when grinding stones. Although

diamonds are extremely hard, they are also quite brittle and can be

easily shattered by excessive pressure or the bumping of a heavy

rock. The wheels cut most effectively with a light to medium

pressure and will last longer as well.

2. Use a steady rest to avoid uneven wear patterns. Steadying your

hand while grinding will help prevent bumping and chattering that

causes uneven wear of wheels. It will also help prevent damage to

stones.

3. Use a coolant while grinding. Water is best and a small amount will

normally do to keep the wheels wet. This prevents the formation of

rock dust, keeps your stone cool, and stops the buildup of rock

residue on the wheel surface which can slow down cutting action.

When grinding soft materials such as onyx or turquoise you can

place both geysers under the same wheel as more water is needed

in order to keep the wheel clean.

4. Use the entire surface of the wheel as you grind your stone. Avoid

using just the center or edge or any one area of the wheel surface

as this will cause excessive wear in that area and shorten the

effective life of the wheel. When grinding crosses, hearts, fire

agate, etc. be certain you grind with the diamond covered surface,

not on the bare metal side of the wheel, as this will undermine the

diamonds and cause excessive wear of the wheel edge.

7

5. A few drops of Water Aid in the pan will improve the cutting ability

of the Galaxy Wheels.

6. Reverse the wheels occasionally so that the diamonds cut from the

opposite direction. The edges of the diamonds will wear with use,

and the cutting speed will decrease. By reversing the wheel, the

cutting edges of the diamonds are renewed. (The 80 and 220 grit

wheels will be interchanged when you reverse the direction of the

two wheels.) See instructions for “Remounting and balancing

Galaxy Wheels” when reversing them.

Nova Resin-Bond Diamond

Sanding and Polishing Wheels

Description:

Nova Wheels are specially designed to produce an excellent finish

on stones with a minimum of time and effort. The diamonds in Novas

are embedded within a tough, flexible, plastic resin backed by an extra

soft, thick, sponge rubber backing. This soft, flexible construction

enables the surface of the Nova Wheel to conform to the stone,

eliminating flat spots and scratches.

Use and Maintenance:

1. Nova wheels must be used with a water lubricant. This fact cannot

be stressed too strongly, for if the wheels are run dry for more than

a few moments, rapid wear and damage can result. Make certain

that the geyser is supplying sufficient water to the Nova Wheel

before using it, and remember to move the geyser to the next wheel

as you progress through the sanding and polishing procedure.

2. Nova Wheels should be broken in by sanding and polishing a large

agate cab prior to working on others. This is necessary in order to

remove excess resin coating surfaces of the diamonds. Spend from

two to five minutes on each wheel with the first cab, working it over

the entire surface of the wheel. The finer grit wheels, especially the

3000 grit wheel and 14000 grit disc, will take longer to remove the

excess resin, and will continue to improve in speed and finish as

more stones are worked.

3. Use sufficient pressure to cause the surface of the wheel to

8

depress slightly to conform to your stone. This eliminates the flat

spots left by the grinding wheels and will cause fewer scratches

than would be produced by pressure that is too light.

4. It is important to hold your stone so that you do not allow the upper

or leading edge to act as a plow and dislodge diamonds from the

surface of the wheel. The diamonds in Nova Wheels are firmly

embedded in the resin and with proper use cannot be dislodged to

cause contamination in proceeding from one wheel to the next. But

they can be dislodged with the sharp edge of a stone.

5. To prolong the life of your Nova Wheels, be certain to prepare your

stone properly on the grinding wheels prior to sanding. Use the

metal bond wheels to grind your stone to its final size and shape,

and to remove all sharp edges and corners. This leaves only the

final sanding and polishing to the Nova Wheels. Similarly, it is

important to do a good job of sanding at each stage before going

to the next as the finer grit wheels will take much longer to remove

scratches than do the coarser wheels.

6. If your stone still has scratches after the final polish, check the

following procedures:

A. Make certain all deep scratches left by the coarse (80

grit) grinding wheel are removed by the fine (220 grit)

grinding wheel.

B. Make certain you are using enough pressure on the

Nova Wheels. Too light a pressure can cause scratches.

C. Make certain your Nova Wheels have been broken in

properly, especially the 3000 grit wheel and 14000 grit

disc. If any one wheel seems to be causing the

scratching, take a large agate cab and work it across the

entire surface of the wheel.

D. Almost all problems with scratches are caused by

improper procedure in the above three areas.

Procedure for Grinding and

Polishing Cabochons

Pre-Forming – Preparing Stone for Grinding Wheels:

9

Since most gem material comes in sizes and shapes larger than

desired for a single cabochon, it must be pre-formed. This is usually

done by cutting the rock into slabs about 1/4 inch thick with a lapidary

or rock saw. The best areas of the slab are then selected and marked

with a template for shape and size of desired stones. Excess material

is removed with a trim saw or one of the other tools available for this

purpose. The more material that can be removed from a pre-formed

stone at this step, reducing it to as near its finished size as possible, the

less time will be taken in the grinding process. Just as important, the life

of the grinding wheels will be increased.

Grinding on the Galaxy Grinding Wheels:

The basic procedure is to grind your stone to proper size and shape

on the Galaxy Grinding Wheels. If the stone is properly prepared on the

grinding wheels, it is only a matter of minutes more to polish it on the

Nova Polishing Wheels.

First grind your cabochon to the approximate size of the template

outline using the left hand or coarse (80 grit) Galaxy Wheel. Use light

to medium pressure and work the stone over the entire surface of the

wheel. Check the stones size as you work, either with the template or

the mounting in which it will be set. Leave a small amount of material

outside the outline so that the stone is slightly larger than the template

or mounting. The balance of the excess material will be removed in fine

grinding and some in the sanding process. Using the Cab Rest during

the above procedure will make it easy to grind a uniform 12-½degree

bezel angle all around your stone.

Proceed to the fine (220 grit) Galaxy Wheel, making certain that

you move the geyser to the wheel you are using. Again, a light to

medium pressure is all that is necessary. Finish grinding the bezel of

the stone, leaving only a small amount of material that makes the stone

just a fraction too large.

Now move back to the coarse grinding wheel to grind the face or

dome of the cab to shape. For best results, the stone should be dopped

(glued to the end of a dowel with dop wax or other adhesive) to enable

you to hold it more easily.

Grind from the edge towards the center of the stone, and then back

to the edge using a circular and oscillating motion as you work. The

circular component of this motion is accomplished by continually

rotating the base of the dop stick using your right hand. At the same

time, your left hand is used to move the stone back and forth in an

10

oscillatory manner so that its point of contact with the wheel spirals from

the edge of the stone to the center and back without stopping, since

stopping produces a flat spot.

This circular, oscillating motion is the key to well shaped stones and

the prevention of flat spots. Check the curvature of your stone

frequently to achieve symmetry. The outline should form a smooth arc

when viewed in any direction, with no high spots or flats, especially at

the top of the dome.

Once you have achieved a uniform shape, move to the finer grit

wheel and remove all the scratches left by the coarse wheel. It is

important to remove all scratches possible before proceeding to the

Nova Wheels.

Sanding and Polishing with the Nova Wheels:

Before using any Nova Wheel, make certain that the geyser is

supplying water to that wheel. NOVA WHEELS MUST NOT BE USED

DRY.

1. Start with the 280 grit Nova Wheel, making certain that the geyser

is supplying water to that wheel. Use a firm pressure, depressing

the rubber backing so that it conforms to the surface of the cab, and

keep moving your stone with a circular and oscillating motion at all

times. This firm pressure (in contrast to the light to medium

pressure used on the grinding wheels) and the circular and

oscillating motion are important procedures in eliminating flat spots

and scratches. Using too light a pressure, or allowing the stone to

remain in one position, can result in more scratches and flat spots.

2. Spend enough time on the 280 grit Nova Wheel to completely sand

away the scratches and facets left by the grinding wheels. This

should only take a minute or two, leaving the stone with a uniform

finish over its entire surface and reduced to very near its final size.

3. Proceed to the 600 grit Nova Wheel, making certain that you move

the geyser first. Continue using firm pressure and the circular and

oscillating motion. You should only need to spend a minute or two

on each of the 600, 1200, and 3000 grit Nova Wheels to achieve a

fine polish on your stone.

4. It is important to do as good a job of sanding and polishing as

11

possible at each stage before going on to the next, as the finer grit

wheels take longer to remove scratches than do the coarser grit

wheels

5. Some hard to polish materials, such as Jade, may require a finer

grit polish than the 3000 grit Nova Wheel. A 14,000 grit Nova Disc

is provided with the machine and will generally give an excellent

polish. Other polishes such as cerium and tin oxide can also be

used with canvas or leather pads to provide the final polish.

Using Nova Discs:

For stones requiring an additional step to achieve a satisfactory

polish (jade and some soft stones, for instance), we recommend using

the 14,000 grit Nova Disc that comes with the machine. Other types of

fine polishing compound such as cerium and tin oxides also produce

excellent results, and canvas and leather pads are available for use with

these compounds.

1. Remove the end panel from the right side hood and thread the

Nova Disc into the 1/4-20 mounting hole in the right end of the

machine (see page 13).

2. Snap the small, white plastic, geyser base that came with your

machine onto the bottom of the brass geyser to angle it to spray on

the Nova Disc. NOVA DISCS MUST NOT BE USED DRY.

3. To allow for working room when using the Nova Disc or other right

end attachment rotate the pan so that the front of the pan is on the

right end of the machine .

4. Additional Nova Discs are available in seven grits ranging from 280

to 50,000.

12

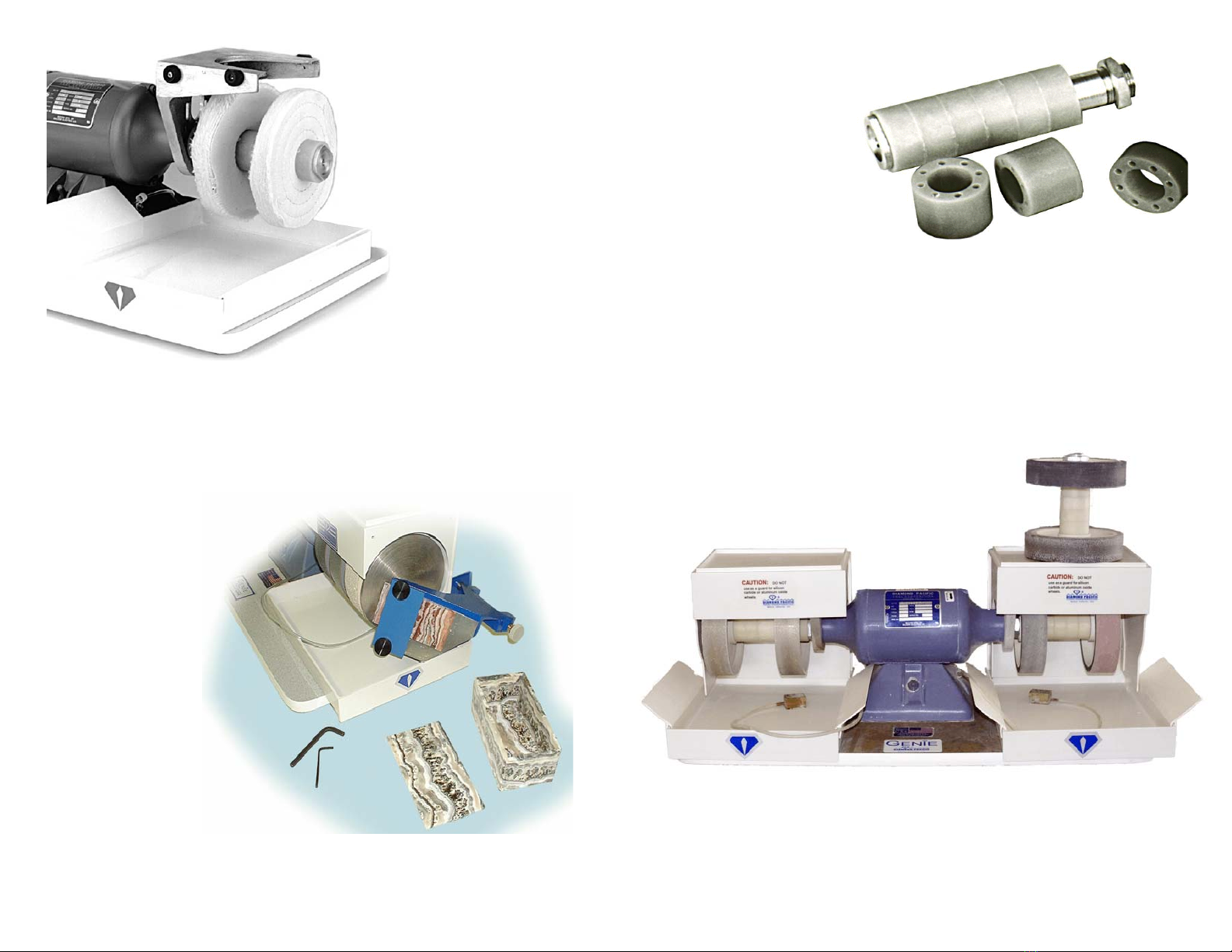

Optional Accessories

Although the Genie comes complete and ready to operate there are

a number of optional accessories available that make it more versatile

to better suit your personal needs.

A trim saw attachment is available that can be mounted on the right

hand side of the Genie. The saw comes with an eight inch blade and

uses water as a coolant, so that it can be used wherever your Genie is

set up.

Quickly converts your Genie into an eight inch trim saw.

Just spin off the right hand wheel adaptor with the wheels still attached

and spin on the saw adaptor with blade. The whole process takes only

a minute and changing back is just as easy!

Right Hand Laps, Pads

6 inch diameter Nova Pads or

Magnetic Laps, leather and

canvas pads, “No-Hole” metal

bond laps or other discs that use

a 1/4-20 attachment can be

easily attached to the right end

of your Genie.

13

Left Hand Laps, Discs

6 inch diameter laps with

a ½" arbor hole can be

fastened on the left hand

side with the special lap

connector that comes

installed on the Genie.

Use these laps for

grinding and polishing flat

surfaces.

When using laps on either

end of the Genie the outside

plate of either hood is easily

removed by removing the

screws which hold it in place.

The lap connector on the left

hand side has left hand

threads. Turn clockwise to

remove screw to attach lap,

counter-clockwise to tighten.

Note that the pans can be

rotated to allow more

working room on the ends of

the machine as shown here.

14

Jewelers Buff Kit

This kit contains buffs

and jewelers rouge for

finishing metals. The

wheel adaptor and

spacers included allow

the buffs to be

mounted on the right

side of the Genie.

The Boxer

Attachment

Holds your slabs at

a 45 degree angle

to make perfect

miter joints for

fabulous looking

boxes. Mounts on

the left side of your

Genie for use with

standard flat laps

(½" center hole), or

on the right side for

use with “no hole”

laps (1/4-20 thread)

Extra right hand

adaptors and spacers

15

Using an extra right hand adaptor and spacers allows the gem carver

to mount the wheels just four at a time as shown below. The two sets

of Novas can be interchanged on the right side of the machine in about

20 seconds and the space between wheels will be 3" rather than the

usual 3/4" allowing room to carve fancy shapes such as hearts and

crosses.

(Adaptor and spacers sold separately or in a kit)

16

Extra right hand adaptors are also used for mounting extra grits in Nova

or Galaxy wheels or special shaped wheels such as our Convex

Carving wheels. Wheels can even be mounted one at a time for even

more working room.

See our current catalog or call us for more information regarding

these accessories.

17

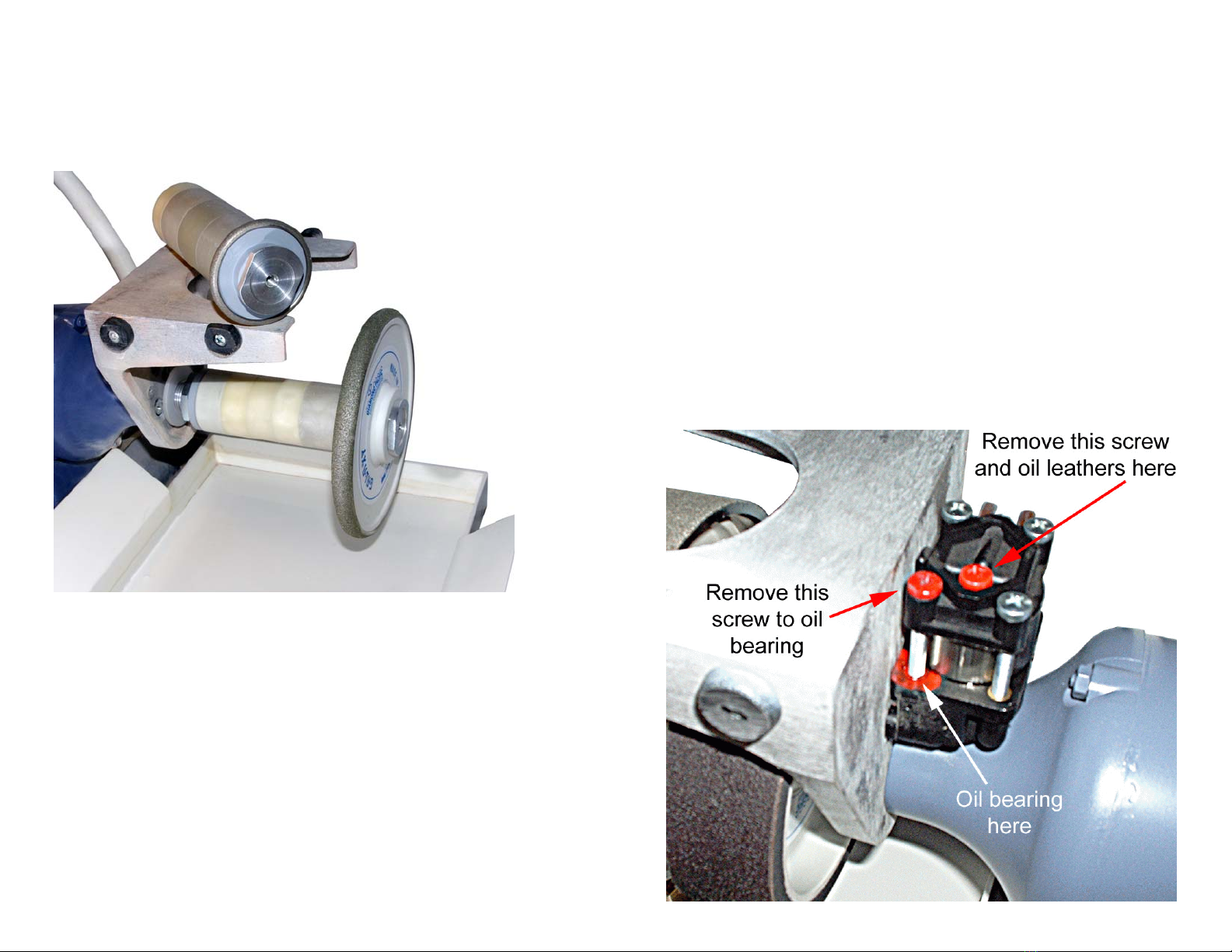

Pump Maintenance

Oiling Pump Leathers and Bearings:

To maintain maximum output, the leathers and bearings in the

pump should be lubricated about every forty hours of machine use. Use

the following procedure:

1. UNPLUG THE MACHINE.

2. To oil the leathers, remove the left hand hood. The pump will then

be exposed. Remove the middle screw (see picture) that is painted

red. Place one drop of 30 weight motor oil in the hole and replace

the screw. This hole oils the leathers, and any excess oil will

eventually come out the air outlet tubing and into the water pan.

3. To oil the bearings, remove the corner screw that is painted red (see

picture on preceding page) Place one drop of 30 weight motor oil in

the screw hole that is painted in the bottom pump block, not in the

18

top where the screw was removed. Do not use too much oil or allow it

to run out of the hole, as excess oil can leak onto the pump belt and

cause belt slippage. Replace the screw and hood.

4. Regularly oiling as explained above will normally keep the pump

operating properly, but the two usual causes of decreased air

output, dried out pump leathers and belt slippage, are easily

corrected.

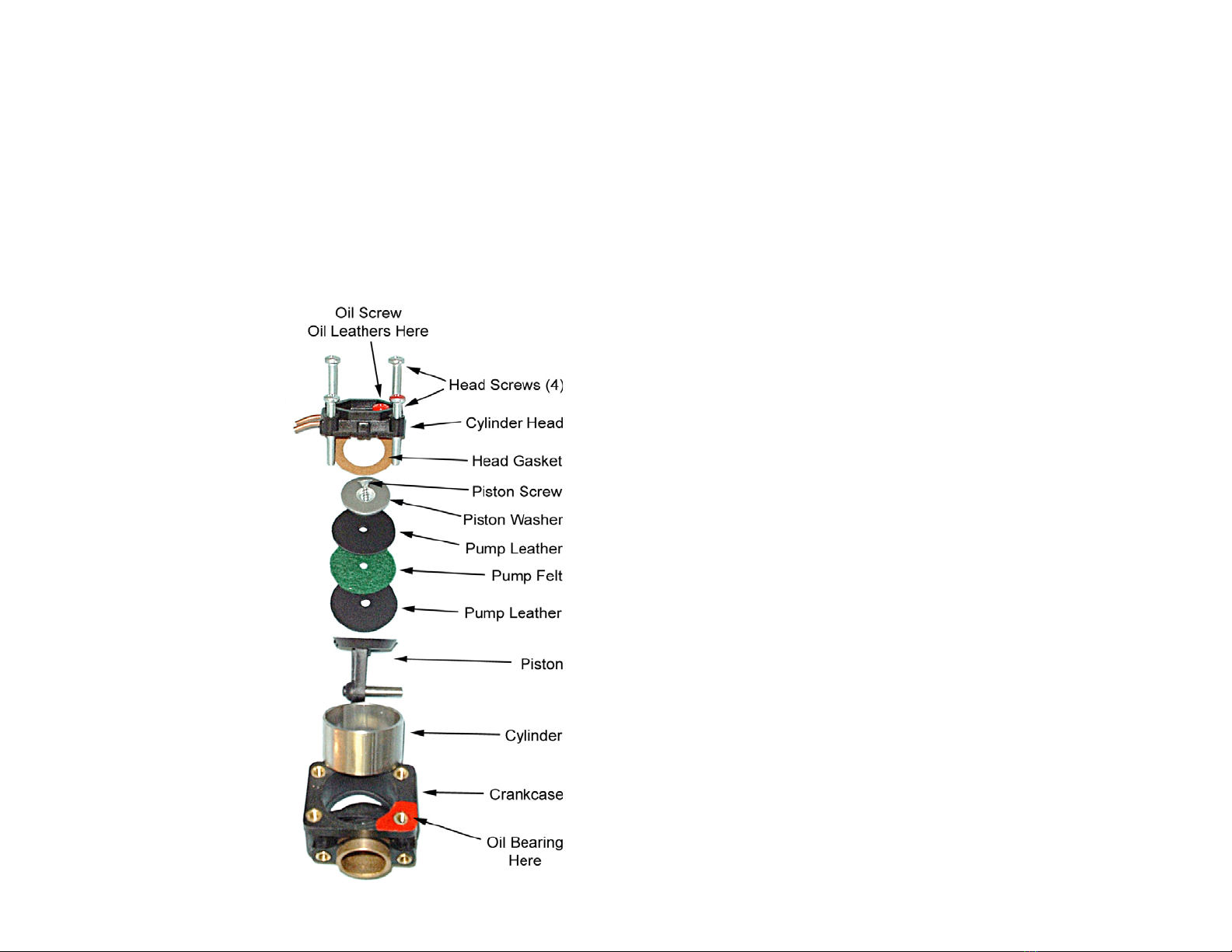

Dried Out Pump Leathers:

Decreased air flow with the pump still operating is usually caused by

dried out pump leathers. The leathers should be removed and

thoroughly oiled, or replaced.

This can be done by

disassembling the pump with a

phillips screwdriver as follows:

1. UNPLUG THE MACHINE.

2. Remove the four head

screws on the top of the air

pump. One is painted red

and the other three are

unpainted. Once the

screws are out, remove the

cylinder head and cylinder.

The piston will then be

exposed.

3. Remove the leathers and

felt from the piston by

unscrewing the screw in

the top of the piston.

Stretch the leathers and

felt with the fingers, and oil

them generously with 30

weight oil.

4. When ready to reassemble

the piston, it is important

that it be done in the

following order: (see photo)

19

A. Place the felt between the two leathers. The smooth or shiny

side of the leathers should be away from the felt.

B. Place the piston washer on top of the leathers, countersink side

of the washer hole facing up. Center the washer so that the

edge of the leathers shows evenly around it.

C. Slip the screw through the washer and leathers and into the

hole of piston top. Tighten the screw securely so that it cannot

loosen.

D. Slip cylinder and head back over the piston with the air outlet

tubing to rear of machine

E. Start the red screw back into the front left hole, then start the

other three corner screws before tightening all four evenly and

securely. Avoid excessive tightening of these screws as this

may distort the main bearing of the pump, causing hard turning

and overheating.

Belt Slippage:

Intermittent air output or no air output is caused by a slipping belt.

This problem indicates that excess oil from the pump has leaked onto

the pulley and belt, and can be corrected by cleaning and tightening (or

replacing) the belt as follows:

1. UNPLUG THE MACHINE.

2. Remove the left hand hood and wheels. IMPORTANT: See

sections on removing and replacing wheels on the left hand side of

the machine, and on balancing Galaxy Wheels when you replace

the wheels.

3. When the left hand wheels are removed, the pump pulley will be

exposed. Rotate the pump pulley by hand until the two holes in the

pulley are in a horizontal position and you can see two phillips head

pump mounting screws in the pump base behind the pulley. (See

picture on following page). Line up one of the holes with one of the

screws and loosen the screw with a phillips screwdriver. Do not

remove the screw. Then line up the other hole in the pulley with the

other screw and loosen it slightly.

20

4. The pump will

now slide down

and the belt can

be removed for

inspection.

Remove all oil

from the belt and

pulley grooves.

Replace the belt,

making certain it

fits in the grooves

in both the pump

and shaft pulleys.

5. The belt can be

tightened by

raising the pump,

either by holding

it by hand or by

using a screwdriver to hold it up from beneath the pump base.

Either way, raise the pump until the belt is taut, and tighten the two

screws behind the pulley. When the belt is the proper tautness, you

will be able to depress it slightly. If it is too tight, the motor may not

start or may run slow. If this happens, simply lower the pump base

a little using the same procedure.

6. Replace the wheels and hood.

Procedure for Replacing Wheels on the Genie

Removing and Replacing Wheels on the Right Side:

Nova resin-bond wheels are normally used on the right hand side

of the machine. Because of their soft construction, Novas generally do

not need balancing. If you wish to try balancing the Novas, or wish to

use a Galaxy metal-bond wheel on the right side, see the instructions

for balancing Galaxy Wheels on the left hand side of the machine. The

procedures will be similar. To remove or replace wheels on the right

hand side, proceed as follows:

1. UNPLUG THE MACHINE. Remove the right hand hood.

2. Hold the left hand wheels with your left hand, and turn the right

hand wheels in the same direction they spin while running. The

21

wheels will come off in a unit on the right hand adaptor.

3. Use an adjustable wrench to remove the nut on the adaptor. (This

nut has left hand threads.) Once the nut is removed, the wheels

and spacers will slide off the adaptor.

4. Clean the adaptor with fine sand paper, and oil with a very small

amount of light weight oil.

5. Replace wheels and spacers on the adaptor, replace the nut, and

tighten. Slide the adaptor over the shaft. Hold the left hand wheels

and spin the right hand unit of wheels onto the shaft until the

adaptor is tight. Hand tighten only.

Removing and Replacing Wheels on the Left Side:

The standard wheels on the left hand side of the Genie are two

Galaxy metal-bond wheels (80 and 220 grits) and one 280 grit Nova

resin-bond wheel. These three wheels are mounted on an adaptor that

slides over the motor shaft. This left hand adaptor is balanced and

tightened onto the shaft at the factory, and normally should not be

removed to replace or exchange wheels. Follow the procedures below.

1. UNPLUG THE MACHINE. Remove the left hand hood.

2. Use an adjustable wrench to remove the brass lap connector (not

just the slotted bolt) on the left end of the adaptor. The lap

connector has left hand threads. You will have to hold the left hand

wheels while turning the lap connector in the same direction that

the wheels spin while running.

3. Once the lap connector is removed, the wheels and spacers will

slide off the adaptor. Note the sequence of wheels and spacers

before removing so that you can replace them properly. (If

reversing the cutting direction of the 80 and 220 grit wheels, it is

necessary to interchange them so that the 220 will be the first

wheel and the 80 the second wheel.)

4. Clean the adaptor with fine sand paper, and oil with a very small

amount of light weight oil before replacing wheels and spacers.

5. The Galaxy wheels should be balanced again following the

procedures under “Balancing Galaxy Wheels”.

22

The left hand set of wheels can also be removed as a unit while still

mounted on the adaptor if necessary. This can be done as follows:

1. Remove the right hand wheels first. Hold the right hand shaft with

a pair of visegrips or channel-lock pliers to prevent the motor shaft

from turning. Use a piece of leather or thick cloth to protect the

shaft from the pliers.

2. While holding the right hand shaft with the pliers, turn the left hand

wheels in the same direction that they turn while running, as the

adaptor has left hand threads.

3. If the shaft is marred by the pliers, clean it with a fine file or

sandpaper, removing any burrs. Be careful not to create uneven

spots in the shaft. Oil each shaft lightly with lightweight oil. Excess

oil will cause belt slippage.

Remounting and Balancing Galaxy Wheels:

Galaxy Wheels are machined to run true, but must be adjusted to

the individual adaptor and arbor. This is especially important when

wheels are reversed or a new wheel is mounted.

When mounting a wheel, its position should be adjusted so the

imperfections tend to cancel rather than add. For example, a high spot

on a wheel should not be positioned over a high spot on an arbor shaft.

Also, when two wheels are mounted side by side, the heaviest points on

their rims should be positioned opposite each other rather than

together. Since the imperfections referred to would be measured in

thousandths of an inch, or tiny fractions of an ounce, you might think

that precision instruments are needed for aligning wheels. Actually,

proper adjustment can be simply accomplished by the following

procedure:

1. First make certain the spacers, adaptor, and wheel hubs are clean

and smooth. Mount the wheels and spacers on the adaptor and

thread it onto the shaft.

2. Turn the motor on just long enough to rotate the wheels and

observe whether they are running true. If there is a “wobble” or

“bounce”, you will need to balance all three wheels.

23

3. Start with the inside wheel which is usually the 280 Nova. Loosen

the brass lap connector and rotate the inside wheel about one

eighth of a turn. Tighten the lap connector, turn on the motor for a

moment and check to see if the wheels are running true. If not,

repeat the process. These random displacements of the wheel

should eventually place it in a position where it performs

satisfactorily. And remember, the Nova Wheels will not necessarily

run as true as the Galaxy Wheels, and it is not necessary that they

do because of their soft construction.

4. Once the inside wheel is balanced, hold it in place while you loosen

the lap connector to rotate and balance the middle wheel. Make

certain that any time you loosen the lap connector to turn a wheel,

that you hold your balanced wheels in place; otherwise, they may

slip and become out of balance again.

5. The first wheel (usually the 80 grit) should be balanced last using

the procedure in #3.

6. When all three wheels are balanced, it is very important that all

three be held securely in place while the lap connector is tightened.

7. A Galaxy Wheel that is not balanced properly will begin to wear

prematurely at the “high spot”. If such a spot should begin to

appear on your wheel, check it once again to make certain it is

properly balanced.

24

Parts and Accessories

Genie Trim Saw Attachment 100-TSG-105

Replacement Trim Saw Blade 100-TSB-106

Jewelers Buff Kit 100-JBK-G

The Boxer 100-BOXER

Right Hand Adaptor Kit (includes 7 spacers) 101-ADP-GRK

Extra Right Hand Adaptor (spacers not included) 101-ADP-GR

Wheel Spacer, 1/4" 101-GSP-1/4

Wheel Spacer, ½" 101-GSP-1/2

Wheel Spacer, 5/8" 101-GSP-5/8

Wheel Spacer, 3/4" 101-GSP-3/4

Wheel Spacer, 1" 101-GSP-1

Wheel Spacer, 1-3/8" 101-GSP-1-3/8

Extra Flex Stem Lamp (18") 117-0618-G

Flex Stem Magnifier (15") 117-MV15

Water Aid, 8 oz bottle (call for other sizes) 410-WA-108

Replacement Brass Geyser 101-GSG-25

Splash Guard (set) 101-GUO-105

Pump Leathers (set) 101-GPL-145

Pump Belt 101-GPB-150

Pump Maintenance Kit 101-GMK

Complete Pump Assembly 101-G-PUMP

Replacement Motor Bearings (each) 101-GBE-148

Replacement Pan 101-GPA-130

Replacement Hood (left hand) 101-GHO-128-L

Replacement Hood (right hand) 101-GHO-128-R

10/13

25

Orders/Technical Support:

Toll Free: (800)253-2954

Outside US: (760)255-1030

Fax: (760)255-1077

E-mail: [email protected]

Website: www.diamondpacific.com

2620 W Main St, Barstow CA USA, 92311

26

Table of contents

Popular Grinder manuals by other brands

Metabo HPT

Metabo HPT G 12SQ Safety instructions and instruction manual

Parkside

Parkside PDOS 200 A1 - 3 Operation and safety notes

Rubi

Rubi A230 PRO Original instructions

Alpha tools

Alpha tools ES 125 E Original operating instructions

Worx

Worx Brushless WX813 Original instructions

HOLZMANN MASCHINEN

HOLZMANN MASCHINEN UWS 320 user manual