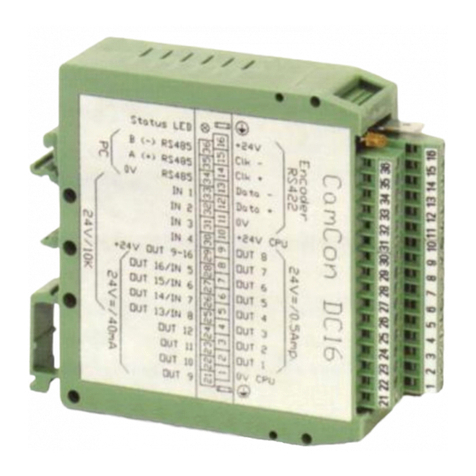

Digitronic CamCon DC16 User manual

DigitalCamSwitch Unit

CamConDC16

DigitronicAutomationsanlagen GmbH

Steinbeisstraße 3

•

D -72636 Frickenhausen

•

Tel. (+49)7022/40590-0

•

Fax -10

Auf derLangwies 1

•

D -65510 Hünstetten-Wallbach

•

Tel.(+49)6126/9453-0

•

Fax -42

Internet: http://www.digitronic.com

•

E-Mail: mail@digitronic.com

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:[email protected]

Site web : www.hvssystem.com

Digitronic DigitalCamSwitchUnit

AutomationsanlagenGmbH CamCon DC16

Foryourattention

Thisinstruction manualrelatesto the CamCon DC16 from10/2003. The companyDigitronic

Automationsanlagen GmbH reservesthe right to makechangeswhichpresent an improvement ofthe

qualityorfunctionalityofthe devicewithout priornotice. The instruction manualwascreated with great

care, although itmaynot be error-proof.Wewouldbe gratefulforanycommunication relating to any

errors you mayhave found.

UP-date

You can alsoobtainthisinstruction manualon the Internet at http://www.digitronic.com inthe latest

version asPDFfile.

Qualifiedpersonnel

Thisdevicemayonlybe started and operated byqualified staff.Byqualified wemean personnelwho

areentitled to handle, to earth and to labledevices,systemsand powercircuitsinaccordancewith the

technologysafetystandards.

Liability

(1)The supplierisliablefordamagescaused byhimselforbythe ownerofthe rightsup to the sumof

the salesprice. He isnot liableforloss ofprofits,forfeited savings,intermediate and successive

damages.

(2)The abovementioned limitsto liabilitydo not applyto insuranceofnamed characteristics and

damageswhich were caused deliberatelyorthrough negligence.

Protection

The CamCon DC16 and thisinstruction manualareprotected bycopyright. All rightsarereserved.

Neitherthe CamCon DC16, northisdocument maybe copied asawholeorpartially,photocopied,

reproduced, translated ortransferred to electronicmediaofanykind orinto machine readableformat

without priorwritten permission bythe companyDigitronicAutomationsanlagen GmbH.

Note: Wehaveexamined the devicesofthe CamCon seriesforyear2000 compatibilityand

have not found anyadverse effectson anyfunctions.

Note: CamCon isaregistered trademarkofthe companyFirmaDigitronic

Automationsanlagen GmbH.

Note: The devicesofthe CamCon seriescomplywith the standardsforelectromagnetic

compatibility:EN 55011, EN 55022, EN 55024 Part 2, EN 50082 Part 2, ENV50140,

VDE0843 Part 2, VDE0843 Part 4, VDE0871, VDE0875 Part 3 ("N"),

VDE0875 Part 11, VDE0877 Part 2, IEC 801 Part 3, IEC 801 Part 2, IEC 801 Part 4,

IEC 801 Part 5.

(c) Copyright 1992 -2004 / File: DC16E.DOC

DigitronicAutomationsanlagen GmbH

AufderLangwies1

D-65510 Hünstetten -Wallbach

Tel. (+49)6126/9453-0 Fax. (+49)6126/9453-42

Internet: http://www.digitronic.com

E-Mail: mail@digitronic.com

Version: Aug. 04 Page: 2

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:[email protected]

Site web : www.hvssystem.com

Digitronic DigitalCamSwitchUnit

AutomationsanlagenGmbH CamCon DC16

Table of contents

1. Introduction..........................................................................................................................................7

2. Operating Pinciples..............................................................................................................................8

2.1. Speed Compensation .......................................................................................................................9

2.1.1. Measuring delaytime forSpeed Compensation..........................................................................11

2.1.1.1. Measuring delaytime through actualdifferences.....................................................................11

2.1.1.2. Measuring delaytime bymeansofdifferent measuring points.................................................11

2.1.2. Speed Compensation using off-centre pressure, e.g. brake functions........................................12

2.1.3. Separate delaytime forSpeed Compensation ofswitch-ON and switch-OFF points.................13

2.2. Time -Cam.....................................................................................................................................13

3. Installation..........................................................................................................................................14

3.1. Dimensions.....................................................................................................................................14

4. Electricalconnections........................................................................................................................15

4.1. Pin allocation...................................................................................................................................15

4.1.1. Pin allocation ofthe voltage supply..............................................................................................15

4.1.2. Pin allocation ofthe SSI measuring system.................................................................................15

4.1.3. Pin allocation ofthe incrementalmeasuring system....................................................................15

4.1.4. Pin allocation ofthe outputs1-8 (0.5Amp.)..................................................................................15

4.1.5. Pin allocation ofthe outputs9-16 (40mA)....................................................................................15

4.1.6. Pin allocation ofthe inputs...........................................................................................................15

4.1.7. Pin allocation ofthe serialRS485 interface.................................................................................16

4.1.7.1. Closedown-resistors ofa serialRS485 interface.....................................................................17

4.1.7.1.1. Closedown resistors with DIP-switch.....................................................................................17

4.1.7.1.2. Closedown resistors with solding bridges..............................................................................18

4.1.8. Clamping allocation ofa serialRS232 interface (optional)..........................................................18

4.2. Externalinterface (option)...............................................................................................................19

4.2.1. Pin allocation ofthe externalinterface.........................................................................................19

4.2.2. Externalinterface with a cable length of0.5 to 300m..................................................................19

4.3. The measuring system....................................................................................................................20

4.3.1. SSI Measuring systeminput........................................................................................................20

4.3.2. Parallelmeasuring systeminput..................................................................................................20

4.3.3. Incrementalmeasuring systeminput...........................................................................................21

4.3.3.1. Incrementalmeasuring systeminput with 5VRS422 level.......................................................21

4.3.3.2. Incrementalmeasuring systeminput with 24VPNPlevel.........................................................21

4.3.3.3. IncrementalHiperface measuring systeminput with SINCOSlevel.........................................22

4.3.4. Analog measuring systeminput...................................................................................................22

4.3.5. PLL measuring systeminput........................................................................................................23

4.3.6. Timerasa measuring system......................................................................................................23

4.3.7. RS232 asa measuring system....................................................................................................23

4.4. The outputs.....................................................................................................................................24

4.5. The inputs.......................................................................................................................................24

4.6. Precautionarymeasuresforwelding work......................................................................................24

4.7. The statusLED...............................................................................................................................24

5. Generalprogramming information.....................................................................................................25

5.1. Outline ofkeyfunctions...................................................................................................................25

5.2. Menu selection................................................................................................................................25

5.3. Selection ofa menu point ...............................................................................................................25

5.4. Text input........................................................................................................................................26

6. Commissioning ..................................................................................................................................27

7. Operation ofthe CamCon..................................................................................................................29

7.1. The main menu...............................................................................................................................29

7.2. The standard display.......................................................................................................................29

7.2.1. Changing the display....................................................................................................................29

Version: Aug. 04 Page: 3

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:[email protected]

Site web : www.hvssystem.com

Digitronic DigitalCamSwitchUnit

AutomationsanlagenGmbH CamCon DC16

7.2.2. Programchange ..........................................................................................................................30

7.2.3. Programname.............................................................................................................................30

7.3. Camprogramming..........................................................................................................................31

7.3.1. Output selection forprogramming ...............................................................................................31

7.3.2. Programselection forprogramming............................................................................................32

7.3.3. Programming the delaytime/speed compensation......................................................................32

7.3.4. Programing Time-Cams...............................................................................................................33

7.3.5. Programming the output name....................................................................................................34

7.3.6. CamInput ....................................................................................................................................34

7.3.7. Adding cams................................................................................................................................35

7.3.8. CamTeach -In............................................................................................................................35

7.3.9. CamSearch.................................................................................................................................35

7.3.10. Camdeletion..............................................................................................................................36

7.3.11. Output (camtrack)deletion .......................................................................................................36

7.3.12. Copying programmed outputs(camtracks)...............................................................................37

7.3.13. Shifting camtracks ....................................................................................................................37

7.3.14. Deleting programs......................................................................................................................38

7.3.15. Copying programs......................................................................................................................38

7.3.16. Examplesforcamprogramming................................................................................................39

7.3.16.1. First camprogramming...........................................................................................................39

7.3.16.2. Programming additionalcamson an output...........................................................................40

7.3.16.3. Deletion ofa particularcam....................................................................................................41

7.3.17. Programming analog cams........................................................................................................42

7.3.17.1. Creating the first analog cam..................................................................................................43

7.3.17.2. Adding an analog cam............................................................................................................43

7.3.17.3. Changing the analog cam.......................................................................................................43

7.4. Unit configuration (systemsetting)..................................................................................................44

7.4.1. Measuring system........................................................................................................................44

7.4.1.1. The standard measuring systems.............................................................................................44

7.4.1.2. The actualposition hysteresis...................................................................................................44

7.4.1.3. Controlling the measuring system.............................................................................................45

7.4.1.4. The electronicgear...................................................................................................................46

7.4.1.4.1. Electronicallychanging the rotation direction.........................................................................46

7.4.1.5. The displayformat ofthe actualposition..................................................................................46

7.4.1.6. Configuration ofa specialmeasuring system...........................................................................47

7.4.1.6.1. SSI -measuring system.........................................................................................................47

7.4.1.6.2. Parallel-Graymeasuring system..........................................................................................48

7.4.1.6.3. Incremental-measuring system............................................................................................48

7.4.1.6.4. Multiturn measuring systemwith electronicgear...................................................................49

7.4.1.6.5. PLL measuring system ..........................................................................................................50

7.4.1.6.6. Timerwaysimulation (time emitter).......................................................................................50

7.4.1.6.7. RS232 measuring system......................................................................................................51

7.4.1.6.8. AG615 -Single -Multiturn -Measuring system.....................................................................51

7.4.1.6.9. SIM -measuring systemsimulator ........................................................................................52

7.4.1.6.10. HIPER i.e. incremental-measuring systemwith Roll -Over-funktion..............................52

7.4.1.7. Deleting the specialmeasuring system ....................................................................................53

7.4.2. The measuring offset...................................................................................................................54

7.4.2.1. Zero offset with rotatorymovements.........................................................................................54

7.4.2.2. Measuring offset with a linearmoved system...........................................................................54

7.4.2.3. Zero offset with linearmovements............................................................................................54

7.4.2.4. Actualposition preset................................................................................................................55

7.4.3. The speed adjustment.................................................................................................................56

7.4.3.1. The speed factor.......................................................................................................................56

7.4.3.2. The displayformat ofthe speed display...................................................................................56

7.4.3.3. Range adjustment ofthe speed display....................................................................................56

7.4.3.4. Accuracyofthe speed display..................................................................................................57

7.4.3.5. Display, Type ............................................................................................................................57

Version: Aug. 04 Page: 4

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:[email protected]

Site web : www.hvssystem.com

Digitronic DigitalCamSwitchUnit

AutomationsanlagenGmbH CamCon DC16

7.4.4. Cable length / Cycle time.............................................................................................................58

7.4.4.1. The cable length .......................................................................................................................58

7.4.4.2. The cycle time ofthe CamCon..................................................................................................58

7.4.5. The specialoutputs......................................................................................................................58

7.4.5.1. The securityoutput....................................................................................................................58

7.4.5.2. The output ofthe actualposition...............................................................................................59

7.4.5.3. Direction output.........................................................................................................................59

7.4.5.4. The standstill output..................................................................................................................59

7.4.5.5. The hysteresis...........................................................................................................................59

7.4.5.6. The analog speed output..........................................................................................................60

7.4.5.7. Configuration ofthe analog cams.............................................................................................60

7.4.5.8. The analog position output........................................................................................................62

7.4.6. Systemupgrading........................................................................................................................62

7.4.6.1. Setting the inputs......................................................................................................................62

7.4.6.2. Setting the outputs....................................................................................................................62

7.4.6.3. Setting the outputswith speed compensation..........................................................................62

7.4.6.4. Setting the keyboard lock..........................................................................................................62

7.4.6.5. Error-aknowledging Input (EQ)...............................................................................................62

7.4.6.6. Input forenableling Outputs......................................................................................................62

7.4.6.7. Setting the externalprogramselection.....................................................................................63

7.4.6.8. Setting the programselection mode.........................................................................................63

7.4.7. Masterprogram.............................................................................................................................64

7.5. Unit configuration............................................................................................................................65

7.5.1. Userkeyallocation.......................................................................................................................65

7.5.1.1. Creating a newuserkey...........................................................................................................65

7.5.1.2. Deletion ofa userkey...............................................................................................................66

7.5.1.3. Checking the keyconfiguration.................................................................................................66

7.5.2. Complete deletion........................................................................................................................67

7.5.3. Unit configuration.........................................................................................................................68

7.5.3.1. Setting the serialinterface ........................................................................................................68

7.5.3.1.1. The "Cam-BUS" communication mode..................................................................................68

7.5.3.1.2. The "Standard"communication mode...................................................................................68

7.5.3.1.3. The "Multiuser"communication mode...................................................................................68

7.5.3.1.4. The "S5 -L1"communication mode......................................................................................68

7.5.3.1.5. The "3964(R)"communication mode.....................................................................................68

7.5.3.1.6. Input ofthe unit number.........................................................................................................69

7.5.3.1.7. Programming via remote .......................................................................................................69

7.5.3.2. Additionaldevice options..........................................................................................................69

7.5.3.2.1. PLC LogicModule..................................................................................................................69

7.5.3.2.1.1. Examplesforusing the PLC logicmodule..........................................................................69

7.5.3.2.2. PLC LogicModule with text display.......................................................................................70

7.5.3.3. Analog outputs..........................................................................................................................71

7.5.3.3.1. Clearing the integrated analog outputs..................................................................................71

7.5.3.3.2. Adjusting the integrated analog outputs.................................................................................71

7.5.3.3.3. Externalanalog outputs.........................................................................................................71

7.5.3.4. Locking EEPrommemory.........................................................................................................72

7.5.4. Language.....................................................................................................................................73

7.5.5. Configure user .............................................................................................................................73

7.5.5.1. Usertext....................................................................................................................................73

7.5.5.2. User-Menu/OP-functions..........................................................................................................74

7.5.6. Configure Hardware.....................................................................................................................74

7.5.6.1. CP16 Module............................................................................................................................74

8. Device info.........................................................................................................................................75

8.1. StackInfo........................................................................................................................................77

9. Errormessagesand removaloferrors (FAQ)...................................................................................78

9.1. Problem: Displayshows"No contact to unit: XX"...........................................................................78

9.2. Problem: "Pos-Err:1".....................................................................................................................78

9.3. Problem: "Pos-Err:2".....................................................................................................................78

9.4. Problem: "Pos-Err:3".....................................................................................................................79

Version: Aug. 04 Page: 5

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:[email protected]

Site web : www.hvssystem.com

Digitronic DigitalCamSwitchUnit

AutomationsanlagenGmbH CamCon DC16

9.5. Problem: "Pos-Err:5".....................................................................................................................79

9.6. Problem: An "Pos-Error:"occurs during operation..........................................................................79

9.7. Problem: "RAM-Full" =RAM memoryisfull.....................................................................................79

9.8. Problem: The EEPrommemoryisfull.............................................................................................80

9.9. Problem: Outputswill not activate...................................................................................................80

9.10. Problem: "Out -Error"...................................................................................................................80

9.11. Problem: Errorin the EEPROM....................................................................................................80

9.12. Problem: "Error???".....................................................................................................................80

9.13. Problem: "Clear...."........................................................................................................................81

10. Menu outline.....................................................................................................................................82

11. Calculation EEPROM camstorage..................................................................................................83

12. Calculation the RAM storage-requirement forCamCon..................................................................84

13. Technicaldata ofthe CamCon........................................................................................................85

14. Keywords .........................................................................................................................................86

Version: Aug. 04 Page: 6

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:[email protected]

Site web : www.hvssystem.com

Digitronic DigitalCamSwitchUnit

AutomationsanlagenGmbH CamCon DC16

1. Introduction

ElectronicCamSwitchUnitshavebeen successfullyused inindustryforalong time. Experiences

collected incloseliaison with users overthe years havebeen included inthe development ofthe

CamCon series.The resultisacompactdigitalcamswitchunitwhichisuserfriendlyand reliableto a

high degree. The following characteristics testifythe excellence ofthe CamCon:

*Tested and reliable hardware

*Short-circuit-proofoutputs

*Graphicliquid crystaldisplaywith 128x64 pixelsin the CamCon DC50,51.

* Large and clearlyvisible7-Segment displayforprogram,position and speed on

CamCon DC30,33 and 40.

*Anynumberofcamsperoutput can be programmed.

* Up to 32000 Programsforproduct administration

* Master, forexample: machine cams

*Optimising switch pointswhen machine isin operation

* Compensation ofmechanicaldelaytimeofswitchcomponentsforswitch-ONand switch-OFF

pointscan be set in stepsof100µsseparately(DTC =delaytime orSpeed Compensation).

*Position -Triggert -Time -Cams

*Powersupply24VDC +/-20%

* Mounting ofsuspension railsto EN 50022 on CamCon DC16 and 90

*Switchboard panelstandard casing 144 x144 x63mm to DIN 43700 on CamCon DC33,40 and 51

*S5 Componentsgroup forS5 115U, 135U and 155U on CamCon DC115

*S7 Componentsgroup forS7 300 on CamCon DC300

*AB Componentsgroup forControlLogix

1756 on CamCon 1756-DICAM

* S5 Switch-ON via PGinterface with L1 -Buson CamCon DC16,40,50,51 and 90

*PLC LogicModule (optional)

* Shift register(optional)

*OP-Functions

*Analog outputs(optional)

Cam switchunitsareused whereverswitching operationsareperiodicallyrepeated. Digitalcamswitch

unitsarean optimumreplacement ofmechanicalunitsand offerinaddition manyotheradvantages,

such as:

*Simplification ofmounting and adjustment operations

* Repeatable adjustment facility

*Standardised foralmost all areasofapplication

* Reliability

* High switch speed

*Speed Compensation

*Product administration forquickformat change

Version: Aug. 04 Page: 7

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:[email protected]

Site web : www.hvssystem.com

Digitronic DigitalCamSwitchUnit

AutomationsanlagenGmbH CamCon DC16

2. Operating Pinciples

Diagram: Principlesofa CamSwitch Unit

Aprincipleforbettercomprehension ofthe function ofaCamSwitchUnitisherepresented. It has3

outputswith the following cams:

Output 1: Cam1: Switch-ON position60° Switch-OFF position 85°

Cam2: Switch-ON position95° Switch-OFF position 145°

Cam3: Switch-ON position325° Switch-OFF position 355°

Output 2: Cam1: Switch-ON position5° Switch-OFF position 20°

Cam2: Switch-ON position95° Switch-OFF position 145°

Output 3: Cam1: Switch-ON position30° Switch-OFF position 85°

The positionsofthe output signals,herepresented asthree tracks,occurwhen the three camdisks

turn anti-clockwise past a sensor, which scansthe camson the 0°-axis.

In amechanicalcamswitchunit, the switchinterval,i.e. the range between switch-ONand switch-OFF

position aredetermined bythe length ofthe cam.The length and the position ofthe camcan onlybe

varied marginallyand thisismechanicallyhighlydemanding and timeconsuming. With CamCon such

adjustmentscan be realised inafraction oftime; inaddition, therecan be anynumberoftracks.A

measuring systemwhichisfitted to the devicereportsthe position to the CamCon. The CamCon

comparesitwith the programmed switch-ONand Switch-OFF positionsofall outputs.Ifthe position

liesinthe range ofaprogrammed switch-ON/switch-OFF position (cam),then the respectiveoutputs

are active.

Version: Aug. 04 Page: 8

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:[email protected]

Site web : www.hvssystem.com

Digitronic DigitalCamSwitchUnit

AutomationsanlagenGmbH CamCon DC16

2.1. SpeedCompensation

Eachmechanicalswitchcomponent (e.g. shield, magneticvalve)hasadelaytime, i.e. the time

between the startsignaland the actualswitching ofthe contacts.In processeswherepositioning is

executed on amoving system,thiscan causeproblems.Ifsuchaprocess isdriven with different

speeds,different positionsarecaused. Toavoidthishappening, newtimingsforthe switchsignalsof

each speed would have to be calculated.

In orderto ilustrate the complicated issuessurrounding delaytimeorspeed compensation, thiswill be

shownon the exampleofapackaging machine. In the process showninthe diagram,aglue point has

to be placed in an exactlydefined spot on a moving papertrack.

magneticvalve

gluenozzle

drop

paper

Pointswheretheglue

hitsthepaper at the

different speeds .

paper track

encoder

CamCon The systemhasthe following parameters:

vp-Speed ofthe papertrack

vT-Falling speed ofthe drop ofglue

d - Distance between the glue nozzle and

the papertrack

TMV - Delaytime ofthe magneticvalve

Without speed compensation the following would happen:

Assoon asthe measuring systemhasreached acertainposition, the CamCon sendsasignalto the

magneticvalve. The glue nozzle opensfora short time during whichadrop of glue ejects.Between the

startofthe impulseand the exitofthe drop timepasses,whichismainlycaused bythe delaytimeof

the magneticvalveTMV..Afurtherdelayiscaused bythe timewhichthe droplet needsto pass the

distance between the glue nozzle and the surface ofthe paper.

Thisflight time iscalculated asfollows:

tFlight = d

vT

In totaltherethe delaytimeistFlight+TMV. During thistimethe papertrackmoveson byaspecific

distance x.

It wouldnowbe possibleto movethe position, wherethe magneticvalveisswitched on, forwardbya

specificamount, sothat the glue droplet hitsthe samespot againasduring standstill.In thiswaya

speed compensation iscreated whichworksonlyat aspecificspeed ofthe paper.Assoon asthe

speed ofthe deviceand consequentlythat ofthe papertrackis,forexample, doubled, the hitpoint of

the glue droplet isshifted bythe distancex,sothat, without anyspeed compensation, itwouldmove

backward bydouble the distance (2 ⋅x) in total.

The automaticspeed compensation ofthe CamCon makesitnowpossibleto driveprocesseswith

variablespeed; CamCon registers the speed ofthe devicecontinuouslyand adjuststhe camswhich

determine the switchtimepoints"OnLine"depending on the speed. Thishasthe effectthat the

outputsforthe switchcomponentsareswitched ONorOFF earlier.The direction ofthe movement is

ofno significance in thisinstance.

Version: Aug. 04 Page: 9

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:[email protected]

Site web : www.hvssystem.com

Digitronic DigitalCamSwitchUnit

AutomationsanlagenGmbH CamCon DC16

Asmall example in figureswasdesigned to eludicate:

Supposing the drivecylinderwith the measuring systemhasacircumferenceof360mm,sothat one

millimeterofthe circumference correspondsto exactlyone angle degree ofthe measuring system.

The device hasthe following parameters:

vdroplet = 20m/s

d = 20cm

TMV = 20ms

Thisresultsin the following flight time ofthe droplet:

tFlight= d

vT=0,2m

20m/s = 10ms

The totaldelaytime isthen Tdead, altogether =TMV +tFlight =20ms+10ms=30ms

During thistimethe papertrackmoveson bythe distancex=vpaper ⋅Ttotaldelay. =1m/s ⋅30ms=

30mm.In orderto compensate the delaytime, the switchpoint forthe magneticvalvemustbe moved

forward by30°.

Ifthe speed ofthe deviceand consequentlythat ofthe paperisdoubled vpaper,then the distancexis

also doubled bythe speed ofthe papertrack. In thiscase the switch point must be moved by60°.

Note: Pleasetakeinto account intheseexplanationsthat delaytimeisofafixed size, whichis

determined bythe mechanicalconstantsofthe set and switchcomponentsand bythe

dimensionsofthe construction and therefore doesnot change!

Ifthe totaldelaytimeof30mswasprogrammed into the respectiveoutput ofCamCon, then the glue

droplet would alwayshit the right spot, regardless ofthe speed.

Version: Aug. 04 Page: 10

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:[email protected]

Site web : www.hvssystem.com

Digitronic DigitalCamSwitchUnit

AutomationsanlagenGmbH CamCon DC16

2.1.1. Measuring delaytimeforSpeedCompensation

Severalwaysofmeasuring delaytime ofa relayorvalve are available.

2.1.1.1. Measuring delaytimethrough actual differences

Firstthe switch-ONpoint ofavalveorrelayisprogrammed. Weassumethat the programmed switch

point liesat 200 degreesinthiscase. Ifthe machine isdriven with aspeed offorexample40 rpm,a

shiftoccurs due to delaytime. Thisshiftisthen measured and, inthisexample, will amount to 40

degrees.

Warning: Forthe calculation ofthe shiftthe programmed delaytimeinthe camswitchunitmustbe

set to zero!

The delaytime ofthe switch component isnowcalculated asfollows:

Delaytime (in sec. )= ∆way(in °)*60 (sec./min.)

speed (in rpm)*360 (°/turn)

Delaytime (in sec. )= 40 *60

40 *360 =0.1667 sec.

The resultant delaytime isthen entered into the camswitch unit.

See Chapter"7.3.3. Programming the delaytime"an page 32.

2.1.1.2. Measuring delaytimebymeansof different measuring points

Firstthe switchpoint iscalculated at aspeed of,forexample, 50 rpm.Weassumethat the

programmed switchpoint liesat 200°inthiscase. The second measurement istaken at aspeed of80

rpm The necessaryswitchpoint mustbe set to 160°,ifthe exactswitchpoint isto be alsoachieved at

80 rpm.

Warning: Forthe calculation ofthe twoswitchpointsthe programmed delaytimeinthe camswitch

unit must be set to zero!

The delaytime ofthe switch component isthen calculated with the following formula:

Delaytime (in sec. )= ∆way(in °)*60 (sec./min.)

∆speed (in rpm)*360 (°/turn)

Delaytime (in sec. )= 40 *60

30 *360 =0.222 sec.

The resultant delaytime isthen entered into the camswitch unit.

See Chapter"7.3.3. Programming the delaytime"an page 32.

Since the entered delaytime shiftsthe switch point, the previouslyprogrammed cammust be changed.

Forthe calculation ofthe exact switch-ON position, the difference to the speed Orpm(here using 50

rpm)must be added to the first measured switch-ON point (here 200°). The difference iscalculated

with the following formula:

∆way(in degrees) = dead time (in sec. )* ∆time (in min-1)*360 (degrees/rotations)

60 (sec./min.)

∆way(in degrees) = 0.222 *50 *360

60 =66.6 degrees

The switch-ON point ofthe camisnowshifted from200°byapprox. 67°to 267°.

Version: Aug. 04 Page: 11

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:[email protected]

Site web : www.hvssystem.com

Digitronic DigitalCamSwitchUnit

AutomationsanlagenGmbH CamCon DC16

2.1.2. SpeedCompensation using off-centrepressure, e.g. brake functions

The Speed Compensation ofthe CamCon Camswitchunitworksusing alinearfunction. If,for

example, the speed doubles,then the shiftofthe compensated camchangesand alsomovesforward

bytwicethe amount. Ifthe ramon an eccentricpress shouldbe brought to astandstill at the exact

upperstop point, the brakeaction ofthe press underdifferent speedsresultsinaquadraticfunction.

The Speed Compensation can thereforeonlyfind an approximation ofthe exactswitchpoint forthe

stopping ofthe press byadjusting the line ofthe camlinesto the brakecurvesinthe working range of

the press.

In the graphicon the right the curved line representsthe

brake point ofthe ramin relation to the speed.

U/min

Verlauf Nocke1 Nocke2

Forthe calculation ofthe parameters to be programmed

please proceed asfollows:

-Define the working range (e.g. 20-50 rpm)and determine

twomeasuring pointswhichhaveto be specified inthe

working process (e.g. 30 and 40 rpm).

-Nowlet the machine run at 30 rpmand programor

optimiseacam without Speed Compensation sothat, at

switch-OFF,the ramcomesto ahaltintop stop. Note the

switch-ON point ofthe cam(e.g. 340°).

-Nowlet the maching workwith 40 rpmand programor

optimiseone cam without Speed Compensation sothat,

at switch-OFF,the ramcomesto ahaltintop stop. Once

again, note the switch-On point ofthe cam. (e.g. 332°).

-Nowcalculate the delaytime, taking into account the

distance and speed difference, using thisformula:

Delaytime(insec. )= ∆way(in°)*60 (sec./min.)

∆Speed (inrpm.)*360 (°/turn) = 340-332 *60

40-30 *360 =

0.133 sec.

-The calculated delaytime isnowentered into the camswitch unit.

-Sincethe switch-OFF point hasshifted through the entered Speed Compensation, the previously

programmed cammustbe changed first. Forthe calculation ofthe exactswitch-ONposition, the

differenceto the speed 0rpm(here30 rpm)mustbe added to the firstmeasured switch-ONpoint

(first measuring point here 340°)The difference iscalculated with the following formula:

∆way(in°)= delaytime(insec. )* ∆Speed (inrpm.)*360 (°/turn)

60 (sec./min.) = 0.133 *30 *360

60 =23.94°

-The switch-ON point ofthe camhasnowshifted from340°byapprox. 24°to 364°.

Asaresultacamwith aswitch-ONpoint of4°and aspeed compensation of0.133 sechasbeen

calculated. Thisisentered in the camswitch unit asswitch-OFF camofthe press.

Note: Ifthe degree ofaccuracyisno longersufficient when switch-OFF isdone with one cam,two

orseveraloutputscan be switched inparalleland the camofthoseisthen adjusted to the

required working range. Forthe calculation oftwoswitch-OFF camsdivide the working

range in5partswith 4measuring pointsand then calculate the delaytimevalue and the

camvalue with the sameformulaasdescribed above. Forthe calculation ofthe firstcam,

usethe measuring points1+2and forthe calculation ofthe second camusethe

measuring point 3 +4.

Through thisassociation ofthe linearcamfunctionsto the brakefunctionsitisnowpossibleto switch

OFF the camvia the entire working range ofthe press in the top stop.

Version: Aug. 04 Page: 12

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:[email protected]

Site web : www.hvssystem.com

Digitronic DigitalCamSwitchUnit

AutomationsanlagenGmbH CamCon DC16

2.1.3. SeparatedelaytimeforSpeedCompensation of switch-ONand switch-OFF points

ForCamCon devicesofSoftwarefrom3/2002 Speed Compensation isnowavailableforseparate

switch-ONand switch-OFF points.Thisisnecessarysincesomevalvesneed longerto switchOFF

than to switch ON.

Switching attitude of acamprograms from140° to200° with60 min-1.

Camwith111msSpeed compensation for switchon pointand 166ms

compensation for switchoff point.

Camwith111ms Speed compensation.

Camwithout Speed compensation.

Forthe calculation ofboth delaytimesthe sameformuli areused asfora normal compensation. See

Chapter"2.1.1. Measuring delaytime forSpeed Compensation"on page 11 forentering delaytimesee

Chapter"7.3.3. Programming the delaytime"on page 32.

Attention: Ifthe switch-off-point ofa Camovertakesthe switch on point at rising speed, the resultwill

be an non-defined signal.

2.2. Time- Cam

With nomalecambecomeswith increasing plant speed switch-on timeevermorebriefly.Ifcontrolling

a glueing-station, the result would be an insufficent ammount ofspreaded glue.

ATime -camhoweverhaswith each plant speed a firmtemporallength, so that excactlythe same

ammount ofglue could be spread at changing speeds. The switch-on point ofthe Camon anormal as

well ason a Time-Camisappointed bya position-dependent Position value and a delay-time/speed

compensation.

Normal-cam Time-cam

60min-1

30min-1

60min-1

30min-1

ForCamCon devicesofsoftwarereleasesafter3/2002 TimeCamisalsoavailablefordeviceswithout

PLC -Logic-Module.

Forentering a Time -Camsee Chapter"7.3.4. Programing Time-Cams"on page 33.

Version: Aug. 04 Page: 13

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:[email protected]

Site web : www.hvssystem.com

Digitronic DigitalCamSwitchUnit

AutomationsanlagenGmbH CamCon DC16

3. Installation

The deviceissnapped onto an "EN-carrierrail" inthe switchboard(see chapter"3.1. Dimensions"on

page 14).The grounding connectionsand the cablecoveringsareto be put on the shortestpossible

wayon the serialgrounding clipnextto the device. The grounded assemblyplate and itselectrical

connection to the "ENcarrierrail" allowan excelent grounding ofthe disturbancesonto the covering.

All cableconnectionsareto be switched inacoldstate !If yourCamCon hasan externalinterface, itis

connected to the "ext.Int.IN" plug at the CamCon module(e.g. DAC16, DC16/IO,DC91/IOorDC92/I)

with acableofthe type: KKyy/IO-XX (yy =CamCon Type /XX =Length inmeters).The data linesof

the externalinterfacearegalvanicallyseparated through an opticalcoupler,theyhaveto be covered,

and the coverhasto be grounded on both ends.The connection cable(forthe measuring systemor

the serialinterface)alsohasto be covered, and the coverhasto be grounded on both ends.Analog

signalshave to be covered, and the coverhasto be grounded on one end.

Note:

EN -carrier

Encodercable

Typ: KK16/600-XX

Encodercable schild

Device earth

Toguarantee amaximumofEMVprotection against

disturbancesinencodercables(SSI -measuring system)in

strong electromagneticmachines,the illustration to the right

demonstratesinaconnection example, howthe high EMV

resistance ofthe CamCon DC16 can still be increased.

Herethe devicegrounding and the coverconnection ofthe

encodercableareput directlyon aserialgrounding pinlocated

left ofthe CamCon. Through the grounded assemblyplate and

itselectricalconnection to the EN-carrierrail,wereacha

maximumdeflection ofthe disturbancesonto the mantling of

the encodercable.

The second flat plug nextto the statusLEDofthe CamCon

remainsunswitched.

3.1. Dimensions

Version: Aug. 04 Page: 14

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:[email protected]

Site web : www.hvssystem.com

Digitronic DigitalCamSwitchUnit

AutomationsanlagenGmbH CamCon DC16

4. Electrical connections

Beforeyou beginwith wiring, pleaseconsultthe following chapters:"4.4. The outputs"on page 24,

"4.5. The inputs"on page 24 and "4.3. The measuring system"on page 20.

4.1. Pinallocation

.

4.1.1. Pinallocation of thevoltagesupply

Pin 1: 0Vvoltage supply

Pin 10: +24VDC voltage supply

Pin 29: +24VDC voltage supply

4.1.2. Pinallocation of theSSI measuring system

Pin 11: 0Vvoltage supplyofthe SSI measuring system(encoder)

Pin 12: Data Aor+

Pin 13: Data Bor-

Pin 14: ClockAor+

Pin 15: ClockBor-

Pin 16: +24VDC voltage supplyofthe SSI measuring system(encoder)

4.1.3. Pinallocation of theincremental measuring system

Pin 11: 0Vvoltage supplyofthe incrementalmeasuring system

(encoder)

Pin 12: Aimpulse

Pin 13: Bimpulse

Pin 14: Clear1

Pin 15: Clear2

Pin 16: +24VDC voltage supplyofthe incrementalmeasuring system(encoder)

4.1.4. Pinallocation of theoutputs1-8(0.5Amp.)

Pin 2: Output 1 Pin 6: Output 5

Pin 3: Output 2 Pin 7: Output 6

Pin 4: Output 3 Pin 8: Output 7

Pin 5: Output 4 Pin 9: Output 8

4.1.5. Pinallocation of theoutputs9-16 (40mA)

Pin 21: Output 9 Pin 25: Output 13 (Input 8)

Pin 22: Output 10 Pin 26: Output 14 (Input 7)

Pin 23: Output 11 Pin 27: Output 15 (Input 6)

Pin 24: Output 12 Pin 28: Output 16 (Input 5)

4.1.6. Pinallocation of theinputs

The connection pinsof inputs5-8function intwoways.Ifyou e.g. set output 13, you alsoautomatically

activate input 8.

Pin 33: Input 1 Pin 28: Input 5 (Output 16)

Pin 32: Input 2 Pin 27: Input 6 (Output 15)

Pin 31: Input 3 Pin 26: Input 7 (Output 14)

Pin 30: Input 4 Pin 25: Input 8 (Output 13)

Attention: Pins1, 11 and 34 are linked.

Pins10 and 29 are linked.

Version: Aug. 04 Page: 15

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:[email protected]

Site web : www.hvssystem.com

Digitronic DigitalCamSwitchUnit

AutomationsanlagenGmbH CamCon DC16

4.1.7. Pinallocation of theserial RS485 interface

The CamCon DC16 hasaserialRS485 interfaceasastandard. Thisisused forprogramming froma

PCorviaaCamCon DC50/51 terminal.The cablelength ofthisRS485 interfaceislimited to a

maximumof1000m.

Pin 34: 0Vsignalmass

Pin 35: A(+)

Pin 36: B(-)

Knowledge ofthe chapter7.5.3. Unit configuration on page68 isnecessary.

Interfaceconverter

withbridged closedown resistors

CamCon DC16

Unit number0

withbridged closedown resistors

CamCon DC16

Unit number0

withbridged closedown resistors

CamCon DC16

Unit number1

without bridged close-down resistors

CamCon DC16

Unit number2

without bridged closedown resistors Interfaceconverter

withbridged closedown resistors PC

PC

Please note: Atthe RS485 interfacethe endsofthe data cableshaveto be switched with

closedownresistors.Forfurtherinformation concerning thisproblem,pleaseread

the following chapter.

Version: Aug. 04 Page: 16

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:[email protected]

Site web : www.hvssystem.com

Digitronic DigitalCamSwitchUnit

AutomationsanlagenGmbH CamCon DC16

CamCon DC16

Unit number0

without bridged closedown resistors

CamCon DC16

Unit number1

without bridged closedown resistors

CamCon DC16

Unit number2

without bridged closedown resistors Interfaceconverter

withbridged closedown resistors PC

CamCon DC50/T4

Unit number60

withbridged closedown resistors

4.1.7.1. Closedown-resistorsof aserial RS485 interface

Atthe RS485 interfacethe endsofthe data cableshaveto be switched with closedownresistors.For

thispurposethe CamCon DC16 hassoldering bridgesthat haveto be adjusted beforecommisioning.

Thesebridgesmayonlybe closed at the beginning orend of alinked chainorsingledevice, aswell as

at the interfaceconverter(Pin1with Pin2and Pin3with Pin4).AnewCamCon comeswith these

soldering bridgesclosed, sothat theyhaveto be opened bythe user,ifhe wantsto run several

devices. Since february2002 there are to possibilitysto do so.

DIP-switch

4.1.7.1.1. ClosedownresistorswithDIP-switch

Devicesprouced sincefebruary2002 orlater,conversion stage DC16/S5or

DC16/J5 offerthe possibilityto adjustthe closedownresistors byusing to DIP-

switcheslocated at the side ofthe device.

Ifthe resistors areclosed, the RS485 conduction isclosed downbyaresistance

of4.7/0.22/4.7 kOhm(ON).Ifthe switchesaretoppled towardsthe texton the

switch'scase, theyare activated (ON).

Attention: You alwayshaveto open orcloseboth switches,sincean

assymetricalload disturbsdata-transfer.

Version: Aug. 04 Page: 17

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:[email protected]

Site web : www.hvssystem.com

Digitronic DigitalCamSwitchUnit

AutomationsanlagenGmbH CamCon DC16

4.1.7.1.2. Closedownresistorswithsolding bridges

Tobe ableto adjustthe bridgesofthe closedownresistors ofthe CamCon 16 the devicehasto be

opened. The covercan be pushed appartinthe middlewith ascrewdriver.Therearetwosoldering

bridgeslabled "TERM 485"on the soldering side ofthe largestcircuitboard. Iftheseareclosed, the

RS485 conduction isclosed with a resistance of390/150/390 Ohm. Both bridgeshave to be eitherboth

open orboth closed, since an asymmetricalcharge disturbsthe data transfer.

4.1.8. Clamping allocation of aserial RS232 interface (optional)

Sincefebruary2002 CamCon DC16 maybe equiped with an RS232 interface(optinal).The wiring

distance ofthisinterface islimited to a maximumof10 meters.

Clamp 34: 0Vsignalmass

Clamp 35: RxD

Clamp 36: TxD

Please also regard chapter"7.5.3. Unit configuration"on page 68.

0V

RxD

TxD

RS232

Version: Aug. 04 Page: 18

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:[email protected]

Site web : www.hvssystem.com

Digitronic DigitalCamSwitchUnit

AutomationsanlagenGmbH CamCon DC16

4.2. External interface (option)

Ifyou ordered yourCamCon DC16 with the externalinterface (an Xat the end of the ordering number),

you can laterupgrade yourCamCon with one ofthe following modules:CP16, DC16/IO,orDAC16.

Theseextension modulesaresnapped onto the carrierrail inthe switchboardwith a distance of 1cm

to the DC16 and arethen connected viaa4.5 cmlong 10 pol.flat cable. The externalinterfaceofthe

CamCon DC16 isplugged into the 10 pol.plug "ext.Int.IN" at the CamCon module. The cableis

included inyourorderofthe extension modules.The data transferismade free ofpotentialwith an

opticalcoupler.

DC16/IO DC16 4.2.1. Pinallocation of theexternal interface

Pin 1,4,7,10: ground

Pin 2: TxD-

Pin 3: TxD+

Pin 5: CLK-

Pin 6: CLK+

Pin 8: RxD-

Pin 9: RxD+

4.2.2. External interface withacablelengthof 0.5to300m

The maximumcablelength ofthe externalinterfaceis300

meters.Needed hereforeisacovered 6pol.data cablewith

pairwisewired conductors and an adaptercableof10 pol.flat

cableon a9pol.DSUBplug. The coverofthiscablehasto be

grounded on both ends.

Version: Aug. 04 Page: 19

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:[email protected]

Site web : www.hvssystem.com

Digitronic DigitalCamSwitchUnit

AutomationsanlagenGmbH CamCon DC16

4.3. Themeasuring system

The measuring systemisdesigned to recordthe necessaryactualvalues(positions) forthe Cam

Switch Unit. Manydifferent measuring systemcan be linked with the CamCon.

See chapter"4. Electricalconnections"on page 15 and foradjustment ofthe measuring systemto the

software ofthe CamConsplease also consult Chapter"7.4.1. Measuring system"on page 44.

Note: Please also consult the instruction manualforyourmeasuring system.

4.3.1. SSI Measuring systeminput

Systemswith asynchronousseriesinterface=SSI. The SSIinterfaceiswidelyused inindustryfor

absolute singleand multi-turnangleencoder.Atthisinterfacethe CamCon suppliesthe measuring

systemwith 24Volt. Forthe purposeofdata reading the CamCon sendsastrokesignal(clock)with

RS422 levelto the measuring system.Thisanswers synchronouslywith the data output ofthe position

inthe greycode. The frequencyofthe pulsesignaldependson the length ofthe cableto the

measuring systemand can be set in the CamCon.

Note: The data record correspondsto the Stegmann SSI Standard!

Clock

Data

Tp = clockimpulse

max. 1MHzto min. 66kHz.

(adjustable through the cable

length)

Tmono = Mono flop time 25µs

CamCon

Encoder

+24VDC

0V

Clock +

Clock -

Data+

Data-

Please note:

Useascreened dualstrand connection cable. Do not place

the cableparallelto ahigh voltage cable. Ifpossible, laythe

screening down on both sides.

4.3.2. Parallel measuring systeminput

Systemswith parallel24Vdata leads,e.g. singleturn-angleencoderorviaatransformerwith parallel

data output.

In thisinstanceagrayorbinaryencoded value isattached to the free inputsofthe CamCon and this

will be read asactualvalue. Sincethe connection cablearequite expensiveand the EMV-

compatibilityislimited, thisinterface type israrelyused in industrynowadays.

Note: Sincethe outputsarepartlyswitched parallelto the inputsinCamCon DC16, DC115,

DC300 and CamCon 1756-DICAM, thesemustnot be programmed underany

circumstancesand thisreducesthe numberofavailable outputs.

Warning: Reading abinaryencoded value into the CamCon isonlypermitted afterconsultation with

the Service department ofthe companyDigitronic.

Version: Aug. 04 Page: 20

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:[email protected]

Site web : www.hvssystem.com

Table of contents

Other Digitronic Switch manuals

Popular Switch manuals by other brands

Huawei

Huawei OptiX OSN 3500 Quick installation guide

schmersal

schmersal TESK-S Series operating instructions

Endress+Hauser

Endress+Hauser Liquiphant FTL33 IO-Link operating instructions

Ross

Ross Acuity Ultrix Acuity Setup manual

schmersal

schmersal EX-ZQ 900 operating instructions

ATEN

ATEN Slideaway CL1008 user manual

GE

GE "ExecutiveSeries"USB2.0 HO97863 instruction manual

Allied Telesis

Allied Telesis AT-8800 Series Quick install guide

CTC Union

CTC Union JB130 Series product manual

Weidmüller

Weidmüller IE-SW-AL08M-8GT Hardware installation guide

Di-soric

Di-soric KDCT 08 V 02 G3-T3 manual

QCT

QCT QuantaMesh installation guide