Digitronic CamCon DC30 User manual

Digital Cam Switch Unit

CamCon DC30

Digitronic Automationsanlagen GmbH

Steinbeisstraße 3

•

D - 72636 Frickenhausen

•

Tel. (+49)7022/40590-0

•

Fax -10

Auf der Langwies 1

•

D - 65510 Hünstetten-Wallbach

•

Tel.(+49)6126/9453-0

•

Fax -42

Internet: http://www.digitronic.com

•

E-Mail: [email protected]

Digital CamSwitch UnitDigitronic

CamCon DC30Automationsanlagen GmbH

For your attention

This instruction manual relates to the CamConDC30fromNovember 1996.The companyDigitronic

Automationsanlagen GmbH reserves the right to makechanges which present an improvement ofthe

qualityor functionalityofthe device without prior notice. The instruction manual was created with great

care, although it maynot be error-proof.Wewould be grateful for anycommunication relating to any

errors you mayhave found.

UP-date

You can also access this instruction manual on the Internet at http://www.digitronic.comin the latest

version as PDF file.

Qualified personnel

This device mayonlybe started and operated byqualified staff.Byqualified wemean personnel who

are entitled to handle, to earth and to lable devices, systemsand power circuits in accordance with the

technologysafetystandards.

Liability

(1) The supplier is liable for damages caused byhimselfor bythe owner ofthe rights up to the sumof

the sales price. He is not liable for loss ofprofits, forfeited savings, intermediate and successive

damages.

(2) The above mentioned limits to liabilitydo not applyto insurance ofnamed characteristics and

damages which were caused deliberatelyor through negligence.

Protection

The CamConDC30and this instruction manual are protected bycopyright. All rights are reserved.

Neither the CamConDC30, nor this document maybe copied as awhole, photocopied, reproduced,

translated or transferred to electronic media ofanykind or into machine readable format without prior

written permission bythe companyDigitronic Automationsanlagen GmbH.

Note: Wehave examined the devices ofthe CamCon series for year 2000 compatibilityand

have not found anyadverse effects on anyfunctions.

Note: CamCon is aregistered trademarkofthe companyFirmaDigitronic

Automationsanlagen GmbH.

Note: The devices ofthe CamCon series complywith the standards for electromagnetic

compatibility:EN55011, EN55022, EN55024Part2, EN50082Part2, ENV50140,

VDE0843Part2, VDE0843Part4, VDE0871, VDE0875Part3("N"),

VDE0875Part11, VDE0877Part2, IEC801Part3, IEC801Part2, IEC801Part4,

IEC801Part5.

(c) Copyright 1992 -2002/ File:DC30_E.DOC

Digitronic Automationsanlagen GmbH

Aufder Langwies 1

D-65510 Hünstetten - Wallbach

Tel. (+49)6126/9453-0 Fax. (+49)6126/9453-42

Internet: http://www.digitronic.com

Page:2Version from:04.06.2002

DigitronicDigital CamSwitch Unit

Automationsanlagen GmbHCamCon DC30

TABLE OF CONTENTS

1. Introduction...........................................................................................................................................4

2. Principle offunction..............................................................................................................................5

2.1. Delaytime compensation..................................................................................................................6

2.1.1. Calculating the delaytime..............................................................................................................8

2.1.1.1. Calculating the delaytime through relocations that have alreadyoccured.................................8

2.1.1.2. Calculating the delaytime through the difference ofmeasured values.......................................8

3. Installation............................................................................................................................................9

3.1. Dimensions .......................................................................................................................................9

4. Electrical connections ........................................................................................................................10

4.1. Pin allocation CamCon with 8 or 16 outputs...................................................................................10

4.2. The encoder....................................................................................................................................11

4.3. The outputs.....................................................................................................................................11

4.4. Precautions to be taken at welding operations...............................................................................11

5. Outline ofthe operator terminal..........................................................................................................12

5.1. FrontviewCamCon .........................................................................................................................12

5.2. The output display...........................................................................................................................12

5.3. The seven-segment display............................................................................................................12

5.3.1. Displayofposition or speed.........................................................................................................12

5.4. The keyboard..................................................................................................................................12

6. Commissioning...................................................................................................................................13

6.1. Complete deletion...........................................................................................................................13

6.2. Initialization......................................................................................................................................13

6.2.1. User keyfor the systemregisters.................................................................................................13

6.2.2. The encoder resolution ................................................................................................................14

6.2.3. The Forwards/Reverse change over............................................................................................14

6.2.4. The zero point correction .............................................................................................................14

6.2.5. The dead time compensation.......................................................................................................14

6.2.6. Setting ofthe programming mode................................................................................................14

6.3. Camprogramming in the programming mode "0"..........................................................................15

6.3.1. Selecting an output.......................................................................................................................15

6.3.2. Searching for cams......................................................................................................................15

6.3.3. Setting the preset value................................................................................................................15

6.3.4. Shifting the activation point..........................................................................................................15

6.3.5. Shifting the deactivation point......................................................................................................15

6.3.6. Leaving camprogramming ..........................................................................................................16

6.3.7. Examples for camprogramming in the programming mode "0"..................................................16

6.3.7.1. Programming the first cam........................................................................................................16

6.3.7.2. Programming additional cams on an output.............................................................................17

6.3.7.3. Deletion ofa particular cam ......................................................................................................18

6.4. Camprogramming in the programming mode "1"..........................................................................19

6.4.1. Selecting an output.......................................................................................................................19

6.4.2. Shifting the activation point..........................................................................................................19

6.4.3. Shifting the deactivation point......................................................................................................19

6.4.4. Leaving camprogramming ..........................................................................................................19

6.4.5. Examples for camprogramming in the programming mode "1"..................................................20

6.4.5.1. Camprogramming....................................................................................................................20

6.4.5.2. Deletion ofcams.......................................................................................................................20

7. Outline ofoperations..........................................................................................................................21

7.1. Switching the standard display........................................................................................................21

7.2. Programming ofthe systemconstants............................................................................................21

7.3. Camprogramming..........................................................................................................................21

8. watch doc...........................................................................................................................................22

9. Troubleshooting .................................................................................................................................22

10. Technical data ofthe CamCon.........................................................................................................23

11. Keyword table..................................................................................................................................24

Version from:04.06.2002Page:3

Digital CamSwitch UnitDigitronic

CamCon DC30Automationsanlagen GmbH

1. Introduction

Electrical camswitch units have been used successfullybythe industryfor along time.The

experiences which have been collected in close co-operation during these years have been considered

during the development ofthe CamCon. The result is acompact digital camswitch unit which owns a

maximumofuser friendliness and reliability.

The following characteristics distinguish the CamCon:

*Experienced and reliable hardware

*Short circuit-proofoutputs

*Graphical liquid crystal displaywith 128x64 picture elements on CamCon DC50/51

*As manycams per output as programmable

*Optimizing ofthe switching points while the machine operates

*In steps of100µs adjustable compensation ofthe mechanical delaytime ofswitch units

*Voltage supply24V DC +/- 20%

*Carrier rail assemblyaccording to EN 50022 on CamCon DC16 and DC90.

*Switchboard normencasement 144 x 144 x 63mm according to DIN 43700 on CamCons DC40,50

and 51.

*S5 operation group for SimaticS5 115U, 135U and 155U on CamCon DC115.

*S5 connection via PG interface with L1 - BUS.

*S7 operation group for SimaticS7 300 on CamCon DC300.

*PLC logic module (optional)

*Analog outputs (optional)

Note: Simaticis a registered trademarkofthe Siemens company.

Camswitch units are being used everywhere where switching procedures are being periodically

repeated. Digital camswitch units replace mechanical ones optimallyand furthermore offer other

advantages, for example:

*Simplification ofassemblyand adjustment procedures

*Reproducible adjustments

*Standardisation for all possible ranges ofoperation

*Reliability

*High switching speed

*Delaytime compensation

Page:4Version from:04.06.2002

DigitronicDigital CamSwitch Unit

Automationsanlagen GmbHCamCon DC30

2. Principle of function

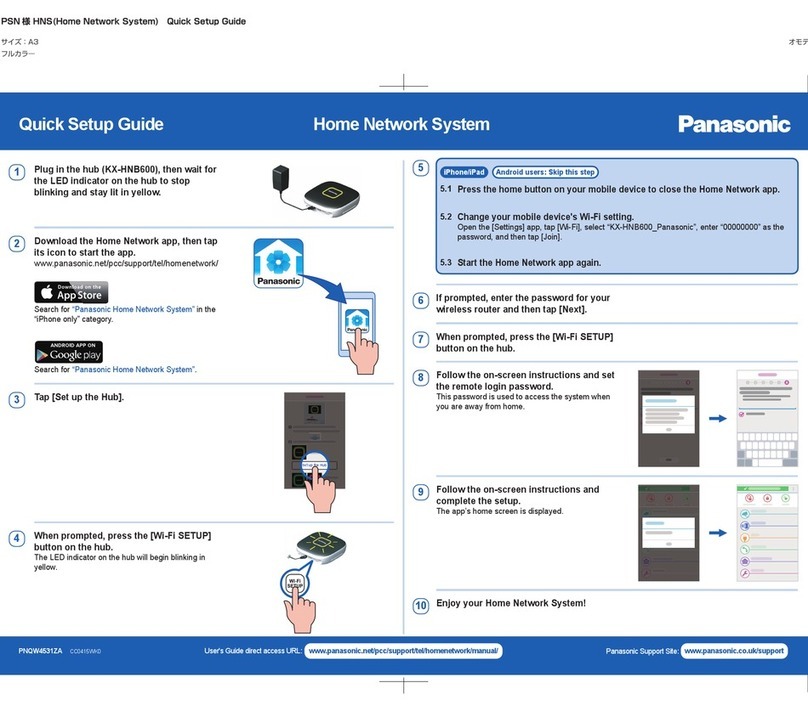

Fig.:Presentation ofthe principle ofa camswitch unit

For abetter understanding ofthe function ofacamswitch unit, its principle is presented here. It has 3

outputs containing the following cams:

Output 1:Cam1:Activation point60°Deactivation point85°

Cam2:Activation point95°Deactivation point145°

Cam3:Activation point325°Deactivation point355°

Output 2:Cam1:Activation point5°Deactivation point20°

Cam2:Activation point95°Deactivation point145°

Output 3:Cam1:Activation point30°Deactivation point85°

The 3as beds presented progressions ofthe output signals occur, ifthe 3camplates turn

anticlockwise past a sensor, which scans the cams on the 0° axis.

The duration ofthe activation ofamechanical camswitch unit, i.e. the range between the on and off

position, is determined bythe length ofthe cams.The length and the position ofthe camscan onlybe

limitedlyvaried, which additionallydemands arelativelyhigh mechanical and chronological

expenditure.With the CamCon, these adjustments are realisable in afraction ofasecond, besides the

numberof the camsper bed is optional.Ameasuring system,which has been connected to the device

reports the position to the CamCon.The CamConcompares this with the programmed on and off

positions fromall the outputs.Ifaposition appears in arange ofaprogrammed on /off position

(cams), all affected outputs will be switched.

Version from:04.06.2002Page:5

Digital CamSwitch UnitDigitronic

CamCon DC30Automationsanlagen GmbH

2.1. Delaytime compensation

Everymechanical switching part (e.g. relays, magnetic valves) possesses adelaytime, i.e. between

the triggering signal and the actual switching of the contacts passes acertain amount of time. Because

of that, problemscan arise during procedures in which positionings are carried out in amoved system.

Ifsuch aprocess is driven with different speeds, different positionings will arise. One would have to

generate new(de)activation points for the switching signals for everyspeed in order to overcome this.

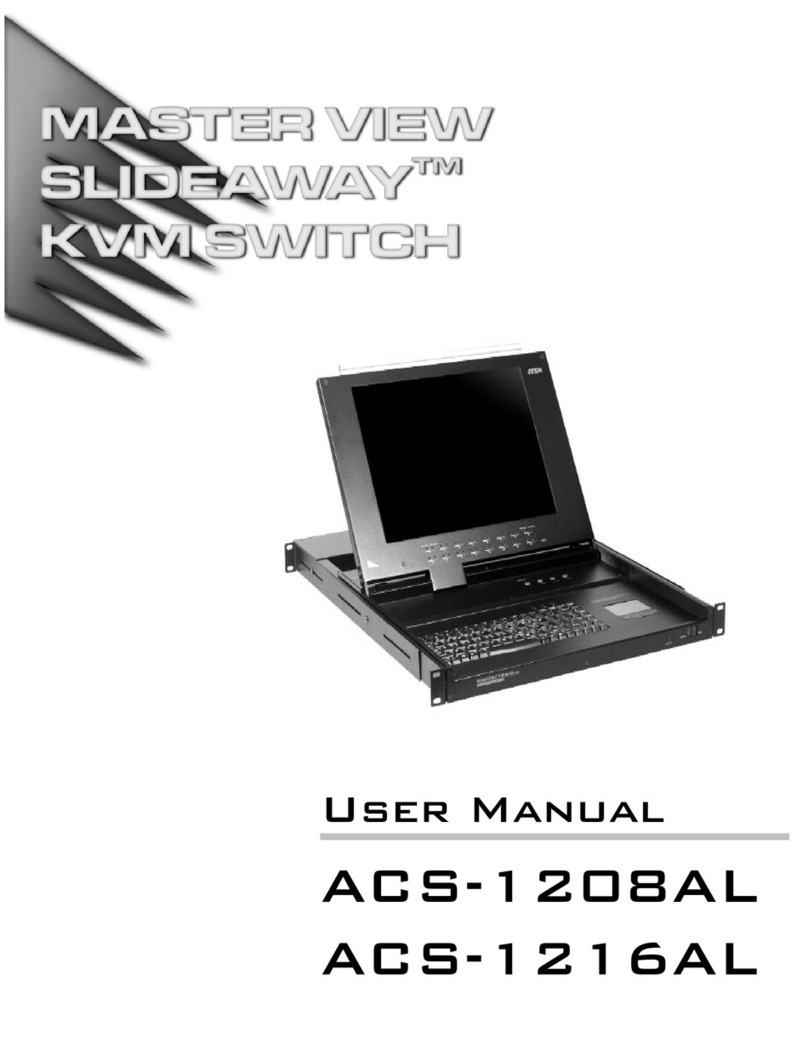

Toexplain the problemofthe delaytimecompensation, the context shall be clarified using the

example ofapackaging machine. During the process which is presented bythe drawing, adot ofglue

is to be applied onto a precicelydefined spot ofa past going paber web.

magnetic valve

gluenozzle

drop

paper

Points wheretheglue

hits thepaper at the

different speeds.

paper track

encoder

CamCon

The systemhas the following parameters:

vp-Speed ofthe paper web

vT-Falling speed ofthe drop ofglue

d-Distance between the glue nozzle and

the paper web

TMV -Delaytime ofthe magnetic valve

This happens without delaytime compensation:

As soon as the measuring systemreaches acertain position, the CamCon sends out an impulse to the

magnetic valve. This opens the glue nozzle for ashort time, out ofwhich the drop ofglue then shoots.

Between the placing ofthe impulse and the falling ofthe drop passes acertain time, which is mainly

based on the delaytimeof the magnetic valve TMV Another delayresults in the timein which the drop

needs to cover the distance d between the glue nozzle and the surface ofthe paper.

This flight time can be calculated with:

tFlight =d

vT

So adelaytimeoftFlight+TMV results altogether. During this time,, the paper web moves acertain

distance further on. One could nowdecrease the position at which the magnetic valve is activated, so

that the drop ofglue hits the samespot as during standstill. One gains adelaytimecompensation in

this way,which however can onlyfunction at one single speed ofthe paper. As soon as the speed of

the system and the paper web is e.g. doubled, the landing range ofthe drop ofglue is moved again by

the distance x, so that it would, without delaytimecompensation, move to the rear bytwice the

distance (2 ⋅x) altogether.

The automatic delaytimecompensation ofthe CamCon makes it nowpossible to operate with

processes with variable speeds. The CamCon gathers the speeds ofthe systemcontinuallyand

adjusts the cams, which define the moments ofswitching, on line in dependence ofthe speed.

According to this, the outputs ofthe switching parts are being switched on or off earlier. The direction

ofmovement is ofno importance.

Page:6Version from:04.06.2002

DigitronicDigital CamSwitch Unit

Automationsanlagen GmbHCamCon DC30

A small numerial example shall serve the illustration:

Assuming that the drive roll with the measuring systemhas acircumference of360mm,so that one

millimeter at the circumference corresponds exactlyto one angle degree ofthe measuring system.

The unit has the following parameter:

vdrop=20m/s

d=20cm

TMV =20ms

Out ofthis results a flight time ofthe drop to

tFlight= d

vT=0,2m

20m/s =10ms

So the complete delaytime amounts to Tdead, altogether = TMV + tFlight = 20ms + 10ms = 30ms

During this timethe paper web travels bythe distance x=vpaper ⋅Tdead,altogether =1m/s ⋅30ms=

30mm further on.

The switching point ofthe magnetic valve has to be transfered 30° to the front to compensate this

delaytime.

If one doubles the speed ofthe system and with that vpaper, the distance x, bywhich the paper web is

moving on, is also doubled. In this case the switching point has to be transfered by60° .

Tip: Note that in this explanation the delaytimeis asolid quantity,which is determined bythe

mechanical regulation and switching parts as well as bythe measurement ofthe construction,

hence it does not change.

Ifone were nowto programthe complete delaytimeof30mson the appropriate output ofthe

CamCon, the drop ofglue would always hit the exact spot at anyspeed.

Version from:04.06.2002Page:7

Digital CamSwitch UnitDigitronic

CamCon DC30Automationsanlagen GmbH

2.1.1. Calculating the delaytime

There are several possibilities for calculating the delaytime ofa relayor a valve.

2.1.1.1. Calculating the delaytime through relocations that have alreadyoccured

Programthe switching point ofthe relayor valve during astandstill ofthe machine. Weuse the

switching point of 200 degrees in our example. Ifthe machine is nowrun with aspeed ofe.g 40 min-1,

arelocation occurs because ofthe delaytime. This relocation is measured and is 40 degrees in our

example.

Attention: Tocalculate the relocation correctlyyou have to set the programmed delaytimeofthe

camswitch unit to zero.

The delaytime ofthe switching member is calculated according to the following formula:

Delaytime ( in sec. ) = ∆way(indegrees)*60(sec./min.)

speed(inmin-1)*360(degrees/rotations)

Delaytime ( in sec. ) = 40*60

40*360 = 0.1667 sec.

The calculated delaytime is nowset in the CamCon.

2.1.1.2. Calculating the delaytime through the difference of measured values

The switching point is determined at aspeed ofe.g. 50 min-1.In our example, the programmed

switching point is at 200 degrees. The second measurement occurs at aspeed of80 min-1.The

needed switching point has to be set to 160 degrees to reach the exact switch point again at 80 min-1.

Attention: Todetermine the twoswitching points you have to set the programmed delaytimeofthe

camswitch unit to zero.

The delaytime ofthe switching member is calculated with the following formula:

Delaytime ( in sec. ) = ∆way(indegrees)*60(sec./min.)

∆speed(inmin-1)*360(degrees/rotations)

Delaytime ( in sec. ) = 40*60

30*360 = 0.222 sec.

The determined delaytimeis nowentered into the cam mechanism.Since this delaytimeis set for the

whole range ofthe speed, it nowbecomes necessaryto adjust the camto the speed at 0min-1.To

determine the exact activation point you have to enter the difference to the speed 0min-1 at the first

measured activation point. The difference is calculated according to the following formula:

∆way(in degrees) = deadtime(insec.)*∆time(inmin-1)*360(degrees/rotations)

60(sec./min.)

∆way(in degrees) = 0.222*50*360

60 = 66.6 degrees

The activation point ofthe camis nowrelocated by67 degrees, from200 degrees to 267 degrees.

Page:8Version from:04.06.2002

DigitronicDigital CamSwitch Unit

Automationsanlagen GmbHCamCon DC30

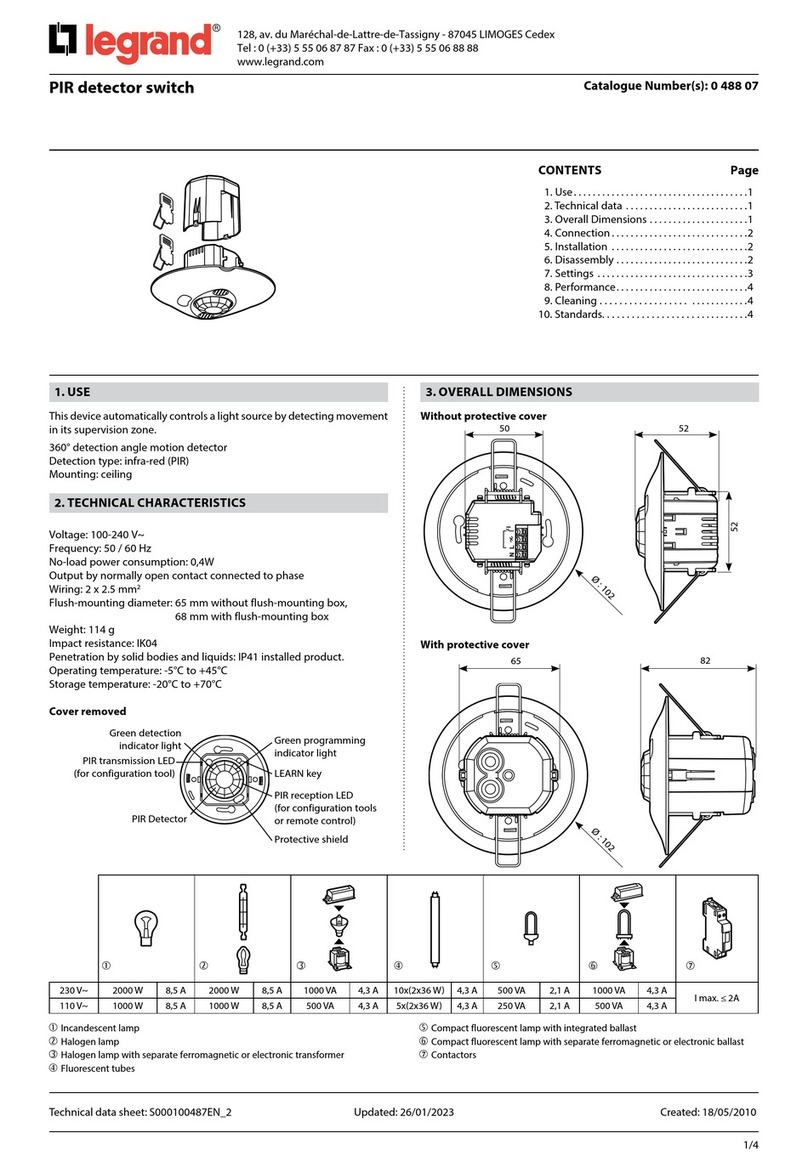

3. Installation

The unit is inserted into acutout for front plate installation (see chapter "3.1. Dimensions" on page9).

Connect the groundig pins on the backofthe encasement as well as the cable cover to agrounding

point ofthe switchboard door in the shortest possible way.All cable connections must be done in a

cold state! The connection cables, e.g. for the measuring systemor the serial interface, must be wired

with covers, and the covers have to grounded on both ends. Analog signals must also be wired with

covers, and the covers have to be grounded on one end.

3.1. Dimensions

cutout as per DIN 138

+1

x 138

+1

Fig.:Drawing to aid the installation ofCamCon

Version from:04.06.2002Page:9

Digital CamSwitch UnitDigitronic

CamCon DC30Automationsanlagen GmbH

4. Electrical connections

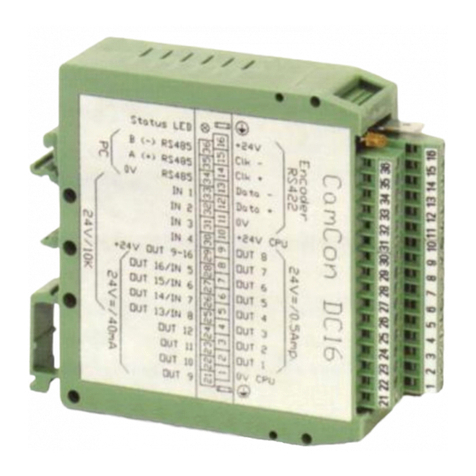

4.1. Pin allocation CamCon with 8 or 16 outputs

Pin 1:0V for encoder

Pin 2:Data A or +

Pin 3:Data B or -

Pin 4:ClockA or +

Pin 5:ClockB or -

Pin 6:+24V DC for encoder

Pin 7:0V supply

Pin 8:Output 1

Pin 9:Output 2

Pin 10:Output 3

Pin 11:Output 4

Pin 12:Output 5

Pin 13:Output 6

Pin 14:Output 7

Pin 15:Output 8

Pin 16:+24V DC supply

onlyfor the CamCon with 16 outputs:

Pin 17:0V supply

Pin 18:Output 9 (A)

Pin 19:Output 10 (B)

Pin 20:Output 11 (C)

Pin 21:Output 12 (D)

Pin 22:Output 13 (E)

Pin 23:Output 14 (F)

Pin 24:Output 15 (G)

Pin 25:Output 16 (H)

Pin 26:+24V DC supply

Page:10Version from:04.06.2002

DigitronicDigital CamSwitch Unit

Automationsanlagen GmbHCamCon DC30

4.2. The encoder

The encoder is used for getting the actual position, necessaryfor the camcontroller. Onlyencoders

with an SSI interface can be connected to CamConDC30. The SSI interface is acommon interface for

absolute single and multiturn encoders. The CamCon supplies the measuring systemwith 24Volt via

this interface. Toread the data, CamCon sends aclock signal with an RS422 level to the encoder. The

encoder the answers synchronouslywith the output (data) ofthe position in Graycode. The frequency

ofthe clocksignal depends on the length ofthe cable connecting ecoder and CamCon.The cable

length can be maximumof200 metre.

Note: The data protocol corresponds with the Stegmann SSI Norm.

Tp=clockimpulse

Tmono=mono flop time 25µs

Attention:

Use onlyacovered double entwined connection cable. The

wiring should not be near power current lines. Ground the

covers at both sides.

4.3. The outputs

CamCon is equipped with either 8or 16 short circuit-proofoutputs, depending on the version. They

emmit 24V high active signals and are not potentiallyfree. Theysupplyup to 500mApermanent

current in asurrounding temperature of25°C. Ifan output short circuits or overloads, the device

switches off with the "A-Err" message.

Attention: With inductive loads the outputs have to be switched with free wheeling

diodes.

4.4. Precautions to be taken at welding operations

For the duration ofwelding operations carried out at the machine, the connecting wires concerning the

data exchange fromthe measuring systemto the CamCon and the power supplyas well as the

grounding connections and inputs and outputs have to be separated fromthe CamCon.

Version from:04.06.2002Page:11

Digital CamSwitch UnitDigitronic

CamCon DC30Automationsanlagen GmbH

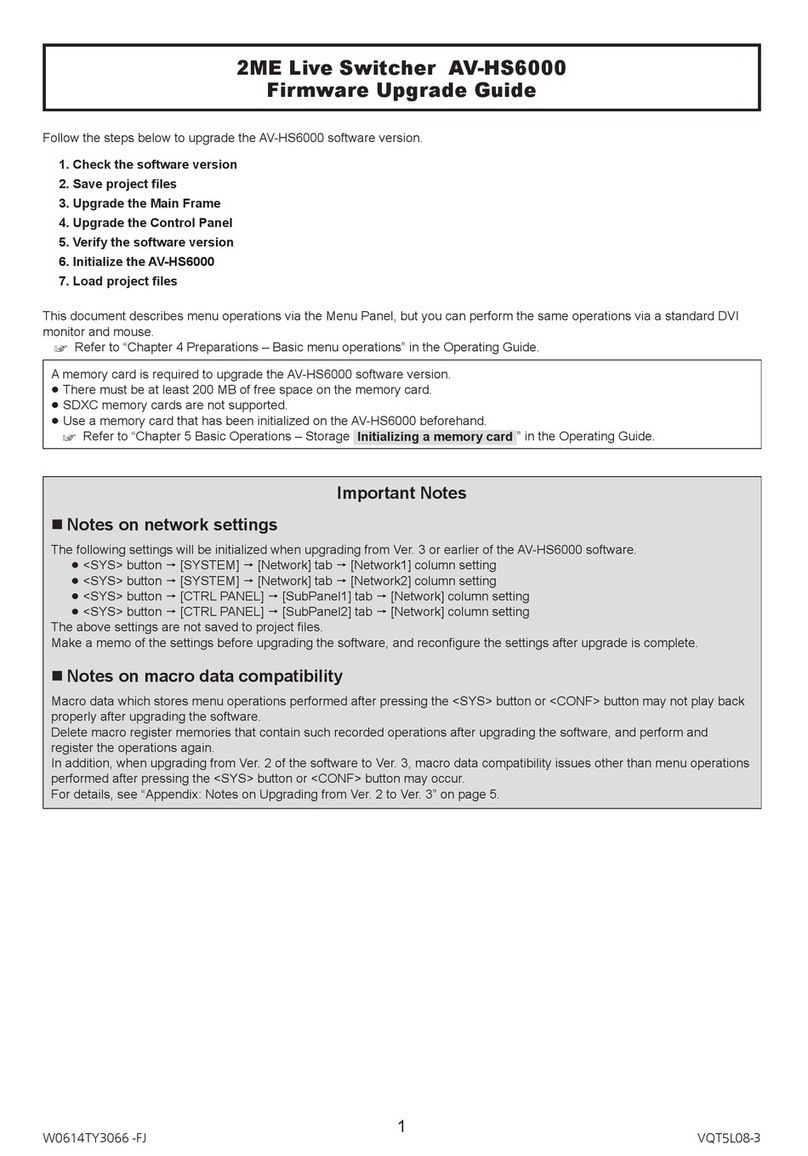

5. Outline of the operator terminal

5.1. FrontviewCamCon

5.2. The output display

The output displayshowsthe current states ofthe outputs. IfaLED is illuminated, the corresponding

output is active.

5.3. The seven-segment display

This displayis divided into tworanges. The 1. and the 2. segment showthe current mode ofCamCon,

and the segments 3, 4 and 5 displaythe value pertaining to this mode.

5.3.1. Displayof position or speed

After the activation and after having leftthe programming modes the 7-segment displayshowsthe

rotatoryspeed in rotations/minute. Bypressing the key,the angular position ofthe encoder, e.g.

is displayed. Ifthe keyis pressed, the displaywill showthe rotatoryspeed.

5.4. The keyboard

The key serves for increasing the input values bythe value one. Ifyou keep the keypressed for

about two seconds, the input values will increase automaticallyuntil released.

The key is used to reduce the input values bythe value one. Keeping the keypressed for about

two seconds will cause the input values to decrease automaticallyuntil the release ofthe key.

The key serves for the initiation ofthe programming mode and/or for the modification ofthe input

type.

The key is used for the initiation ofthe systemmode, for the selection ofthe systemconstants

and/or for selecting the outputs in the programming mode.

Page:12Version from:04.06.2002

DigitronicDigital CamSwitch Unit

Automationsanlagen GmbHCamCon DC30

6. Commissioning

Before activating the device for the first time, please checkits wiring (see chapter4. Electrical

connections).

Attention:With induced loads the outputs have to be switched with afreewheeling

diode. Covers or inductivities very close to the device inside the

switchboard have to be switched with adeletion unit as do those that are

wired to or influence the wiring of the device.

6.1. Complete deletion

After the first activation ofthe supplyvoltage the programmemoryis not in an initialized mode. This

leads to the CamCon' sdisplayshowing uncomprehendable symbols. That is whyyou (at the first

activation ofyour CamCon) have to put a complete deletion into process as follows:

1.Activate the device (supplywith voltage, +24V DC).

2.Wait until the displayshows either a number or .

3.Press the keyfour times.

4.Press the keyfour times.

5.Press the key(about 2sec.), until is displayed.

6.Press the key(about 2sec.), until the displaygoes out.

7.Release the key.

After awhile (up to 40sec.) the displayis reactivated. This completes the complete deletion. All cams

are erased, and all systemregisters have the standard value.

6.2. Initialization

After an activation ofthe voltage supplyor acomplete deletion the CamCon is in the standard mode.

This mode normallydisplaysthe rotational speed, the angular position ofthe encoder, or an error

message. The error message continues to be displayed until the systemregisters have been adjusted

to the encoder, provided the wiring is correct.

6.2.1. User keyfor the system registers

In order to be able to programthe systemregisters, the following keysequence must be maintained:

1.Press the keyfour times.

2.Press the keyfour times.

3.Keep the keypressed for about 2 seconds, until the displayshows .

Version from:04.06.2002Page:13

Digital CamSwitch UnitDigitronic

CamCon DC30Automationsanlagen GmbH

6.2.2. The encoder resolution

The display showsthe resolution ofthe encoder in steps per rotation. The CamCon

operates with astandard encoder with aresolution of360 steps per rotation. The resolution cannot be

adjusted or changed.

6.2.3. The Forwards/Reverse change over

After pressing the keythe displayshows .The display showsthat the

encoder is counting upwards clockwise, when looking at the shaft. You can reverse the rotational

direction ofthe encoder bypressing the or the key. is displayed.

6.2.4. The zero point correction

Ifyou press the key,the displayshowse.g.: . 123 represents the current angular

position ofthe encoder. After having positioned the drive to mechanical "0",you can also shiftthe

current angular position to "0" bypressing the keyor the key,so that the mechanical and the

electronic zero point coincide. The displayshows .

6.2.5. The dead time compensation

After you press the keythe displayshows . Here you enter the dead timewithin arange

from0msto 255ms. You can change this value in steps of1msbypressing the or the key.The

outputs 1 through 8 are (de)activated earlier bythis time factor.

6.2.6. Setting of the programming mode

appears on the displayafter you press the key.Here you can set the mode for cam

programming. Pressing either the or the keyresults in achange over fromprogramming mode

0to programming mode 1. The programming mode 1is easier to use than the programming mode 0,

but it is not possible (in programming mode 1) to programseveral cams on one output.

You can leave the standard displaywith an additional pressing ofthe key.CamCon should now

displaythe current speed, e.g.: . Ifnot, please refer to the chapter "Troubleshooting".

Page:14Version from:04.06.2002

DigitronicDigital CamSwitch Unit

Automationsanlagen GmbHCamCon DC30

6.3. Cam programmingin the programming mode "0"

6.3.1. Selecting an output

Toinitiate camprogramming press the keyfor about 2sec., until the displayshowse.g.

.This indicates that there is no programmed camon output 1in the 'Output selection'

mode. Bypressing the keyor the keyyou can nowselect the output on which you want to

programcams.

6.3.2. Searching for cams

Bypressing the keyyou leave the 'Output selection' mode and enter the mode 'Cam

search' . In the 'Camsearch' mode you can search for the camactivation

points bypressing the key.Everytimethe keyis pressed, CamCon searches the memoryfor

activation points ofthe camson the corresponding output. Ifno camhas been programmed,

is displayed. Ifacamhas been programmed over the whole perimeter, the displayshows

.

6.3.3. Setting the preset value

You leave the 'Camsearch' mode and enter the 'Preset' mode with the

pressing ofthe key.Bypressing the or the keyyou can nowselect avalue, e.g. 100. This

value is the originator fromwhich camsmayeither be reconstructed or erased bychanging the

activation and the deactivation points.

6.3.4. Shifting the activation point

Bypressing the keyyou leave the 'Preset' mode and enter the 'Activation point' mode

.Apressing ofthe keyor the keyshifts the activation point byone step. This is

done according to the following system:

Ashort single pressing ofthe keywill erase the activation point at the previouslydisplayed preset

value, e.g. 100, and then the preset value is increased by1, e.g. to 101. Ashort pressing of the key

will lower the preset value (100 in our example) by1 and then set a newactivation point at e.g. 99.

6.3.5. Shifting the deactivation point

Pressing the keyonce more leads you fromthe 'Activation point' mode into the

'Deactivation point' mode . CamCon will first search for the deactivation point of the current

cam(e.g.: ). Bypressing the or the keythe deactivation point is shifted byone step.

This is done according to the following system:

Asingle short pressing ofthe keywill set anewswitching point at the previouslydisplayed preset

value, e.g. 100. Then the preset value is increased byone, e.g. to 101. Ashort pressing ofthe key

will lower the preset value, e.g. 100, by1and then delete the switching point 99. The newdeactivation

point is then 99. Afurther pressing ofthe keybrings you backto the 'Output selection' mode

.

Version from:04.06.2002Page:15

Digital CamSwitch UnitDigitronic

CamCon DC30Automationsanlagen GmbH

6.3.6. Leaving cam programming

No matter in which programming mode you are, you can alwaysleave camprogramming bypressing

the key. The standard displayappears

6.3.7. Examples for cam programmingin the programming mode "0"

6.3.7.1. Programming the first cam

Task:

After acomplete deletion ofthe programmemoryand asuccessful initialization ofthe system,acam

shall be programmed for output 2 from100 to 200.

Solution:

1.Press the key(for about 2 sec.), you enter the 'Output selection' mode .

2.Press the keyto select output 2, .

3.Press the key, you enter the 'Camsearch' mode .

4.Press the key, for the input ofthe preselection .

5.Press the keyand keep it pressed until is displayed.

6.Ifyou have released the keytoo earlyor too late, you can adjust the preselection to 100 with

the or the key.

7.Press the key, the activation point is displayed.

8.Press the keyto programthe deactivation point.

9.Press the keyand keep it pressed until the displayshows .

CAUTION! Do not keep the keypressed too long. It is best to keep the keypressed until 190

and then adjust to 200 step bystep.

10.Press the key. You return to the standard display.

NOTE:

When programming the activation and the deactivation points you are programming "on line", i.e. ifyou

keep the keypressed for too long, the camwill be programmed too long. Although you can correct

this subsequentlywith the key,the range between the desired end ofthe cam and camsentered in

excess is erased. All cams alreadyprogrammed in this range are lost.

Page:16Version from:04.06.2002

DigitronicDigital CamSwitch Unit

Automationsanlagen GmbHCamCon DC30

6.3.7.2. Programming additional cams on an output

Task:

Acamshall be programmed on output 2from300 to 330 in addition to an alreadyexisting cam,e.g.

from100 to 200.

Solution:

1.Press the key(for about 2 sec.), you enter the 'Output selection' mode .

2.Press the keyto select output 2, . The displayalso showsthe begin ofthe

alreadyprogrammed cam.

3.Press the key, you enter the 'Camsearch' mode .

4.Press the keyfor the input ofthe preselection .

5.Press the keyand keep it pressed until appears on the display.

6.Ifyou have released the keytoo earlyor too late, you can adjust the preselection to 300 with

the or the key.

7.Press the key, the activation point is displayed.

8.Press the keyto programthe deactivation point.

9.Press the keyand keep it pressed until is displayed.

CAUTION! Do not keep the keypressed too long. It is best to keep the keypressed until 320

and then adjust to 330 step bystep.

10.Press the key. You return to the standard display.

NOTE:

When programming the activation and the deactivation points you are programming "on line", i.e. ifyou

keep the keypressed for too long, the camwill be programmed too long. Although you can correct

this subsequentlywith the key,the range between the desired end ofthe cam and camsentered in

excess is erased. All cams alreadyprogrammed in this range are lost.

Version from:04.06.2002Page:17

Digital CamSwitch UnitDigitronic

CamCon DC30Automationsanlagen GmbH

6.3.7.3. Deletion of a particular cam

Task:

The camfrom300 to 330 on output 2 shall be deleted.

Solution:

1.Press the key(for about 2 sec.), you enter the 'Output selection' mode .

2.Press the keyto select output 2, . The start ofthe first camfound is displayed.

3.Press the key, you enter the 'Camsearch' mode .

4.Press the key, the device searches for the start ofthe next cam. is displayed.

5.Press the key. The preselection is displayed.

6.Press the keyto programthe activation point. The displayshows .

7.Press the keyand keep it pressed until the displayshows .

CAUTION! Do not keep the keypressed too long. It is best to keep the keypressed until 320

and then adjust to 330 step bystep.

8.Press the key. You return to the standard display.

NOTE:

Byshifting the camactivation point to the camdeactivation point the programmed camis deleted. By

shifting the activation point beyond the deactivation point deletes the range after the cam(e.g. from

330 to 350). All camsprogrammed in this range are deleted. Anewcamwill be placed between 330

and 350 when you move the activation point backto the desired position of330 !

Page:18Version from:04.06.2002

DigitronicDigital CamSwitch Unit

Automationsanlagen GmbHCamCon DC30

6.4. Cam programmingin the programming mode "1"

6.4.1. Selecting an output

The camprogramming is initiated as follows: Press the keyfor about 2sec., until the displayshows

e.g. . This indicates that no camhas been programmed on output 1in the 'Output

selection' mode. Bypressing the keyor the keyyou can nowselect the output on which you

want to programcams.

6.4.2. Shifting the activation point

Bypressing the keyyou leave the 'Output selection' mode and enter the 'Activation

point' mode . A pressing ofthe keyor the keyshifts the activation point byone step.

This is done according to the following system:

Ashort single pressing ofthe keywill erase the activation point at the previouslydisplayed preset

value, e.g. 100, and then the preset value is increased by1, e.g. to 101. Ashort pressing of the key

will lower the preset value (100 in our example) by1 and then set a newactivation point at e.g. 99.

6.4.3. Shifting the deactivation point

Pressing the keyonce more leads you fromthe 'Activation point' mode into the

'Deactivation point' mode . CamCon will first search for the deactivation point of the current

cam(e.g.: ). Bypressing the or the keythe deactivation point is shifted byone step.

This is done according to the following system:

Asingle short pressing ofthe keywill set anewswitching point at the previouslydisplayed preset

value, e.g. 100. Then the preset value is increased byone, e.g. to 101. Ashort pressing ofthe key

will lower the preset value, e.g. 100, by1and then delete the switching point 99. The newdeactivation

point is then 99. Afurther pressing ofthe keybrings you backto the 'Output selection' mode

.

6.4.4. Leaving cam programming

No matter in which programming mode you are, you can alwaysleave camprogramming bypressing

the key. The standard displayappears

Version from:04.06.2002Page:19

Digital CamSwitch UnitDigitronic

CamCon DC30Automationsanlagen GmbH

6.4.5. Examples for cam programmingin the programming mode "1"

6.4.5.1. Cam programming

Task:

After acomplete deletion ofthe programmemoryand asuccessful initialization ofthe system,acam

shall be programmed on output 2 from100 to 200.

Solution:

1.Press the key(for about 2 sec.), you enter the 'Output selection' mode .

2.Press the keyto select output 2, .

3.Press the keyfor the programming ofthe activation point .

4.Press the keyand keep it pressed until is displayed.

5.If you released the keytoo earlyor too late, you can adjust the preselection to 100 with the

or the key.

6.Press the keyto programthe deactivation point.

7.Press the keyand keep it pressed until the displayshows .

8.Ifyou have released the keytoo earlyor too late, you can adjust the deactivation point to 200

with the or the key.

9.Press the key. You return to the standard display.

6.4.5.2. Deletion of cams

Task:

You want to delete the cam100 to 200 on output 2.

Solution:

1.Press the key(for about 2 sec.), you enter the 'Output selection' mode .

2.Press the keyto select output 2, . The start ofthe found camis displayed.

3.Press the keyto programthe activation point. The displayshows .

4.Press the keyand keep it pressed until is displayed.

5.Ifyou released the keytoo early,shiftthe deactivation point to 200 byrepeatedlypressing the

key.Ifyou released the keytoo late, do not correct it !The camis then alreadyerased.

Shifting the activation point backwards programsanewcam in consequence. This cam should be

deleted.

6.Press the key. You return to the standard display.

Page:20Version from:04.06.2002

Table of contents

Other Digitronic Switch manuals