DIMAX GROUP Konner & Sohnen KS 4HP-70 User manual

KS 4HP-70

GASOLINE TILLERS

EN

Please, read this manual before

use!

Manual

PREFACE

We are grateful to you for your purchase of ТМ Könner & Söhnen series gasoline tiller. This manual con-

tains safe working recommendations, operation and adjustment description of these tillers and maintenance

instructions.

All data, specied in this operation manual is the most up to date for the moment of its publishing. At the end

of this manual, you may nd contact information which you are free to use in case of any issues occurrence.

Manufacturer reserves the right to make alterations into the tillers, which may not be reected in this

manual. Pictures and photos of the product may vary from its actual appearance.

More information and contacts can be found on the website: www.ks-power.de/en.

Model KS 4HP-70A – see picture 1 in the Appendix.

We care about the environment, therefore, we consider it expedient to save

paper and leave in print a short description of the most important sections.

Be sure to read the full version of the manual before getting started!

Safety symbols and description of inscriptions can be found in the full web version of the manual.

OVERVIEW AND COMPONENTS 1

Fig. 1 1. Operator’s panel

2. Engine

3. Fenders

4. Plant shielding wheel

5. Transport wheel

6. Gearbox

7. Cutters

8. Coulter

9. Air lter

10. Fuel tank

SAFETY TECHNIQUE 2

Illustrations are for reference only and may

vary with the cultivator model.

Before operating the cultivator, please carefully read the owner’s manual. Do not allow unauthorized

people and children to operate the device. Do not use the device in close proximity to the working area

of adults, children and animals - the user of the cultivator is solely responsible for personal injury and

property damage. The Könner & Söhnen power cultivator complies with the current European safety

standards. Never attempt to make any changes to the design of the device.

WARNING THESE REQUIREMENTS FOR WORKING WITH THE TILLER:

1. Before getting started, please carefully read the owner’s manual. Keep the owner’s manual in a safe

place for future reference; follow the recommendations contained therein in order to avoid personal

injury and property damage.

2. Familiarize yourself with the cultivator controls and functions. In case of an emergency, the operator must

know how to stop the working parts of the cultivator and its engine.

3. The operator of the device must be in good physical and mental health and be quick in decisions, if

necessary. Do not operate the cultivator under the influence of alcohol, drugs or medications that can

slow down the reaction.

4. The cultivator is designed to cultivate soil when sowing, as well as to handle and process plants. Do not

use the cultivator for purposes other than those initially intended.

www.ks-power.de/en |12

Warning! Stop the engine before refueling, transporting

and if the unit is unattended.

ATTENTION - DANGEROUS

The fuel contaminates the earth and groundwater. Do not

allow gasoline to run out of the tank!

ATTENTION - DANGEROUS

The operating conditions of the device, storage and transportation can be found in the full web version

of the manual.

WORKING WITH THE TILLER

The device should be turned on in accordance with the instructions in the owner’s manual. Make sure the

operator keeps a safe distance from the working parts of the cultivator. Never place your legs or arms on the

rotating parts or underneath them. To lift the device, two people must grab the handles and shafts of the

cultivator. Wear special safety gloves to protect your hands and safety shoes; do not operate the cultivator

in open toe shoes.

BE CAREFUL!

- The engine and exhaust pipe must be kept clean to avoid potential fire. Thoroughly check them for

foliage, grass, and oil or fuel leaks.

- Watch out for the rotating parts. Do not touch the rotating cutters

COMPOSITION 3

1. Cultivator with cutters

2. Left handle

3. Clutch handle

4. Tilling depth limiter

5. Steering column

6.Transport whee

7. Right handle (ON/OFF, speed)

COLLECTING THE TILLER 4

ASSEMBLE THE CULTIVATOR AS ILLUSTRATED IN THE APPENDIX:

1. Insert the coulter in the bracket - see fig. 2 in the Appendix.

2. Mount the transport wheel - see fig. 3 in the Appendix.

3. Pull the spring - see fig. 4 in the Appendix.

4. Mount the steering column - see fig. 5 in the Appendix.

5. Install the right and left handles on the control panel - see fig. 6 in the Appendix.

Be sure to read the full version of the manual

before getting started!

www.ks-power.de/en |13

OPERATION INSTRUCTION 6

The tiller is supplied without oil and fuel.

Before first start-up, be sure to fill in the oil and refuel

the device! Use a funnel to refuel.

IMPORTANT!

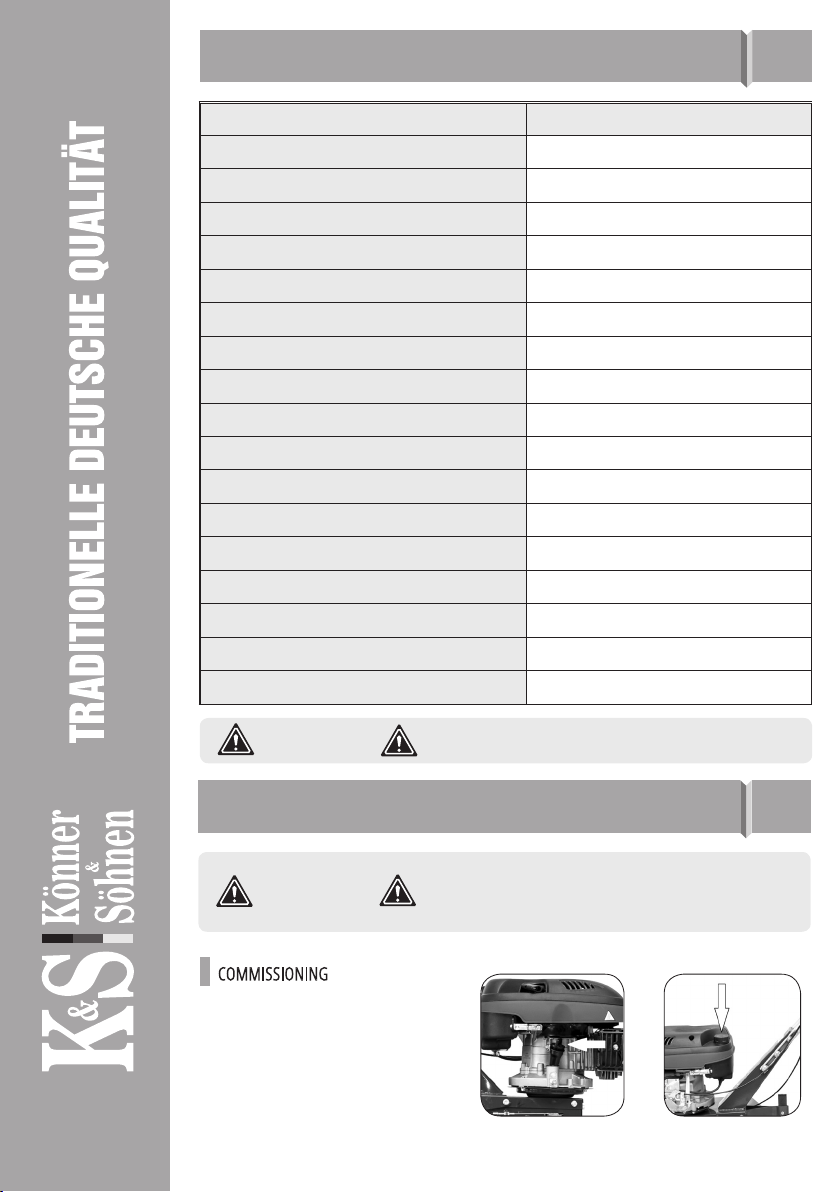

SPECIFICATIONS 5

Recommended oil – SAE 10W30, SAE 10W40

PLEASE NOTE!

Tiller KS 4HP-70

Engine power, HP/kW 4,0/2,6

Engine model KS 160

Engine capacity, сm3139

Tilling width, cm ≤ 70

Tilling depth, cm ≤ 27

Fuel tank volume, l 1,5

Crank case volume, l 0,6

Transmission case volume, l 0,1

Blades, psc. 24

Engine start manual

Drive type Belt drive, worm drive

Forward speed +1 0

Noise level Lpa (7m)/Lwa, dB 68/93

Net weight, kg 36

Gross weight, kg 39

Net dimensions (L*W*H), mm 1350*600*800

Gross dimensions (L*W*H), mm 680*380*650

COMMISSIONING

During the commissioning:

1. Fill the crankcase with oil

2. Fill the fuel tank with gasoline

Fill the crankcase with engine oil Fill the fuel tank with gasoline

www.ks-power.de/en |14

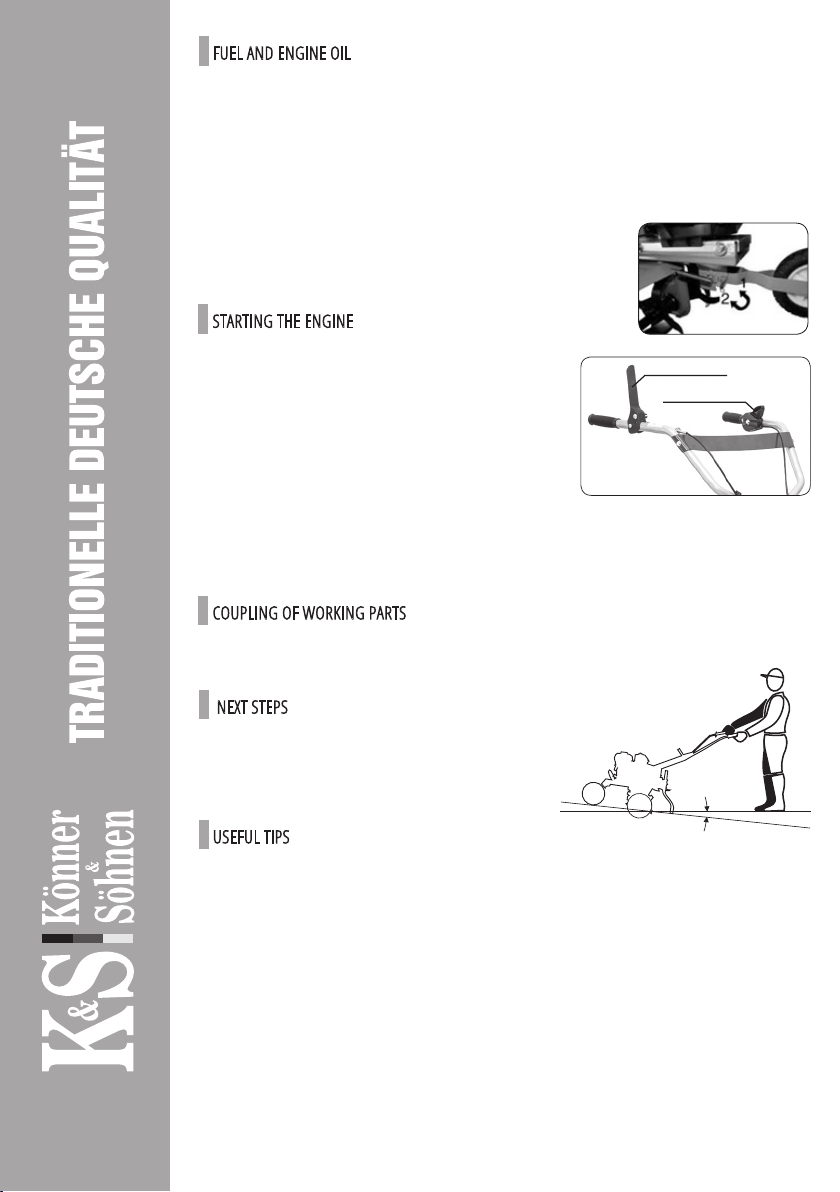

FUEL AND ENGINE OIL

Only unleaded gasoline is recommended for the generator. Only use fresh,

premium-grade gasoline. Use a funnel (not included) to refuel the device.

Just like without fuel, the cultivator cannot work without oil, so be sure to fill the oil tank before the first

start. To do this, place the device on a flat horizontal surface, open the oil tank cap and add the oil to the

minimum mark. Use the oil dipstick to check the oil level. The oil filling level must be monitored at all times.

Do not exceed or fall short of the oil level. Information on the used engine oil can be found in technical

data of the cultivator.

USEFUL TIPS

1. To determine the plowing depth, use the coulter at different heights. With the coulter driven deeper into

the soil, the cutters also go deep into the soil and the advancement of the device forward slows down

considerably.

2. The cultivator speed is determined by adjusting the engine speed. The cutters go deep into the soil with

the device in the fixed position.

3. To speed up the cultivator advancement, adjust the coulter higher to lift the cutters.

4. Dry and hard ground may possibly contain big lumps and thus require two passes. Do not process raw

soil, because it is difficult to break loose.

5. Immediately release the clutch lever when the cultivator is blocked by foreign objects. Kill the engine,

remove obstacles and check the cultivator for deformation and damage. Replace damaged parts as

necessary.

Always transport the device with the front wheel lowered. After completion of work or in between the

plowing sessions, release the clutch lever and stop the engine.

COUPLING OF WORKING PARTS

The engine clutch transmits torque from the engine to the transmission. When the clutch lever is pressed,

the belts start to rotate merely to transmit the movement to the chain transmission.

STARTING THE ENGINE

1. Turn the engine speed control to “MAX”.

2. Grasp the starter handle and slowly pull it until resistance

is felt.

3. Pull the manual start cord to the full length with a sharp

movement.

4. The engine will start at maximum speed.

5. Use the engine speed control to decrease the speed.

6. Press and hold down the clutch lever.

7. By pressing and holding the lever, the cultivator will begin to

deepen into the ground while moving forward.

Transport the cultivator to the land plot that needs to be plowed.

Start the engine.

Before cultivating the soil, raise the transport wheel.

Clutch lever

Engine speed adjustment

NEXT STEPS

Gradually increase the plowing depth when cultivating

hard soil, for which purpose apply pressure on the

steering wheel to increase the coulter depth.

6 ~ 80

www.ks-power.de/en |15

This manual suits for next models

1

Table of contents

Popular Lawn And Garden Equipment manuals by other brands

Sunforce

Sunforce SOLAR user manual

GARDEN OF EDEN

GARDEN OF EDEN 55627 user manual

Goizper Group

Goizper Group MATABI POLMINOR instruction manual

Rain Bird

Rain Bird 11000 Series Operation & maintenance manual

Cub Cadet

Cub Cadet BB 230 brochure

EXTOL PREMIUM

EXTOL PREMIUM 8891590 Translation of the original user manual

Vertex

Vertex 1/3 HP Maintenance instructions

GHE

GHE AeroFlo 80 manual

Land Pride

Land Pride Post Hole Diggers HD25 Operator's manual

Yazoo/Kees

Yazoo/Kees Z9 Commercial Collection System Z9A Operator's & parts manual

Premier designs

Premier designs WindGarden 26829 Assembly instructions

Snapper

Snapper 1691351 installation instructions