TABLE OF CONTENTS

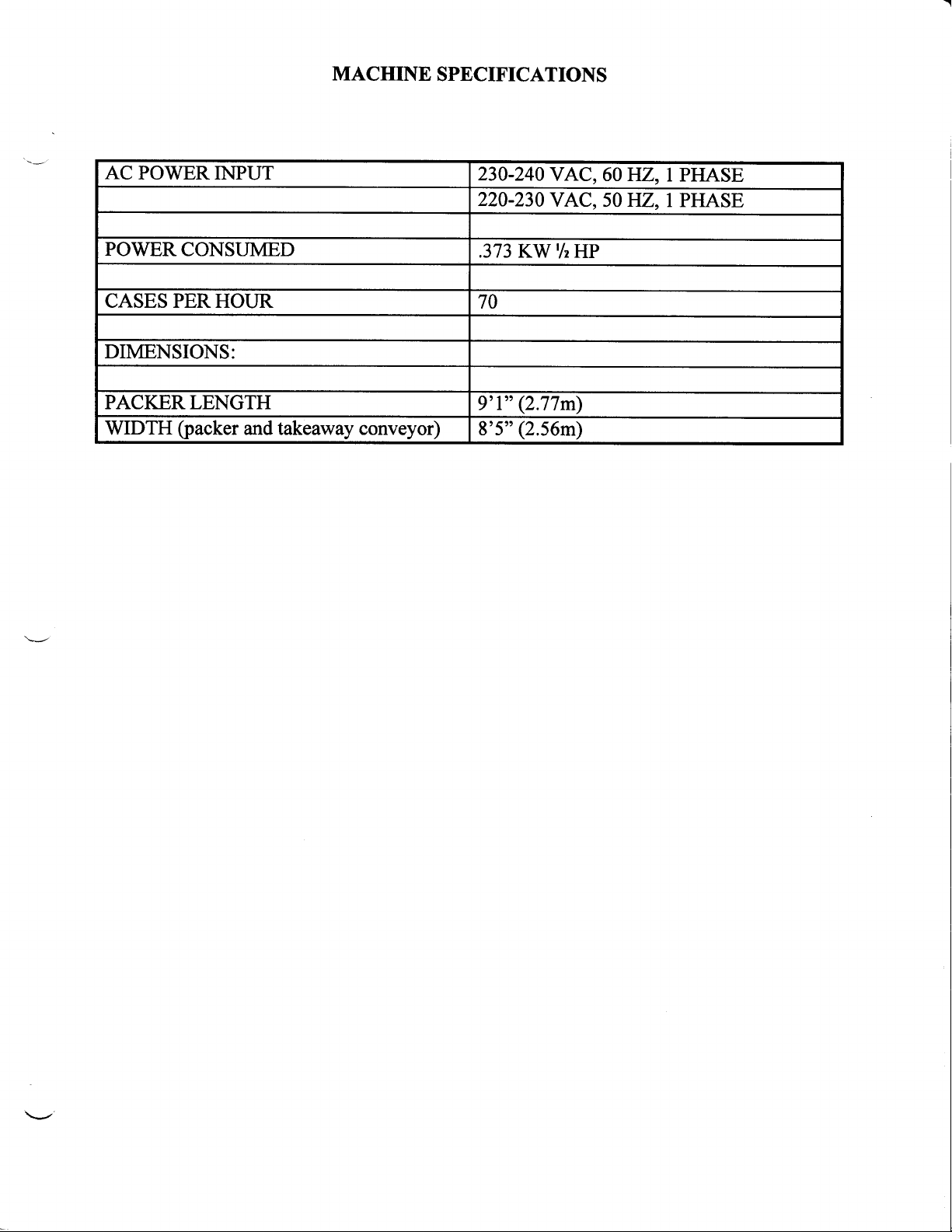

I|ACEIIIESPECIFICiAIIONS .. .. . 1

INgraLLtrroil . . 3

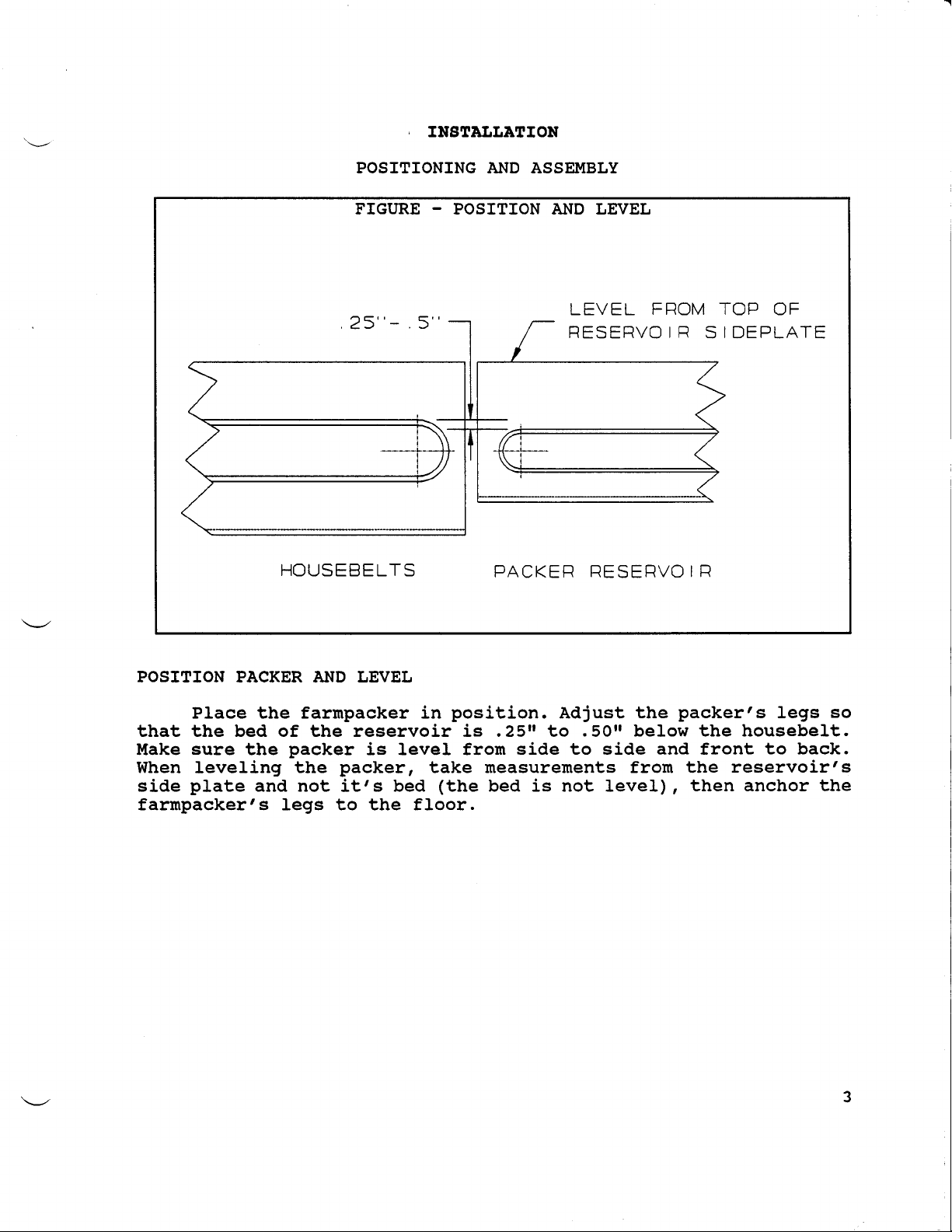

POSITIONINGAI{DASSWBLY .... . 3

INSTALL TAIG.AWAY COM/EYOR TO THE RIGHT 4

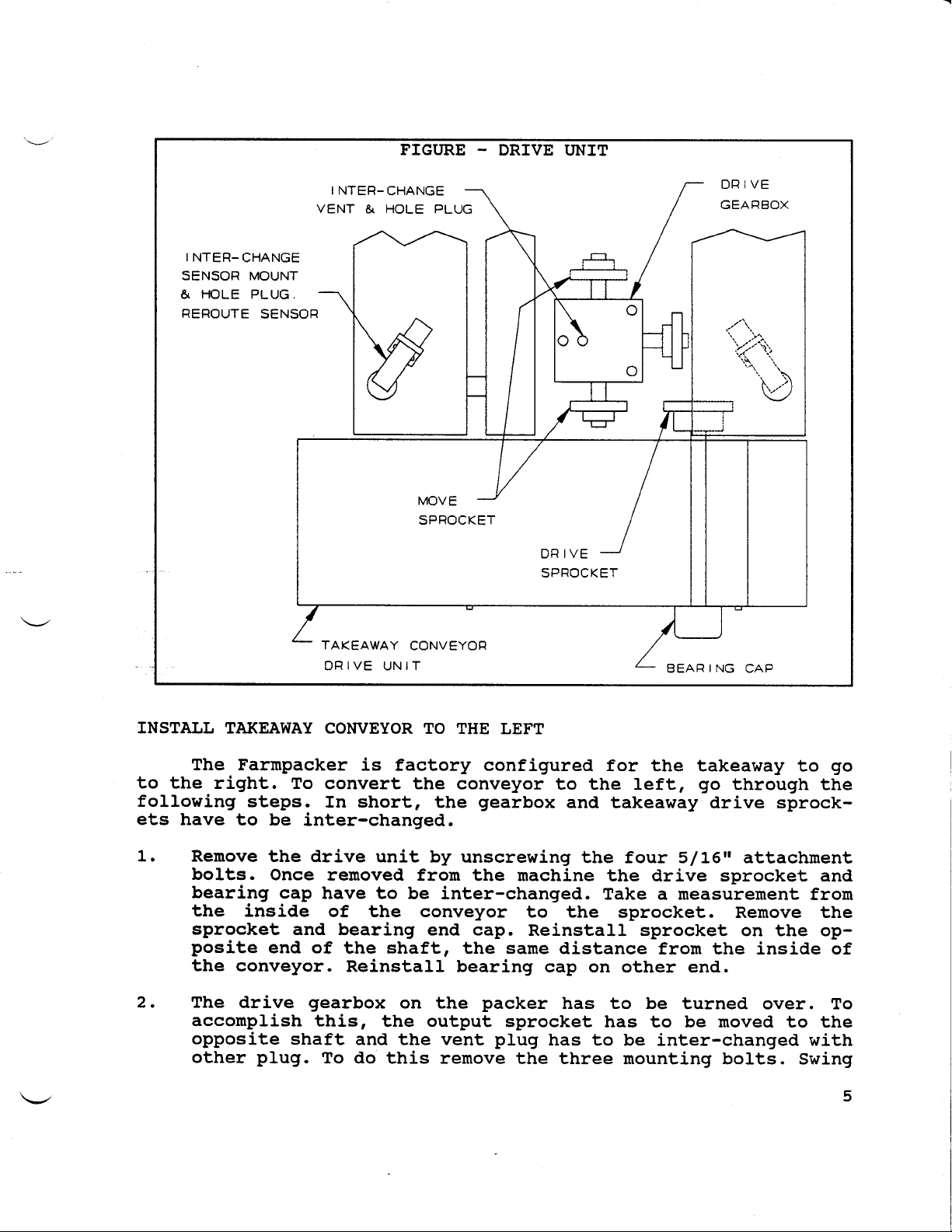

INSTALL TAKE.AWAY COM/EYOR TO THE LEFT O O " " ' 5

ELESIRTCAL HOOKT'P . 7

AC INPIIT . 7

HOUSEBELTS(ELECTRICAL)....o. I

AC HOOKT'P DIAGRAIT{ . 9

FERUPAC.trER CIJEAITIT{G

FERUPAC.trEI, IJUBRICAIION

OPERA!ION

CONTROL PAI.IEL FI'NCTIONS

PACKER OPER.ATION

aDitugruENr

TIITIE DEI,AY ADJUST!{ENT

DENESTERADWST!{ENT

ADJT'ST THE JAW CENTERSTO FI,AT.

ADJUST THE JAW OPENTNG. O ' ' '

ADJUST THE CI,AI.TPPLATES TO THE STACK OF FI,ATS.

SENSORADJUST!{ENT

DENESTERSTART SENSOR

DENESTER STOP SENSOR

10

10

11

11

13

15

15

16

16

L7

18

20

20

20

CYCLE STOP SENSOR . 2L

MOTOR CONTROL ADJUSTI{ENT 22

HEJADTIMING ADJUSTMENT . 23

CI,AII{SHELL ADJUS$IENTS . 24

CI,AI{SHELL RELEASE ADJUSTMENTS . 25

LONG AI.ID SHORT ADVANCE ADJUSTMENTS . 27

TROI'BIJESEOOrING . 29

ELECTRICAL . 29

P.C.B. LIGHT . 29

PACKER UALFT'NCTIONS 30

REFEREXCE / ELECARICAL, DRtrINcs . 35

UISCELI,ANEOUS DRAWINGS . 35

ELECTRICAL DEVICE LOCATION 35

TB-2 I.{IRING DTAGR,N! 35

scHnMATrcs . 37

SYSTEIT{ FLOWCTTART 39

ELECTRICAL BOX ASSEMBLY 41