Dicon 650M User manual

SMOKE ALARMS

& HEAT ALARMS

A: GUIDANCE ON INSTALLATION

WARNING: Wiring should be installed by a qualified electrician in accordance with BS7671.

Permanent connection to the fixed wiring of the building should be made in a suitable junction box.

This alarm must not be exposed to dripping or splashing. Connect the alarm as late as possible in an

installation, particularly in new build, to avoid contamination. Remove the dust cover before applying

power.

NOTE: For detailed guidance on the siting of this alarm refer to section C of this handbook.

IM ORTANT: The circuit used to power the alarm must be a 24 hour voltage circuit that cannot be

turned off by a switch. BS5839 Part 6 states that: -

For mains powered alarms, each with an integral standby supply (Grade D), the mains electricity

supply should take the form of either:

a) an independent circuit at the dwelling’s main circuit board, in which case no other electrical

equipment should be connected to this circuit (other than a dedicated monitoring device installed to

indicate failure of the mains electricity supply to the alarms); or

b) a separately electrically protected, regularly used local lighting circuit.

For mains powered alarms, with no standby supply (Grade E), the mains electricity supply may only

take the form of an independent circuit as per a) above. If it is necessary to use an RCD for protection,

it should operate independently of any RCD protection for circuits supplying sockets or portable

equipment.

All interconnected alarms should be installed on a single final circuit.

NOTE: The maximum interconnect wiring length is 250 metres. The maximum number of alarms

interconnected together is 12. BRK Dicon smoke alarms should not be connected to any model

produced by another manufacturer.

The location of the alarms must comply with the applicable building codes and the advice in section C:

WHERE TO OCATE below.

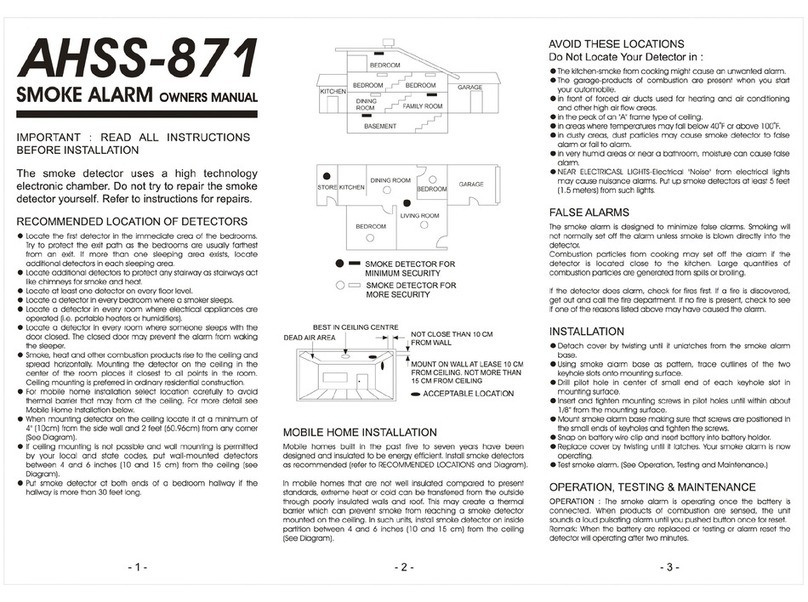

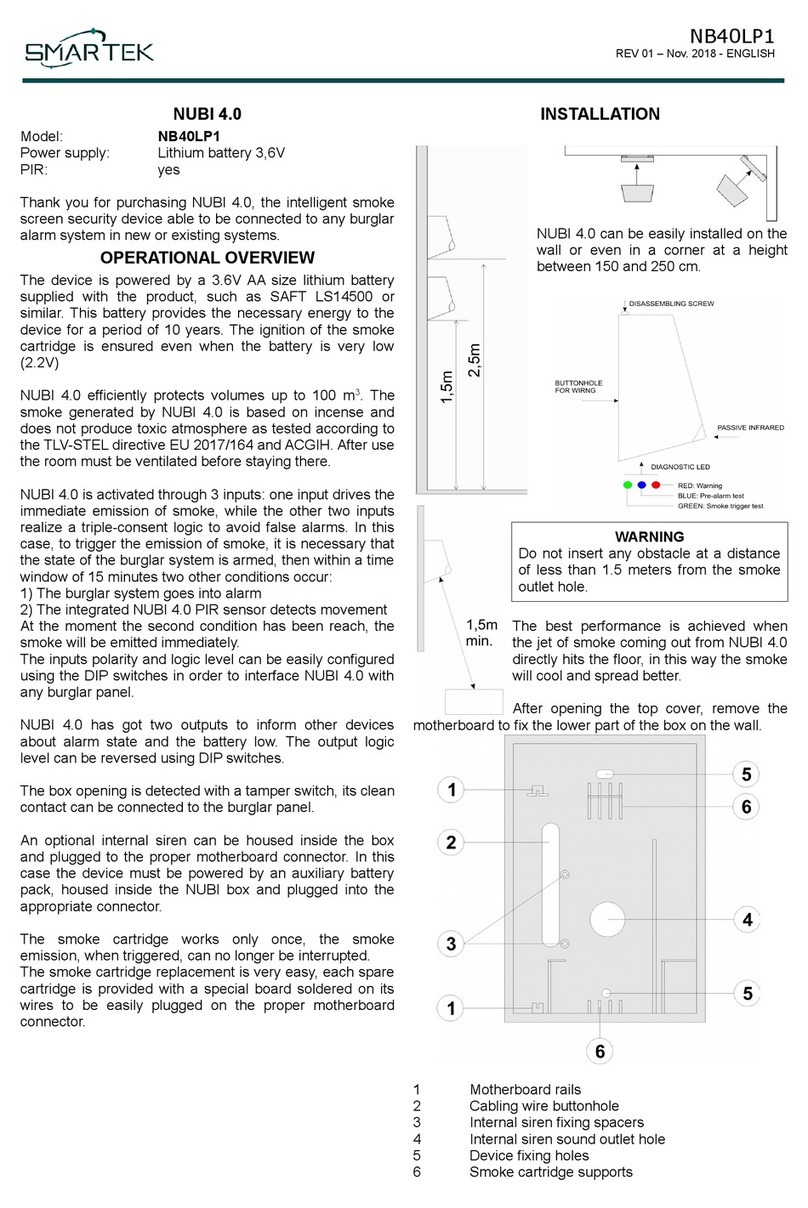

B: INSTALLATION (See Diagrams 1 & 2)

1. Use either of the methods of installation

shown in diagrams1 and 2.

When selecting cable for connecting

interlinked smoke alarms the interlink wire

should be treated as live.

The installation method shown in diagram

1 is suitable for a plasterboard or similar

ceiling where access to the void behind it

is available and suitable to mount the

junction box.

The installation method shown in diagram

2 is suitable for concrete or similar

ceilings where access is insufficient or

where surface wiring is necessary.

2. Connect the brown wire to the brown (live)

in the house wiring and the blue wire to the

blue (neutral). NO CONNECTION SHOU D

BE MADE TO THE MAINS E ECTRICITY

SUPP Y EARTH TERMINA . TERMINATE

HOUSE WIRING EARTH

IN SPARE CONNECTOR.

3. For multiple alarm installations use a “three

core and earth” style cable between all the

alarms to be interconnected and connect the third core of that cable to the white wire from the

smoke alarm. DO NOT use the earth wire for the interconnect line. This must be treated as live,

i.e. insulated and sheathed. If the alarm is not going to be interconnected, cap the unused

wires.

4. Remove the baseplate from the back of the alarm by twisting anti-clockwise as far as it will go.

(about 12 mm). Detach the locking pin.

650MBX, 670MBX and 680MBX

Detach battery door screw from the base plate. Open the battery door on the back of the

alarm, connect the battery, close the door and secure with the screw provided before fitting

the alarm to the baseplate.

Test the alarm using the test button.

5. Attach the flat side of the mounting plate and tighten screws to fit snugly against the pattress

or junction box and ceiling or wall.

6. Bring the power connector through the centre opening of the plate.

CHECKS BEFORE USE

650MBX, 670MBX, and 680MBX:

• Check battery has been fitted correctly.

• Check alarm is not beeping.

• Test alarm before switching on the electricity supply.

All Alarms:

• Check the green light is on (behind the front grille).

• Check the red light flashes every 45 seconds or so.

• When testing linked alarms check that they all

interconnect within 10 seconds.

IM ORTANT NOTES

• Alarms with rechargeable batteries or capacitor

back up may beep for up to 2 hours while the

batteries / capacitors charge.

• eave a copy of this handbook with the user and ensure

they know how to use and maintain the alarm.

IM ORTANT: THE PAPER GASKET SUPP IED

MUST BE FITTED BETWEEN THE REAR OF THE

A ARM AND THE MOUNTING P ATE TO PREVENT

THE A ARM FROM BECOMING CONTAMINATED

BY DUST AND TO ENSURE THE CORRECT

OPERATION OF THE A ARM. Gasket not required

on alarms fitted with protective film on the back.

7. Plug the lead into the rear of the alarm.

8. Place the alarm on the baseplate by lining up

arrows on the baseplate and the alarm rim and

twist clockwise to fasten.

To secure the alarm to the baseplate, insert the

locking pin (removed from the base in 5

above) into the ‘T’ shaped slot located above

the arrow on the rim of the alarm.

Fit either locking key into the ‘Key Slot

’

above

the battery drawer handle. Key number 1 locks

the alarm to the base, key number 2 locks the

alarm to the baseplate AND the battery drawer

closed. These keys remain in place and should

only be removed when opening the battery

drawer or removing the alarm from the

baseplate.

OCKING PINS / KEYS MUST BE FITTED. DO

NOT ATTEMPT TO REMOVE THE A ARM

FROM THE BASEP ATE WITHOUT FIRST

REMOVING THEM.

9. Switch on the mains electricity supply.

10. Check that the green light is on and that the red light is flashing every 45 seconds or so.

The lights are located behind the grille on the front of the alarm.

11. Press and hold the test button until the alarm sounds. NOTE: On the 670 series, pressing this

button places the alarm in pause mode.

SYSTEMS OF MORE THAN ONE ALARM

Test each alarm in the system checking that all other alarms in the system are triggered within 10

seconds.

WARNING

Do not attempt to test the alarm with flame heat or smoke, the results may be misleading and may

damage the alarm.

The dust cover must be removed as late as possible before commissioning. This will reduce the

chances of the alarm being contaminated by building dust etc.

Remove the alarm from the system before testing the wiring with high voltage insulation testing

equipment otherwise this will damage the alarm and will invalidate the warranty.

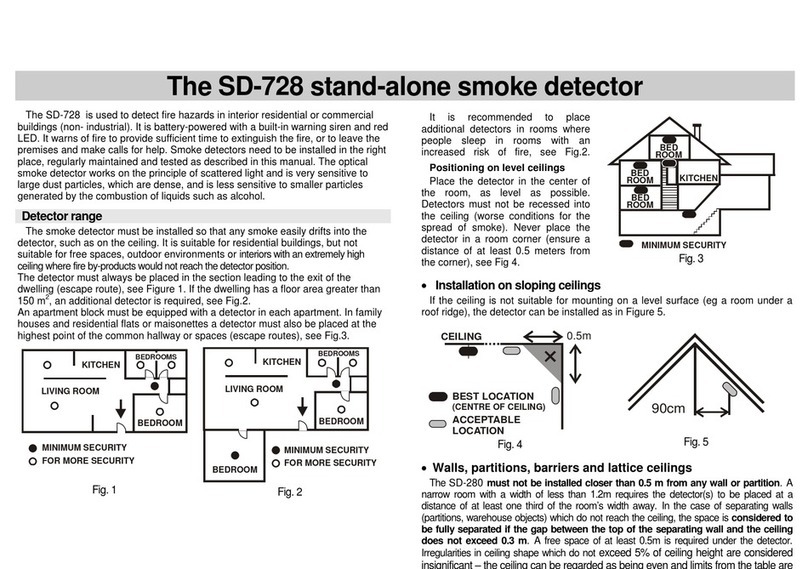

C: WHERE TO LOCATE

1. As a minimum smoke alarms should be located between sleeping areas and potential sources of

fire such as living rooms and kitchens. In single storey homes with one sleeping area a smoke

alarm should be installed in the hallway as close as possible to the living accommodation. To

ensure audibility in the bedrooms it may be necessary to install more than one smoke alarm,

particularly if the hallway is more than 15m long. In single storey homes with two separate

sleeping areas, a minimum of two smoke alarms is required, one outside each sleeping area. In

multilevel or split level homes as a minimum a smoke alarm should be installed on the ground floor

between the staircase and any rooms in which a fire might start and on each storey in circulation

areas which form part of the escape route (normally hallways and landings).

NOTE: Heat alarms should not be used in escape routes instead of smoke alarms. They should

only be used in the applications listed below in addition to smoke alarms and should always be

interconnected to smoke alarms.

2. Additional alarms should be installed in bedrooms in anticipation of fires originating there, caused

by faulty wiring, lights, appliances, smokers or other hazards.

3. For best protection, smoke alarms should be installed in every room in your home, apart from

those listed in the ‘ OCATIONS TO AVOID’ section. Heat alarms should be used in kitchens, boiler

rooms, laundry rooms, garages and such like where smoke alarms would be unsuitable. All alarms

must be interconnected.

OWNERS

MANUAL

BRK Electronics®, Dicon™

BRK Brands Europe Ltd.

Unit 6, Carter Court

Davy Way

Waterwells Business ark

Quedgeley

Gloucester

GL2 2DE

United Kingdom

COVERS • Simple Fitting Instructions • Location Guide

• User Information • Basic Fire Safety Tips

• Simple Maintenance Instructions

IM ORTANT: LEASE READ

AND RETAIN THIS OWNERS MANUAL

MAINS POWERED

When installing this alarm for use by others, please

leave this manual or a copy with the end user.

EARTH

BLACK or GREY (INTERLINK)

BLUE (NEUTRAL)

BROWN (LIVE)

WHITE

BROWN

BLUE

BASEPLATE

INSTALLATION USING JUNCTION BOX

ALARM

JUNCTION BOX

BATTERY

ACCESS

DOOR

Diagram 1

INSTALLATION USING PATTRESS

WHITE

BROWN BLUE

BASEPLATE

ALARM

EARTH

BLUE (NEUTRAL)

BROWN (LIVE)

BLACK or GREY (INTERLINK)

PATTRESS

BATTERY

ACCESS

DOOR

Diagram 2

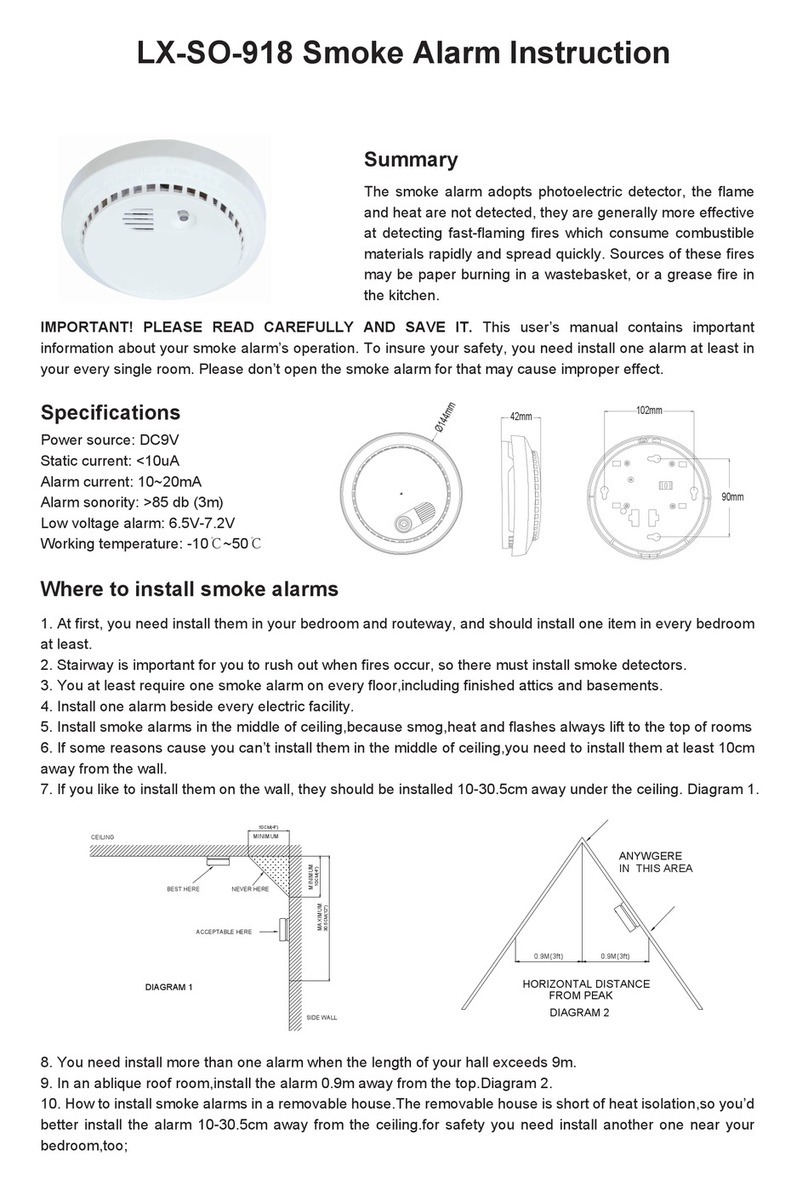

4. Install smoke alarms in circulation areas at a distance no greater than 7.5m from the farthest wall,

no greater than 7.5m from a door to any room in which a fire might start and no greater than 7.5m

from the next smoke alarm.

5. When heat alarms are installed in a room, they should be at a distance no greater than 5.3m from

the farthest wall no greater that 5.3m from a door to any room in which a fire might start and no

greater than 5.3m from the next heat or smoke alarm.

6. As it is impossible to predict the source of a fire the best location for an alarm is the centre of the

room or hallway. If it is necessary to locate the smoke alarm on a wall always locate the detection

element of the alarm 150mm to 300mm (6 to 12 inches) below the ceiling and the bottom of the

alarm above the level of doors and other openings.

NOTE: Heat alarms should not be wall mounted.

7. In rooms with simple sloped, peaked or gabled ceilings install smoke alarms 900mm (3 feet) from

the highest point of the ceiling. ‘Dead air’ at the peak of the ceiling may prevent smoke from

reaching the alarm in time to provide an early warning.

8. Closed doors and other obstructions will interfere with the path of smoke and heat to an alarm and

may prevent occupants from hearing an alarm on the other side of a closed door. Install sufficient

alarms to compensate for closed doors and other obstacles.

9. Your local fire brigade or insurance company may be able to give you further advice. Call them and

ask. Further help and information may also be found in BS5839 Part 6 and the Fire Safety guidance

given by the Department of Transport, ocal Government and the Regions (DT R).

CAUTION: Research indicates that substantial increases in warning time can be obtained with each

properly installed additional alarm, It is strongly recommended that the advice above be followed to

ensure maximum protection.

IM ORTANT: These smoke and heat alarms are intended primarily for use in single-family occupancy

private dwellings. For use in other applications the manufacturers advice should be sought.

LOCATIONS TO AVOID

DO NOT locate alarms: -

1. In turbulent air from fans, heaters, doors, windows, etc.

2. In high humidity areas such as bathrooms and shower rooms or where the temperature exceeds

39ºC (100ºF) or falls below 5ºC (40ºF)

3. At the peak of an ‘A’ frame ceiling – dead air at the top may prevent smoke and heat from reaching

the alarm to provide an early warning.

4. ess than 300mm (12 inches) from a wall when mounted on the ceiling.

5. In insect infested areas. Tiny insects may affect performance.

6. (Smoke alarms) in poorly ventilated kitchen or garage. Combustion particles from cooking or car

exhaust could trigger a nuisance alarm

7. In very dusty or dirty areas – dirt and excessive dust can impair the performance of the alarm.

8. Within 300mm (12 inches) of a light fitting or room corners.

9. In locations that would make routine testing or maintenance hazardous. (e.g. over a stairwell).

10. On poorly insulated walls or ceilings.

11. Near objects such as ceiling decorations that might impede the path of smoke or heat to the

alarm.

12. Within 1500mm (5 feet) of a fluorescent light fitting and keep wiring at least 1000mm (39 inches)

from these fittings. Do not install alarms on circuits containing fluorescent light fittings or dimmer

switches.

Further help and information may be found in BS5839 Part 6

D: USER INFORMATION

Features

• Operating ights – A continuous green light indicates the alarm is receiving mains power. The red

light doubles as an alarm source indicator and flashes approximately every 45 seconds to confirm

circuitry integrity.

• Alarm Source Indicator – Red light will flash every second in the unit originating the alarm. Red lights

on other alarms flash every 45 seconds.

• Alarm Pause (670 range only) – Silence your smoke alarm by momentarily pressing the test button.

Ideal when non-emergency smoke (e.g. cooking fumes) cause nuisance alarms. Red light flashes

every ten seconds to remind you that the alarm has been silenced. Double beep indicates that the

alarm has automatically reset after approximately 10 minutes.

Be repared

Smoke and heat alarms properly installed and maintained are an essential part of a good home fire

safety programme. Review fire hazards and eliminate dangerous conditions wherever possible. When

fire strikes a prepared and practiced escape plan could prove vital. Your local fire brigade may be

willing to advise you. Call them and ask. Consider and discuss the following safety hints:

• Ensure everyone is familiarized with the alarm signal.

• Always test doors with your hands before flinging them open. If they feel warm, fire may be walled

up behind them – leave closed and find another escape route.

• Don’t waste time collecting possessions. Rouse all occupants and leave the building; your life is

more valuable.

•GET OUT, STAY OUT, GET THE FIRE BRIGADE OUT!

• Keep everyone in a set meeting place after your escape.

• If trapped inside, stay close to the floor, cover your mouth with cloth and conserve breath while you

crawl to safety.

• Keep all windows and doors closed except for escape purposes.

• Prepare and practice an escape plan before a fire starts.

Draw a floor plan. Have fire drills often. Practise your escape.

Simple Maintenance

Vacuum every six months to keep unit working efficiently by firstly turning off the mains electricity

supply and vacuuming through the vents using a soft brush attachment. Keep the nozzle from

touching the unit. SWITCH POWER BACK ON WHEN YOU HAVE FINISHED.

Test the alarm once a week by: -

• Checking that the green light is on and that the red light is flashing every 45 seconds or so. The

lights are located behind the grille on the front of the alarm.

• Press and hold the test button until the alarm sounds. NOTE: Pressing this button on alarms in the

670 series also places the alarm in pause mode.

MBX MODELS.

Change the battery with a new one when the alarm beeps every 45 seconds.

All MBX Models

Turn off the mains electricity supply, remove locking key, rotate the alarm approximately 10mm anti-

clockwise and remove the alarm from the ceiling. Unplug the alarm from the mains supply. Remove

the screw and prise open the battery compartment door on the back of the alarm to replace the battery

with one of the following: Duracell MN1604, MX1604, Eveready PP3B PP3S, 6 F22 Gold Peak

1604A, 1604S. Close the battery door refit the screw and re-assemble the alarm to the ceiling

ensuring that the mains plug is securely fitted. Test the alarm using the test button then turn on the

mains electricity supply. P EASE NOTE: The alarm cannot be fitted to the baseplate without a battery

installed.

650MRL, 670MRL, 680MRL

Rechargeable ithium batteries provide approximately 6 months back up power supply in the event of

a mains supply failure. The alarm may beep every 45 seconds for a few hours after a mains supply

failure while the batteries re-charge.

650MC, 670MC, 680MC.

High performance capacitors provide a back up power supply in the event of a mains supply failure.

The alarm may beep every 45 seconds for a few hours after a mains supply failure while the

capacitors re-charge.

Troubleshooting

Problems are indicated by four events: -

1. Alarm does not sound upon pressing the test button

2. Green light does not illuminate when mains power is on.

3. Red operating light remains steadily on, or off (i.e. does not flash every 45 seconds when alarm is

in standby).

4. Alarm emits a beep every 45 seconds when back up power supply should be fully charged.

Try the following: -

1. Inspect the fuse in the power circuit to the alarm

2. Gently vacuum as detailed in ‘Simple Maintenance’.

3. For MBX models only, replace the battery.

4. Call a qualified electrician to inspect the house wiring and connections to the alarm.

If these procedures do not eliminate the problem. DO NOT ATTEMPT REPAIRS. In the first instance

contact the manufacturer for further advice.

If the alarm is still within warranty period and terms, return the unit with proof of purchase to the

distributor, indicating the nature of the problem. Units beyond warranty cannot be economically repaired.

For address see the bottom of this page.

False Alarms

Abnormal air conditions may cause the highly sensitive alarm to give a ‘false’ alarm. DO NOT

DISCONNECT THE A ARM. If no fire is apparent, ventilate the room and/or operate the alarm pause (If

fitted).

WARNING: IF THERE IS ANY QUESTION AS TO THE CAUSE OF AN A ARM, A WAYS ASSUME THAT

IT IS DUE TO AN ACTUA FIRE AND FO OW YOU FIRE EMERGENCY P ANS. Do not assume the

alarm is a nuisance alarm and activate alarm pause (if fitted).

Dust can have an adverse effect. Vacuum as recommended above.

Do not paint the unit.

Other factors such as nicotine contamination may also adversely affect the alarm.

Radioactive Contents

Ionization type smoke alarms utilise a tiny amount of radioactive material, 0.9 microcuries (30

kilobequerels) of Americium 241, to detect smoke. This material is in the form of a sealed source and

represents no hazard whatsoever to anyone installing or using the smoke alarm. Any stray particles would

be unable to “penetrate the dead layer of skin and thus do not constitute an external hazard”. (Radiation

Protection Guidance for Scientists and Physicians). All BRK®Dicon™ ionization smoke alarms have been

rigorously tested by the National Radiological Protection Board to ensure absolute safety.

Disposal

This product, the batteries and other accessories must not be disposed of as unsorted municipal waste

and must be collected separately at the end of the products life. Contact your local authority for

information about collection points in your area.

Limited guarantee

BRK brands Europe td., ("the Company"), guarantees its enclosed alarm to be free from defects in

materials and workmanship under normal use and service for a period of five years from the date of

purchase. BRK Brands Europe td. Makes no other express guarantee for this alarm. No agent,

representative, dealer or employee from the Company has the authority to increase or alter the obligations

or limitations of the Guarantee. The Company's obligation of this guarantee shall be limited to the repair or

replacement of any part of the alarm which is found to be defective in materials or workmanship under

normal use and service during the five year period commencing with date of purchase. The Company

shall not be obligated to repair or replace alarms which are found to be in need of repair because of

damage, unreasonable use, modifications or alterations occurring after the date of purchase.

How to obtain guarantee service

If service is required, return the product to your retailer.

Battery: BRK Brands Europe td. make no guarantee, express or implied, written or oral, including that of

merchantability or fitness for any particular purpose with respect to battery.

YOUR A ARM IS NOT A SUBSTITUTE FOR PROPERTY, DISABI ITY OR OTHER INSURANCE OF ANY

KIND. APPROPRIATE COVERAGE IS YOUR RESPONSIBI ITY. CONSU T YOUR AGENT.

This warranty does not affect your statutory rights in any way.

In the event of a problem with your alarm or you have any questions concerning its use; care and

service please consult this manual.

If you require any further help or clarification please write to:

BRK®Dicon™, BRK Brands Europe Ltd

Unit 6, Carter Court - Davy Way - Waterwells Business ark - Quedgeley - Gloucester - GL2 2DE

United Kingdom

or phone our Helpline on: 01452 887570

www.brkdicon.eu

LEASE KEE THIS MANUAL IN A SAFE LACE

Please note that specifications may be subject to change.

MODELS:

PHOTOE ECTRIC SMOKE A ARMS

650M, 650MC, 650MRL, 650MBX

IONIZATION SMOKE A ARMS

670M, 670MC, 670MRL,670MBX,

HEAT A ARMS

680M, 680MC, 680MRL, 680MBX

220-240VAC ( )

MAINS POWERED A ARMS

C ASS II APPARATUS

BS5446-2: 2003

Licence No: KM 85855

2502-A0108-Rev A

SMOKE ALARMS

& HEAT ALARMS

A: GUIDANCE ON INSTALLATION

WARNING: Wiring should be installed by a qualified electrician in accordance with BS7671.

Permanent connection to the fixed wiring of the building should be made in a suitable junction box.

This alarm must not be exposed to dripping or splashing. Connect the alarm as late as possible in an

installation, particularly in new build, to avoid contamination. Remove the dust cover before applying

power.

NOTE: For detailed guidance on the siting of this alarm refer to section C of this handbook.

IM ORTANT: The circuit used to power the alarm must be a 24 hour voltage circuit that cannot be

turned off by a switch. BS5839 Part 6 states that: -

For mains powered alarms, each with an integral standby supply (Grade D), the mains electricity

supply should take the form of either:

a) an independent circuit at the dwelling’s main circuit board, in which case no other electrical

equipment should be connected to this circuit (other than a dedicated monitoring device installed to

indicate failure of the mains electricity supply to the alarms); or

b) a separately electrically protected, regularly used local lighting circuit.

For mains powered alarms, with no standby supply (Grade E), the mains electricity supply may only

take the form of an independent circuit as per a) above. If it is necessary to use an RCD for protection,

it should operate independently of any RCD protection for circuits supplying sockets or portable

equipment.

All interconnected alarms should be installed on a single final circuit.

NOTE: The maximum interconnect wiring length is 250 metres. The maximum number of alarms

interconnected together is 12. BRK Dicon smoke alarms should not be connected to any model

produced by another manufacturer.

The location of the alarms must comply with the applicable building codes and the advice in section C:

WHERE TO OCATE below.

B: INSTALLATION (See Diagrams 1 & 2)

1. Use either of the methods of installation

shown in diagrams1 and 2.

When selecting cable for connecting

interlinked smoke alarms the interlink wire

should be treated as live.

The installation method shown in diagram

1 is suitable for a plasterboard or similar

ceiling where access to the void behind it

is available and suitable to mount the

junction box.

The installation method shown in diagram

2 is suitable for concrete or similar

ceilings where access is insufficient or

where surface wiring is necessary.

2. Connect the brown wire to the brown (live)

in the house wiring and the blue wire to the

blue (neutral). NO CONNECTION SHOU D

BE MADE TO THE MAINS E ECTRICITY

SUPP Y EARTH TERMINA . TERMINATE

HOUSE WIRING EARTH

IN SPARE CONNECTOR.

3. For multiple alarm installations use a “three

core and earth” style cable between all the

alarms to be interconnected and connect the third core of that cable to the white wire from the

smoke alarm. DO NOT use the earth wire for the interconnect line. This must be treated as live,

i.e. insulated and sheathed. If the alarm is not going to be interconnected, cap the unused

wires.

4. Remove the baseplate from the back of the alarm by twisting anti-clockwise as far as it will go.

(about 12 mm). Detach the locking pin.

650MBX, 670MBX and 680MBX

Detach battery door screw from the base plate. Open the battery door on the back of the

alarm, connect the battery, close the door and secure with the screw provided before fitting

the alarm to the baseplate.

Test the alarm using the test button.

5. Attach the flat side of the mounting plate and tighten screws to fit snugly against the pattress

or junction box and ceiling or wall.

6. Bring the power connector through the centre opening of the plate.

CHECKS BEFORE USE

650MBX, 670MBX, and 680MBX:

• Check battery has been fitted correctly.

• Check alarm is not beeping.

• Test alarm before switching on the electricity supply.

All Alarms:

• Check the green light is on (behind the front grille).

• Check the red light flashes every 45 seconds or so.

• When testing linked alarms check that they all

interconnect within 10 seconds.

IM ORTANT NOTES

• Alarms with rechargeable batteries or capacitor

back up may beep for up to 2 hours while the

batteries / capacitors charge.

• eave a copy of this handbook with the user and ensure

they know how to use and maintain the alarm.

IM ORTANT: THE PAPER GASKET SUPP IED

MUST BE FITTED BETWEEN THE REAR OF THE

A ARM AND THE MOUNTING P ATE TO PREVENT

THE A ARM FROM BECOMING CONTAMINATED

BY DUST AND TO ENSURE THE CORRECT

OPERATION OF THE A ARM. Gasket not required

on alarms fitted with protective film on the back.

7. Plug the lead into the rear of the alarm.

8. Place the alarm on the baseplate by lining up

arrows on the baseplate and the alarm rim and

twist clockwise to fasten.

To secure the alarm to the baseplate, insert the

locking pin (removed from the base in 5

above) into the ‘T’ shaped slot located above

the arrow on the rim of the alarm.

Fit either locking key into the ‘Key Slot

’

above

the battery drawer handle. Key number 1 locks

the alarm to the base, key number 2 locks the

alarm to the baseplate AND the battery drawer

closed. These keys remain in place and should

only be removed when opening the battery

drawer or removing the alarm from the

baseplate.

OCKING PINS / KEYS MUST BE FITTED. DO

NOT ATTEMPT TO REMOVE THE A ARM

FROM THE BASEP ATE WITHOUT FIRST

REMOVING THEM.

9. Switch on the mains electricity supply.

10. Check that the green light is on and that the red light is flashing every 45 seconds or so.

The lights are located behind the grille on the front of the alarm.

11. Press and hold the test button until the alarm sounds. NOTE: On the 670 series, pressing this

button places the alarm in pause mode.

SYSTEMS OF MORE THAN ONE ALARM

Test each alarm in the system checking that all other alarms in the system are triggered within 10

seconds.

WARNING

Do not attempt to test the alarm with flame heat or smoke, the results may be misleading and may

damage the alarm.

The dust cover must be removed as late as possible before commissioning. This will reduce the

chances of the alarm being contaminated by building dust etc.

Remove the alarm from the system before testing the wiring with high voltage insulation testing

equipment otherwise this will damage the alarm and will invalidate the warranty.

C: WHERE TO LOCATE

1. As a minimum smoke alarms should be located between sleeping areas and potential sources of

fire such as living rooms and kitchens. In single storey homes with one sleeping area a smoke

alarm should be installed in the hallway as close as possible to the living accommodation. To

ensure audibility in the bedrooms it may be necessary to install more than one smoke alarm,

particularly if the hallway is more than 15m long. In single storey homes with two separate

sleeping areas, a minimum of two smoke alarms is required, one outside each sleeping area. In

multilevel or split level homes as a minimum a smoke alarm should be installed on the ground floor

between the staircase and any rooms in which a fire might start and on each storey in circulation

areas which form part of the escape route (normally hallways and landings).

NOTE: Heat alarms should not be used in escape routes instead of smoke alarms. They should

only be used in the applications listed below in addition to smoke alarms and should always be

interconnected to smoke alarms.

2. Additional alarms should be installed in bedrooms in anticipation of fires originating there, caused

by faulty wiring, lights, appliances, smokers or other hazards.

3. For best protection, smoke alarms should be installed in every room in your home, apart from

those listed in the ‘ OCATIONS TO AVOID’ section. Heat alarms should be used in kitchens, boiler

rooms, laundry rooms, garages and such like where smoke alarms would be unsuitable. All alarms

must be interconnected.

OWNERS

MANUAL

BRK Electronics®, Dicon™

BRK Brands Europe Ltd.

Unit 6, Carter Court

Davy Way

Waterwells Business ark

Quedgeley

Gloucester

GL2 2DE

United Kingdom

COVERS • Simple Fitting Instructions • Location Guide

• User Information • Basic Fire Safety Tips

• Simple Maintenance Instructions

IM ORTANT: LEASE READ

AND RETAIN THIS OWNERS MANUAL

MAINS POWERED

When installing this alarm for use by others, please

leave this manual or a copy with the end user.

EARTH

BLACK or GREY (INTERLINK)

BLUE (NEUTRAL)

BROWN (LIVE)

WHITE

BROWN

BLUE

BASEPLATE

INSTALLATION USING JUNCTION BOX

ALARM

JUNCTION BOX

BATTERY

ACCESS

DOOR

Diagram 1

INSTALLATION USING PATTRESS

WHITE

BROWN BLUE

BASEPLATE

ALARM

EARTH

BLUE (NEUTRAL)

BROWN (LIVE)

BLACK or GREY (INTERLINK)

PATTRESS

BATTERY

ACCESS

DOOR

Diagram 2

4. Install smoke alarms in circulation areas at a distance no greater than 7.5m from the farthest wall,

no greater than 7.5m from a door to any room in which a fire might start and no greater than 7.5m

from the next smoke alarm.

5. When heat alarms are installed in a room, they should be at a distance no greater than 5.3m from

the farthest wall no greater that 5.3m from a door to any room in which a fire might start and no

greater than 5.3m from the next heat or smoke alarm.

6. As it is impossible to predict the source of a fire the best location for an alarm is the centre of the

room or hallway. If it is necessary to locate the smoke alarm on a wall always locate the detection

element of the alarm 150mm to 300mm (6 to 12 inches) below the ceiling and the bottom of the

alarm above the level of doors and other openings.

NOTE: Heat alarms should not be wall mounted.

7. In rooms with simple sloped, peaked or gabled ceilings install smoke alarms 900mm (3 feet) from

the highest point of the ceiling. ‘Dead air’ at the peak of the ceiling may prevent smoke from

reaching the alarm in time to provide an early warning.

8. Closed doors and other obstructions will interfere with the path of smoke and heat to an alarm and

may prevent occupants from hearing an alarm on the other side of a closed door. Install sufficient

alarms to compensate for closed doors and other obstacles.

9. Your local fire brigade or insurance company may be able to give you further advice. Call them and

ask. Further help and information may also be found in BS5839 Part 6 and the Fire Safety guidance

given by the Department of Transport, ocal Government and the Regions (DT R).

CAUTION: Research indicates that substantial increases in warning time can be obtained with each

properly installed additional alarm, It is strongly recommended that the advice above be followed to

ensure maximum protection.

IM ORTANT: These smoke and heat alarms are intended primarily for use in single-family occupancy

private dwellings. For use in other applications the manufacturers advice should be sought.

LOCATIONS TO AVOID

DO NOT locate alarms: -

1. In turbulent air from fans, heaters, doors, windows, etc.

2. In high humidity areas such as bathrooms and shower rooms or where the temperature exceeds

39ºC (100ºF) or falls below 5ºC (40ºF)

3. At the peak of an ‘A’ frame ceiling – dead air at the top may prevent smoke and heat from reaching

the alarm to provide an early warning.

4. ess than 300mm (12 inches) from a wall when mounted on the ceiling.

5. In insect infested areas. Tiny insects may affect performance.

6. (Smoke alarms) in poorly ventilated kitchen or garage. Combustion particles from cooking or car

exhaust could trigger a nuisance alarm

7. In very dusty or dirty areas – dirt and excessive dust can impair the performance of the alarm.

8. Within 300mm (12 inches) of a light fitting or room corners.

9. In locations that would make routine testing or maintenance hazardous. (e.g. over a stairwell).

10. On poorly insulated walls or ceilings.

11. Near objects such as ceiling decorations that might impede the path of smoke or heat to the

alarm.

12. Within 1500mm (5 feet) of a fluorescent light fitting and keep wiring at least 1000mm (39 inches)

from these fittings. Do not install alarms on circuits containing fluorescent light fittings or dimmer

switches.

Further help and information may be found in BS5839 Part 6

D: USER INFORMATION

Features

• Operating ights – A continuous green light indicates the alarm is receiving mains power. The red

light doubles as an alarm source indicator and flashes approximately every 45 seconds to confirm

circuitry integrity.

• Alarm Source Indicator – Red light will flash every second in the unit originating the alarm. Red lights

on other alarms flash every 45 seconds.

• Alarm Pause (670 range only) – Silence your smoke alarm by momentarily pressing the test button.

Ideal when non-emergency smoke (e.g. cooking fumes) cause nuisance alarms. Red light flashes

every ten seconds to remind you that the alarm has been silenced. Double beep indicates that the

alarm has automatically reset after approximately 10 minutes.

Be repared

Smoke and heat alarms properly installed and maintained are an essential part of a good home fire

safety programme. Review fire hazards and eliminate dangerous conditions wherever possible. When

fire strikes a prepared and practiced escape plan could prove vital. Your local fire brigade may be

willing to advise you. Call them and ask. Consider and discuss the following safety hints:

• Ensure everyone is familiarized with the alarm signal.

• Always test doors with your hands before flinging them open. If they feel warm, fire may be walled

up behind them – leave closed and find another escape route.

• Don’t waste time collecting possessions. Rouse all occupants and leave the building; your life is

more valuable.

•GET OUT, STAY OUT, GET THE FIRE BRIGADE OUT!

• Keep everyone in a set meeting place after your escape.

• If trapped inside, stay close to the floor, cover your mouth with cloth and conserve breath while you

crawl to safety.

• Keep all windows and doors closed except for escape purposes.

• Prepare and practice an escape plan before a fire starts.

Draw a floor plan. Have fire drills often. Practise your escape.

Simple Maintenance

Vacuum every six months to keep unit working efficiently by firstly turning off the mains electricity

supply and vacuuming through the vents using a soft brush attachment. Keep the nozzle from

touching the unit. SWITCH POWER BACK ON WHEN YOU HAVE FINISHED.

Test the alarm once a week by: -

• Checking that the green light is on and that the red light is flashing every 45 seconds or so. The

lights are located behind the grille on the front of the alarm.

• Press and hold the test button until the alarm sounds. NOTE: Pressing this button on alarms in the

670 series also places the alarm in pause mode.

MBX MODELS.

Change the battery with a new one when the alarm beeps every 45 seconds.

All MBX Models

Turn off the mains electricity supply, remove locking key, rotate the alarm approximately 10mm anti-

clockwise and remove the alarm from the ceiling. Unplug the alarm from the mains supply. Remove

the screw and prise open the battery compartment door on the back of the alarm to replace the battery

with one of the following: Duracell MN1604, MX1604, Eveready PP3B PP3S, 6 F22 Gold Peak

1604A, 1604S. Close the battery door refit the screw and re-assemble the alarm to the ceiling

ensuring that the mains plug is securely fitted. Test the alarm using the test button then turn on the

mains electricity supply. P EASE NOTE: The alarm cannot be fitted to the baseplate without a battery

installed.

650MRL, 670MRL, 680MRL

Rechargeable ithium batteries provide approximately 6 months back up power supply in the event of

a mains supply failure. The alarm may beep every 45 seconds for a few hours after a mains supply

failure while the batteries re-charge.

650MC, 670MC, 680MC.

High performance capacitors provide a back up power supply in the event of a mains supply failure.

The alarm may beep every 45 seconds for a few hours after a mains supply failure while the

capacitors re-charge.

Troubleshooting

Problems are indicated by four events: -

1. Alarm does not sound upon pressing the test button

2. Green light does not illuminate when mains power is on.

3. Red operating light remains steadily on, or off (i.e. does not flash every 45 seconds when alarm is

in standby).

4. Alarm emits a beep every 45 seconds when back up power supply should be fully charged.

Try the following: -

1. Inspect the fuse in the power circuit to the alarm

2. Gently vacuum as detailed in ‘Simple Maintenance’.

3. For MBX models only, replace the battery.

4. Call a qualified electrician to inspect the house wiring and connections to the alarm.

If these procedures do not eliminate the problem. DO NOT ATTEMPT REPAIRS. In the first instance

contact the manufacturer for further advice.

If the alarm is still within warranty period and terms, return the unit with proof of purchase to the

distributor, indicating the nature of the problem. Units beyond warranty cannot be economically repaired.

For address see the bottom of this page.

False Alarms

Abnormal air conditions may cause the highly sensitive alarm to give a ‘false’ alarm. DO NOT

DISCONNECT THE A ARM. If no fire is apparent, ventilate the room and/or operate the alarm pause (If

fitted).

WARNING: IF THERE IS ANY QUESTION AS TO THE CAUSE OF AN A ARM, A WAYS ASSUME THAT

IT IS DUE TO AN ACTUA FIRE AND FO OW YOU FIRE EMERGENCY P ANS. Do not assume the

alarm is a nuisance alarm and activate alarm pause (if fitted).

Dust can have an adverse effect. Vacuum as recommended above.

Do not paint the unit.

Other factors such as nicotine contamination may also adversely affect the alarm.

Radioactive Contents

Ionization type smoke alarms utilise a tiny amount of radioactive material, 0.9 microcuries (30

kilobequerels) of Americium 241, to detect smoke. This material is in the form of a sealed source and

represents no hazard whatsoever to anyone installing or using the smoke alarm. Any stray particles would

be unable to “penetrate the dead layer of skin and thus do not constitute an external hazard”. (Radiation

Protection Guidance for Scientists and Physicians). All BRK®Dicon™ ionization smoke alarms have been

rigorously tested by the National Radiological Protection Board to ensure absolute safety.

Disposal

This product, the batteries and other accessories must not be disposed of as unsorted municipal waste

and must be collected separately at the end of the products life. Contact your local authority for

information about collection points in your area.

Limited guarantee

BRK brands Europe td., ("the Company"), guarantees its enclosed alarm to be free from defects in

materials and workmanship under normal use and service for a period of five years from the date of

purchase. BRK Brands Europe td. Makes no other express guarantee for this alarm. No agent,

representative, dealer or employee from the Company has the authority to increase or alter the obligations

or limitations of the Guarantee. The Company's obligation of this guarantee shall be limited to the repair or

replacement of any part of the alarm which is found to be defective in materials or workmanship under

normal use and service during the five year period commencing with date of purchase. The Company

shall not be obligated to repair or replace alarms which are found to be in need of repair because of

damage, unreasonable use, modifications or alterations occurring after the date of purchase.

How to obtain guarantee service

If service is required, return the product to your retailer.

Battery: BRK Brands Europe td. make no guarantee, express or implied, written or oral, including that of

merchantability or fitness for any particular purpose with respect to battery.

YOUR A ARM IS NOT A SUBSTITUTE FOR PROPERTY, DISABI ITY OR OTHER INSURANCE OF ANY

KIND. APPROPRIATE COVERAGE IS YOUR RESPONSIBI ITY. CONSU T YOUR AGENT.

This warranty does not affect your statutory rights in any way.

In the event of a problem with your alarm or you have any questions concerning its use; care and

service please consult this manual.

If you require any further help or clarification please write to:

BRK®Dicon™, BRK Brands Europe Ltd

Unit 6, Carter Court - Davy Way - Waterwells Business ark - Quedgeley - Gloucester - GL2 2DE

United Kingdom

or phone our Helpline on: 01452 887570

www.brkdicon.eu

LEASE KEE THIS MANUAL IN A SAFE LACE

Please note that specifications may be subject to change.

MODELS:

PHOTOE ECTRIC SMOKE A ARMS

650M, 650MC, 650MRL, 650MBX

IONIZATION SMOKE A ARMS

670M, 670MC, 670MRL,670MBX,

HEAT A ARMS

680M, 680MC, 680MRL, 680MBX

220-240VAC ( )

MAINS POWERED A ARMS

C ASS II APPARATUS

BS5446-2: 2003

Licence No: KM 85855

2502-A0108-Rev A

This manual suits for next models

11

Table of contents

Other Dicon Smoke Alarm manuals