Â¥On/Off

valve to exhaust the air

from

the feed hose

before fitting, removing or adjusting the working

attachment fittedtothetool.

-

Beforeusingthetool, makesurethat a

shut

off device

hasbeenfittedtotheair supplylineandthepositionis

known

and

easily accessible

so

that the

air

supply to

the tool canbeshut

off

in

anemergency.

-

Check hose

and

fittings regularlyfor wear.

-Take careagainst entanglement

of

the

moving

partsof

the tool with clothing, hair, ties, cleaning rags, rings,

jewelry, watches, bracelets, etc. This could cause the

bodyor partsof the body tobedrawntowards

and

in

contactwiththe movingpartsof thetoolandcouldbe

very dangerous.

-It is expected that users will adopt safe working

practices and observe all local, regional and country

legal requirements when installing, using or

maintainingthe tool.

-Take care that the exhaust air does notpoint towards

any other person or material or substance that could

becontaminatedbyoildroplets. Whenfirst lubricating

a tool or if the tool exhaust has a highoilcontent, do

not allow the exhaust air to come near very hot

surfaces orflames.

-

Never lay the tool down until the working attachment

hasstopped moving.

-When the tool isnotinuse, shut off the air supply and

press the triggertlever to drain the supply line.

If

the

toolisnottobeusedfor a periodoftime, firstlubricate,

disconnect from air supply and store

in

a dry average

roomtemperature environment.

-If the tool is passed from one user to a new or

inexperienceduser, make sure these instructions are

passedwiththetool.

-

Do not remove any manufacturer fitted safety devices

where fitted, i-e., wheel guards, safety trigger, speed

governors, etc.

-Wherever possible, secure workpiece with clamps, a

vise, etc. tomakeitrigidso

it

doesnotmoveduringthe

work operation. Keepgoodbalanceatalltimes.

Do

not

stretch or overreach.

-Try tomatchthetooltothework operation.

Do

notuse

atoolthat istoolightorheavyforthework operation. If

indoubt, seek advice.

-In general terms, this tool

is

not suitable for

underwater use

or

use

in

explosive environments

-

seek advicefrom manufacturer.

-Try

to makesure that the work areaisdearto enable

the work task to beperformed safely. If practical

and

possible, try toclear unnecessaryobstructions before

startingwork.

-Always use air hose and couplings with minimum

working pressure ratings at least

1

112

times the

maximumworking pressure ratingof the

tool.

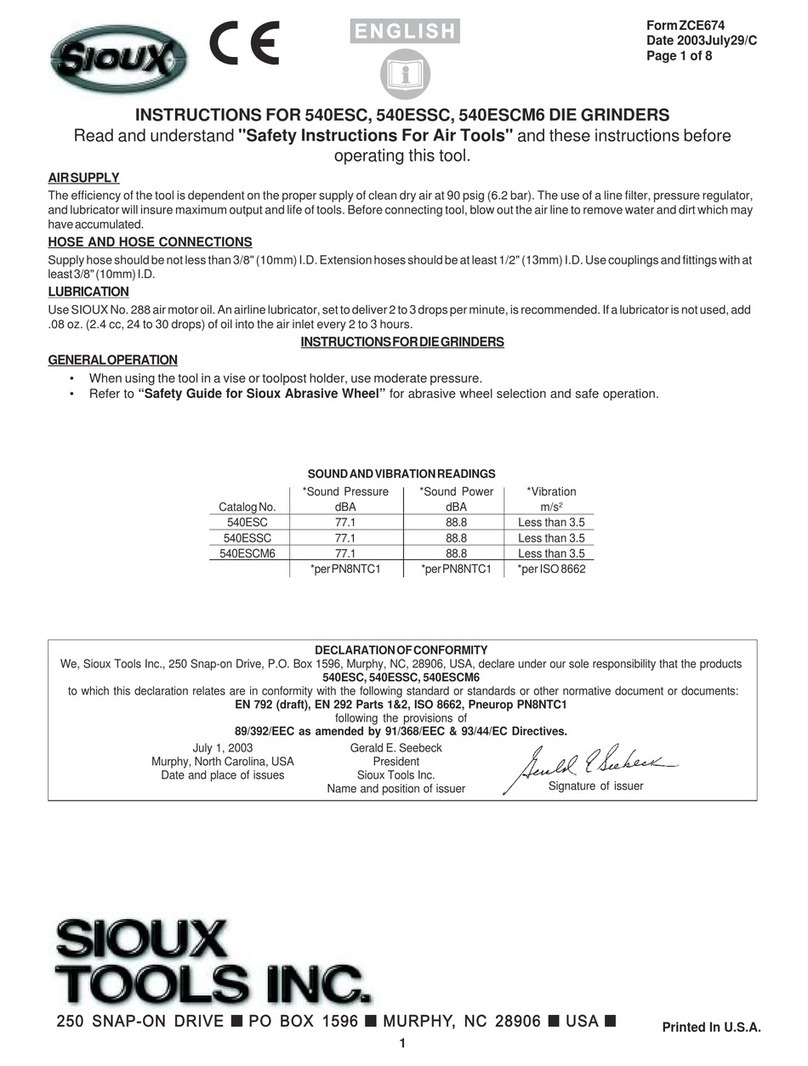

ForeseenUse

Of

TheTool

-

5285

This

rightanglegrinderisdesigned

to

be

used

with

reinforcedresin

bondeddepressedcenter grindingwheels

that

haveapermitted

ro-

tationalspeedinexcessof 12,000

RPM.

The

tool

is

designed

to

be

used

for

light

grinding and

dressing

of

welds, etc.,

but

not

for cutting

off.The

grinder must

never

be

used

if

awheelguard (discguard)

item

(3)

is

not

fitted.

Work

Stations

The

tool

shouldonlybeusedas ahandheld,

hand

operatedtool.It

is

always

recommendedthat

the

tool

isusedwhen standingona

solid

door.

It

can

be

used

inother positions,

but

beforeany such

.

use,

the

operator

nnpl

be

in

asecure position

having

a

firm

grip

and

footing

and

be

aware

of

the

extra

safety

precautionsthat

must

beobservedwhen usinggrindingmachines.

PuttingIntoService

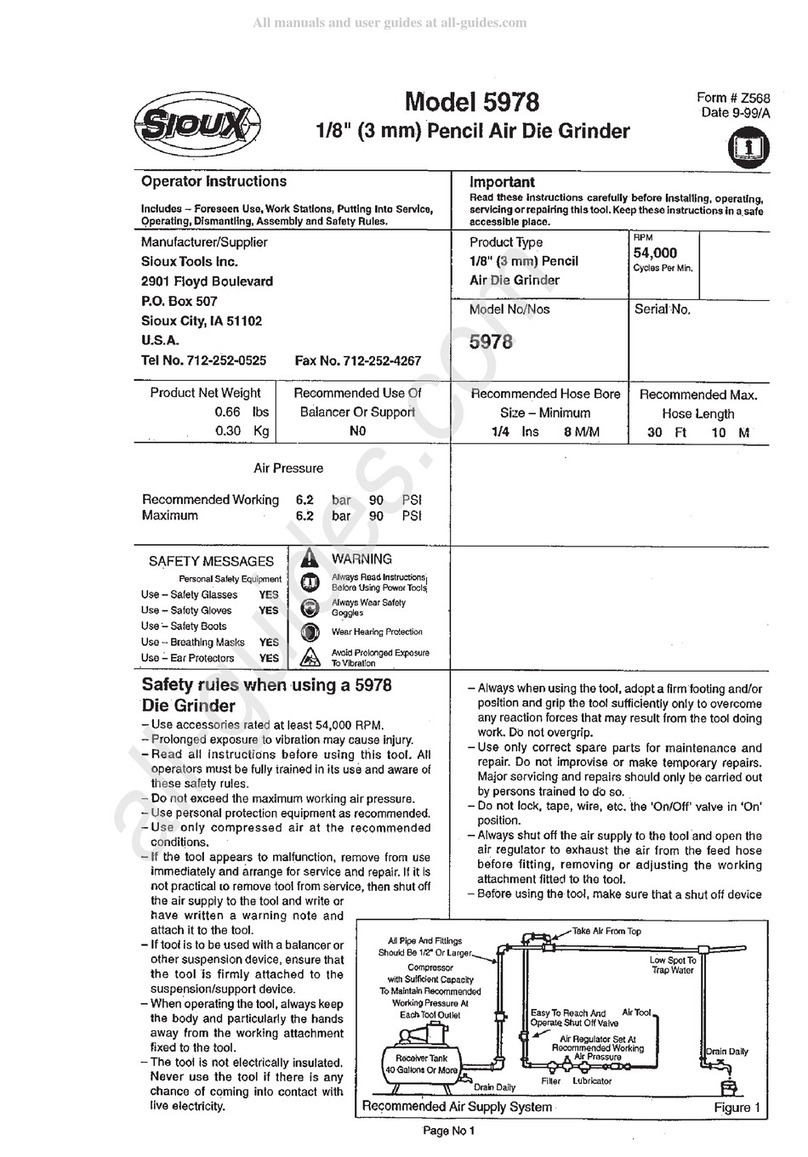

Air

~u~~l~

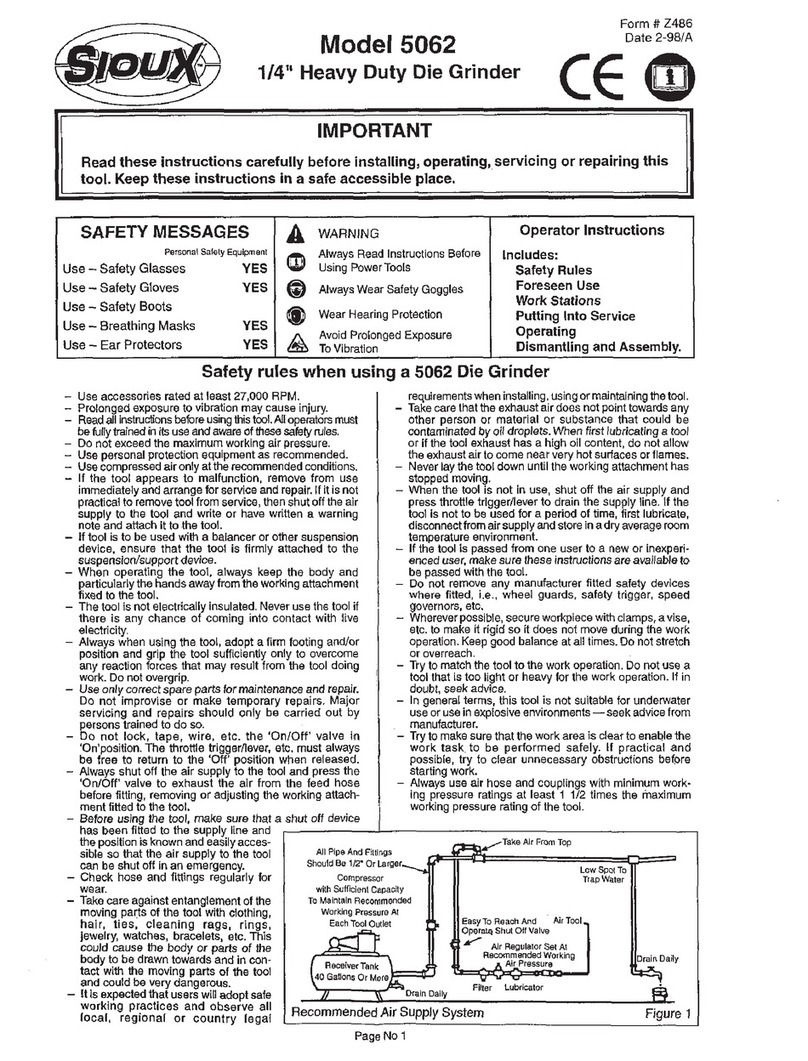

Use a clean lubricated air supply that win

give

a measured air

pressure

at

the tool of

90

p.s.iJ6.2 bar when the tool is running

withthetriggerneverfullydepressed.Userecommendedhosesize

andlength.

It

isrecommendedthat thetoo) isconnected

to

theair

supply as

shown

in

figure 1.

Do

not connect the toolto the air line

system

without

incorporatinganeasytoreachandoperateair

shut

off valve. The air supply should be lubricated. It is strongly

recommendedthat anair fitter, regulator, lubricator

(FRL)

isused

as

shown

inFigure1as

this

willsupply dean, lubricatedair at the

correct pressure to

the

tool.

Details of such equipment can be

obtainedfrom your supplier.

If

such equipment

is

not used, then

the

tool shouldbe lubricated

by

shutting off the air supply to the

tool, depressurizmg

the

line

by

pressing the triggertlever on the

tool. Disconnect the air line and pour into the hose adaptor a

teaspoonful(5ml) of a suitable pneumatic motor lubricating oil

preferably incorporatinga rust inhibitor. Reconnect tool to air

supply and run tool slowly for a few seconds to allow air to

circulatetheoil. Iftool is usedfrequently, lubricateon dailybasis

and

if

toolstartsto slow or losepower.

It

isrecommendedthat the airpressureat the toolwhile thetoolis

runningis

90

psiI6.2 bar.

Operating

With

the

grindercorrectlyconnectedto

the

airsupply,

check

thespeed

of

the

grinder

with

aninletpressureof

90

PSV6.2 bar measured

at

the tool

Met.

Check

with

a

calibratedtachometer. Check that the

guardisinpositionandsecurely

fixed.

Checkthatthegrindingwheel

is of correct dimensions, is not cracked or chipped and has a

permitted speed rating higher than the maximum permissible

running

speed

of

the

grinder,

which

is

12,000

RPM.

Checkthat

(5)

discreceiver,isthe

correct

tvoe

aspartslistandis

screwed

tiohtly

to

the

shalt

and

locates

the

bore

of

the

grinding wheelon the

s&l

of

the

disc receiver and screw

on

disc

nut

(4)

using the spanners

provided.

Do

not

over

tighten

as

this

could

crack thewheel.

It

should

be

tight

enoughtopreventwheel

spin

off whentheair supply

is

shut

ofl.

When

first

starting

the

grinder

with

a new or

changed

wheelfitted,

the

grinder should

first

be

started

ina protectedarea. i.e. under

a

bench

wen

away

from

otherpersonsand

run

for

one

minute.This

will

provide

protection

if

the

wheel shouldbreakbecause

some

fault

was

not

detected

Always

use

eye

protectionandwear protective

gloves

if

there are

sharp

edges

in

the

work

area.The tool

and

thegrinding

process

can

create

a

noise

levelsuchthat

the

use

of

ear protectors

is

advised.

It

the

grinding

process

creates a

dust,

then

usea suitable breathing

mask.

Check

that

the

materialbeing

worked

will

not

causeharmful

dust

or

fumes. If

this

is

so,

then

specialbreathingmasks may

be

required.

H

thegrindervibrateswhen

first

fining

the

wheel or during

operation,

removefrom

service

*mmediately

and

correctfaultbefore

continuing

to

use.

Do

not

apply

excessive pressure as this

will

reduce

the cutting

dkkncy.

Apply

light

loads

to

abw

the

wheel

to

cut

Handle

the

grinder

with

care.

Ã

the grinder is dropped, carefully

examinethe

wheel

lor

damage

and replace if necessary. Start the

machine

as

if

for the

first

time of fittingawheel, i.e. under a

bench.

Makesure

the

object

to beground

is

inafirm

fixed

position.

The

throttlelever (511 is the onlofl valve for the tool. This is a

governedspeed controlledtool. The free runningspeed should

be

checkedfrequently

with

anaccuratetachometer.

If

the

freespeedat

the

maximumallowedoperatingpressureexceeds

12,000

RPM

stop

usingthe toolandarrange for service

to

correct

speed.

PageNo

2