2 - Manual - Fans

6- Bertrand Manufacturer

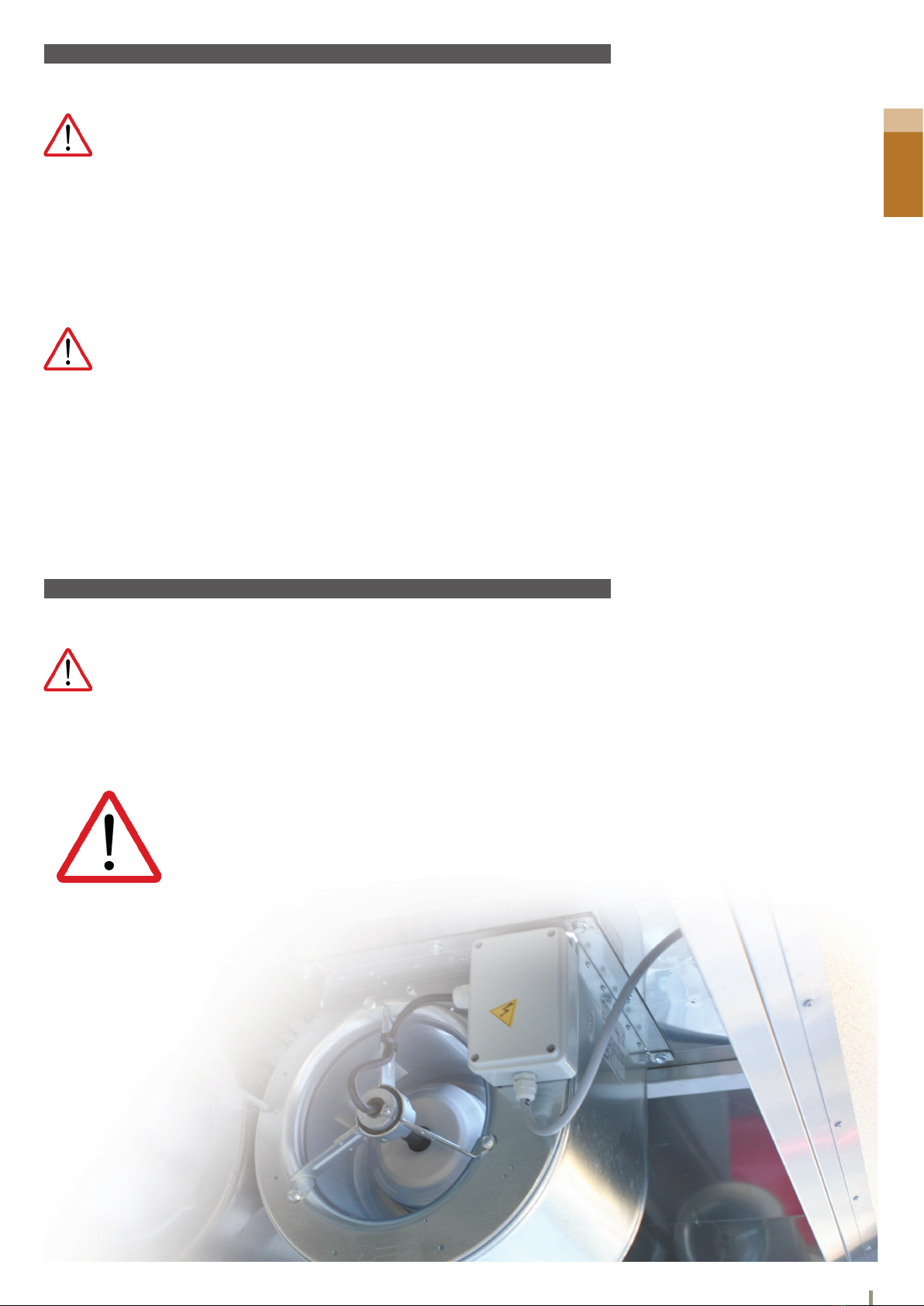

2. FANS DDM 7/7 - DDM 8/9

2.1 General information

2.2 Description and technical characteristics

2.3 Security measure

This manual is directed to manufacturers, installers and service agents of ventilation equipment specialized in the appli-

cation, installation and adjustment of industrial fans.

2.1.1 Purpose and limits of the use of the manual :

This manual is intended for specialized and adequately trained personnel in the realization of machines or equip-

ment using centrifugal electric fans, preventing preventive errors from the use and installation of such devices.

However, the present recommendations are not the only methods, procedures or other devices for obtaining

security in the represented situations. Always be rigorously careful when moving around moving parts or parts

under tension. Safety depends only on skill, experience and reasonable attention in the actions performed on the

machine.

To operate safely on the electronic fan during installation and maintenance, use individual protective equipment (eg.

gloves) as provided for in Directive 89/686 / EEC (and its successive amendments).

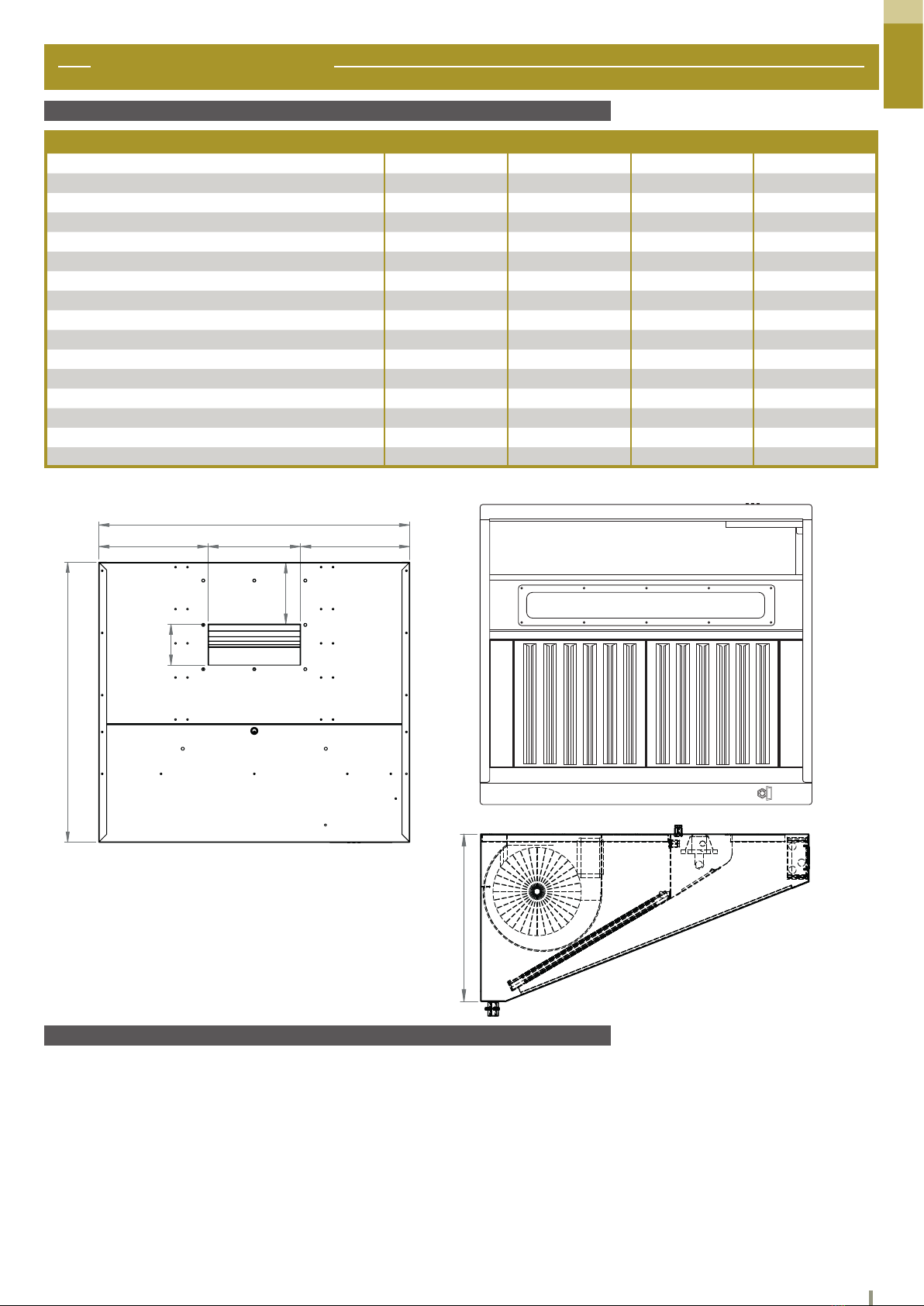

2.2.1 Description :

For a description of the fans, refer to the manual.

2.2.2 Technical features and expected use :

The current electric fan is adapted to transfer non-toxic, non-ammable, non-corrosive air without liquid or solid or

abrasive particles and the temperature does not exceed 40 ° C (UNI EN ISO 13349).

Different temperature and humidity limits are indicated on the fan label. The electric fan must only be operated

with the electrical power supplied by the indication on the label.

In addition to these recommendations, before performing any activities related to the use of this machine, you

must be informed of the required security applications based on the laws, rules and standards applicable to the

installation site

Displacement, installation and maintenance must always be carried out by

trained and trained technicians.

Any installation by unskilled people is therefore prohibited

Attention: The current electrical fan is built to be mounted in a machine and therefore cannot be used

autonomously.

Attention: the present electric fan must be protected against the risks of mechanical type, the risks due

to the projection, the risks due to the electric energy and the risks due to the extreme temperatures (the

engine can reach surface temperatures above 70 °C) in all cases the electric fan must be installed on the

machine taking into account all necessary safety measures, in order to avoid any danger arising from its

application, in accordance with the requirements of Machine Directive 2006/42 / EC (and its successive

amendments). As an indication, we advise you to apply the content of technical standards UNI EN ISO

12100, UNI EN ISO 13857, CEI EN 60204, UNI EN ISO 12499.

Note: the sound power level emitted by the machine is indicated on the label when it exceeds Leq = 85db

(A). The weight of the fan is indicated on the label when it exceeds 30kg. These indications must be taken

into account to provide the appropriate protection for the machine.