DIAQUIP QDS-150 User manual

DIAMOND DRILLING DRILL STANDS

QDS-150

QDS-350

QDS-500

QDS-800

OPERATORS MANUAL

/02 WWW.DIAQUIP.CO.UK

QDS-150 Model

150Ø

N/A

540

330 x 200 x 815

N/A

8.8

QDS-350 Model

350Ø

N/A

660

425 x 245 x 1005

N/A

18

TECHNICAL DATA

TECHNICAL DATA

Model

Capacity w/o extension spacers (mm)

Max. Capacity with extension spacers (mm)

Effective Stroke (mm)

Dimensions L x W x H (mm)

Add on : Other Rig Heights

Net Weight(kg)

60mm clamp bracket for

mounting hand-held drilling

motors. Bolts directly to the

standard mounting spacer.

QDS-150 MODEL QDS-350 MODEL

60MM CLAMP BRACKET

1. Column

2. Clamp Bolt

3. Crank Handle

(Mounts on either side and also doubles as

a wrench for theAngle Lock Clamp Bolt)

4. Guidance Roller

5. Buttress Bar

6. Base

7. Leveling Bolts

8. Cradle

9. Cradle Lock Bolt

10. Adjustable Roller Axle Bolts (on left side only)

11. Carriage Lock Lever

1

1

3

3

3

4

55

66

77

9

8

11

10

2

OPTIONAL FOR QDS-350, QDS-500 & QDS-800

4

9

8

2

10

11

WWW.DIAQUIP.CO.UK /03

QDS-500 Model

300Ø

100mm spacer = 500Ø

690 -1m mast option

1390 – 1.6m mast option

425 x 245 x 1005

1.6m Column (1390mm stroke)

18 - 1m mast option

QDS-800 Model

400Ø

100mm spacer = 600Ø

200mm spacer = 800Ø

760 – 1m mast option

1760 – 2m mast option

2260 – 2.5m mast option

555 x 275 x 1035

2m Column (1760mm stroke)

2.5m Column (2260mm stroke)

26.5 - 1m mast option

TECHNICAL DATA

TECHNICAL DATA

Model

Capacity w/o extension spacers (mm)

Max. Capacity with extension spacers (mm)

Effective Stroke (mm)

Dimensions L x W x H (mm)

Add on : Other Rig Heights

Net Weight(kg)

EXTENSION SPACERS

200mm 150mm 100mm 45mm

QDS-500 MODEL

1. Column

2. Clamp Bolt

3. Crank Handle

(Mounts on either side and also doubles as

a wrench for theAngle Lock Clamp Bolt)

4. Guidance Roller

5. Buttress Bar

6. Base

7. Leveling Bolts

8. Cradle

9. Cradle Lock Bolt

10. Adjustable Roller Axle Bolts (on left side only)

11. Carriage Lock Lever 10

1

2

3

4

5

6

8

7

3

9

11

1

3

3

4

5

6

7

8

2

9

10

11

QDS-800 MODEL

OPTIONAL FOR QDS-500 & QDS 800

/04 WWW.DIAQUIP.CO.UK

INTRODUCTION:

ORIGINAL INSTRUCTIONS: For your personal safety, read and understand before using.

Save these instructions for future reference

This drill stand is designed to mount diamond core drilling motors by using a suitable mounting

spacer. A standard 4 bolt mounting spacer is included with this stand. The drill stand guides

the motor and diamond core bit so that it is possible to drill perfectly straight cuts in a safe and

controlled manner.

The stand is also able to slant so that holes may be cored at an angle as required.

This stand must be securely fastened to the workpiece using a concrete anchor.

WARNING: Do not attempt to use this stand if the mounting system does not t perfectly

to the drilling motor.

MOUNTING THE MOTOR TO THE DRILL STAND

Rig-Mounted Type Motors:

If the drill motor is the 4 bolt rig-mounted type, the drill stand’s mounting spacer must be bolted

to the drill motor. The mounting tenon must t securely in the slot in the back of the drill motor,

then evenly tighten the four bolts. This mounting spacer now acts as a secure and accurate

coupling between the drill motor and the drill stand. The mounting spacer now ts in the dovetail

in the stand’s cradle and is secured by the cradle lock bolt.

Hand-Held Type Motors:

If the drill motor is the hand-held type, the clamp bracket must be used. The clamp bracket

must rst be bolted to the mounting spacer. Then the motor’s gearcase collar must be mounted

in the clamp bracket. Generally, the drill motor’s side handle will need to be rst removed. To

insert, rst loosen the clamp bracket using the crank handle as a wrench, then insert the motor,

turn to the desired orientation and then securely fasten the clamp bolt.

Now the assembly may be tted into the dovetail in the stand’s cradle and the cradle lock bolt

securely tightened.

WWW.DIAQUIP.CO.UK /05

EXTENSION SPACERS

For larger diameter core bits, extension spacers are required to maintain clearance between

the bit and the the stand. Extension spacers in sizes 45, 100, 150 and 200mm are optionally

available. These may also be stacked together as needed to acheive the required distance.

These mount to the cradle using two bolts and both bolts must be securely tightened. The

motor unit in turn mounts to the spacer

WARNING: Always ensure that all mounting fasteners are securely tightened.

WARNING: Never attempt to drill unless the stand is xed securely beyond any doubt.

/06 WWW.DIAQUIP.CO.UK

DRILLING STAND FUNCTIONAL DESCRIPTION

Fastening the drill rig

Once the desired position of the rig is determined, Use a concrete anchor to secure the rig.

Drill a suitable sized hole for the anchor with a hammer drill.

Drive in the anchor.

Use a long threaded rod with a large washer and nut to secure the base.

Before fully tightening the nut, use a spirit level to check if the stand is level. If needed, loosen

the locknuts and adjust the four leveling bolts to achieve levelness. Then retighten the locknuts.

Now fully tighten the securing nut which afxes the base to the work surface.

NOTE: We recommend using the optional Anchoring Plate for the most secure possible

xing of the base to the workpiece. Place the anchoring plate on the base with the

threaded rod through the hole. Then add the washer and nut. Tighten secularly.

(QDS-500 & QDS-800 only).

Note: If mounting on a wall, it is usually more convenient to secure the stand with the

motor head removed. Using the 19mm combination wrench, loosen the cradle lock bolt

on the carriage to lift the motor head up and away. Once the stand is xed, the motor

head may be re-installed on the stand. Be sure to securely tighten the cradle lock bolt(s).

Note: If additional security is needed, use the jackscrew with an appropriate length

bracing column between the opposite wall or ceiling dependent on where the rig is

situated. Be sure to risk assess the surrounding wall/ ceiling construction before using

this method of anchoring the rig.

ADJUSTING THE DRILLING ANGLE

The drilling angle can be tilted from 0 to 45 degrees. To adjust

the angle, use the crank handle as a wrench and loosen the

angle clamp bolt. Refer to the scale on the column indicating

the angle. Adjust to the desired angle and tighten the clamp.

CAUTION: Do not overtighten the clamp. Only tighten the

necessary amount to make the clamp secure. Overtightening

could distort the column.

0 to 45 degrees

WWW.DIAQUIP.CO.UK /07

CARRIAGE LOCK

Slide the carriage lock lever to the left to lock the carriage in

place. Slide the lever to the right to release the carriage. On

some models, the carriage lock is a thumb screw on the right

side of the carriage. Tighten to lock, loosen to release.

CAUTION: Hold the crank lever or motor head whenever

releasing the carriage lock. It could slam down causing

possible injury or damage to the bit or machine.

Carriage Lock Lever

REDUCTION GEARING

On the larger size stands, QDS-500,

QDS-800, there are two crank spindles:

one for standard cranking and one for reduced gear ratio

cranking. The reduced gear ratio allows the operator

to drill with greatly reduced effort when using large

diameter core bits. To switch from standard to reduced

gear ratio cranking, simply remove the crank handle

from the main spindle and connect to the forward spindle

on the left side.

Standard Ratio

Reduced Ratio

ADJUSTING THE DRILLING STAND GUIDANCE

Loose guidance will cause the bit to run out-of-true

and result in poor performance, sticking and possible

damage to the bit. If the rollers can be turned by hand

with the carriage locked, they are too loose.

To adjust the guidance, the two guide rollers on the left

side are on eccentric shafts. Turn the eccentric roller

axle bolt until the clearance is taken up on each roller

in turn. Turn just enough so that the roller cannot be

turned by hand. Now test the tightness of the carriage by

cranking it up and down. There should be no free-play,

yet no binding throughout its travel.

Adjustable Roller

Axle Bolts

Right side Roller Axle Bolts are not adjustable

/08 WWW.DIAQUIP.CO.UK

NOTES

WWW.DIAQUIP.CO.UK /09

NOTES

/10 WWW.DIAQUIP.CO.UK

NOTES

WWW.DIAQUIP.CO.UK /11

NOTES

APPROVED SERVICE CENTRE;

WWW.DIAQUIP.CO.UK

0161 406 0609

SALES@DIAQUIP.CO.UK

DIAQUIP HEAD OFFICE | MANCHESTER, UK

This manual suits for next models

3

Table of contents

Popular Power Tools Accessories manuals by other brands

SCHUNK

SCHUNK ROTA THW Series Translation of original operating manual

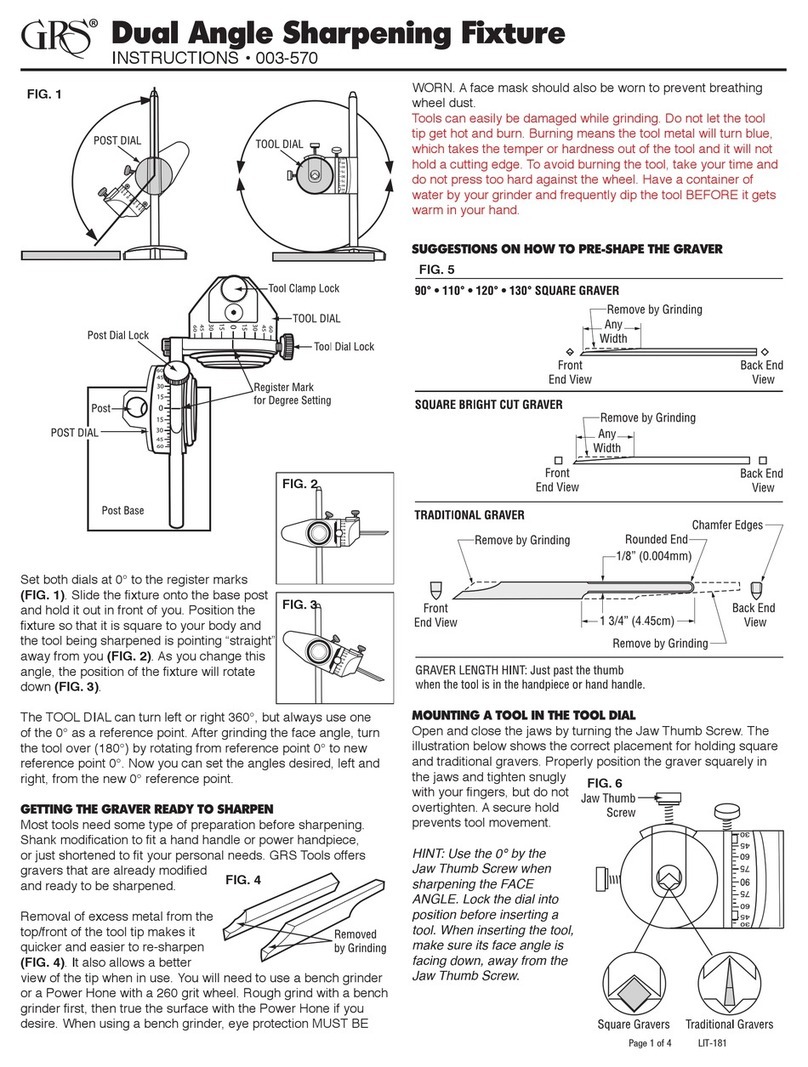

GRS

GRS 003-570 instructions

Milwaukee

Milwaukee 3000 Operator's manual

Kersten

Kersten WKB-H-K 35 Original operating instructions

Renfroe

Renfroe LPA Application, Operation and Maintenance Manual

Record Power

Record Power Coronet Hawk Original instruction manual