Dickey-John seed manager User manual

INTRODUCTION ................................................................................................................. 1

A . SYSTEM OVERVIEW ............................................................................................................ 1

B. SWITCH OVERVIEW ............................................................................................................ 2

1. ON•OFF .................................................................................................................................................. 2

2. ALARM .................................................................................................................................................... 2

3. SETUP ..................................................................................................................................................... 2

4. MIN-AVG-MAX•SCAN ...................................................................................................................... 2

5. SELECT ROW ....................................................................................................................................... 2

6. SELECT, SET, and CLEAR ................................................................................................................. 2

7. START•STOP ....................................................................................................................................... 2

SETUP MODE ........................................................................................................................ 3

A . CUSTOMER SETUP CONFIGURATION ........................................................................ 3

1. Ground Speed Sensor Type ............................................................................................................... 4

2. Shaft Speed Sensor Type .................................................................................................................... 4

3. Hopper Level 1 Sensor Enable ......................................................................................................... 4

4. Hopper Level 2 Sensor Enable ......................................................................................................... 5

5. Pressure 1 Sensor Enable .................................................................................................................... 5

6. Pressure 2 Sensor Enable .................................................................................................................... 6

7. Population Filter Value ....................................................................................................................... 6

8. Population Scaling Factor .................................................................................................................. 6

9. Boot Version Numbers ......................................................................................................................... 7

10. Flash Version Numbers ........................................................................................................................ 8

B. SETUP CONSTANTS ............................................................................................................. 9

1. IMPlement Type Configuration ......................................................................................................... 10

2. ROW Status ............................................................................................................................................ 11

3. POPULATION HI LIMIT .................................................................................................................... 12

4. POPULATION LO LIMIT ................................................................................................................... 12

5. NUMber of ROWS ................................................................................................................................13

6. ROW WIDTH ........................................................................................................................................ 13

7. IMPlement WIDTH ............................................................................................................................... 14

8. Shaft Speed Constant ........................................................................................................................... 14

9. RPM HI LIMIT (Shaft Speed) ........................................................................................................... 15

10. RPM LO LIMIT (Shaft Speed)........................................................................................................... 15

11. Hi Pressure Warning Limit .................................................................................................................. 16

12. Lo Pressure Warning Limit ................................................................................................................. 16

13. Distance Calibration............................................................................................................................. 17

14. Sensor Self-Test ..................................................................................................................................... 18

15. English/METRIC Units Selection ...................................................................................................... 19

OPERATE MODE ................................................................................................................. 21

A . OPERATE MODE .................................................................................................................... 21

1. Run Hours .............................................................................................................................................. 21

2. Population............................................................................................................................................... 22

a. Population SCAN ................................................................................................................................22

b. Population MIN-AVG-MAX .............................................................................................................. 23

c. Population SELECT ROW ................................................................................................................ 23

3. Seed Spacing ......................................................................................................................................... 24

4. Singulation.............................................................................................................................................. 24

5. Speed ....................................................................................................................................................... 25

6. Shaft Speed ............................................................................................................................................ 25

7. Distance Accumulator.......................................................................................................................... 26

8. Area Accumulator 1 ............................................................................................................................ 26

9. Area Accumulator 2 ............................................................................................................................ 27

CONTENTS

10. Area Accumulator 3 ............................................................................................................................. 27

11. Seed Count ............................................................................................................................................. 28

B. SPEED-AREA MODE.............................................................................................................. 28

C . POPULATION BARGRAPH ................................................................................................. 29

D. BARGRAPH LOCK & HOLD ............................................................................................... 31

ALARMS & ERROR CODES ............................................................................................. 33

A. ALARMS..................................................................................................................................... 33

1. Distance Sensor FAILED .................................................................................................................... 33

2. ROW FAILED ........................................................................................................................................ 34

3. All ROWS FAILED .............................................................................................................................. 34

4. Lock-On ROW FAILED ...................................................................................................................... 35

5. POPULATION HI LIMIT Warning ................................................................................................... 35

6. POPULATION LO LIMIT Warning .................................................................................................. 36

7. RPM HI LIMIT (Shaft Speed) Warning .......................................................................................... 36

8. RPM LO LIMIT (Shaft Speed) Warning ......................................................................................... 36

9. HI PRESSURE Limit Warning ......................................................................................................... 36

10. LO PRESSURE Limit Warning ........................................................................................................ 36

11. HOPPER LO Warning ......................................................................................................................... 38

12. Battery Voltage Warning ..................................................................................................................... 38

B. ERROR CODES ........................................................................................................................ 39

SYSTEM INSTALLATION ................................................................................................. 41

A . CONSOLE MOUNTING ........................................................................................................ 41

B. CONSOLE HARNESSES INSTALLATION .................................................................... 42

C . GROUND SPEED SENSOR INSTALLATION ............................................................... 44

D. OTHER SENSORS .................................................................................................................. 45

E. POWER CONNECTION ........................................................................................................ 46

F. SEED SENSORS ....................................................................................................................... 47

G. PLANTER HARNESS ............................................................................................................. 48

1. STANDARD and HI-RATE HARNESSES INSTALLATION ..................................................... 48

2. SQUADRON HARNESS INSTALLATION ..................................................................................... 49

3. SEED SMART® HARNESS INSTALLATION .............................................................................. 50

TROUBLESHOOTING ........................................................................................................ 51

A. MONITOR DEAD .................................................................................................................................... 51

B. BATTERY SYMBOL APPEARS ON DISPLAY .............................................................................. 51

C. ERROR CODE E 020 ............................................................................................................................. 51

D. ERROR CODE E 021 ............................................................................................................................. 51

E. ERROR CODE E 060 ............................................................................................................................. 52

F. ERROR CODE E 062 ............................................................................................................................. 52

G. ERROR CODE E 063 ............................................................................................................................. 52

H. ERROR CODE E 064 ............................................................................................................................. 52

I. ERROR CODE E 065 ............................................................................................................................. 53

J. ERROR CODE E 066 ............................................................................................................................. 53

K. ERROR CODE E 067 ............................................................................................................................. 53

L. ERROR CODE E 080 ............................................................................................................................. 53

M. ERROR CODE E 081 ............................................................................................................................. 54

N. ERROR CODE E 082 ............................................................................................................................. 54

O. ERROR CODE HOPPER FAILURE ................................................................................................... 54

P. ERROR CODE PRESSURE FAILURE ............................................................................................... 54

SETUP RECORD SHEET .................................................................................................... 55

BENCHMARK Series®

OPERATOR'S MANUAL

Dj SEED MANAGER ® PLANTER MONITOR INTRODUCTION/ 1

11001-1103A-200111

A. SYSTEM OVERVIEW

The DICKEY-john Seed Manager®

Population Monitor uses the latest

microprocessor-based technology to

take the guesswork out of the planting

operation. Any time seeds are not going

to the ground at the correct rate or

another error condition occurs, an

alarm is sounded and a message and

row number, if appropriate, are dis-

played.

Seed Manager®offers features such as

improved seed counting accuracy, simpli-

fied harnessing, advanced error diagnos-

tics, and seed singulation when used with

the new Seed Smart®sensors. It is also

compatible with the DICKEY-john

Standard and Hi-Rate seed sensors.

Additional features include a bargraph

presentation of row-to-row planter

performance, high and low population

warnings, faster population updates, and

the ability to disable individual row

sensors from the monitor. An RS-232

interface is available for precision farming

applications.

The Seed Manager®Population Monitor can

monitor up to 36 rows. It stores planter

configuration data and accumulated opera-

tional data in nonvolatile memory, retaining

information even when disconnected from

the tractor battery.

Figure 1 shows the Seed Manager®Popula-

tion Monitor console. It consists of two

custom Liquid Crystal Displays (LCDs) and

twelve membrane switches. The top LCD

display shows messages for the selected

Figure 1

Seed Manager®Console

INTRODUCTION

®

2/ INTRODUCTION

BENCHMARK Series®

OPERATOR'S MANUAL

Dj SEED MANAGER ® PLANTER MONITOR

11001-1103A-200111

Operate Mode function, Setup Mode

constant, or Alarm Mode identifier and the

value on a 5-digit numeric display. A 2-Digit

numeric display identifies the row. The

bottom LCD displays graphically the relative

populations of 12 rows simultaneously.

Larger planters have row groups dis-

played on a time-shared basis.

B. SWITCH OVERVIEW

The switches are used to control system

power, select the mode of operation, and

enter planter configuration constants. To

help distinguish between switch names

and display messages in the text of this

manual, switch names are always shown

in italicized print. An overview of the

switches follows:

1. ON•OFF

Pressing this switch applies power to the

monitor. Upon power up, the monitor

performs internal diagnostic checks,

illuminates all segments of the LCDs,

sounds the alarm, and determines what

type of seed sensor harness is connected.

Depressing the ON•OFF switch for at

least one second causes the monitor to

power down.

2. ALARM

Momentarily pressing this switch silences

the alarm and acknowledges the alarm

condition. Additionally, holding the

switch pressed for more than one second

allows the volume level of the alarm to be

adjusted. As the switch is held pressed,

the alarm sounds continuously and the

volume level slowly decreases to a minimum,

then increases to a maximum. Releasing the

switch establishes the desired volume level.

3. SETUP

This switch is pressed for one (1) second

to enter the Setup Mode and to step from

one Setup constant to the next as detailed

in the SETUP chapter.

4. MIN-AVG-MAX•SCAN

This switch is pressed to toggle between

the MIN-AVG-MAX and SCAN options

for the function selected by the Popula-

tion• Spacing•Singulation switch.

5. SELECT ROW

Pressing this switch while in the Popula-

tion, Spacing, or Singulation functions

freezes the upper LCD display on the

current row data. Successive depressions

then cause stepping from one row to the

next. In the Setup Mode, this switch

allows stepping through the rows while

entering Row Status.

6. SELECT, SET, and CLEAR

These switches are used to change constants

in the Setup Mode as explained in the

SETUP chapter. The CLEAR switch is also

used in the Operate Mode to reset the area

and distance accumulators and the Run

Hours function. The SELECT switch is used

in the Operate Mode to select various

Bargraph Display/Sections.

7. START•STOP

This switch is used in the Operate Mode

Seed Count, Distance Accumulator, and

Bargraph Lock & Hold functions. In the

Setup Mode, it is used for the Distance

Calibration and the Sensor Self-Test.

BENCHMARK Series®

OPERATOR'S MANUAL

Dj SEED MANAGER® PLANTER MONITOR SETUP MODE/ 3

11001-1103A-200111

SETUP MODE

A. CUSTOMER SETUP

CONFIGURATION

Certain parameters must be entered in the

Setup Configuration to the console. This

mode is used to specify the types of ground

speed and shaft speed sensors used, enable

or disable hopper level sensors, to enable or

disable pressure sensors, set population filter

and scaling factor and identify the software

version.

The Setup Configuration is entered by

holding the Setup switch depressed while

powering on the console and continuing to

hold it depressed until the Display Test

begins. A flashing SETUP message indicates

the console is in the Setup Configuration

Mode.

Additional messages uniquely identify the

parameter displayed and available for editing.

Use the SELECT, SET, and CLEAR

switches as described previously to enter or

change parameters. Also, press Setup, as

before, to store the value and advance to the

next parameter. To exit the Customer Setup

Mode, power off the console.

Figure 2 shows the Customer Setup parame-

ters, in the order of their presentation. As

before, record all parameter values on the

SETUP RECORD sheet on the last page of

this manual, immediately after console entry.

Definitions and considerations when entering

values for each parameter are as follows:

Figure 2

Customer Setup Parameter Chart

1 Ground Speed Sensor Type

2 Shaft Speed Sensor Type

3 Hopper Level 1 Sensor Enable

4 Hopper Level 2 Sensor Enable

5* Hopper Pressure 1 Sensor Enable

6* Hopper Pressure 2 Sensor Enable

7* Population Filter Value

8* Population Scaling Factor

9 Boot Version Number

10 Flash Version Number

* New For Version 5.0 Software

4/ SETUP MODE

BENCHMARK Series®

OPERATOR'S MANUAL

Dj SEED MANAGER® PLANTER MONITOR

11001-1103A-200111

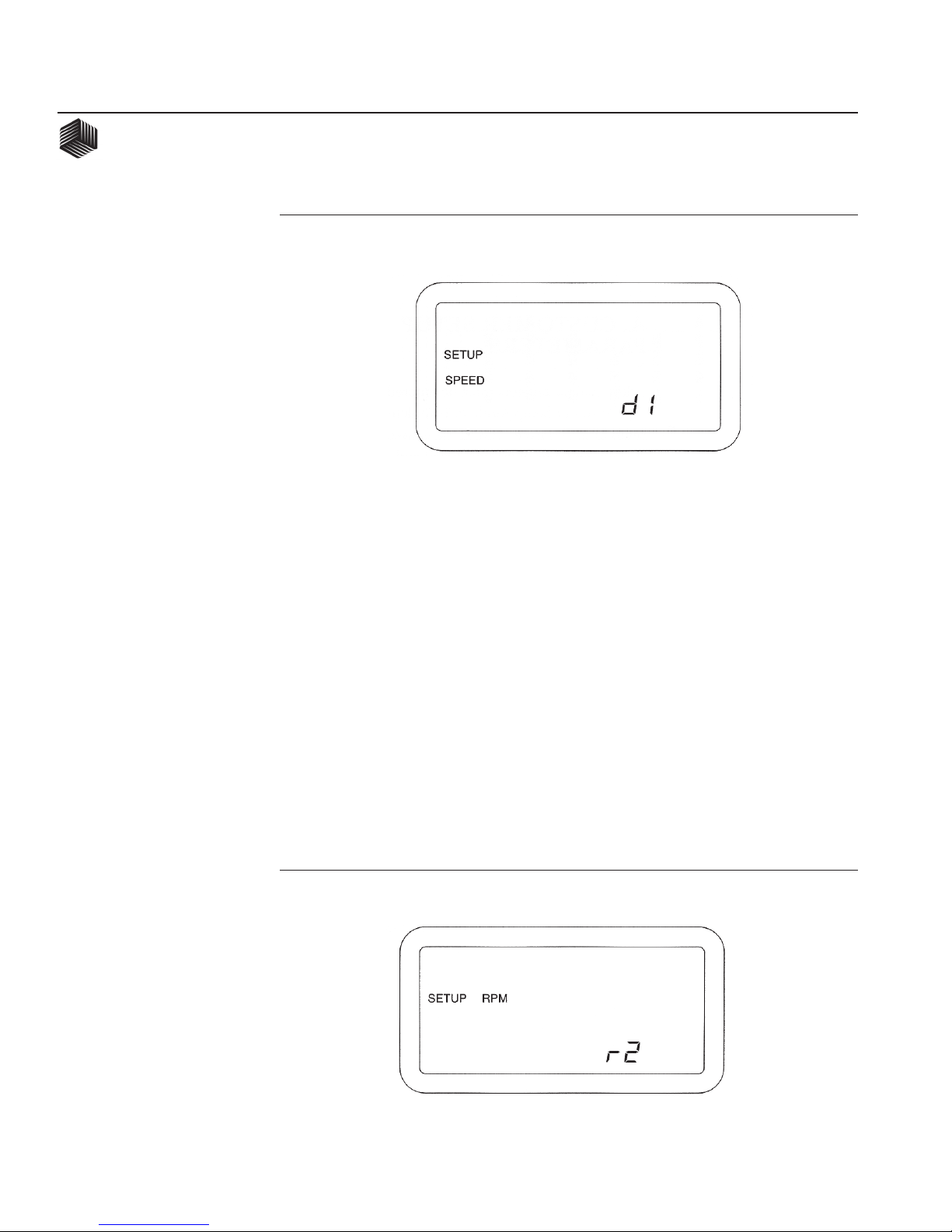

1. Ground Speed Sensor Type

This parameter allows choosing between a

digital (radar or Hall Effect) type or reluc-

tance type ground speed sensor. This

parameter is identified by the message

SPEED and a flashing SETUP message.

Pressing the SET switch causes the lower,

right display to toggle between a flashing

"d1" or "r1". If a digital (radar or Hall

Effect) type ground speed sensor is used,

press the SET switch until "d1" appears. If

a reluctance type ground speed sensor is

used, press the SET switch until "r1"

appears. Figure 3 shows a digital type ground

speed sensor selected.

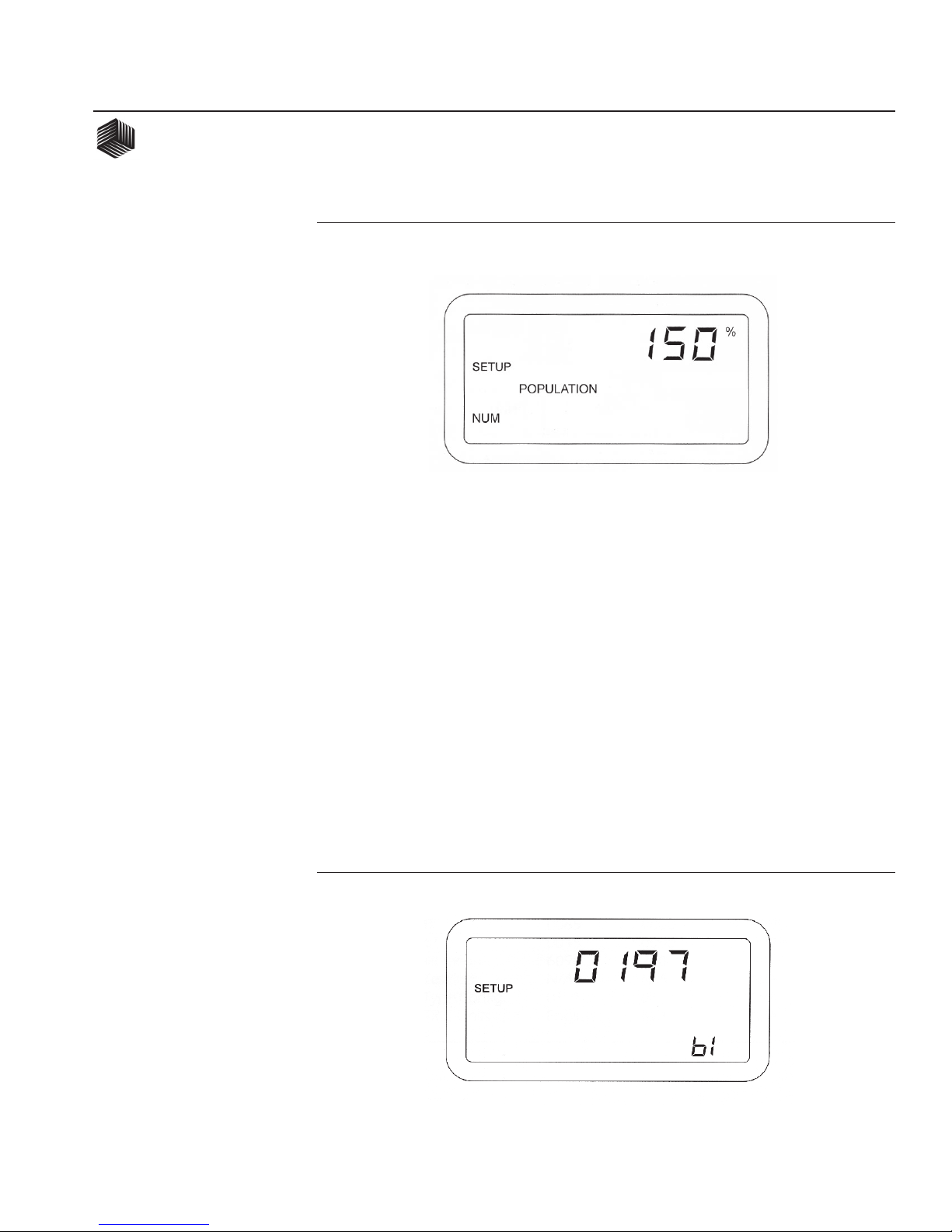

2. Shaft Speed Sensor Type

This parameter allows choosing between a

digital 1, digital 2, reluctance 1, or reluctance

2 type shaft speed sensor. This parameter is

identified by the message RPM and a flashing

SETUP message. Pressing the SET switch

causes stepping between "d1, d2, r1, and r2"

flashing on the lower, right display. The shaft

speed sensor type used is clearly labeled on

the sensor cable. Figure 4 shows a reluctance

2 type shaft speed sensor selected.

3. Hopper Level 1 Sensor Enable

This parameter enables or disables the

DICKEY-john Hopper Level 1 Sensor. It

is identified by the message HOPPER, a "1"

Figure 3

Ground Speed Sensor Type Display

Figure 4

Shaft Speed Sensor Type Display

BENCHMARK Series®

OPERATOR'S MANUAL

Dj SEED MANAGER® PLANTER MONITOR SETUP MODE/ 5

11001-1103A-200111

on the lower, right display, a flashing SETUP

message, and either the ON or OFF message

flashing. To enable or disable, press the SET

switch to select ON or OFF respectively.

Figure 5 shows the hopper level sensor is

enabled.

4. Hopper Level 2 Sensor Enable

This parameter enables or disables the

DICKEY-john Hopper Level 2 Sensor. It

is identified by the message HOPPER, a

"2" on the lower, right display, a flashing

SETUP message, and either the ON or

OFF message flashing. To enable or

disable, press the SET switch to select ON

or OFF respectively.

Figure 5

Hopper Level Sensor Display

5. Pressure 1 Sensor Enable

This parameter enables or disables the

hopper pressure sensor #1. This is identified

on the display by the message “PRESS”, “1”,

and the flashing SETUP icon. To enable

disable, press the SET switch to select ON or

OFF respectively. Figure 6 below shows

PRESSURE 1 enabled.

Figure 6

Pressure I Enable

6/ SETUP MODE

BENCHMARK Series®

OPERATOR'S MANUAL

Dj SEED MANAGER® PLANTER MONITOR

11001-1103A-200111

6. Pressure 2 Sensor Enable

This parameter enables or disables the

hopper pressure sensor #2. This is identified

on the display by the message “PRESS”, “2”,

and the flashing SETUP icon. To enable/

disable, press the SET switch to select ON or

OFF respectively. Figure 7 shows PRES-

SURE 2 disabled.

7. Population Filter Value

In certain applications the Seed Manager®,

due to its rapid update rate, might exhibit

fluctuations in population, spacing, and

singulation that are undesirable to the

operator. The population filtering option

applies an averaging filter to the population,

and seed spacing calculations. The filter

values range from 0 to 99, with 0 having no

filtering effect and 99 being the maximum

filtering value. Use the SET and SELECT

switches to adjust the filtering value. Figure 8

shows a light filter value of 15.

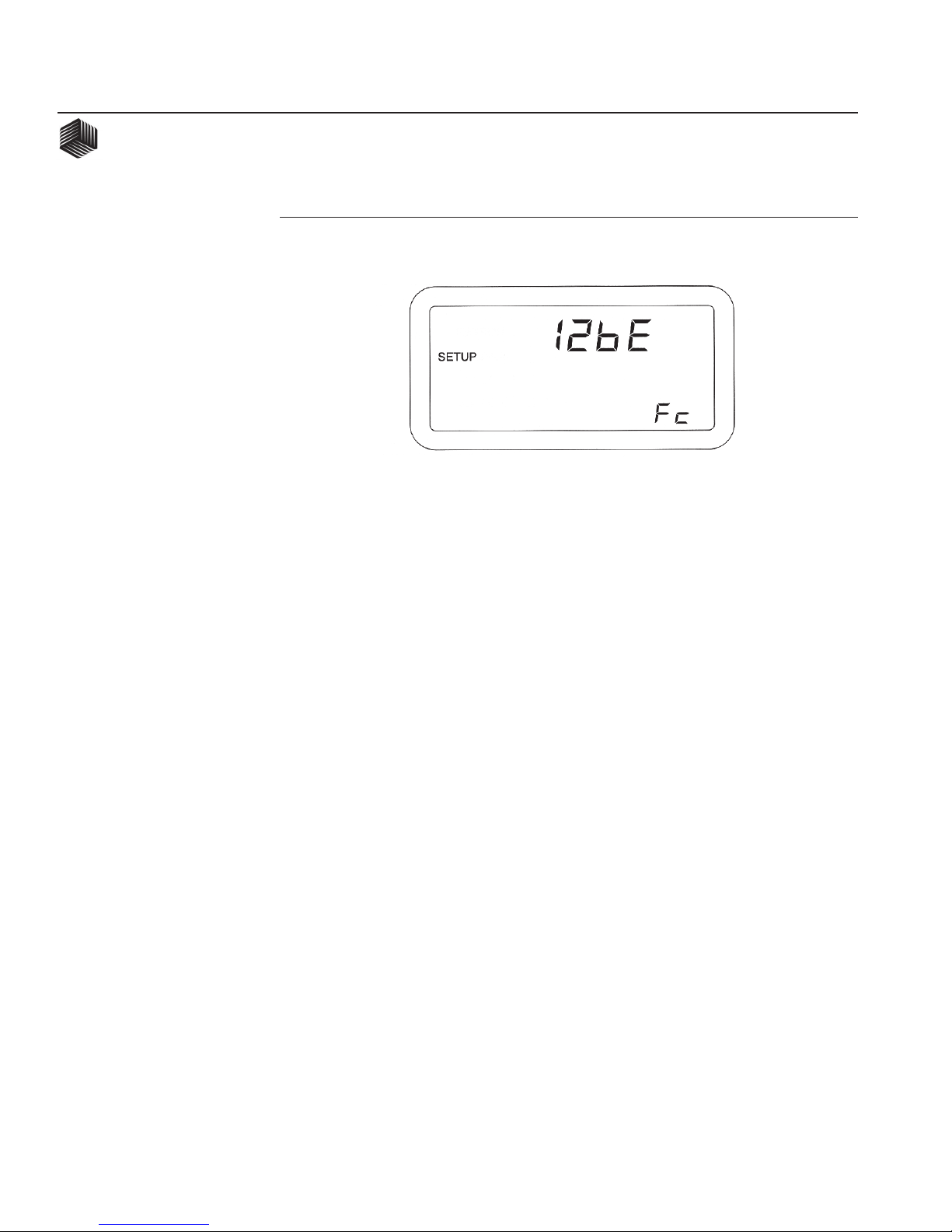

8. Population Scaling Factor

The population scaling factor allows the

operator to make fine adjustments in the

readout of population and spacing on a

Figure 7

Pressure 2 Disable

Figure 8

Filter Value

BENCHMARK Series®

OPERATOR'S MANUAL

Dj SEED MANAGER® PLANTER MONITOR SETUP MODE/ 7

11001-1103A-200111

Figure 10

Boot Number

percentage basis. This value is adjustable

from 1% to 999% with the factory value being

100%. Use the SET and SELECT switches

to adjust to the desired population scaling

factor. Figure 9 shows a population scaling

factor of 150%. Increasing this value results

in an increase of population readout, while

decreasing this value results in a decrease of

the readout..

Examples:

To increase the population display 15%,

enter 115%.

To decrease the population display 13%,

enter 87%.

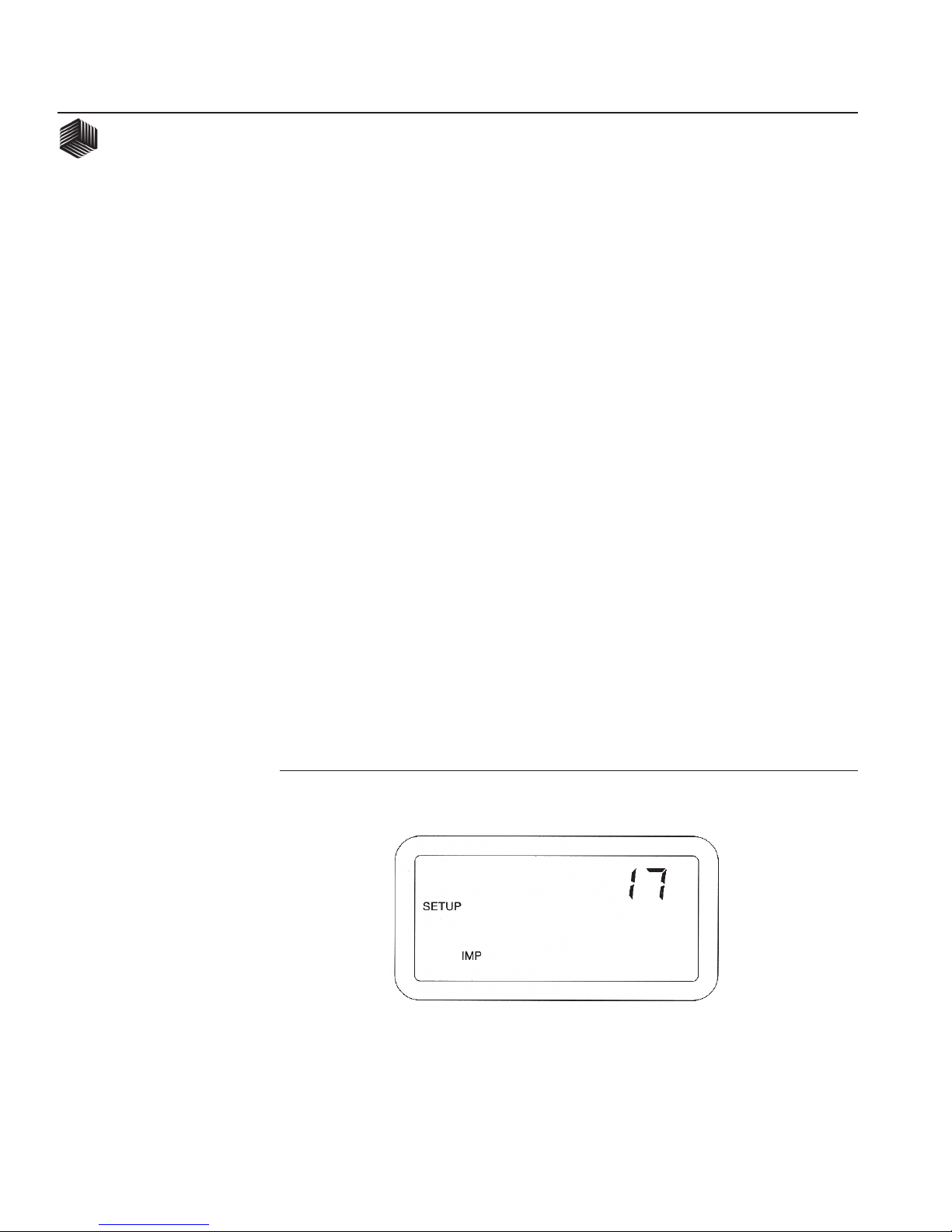

9. Boot Version Numbers

DICKEY-john's Service department may

request the customer to observe, record, and

report back the four different 4-digit num-

bers (to identify the "boot memory" software

version) in the unlikely event field problems

occur.

The first 4-digit number shows on the upper

numeric display at the same time a "b1"

identifier appears on the lower numeric

Figure 9

Population Scaling Factor

8/ SETUP MODE

BENCHMARK Series®

OPERATOR'S MANUAL

Dj SEED MANAGER® PLANTER MONITOR

11001-1103A-200111

display. Record this number, then press and

release the SELECT switch to step to the

"b2", "b3", and "bc" numbers, recording each

4-digit number along with its identifier. (To

return to "b1", press SELECT again.) Press

the SETUP switch to advance to the next

constant. Figure 10 shows "0197" for "b1", the

first Boot Version Number.

10. Flash Version Numbers

DICKEY-john's Service department may

request the customer to observe, record, and

report back the four different 4-digit num-

bers (to identify the "flash memory" software

version) in the unlikely event field problems

occur.

The first 4-digit number shows on the upper

numeric display at the same time a "F1"

Figure 11

Flash Version Number

identifier appears on the lower numeric

display. Record this number, then press and

release the SELECT switch to step to the

"F2", "F3", and "Fc" numbers, recording each

4-digit number along with its identifier. (To

return to "F1", press SELECT again.) Figure

11 shows "12bE" for "Fc", the last Flash

Version Number.

Pressing the SETUP switch again causes a

return to the first Customer Setup param-

eter, Ground Speed Sensor Type. To exit

the Customer Setup Mode, power off the

console.

BENCHMARK Series®

OPERATOR'S MANUAL

Dj SEED MANAGER® PLANTER MONITOR SETUP MODE/ 9

11001-1103A-200111

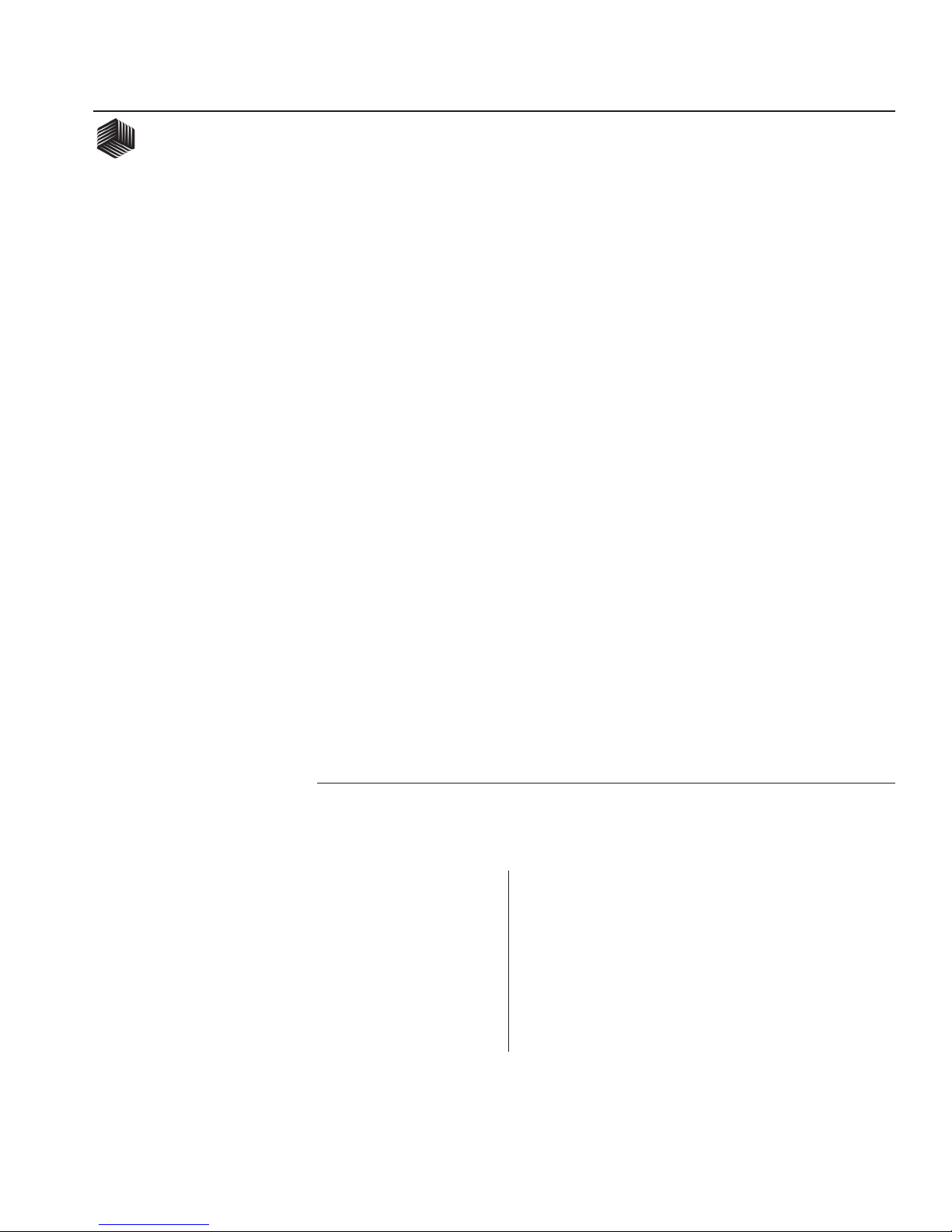

B. SETUP CONSTANTS

The Setup Mode is used to enter the planter

configuration constants which are listed in

Figure 12, in the order of their presentation.

Depressing the Setup switch for one (1)

second places the console in the Setup

Mode, which is identified by the SETUP

message on the display. Additional messages

uniquely identify the constant displayed and

available for editing at any given time.

Each constant has a fixed number of digits.

Leading zeroes are displayed. When it is

desired to change the value of a constant, use

the SELECT, SET, and CLEAR switches as

follows:

Initially, the left most digit flashes on and

off, indicating it is the “selected digit”.

Each depression of the SET switch

increases the selected digit by one count.

After reaching the maximum value of

nine (9), the digit rolls over to zero (0).

Pressing CLEAR zeroes the digit. Each

depression of the SELECT switch makes

the next digit to the right the selected

digit.

When the desired value is entered (or

there is no change from the original

value), press the Setup switch to store

the value and advance to the next

constant on the list. If a value is

entered which exceeds the minimum

or maximum shown for that constant

Figure 12

Setup Mode Parameters

Order SETUP Mode Default Miniuum Maximum

CONSTANT Name

1. IMPlement Type Config. 01 01 N/A

2. Row Status ON N/A N/A

3. POPULATION HI LIMIT 0034.0 0000.0 9999.9

4. POPULATION LO LIMIT 0026.0 0000.0 9999.9

5. NUMber of ROWS N/A 1 36

6. ROW WIDTH 030.0 001.0 999.9

7. IMPlement WIDTH N/A 0001.0 9999.9

8. Shaft Speed Constant 000.00 000.00 999.99

9. RPM HI LIMIT 0065 0000 9999

10. RPM LO LIMIT 0045 0000 9999

11.* Hi Pressure 000.0 000.0 999.9

12.* Lo Pressure 000.0 000.0 999.9

13. Distance Calibration 6096 250 9999

14. Sensor Self-Test N/A N/A N/A

15. English/METRIC Units English N/A N/A

* IF PRESSURE SENSORS HAVE NOT BEEN ENABLED, THESE CONSTANTS ARE SKIPPED

10/ SETUP MODE

BENCHMARK Series®

OPERATOR'S MANUAL

Dj SEED MANAGER® PLANTER MONITOR

11001-1103A-200111

in Figure 12, the alarm sounds for one (1)

second, the value of the exceeded limit

appears on the screen, and the advance to

the next constant is aborted.

CAUTION: To allow rapid recovery from

an entry error, it is important to record all

values of constants on the SETUP

RECORD sheet on the last page of this

manual, immediately after console entry.

To exit the Setup Mode, press any of the

three Operate Mode switches (Population

•Spacing•Singulation, Area• Seed Count,

or Speed•Shaft Speed•Dist Acc). Exiting

automatically stores the last constant

changed.

The first parameter displayed after entering

the Setup Mode is Implement type Configura-

tion. Definitions and considerations when

entering values for each constant are as follows:

Figure 13

IMPlement Type Configuration Display

1. IMPlement Type Configuration

Find the number identifying the specific

planter type on the "Planter Configuration

Instruction" (DICKEY-john Document No.

11001-1107). Enter this number using the

SELECT and SET switches. The SETUP

and IMP messages identify the display. This

parameter defines the number of rows, the

row number for each sensor, and the

bargraph display arrangement. Figure 13

shows IMPlement Type Configuration 17

selected.

BENCHMARK Series®

OPERATOR'S MANUAL

Dj SEED MANAGER® PLANTER MONITOR SETUP MODE/ 11

11001-1103A-200111

2. ROW Status

This parameter allows placing individual seed

sensors in ON, OFF, or SKIP status. For

those situations where it is necessary to turn

off certain rows on the planter (for example,

with skip row planters or when planting point

rows or seed corn), OFF status turns off the

related sensors so alarms do not occur. The

SKIP status setting, available only with Seed

Smart®sensors, allows removing a failed

sensor from the harness “daisy-chain” (and

jumpering with an extension harness) without

disrupting row numbering.

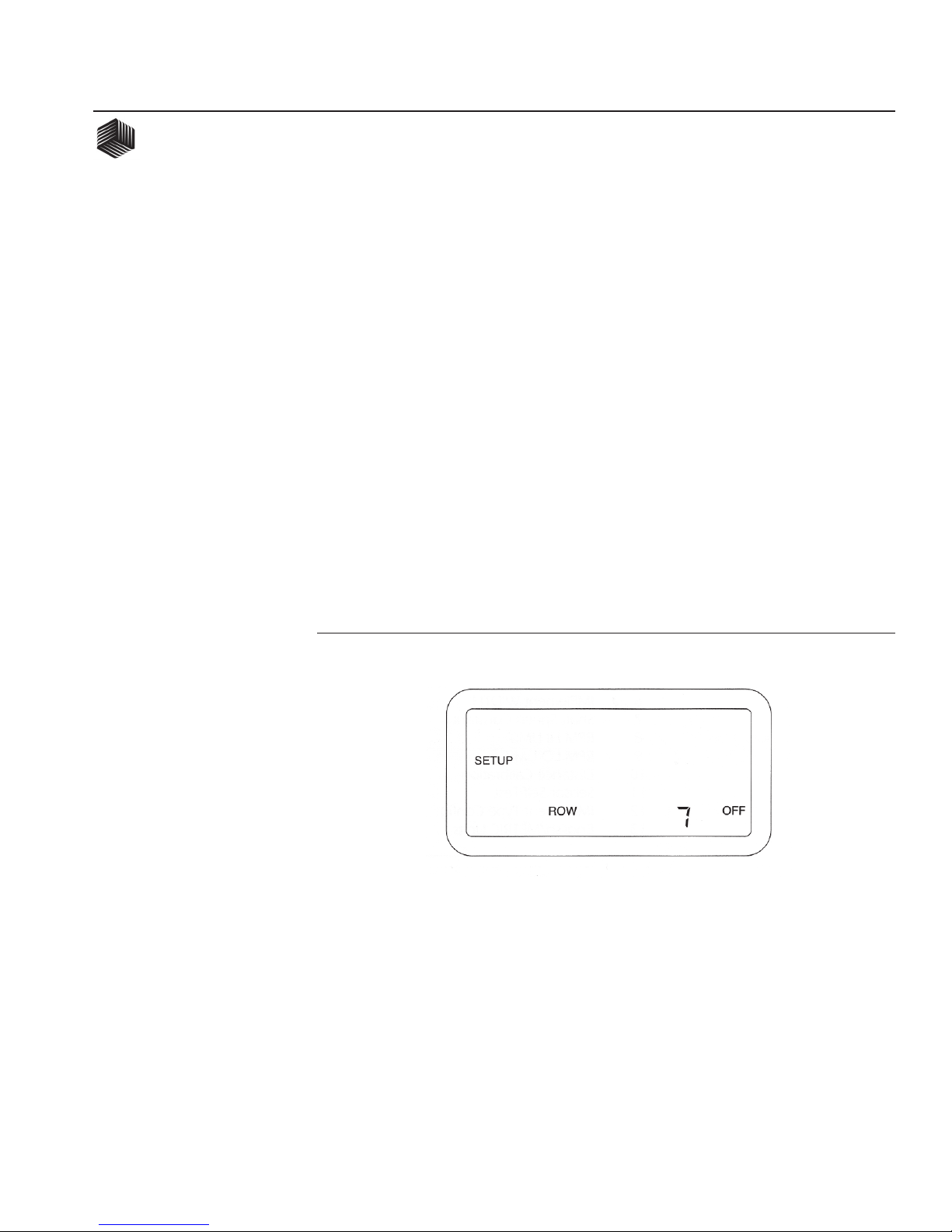

Figure 14

Row Status Display

The display initially shows the messages

SETUP, ROW, 1, and the status of

row 1. Figure 14 shows row 7 status set to

OFF. Press the SET switch to toggle between

ON and OFF for the Standard and Hi-Rate

seed sensors and between ON, OFF, and

SKIP for the Seed Smart®sensor. Press the

SELECT ROW switch to advance to the

next row. When the status of all rows is

correctly entered, press Setup to advance to

the next Setup constant.

12/ SETUP MODE

BENCHMARK Series®

OPERATOR'S MANUAL

Dj SEED MANAGER® PLANTER MONITOR

11001-1103A-200111

3. POPULATION HI LIMIT

When the population on any row exceeds

the value entered for this constant, in

thousands of seeds per acre (hectare), the

alarm sounds, as indicated under the

heading ALARMS, POPULATION HI

LIMIT Warning. Figure 15 shows the display

for a limit of 176,000 seeds/acre.

4. POPULATION LO LIMIT

When the population on any row falls below

the value entered for this constant, in

thousands of seeds per acre (hectare), the

alarm sounds, as indicated under the heading

ALARMS, POPULATION LO LIMIT

Warning. Figure 16 shows the display for a

limit of 144,500 seeds/acre.

Figure 15

POPULATION HI LIMIT Display

Figure 16

POPULATION LO LIMIT Display

BENCHMARK Series®

OPERATOR'S MANUAL

Dj SEED MANAGER® PLANTER MONITOR SETUP MODE/ 13

11001-1103A-200111

5. NUMber of ROWS

This parameter is used to calculate IMPle-

ment WIDTH and is used in checking the

number of sensors detected upon system

power up. This value is displayed for

confirmation and can only be altered by

changing the IMPlement Type Configuration

parameter. Figure 17 shows the display for

sixteen (16) rows.

6. ROW WIDTH

This is the distance in inches (centimeters)

between furrows, with a resolution of 0.1.

Figure 18 shows a ROW WIDTH of 38.0

inches.

Figure 17

NUMber of ROWS Display

Figure 18

ROW WIDTH Display

14/ SETUP MODE

BENCHMARK Series®

OPERATOR'S MANUAL

Dj SEED MANAGER® PLANTER MONITOR

11001-1103A-200111

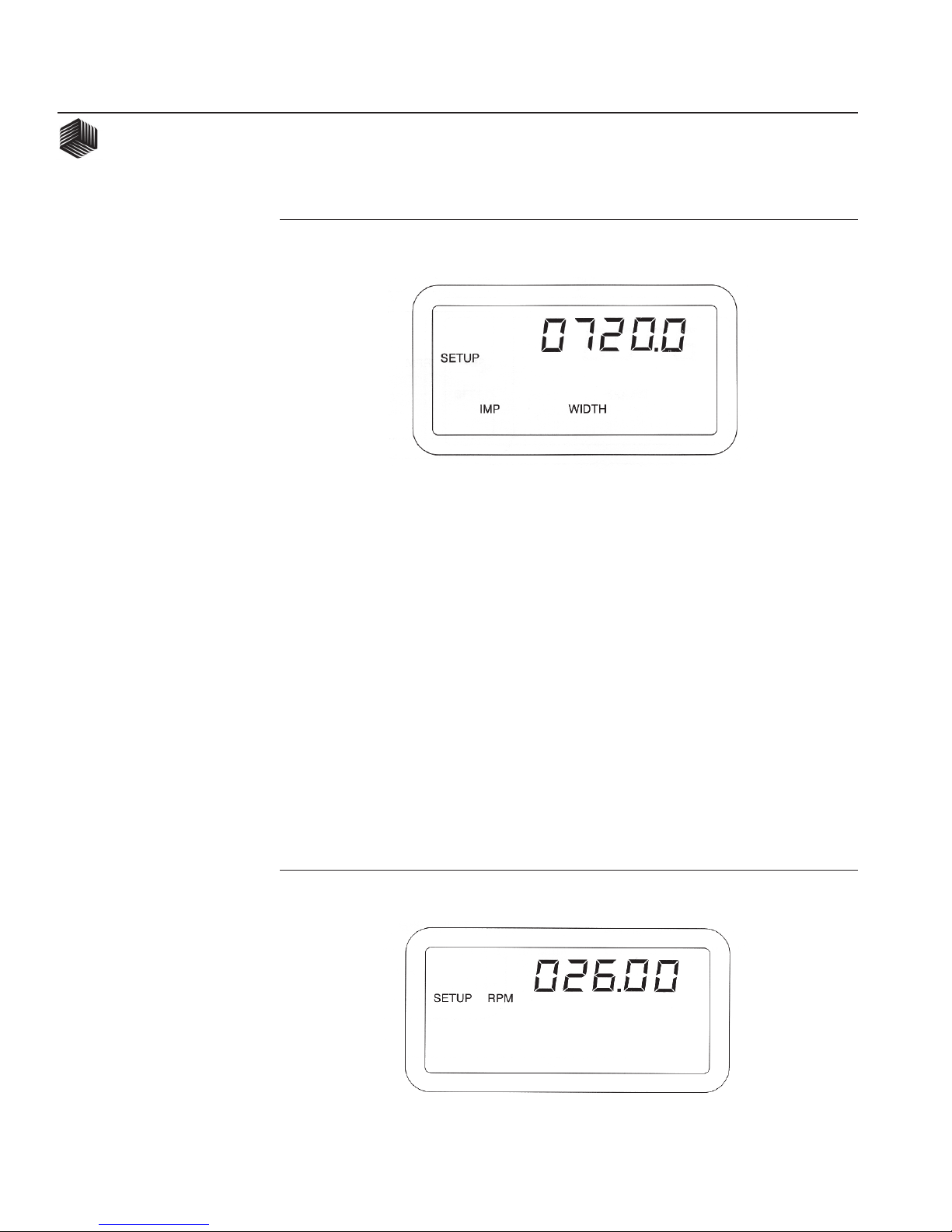

7. IMPlement WIDTH

This is the planting width of the planter in

inches (centimeters) with a resolution of

0.1. It is automatically calculated when

either the NUMber of ROWS or the

ROW WIDTH is changed and can be

edited for special applications such as skip

row planters. Figure 18 shows an IMPlement

WIDTH of 720 inches.

8. Shaft Speed Constant

The Shaft Speed Constant is the number of

pulses the shaft speed sensor generates in

one revolution of the monitored shaft. This is

typically the number of teeth (sense points)

on the gear attached to the monitored shaft.

If the sense gear is not directly attached to

the monitored shaft, the Shaft Speed

Constant can be entered as a decimal with

0.01 resolution. Entering a value of zero

(000.00) disables the Shaft Speed function.

Figure 19 shows the display with the SETUP

and RPM messages and a Shaft Speed

Constant of 26 pulses per revolution.

Figure 18

IMPlement WIDTH Display

Figure 19

Shaft Speed Constant Display

BENCHMARK Series®

OPERATOR'S MANUAL

Dj SEED MANAGER® PLANTER MONITOR SETUP MODE/ 15

11001-1103A-200111

9. RPM HI LIMIT (Shaft Speed)

This constant is the highest shaft RPM

allowed before sounding a warning alarm.

The warning is enabled or disabled by

selecting the ON or OFF message. Use the

SELECT switch to advance one step to the

right of the right most digit, then press the

SET switch to toggle between ON and OFF.

Figure 20 shows a limit of 65 RPM with the

warning enabled.

10. RPM LO LIMIT (Shaft Speed)

This constant is the lowest shaft RPM

allowed before sounding a warning alarm.

The warning is enabled or disabled by

selecting the ON or OFF message. Use the

SELECT switch to advance one step to the

right of the right most digit, then press the

SET switch to toggle between ON and OFF.

Figure 21 shows a limit of 12 RPM with the

warning disabled.

Figure 20

RPM HI LIMIT Display

Figure 21

RPM LO LIMIT Display

16/ SETUP MODE

BENCHMARK Series®

OPERATOR'S MANUAL

Dj SEED MANAGER® PLANTER MONITOR

11001-1103A-200111

Figure 22

Hi Pressure Limit

Figure 23

Lo Pressure Limit

11. Hi Pressure Warning Limit

The Hi Pressure Warning Limit is entered in

oz/in2 (kPa) and applies to both PRESSURE

sensors if used. The Hi and Lo warning

limits are accessible only if PRESSURE 1

and/or PRESSURE 2 sensors have been

enabled in the customer setup mode. Setting

the Hi Pressure Warning Limit will cause the

audible alarm to sound when the pressure

exceeds the value that has been entered.

Utilize the SELECT and SET switch to enter

the Hi Pressure Warning Limit. The Hi

Pressure Warning Limit can be enabled or

disabled by selecting the ON or OFF symbol

after the rightmost digit. Pressing the SET

switch will toggle the status of the warning

from ON to OFF. Figure 22 shows a Hi

Pressure Warning Limit of 15 oz/in2 with the

alarm turned ON.

12. Lo Pressure Warning Limit

The Lo Pressure Warning Limit is entered in

oz/in2 (kPa) and applies to both PRESSURE

sensors if used. The Lo and Hi warning

limits are accessible only if PRESSURE 1

and/or PRESSURE 2 sensors have been

enabled in the customer setup mode. Setting

the Lo Pressure Warning Limit will cause the

audible alarm to sound when the pressure

BENCHMARK Series®

OPERATOR'S MANUAL

Dj SEED MANAGER® PLANTER MONITOR SETUP MODE/ 17

11001-1103A-200111

falls below the value that has been entered.

Utilize the SELECT and SET switch to enter

the Lo Pressure Warning Limit. The Lo

Pressure Warning Limit can be enabled or

disabled by selecting the ON or OFF symbol

after the rightmost digit. Pressing the SET

switch will toggle the status of the warning

from ON to OFF. Figure 23 shows a Lo

Pressure Warning Limit of 5 oz/in2 with the

alarm turned OFF.

13. Distance Calibration

The Distance Calibration Constant is the

number of pulses generated by the

ground speed sensor while traveling a

distance of 400 feet (122 meters). Figure 24

shows the display with the SETUP, SPEED,

and COUNT messages and the default value

of 6096, which is the nominal pulse count for

the radar ground speed sensor. A smaller

number, typically 3100, results with a

reluctance ground speed sensor.

To perform the Distance Calibration:

Step 1.

Carefully measure a 400 foot (122 meter)

course, plainly marking the start and finish

points.

Step 2.

With the tractor moving between 2 and 5

MPH (3.2 and 8Km/h), press the

START•STOP switch when the tractor

is exactly even with the start marker. The

display showing the Distance Calibration

Constant zeroes, then counts the ground

speed pulses.

Step 3.

When even with the finish marker,

press the START•STOP switch.

Step 4.

To ensure best accuracy, perform this

procedure at least three times. Record the

count each time, then enter the average as

the Distance Calibration Constant, using

the SELECT and SET switches.

Figure 24

Distance Calibration Display

18/ SETUP MODE

BENCHMARK Series®

OPERATOR'S MANUAL

Dj SEED MANAGER® PLANTER MONITOR

11001-1103A-200111

14. Sensor Self-Test

This test functions differently depending

upon the type of seed sensors used on the

planter. It is identified on the display by

the SETUP, TEST, and ROW messages.

Start the test by pressing the START•

STOP switch. The TEST message flashes

while the test is executing and PASSED

appears when complete. (This same test is

performed automatically during console

power up.)

If one or more sensors fail, the message

FAILED and the row number of the first

failed sensor is displayed. When multiple

sensors fail, the "S" appears after the

ROW message (displaying the message

ROWS) and the SELECT ROW switch can

be pressed to step through the failed row

numbers. Figure 25 shows the display when

multiple rows have failed.

If Standard or Hi-Rate sensors are used, each

sensor is tested in sequence. The number of

sensors passing is then compared with the

NUMber of ROWS and IMPlement Type

Configuration parameters to ensure agree-

ment.

For Seed Smart® sensors, the light path,

circuitry, and communication link of each

sensor is tested by an instruction which

simulates dropping seeds, resulting in

more comprehensive diagnostic informa-

tion. Figure 26 shows the error codes

possible (See ALARMS & ERROR CODES

Figure 25

Sensor Self-Test Display

Figure 26

Seed Smart® Sensor Error Codes

Other manuals for seed manager

1

Table of contents