Dimensions Unlimited 12X16B3R4T User manual

Dimensions Unlimited 1

ISO 9001:2000 Registered Company

Dimensions Unlimited, Inc.

DC to AC Standby Power Systems

Owners Manual for Models:

12X16B3R4T

12X20B3R4T

12X25B3R4T

12X30B3R4T

12X36B3R4T

Including Options:

R1: LCD Remote Control/Status Panel

with master disconnect

Form: 121954D

April 2006

Dimensions Unlimited 2

Table of Contents:

Section Description Page

1 Safety Instructions ..…………………………………………………..… 3

1.1 Warning and Danger Symbols ……..……..…………….…….….. 3

1.2 Standby Power System Precautions ……….……………….……… 3

1.3 Battery Precautions …………………….……..………………...…… 3

2 Specifications ……..……………………..…...……………………..…… 4

3 Technical description …..……………………………………………..… 5

3.1 Standby Power Systems …….……….…………………...……....… 5

3.1.1 Inverter Power Mode …………………………………….…. 5

3.1.2 External Power Mode ….……………………………………. 5

3.2 Features ………………………………………………………………….…. 6

3.2.1 Battery Charger – “B3” …………….…….…………………. 6

3.2.2 LCD Remote Control/Status Panel – “R4” ……………... 6

3.2.3 Transfer Switch – “T” …………..…………………..……… 6

3.3 Options 6

3.3.1 LCD Remote Control/status Panel – “R1” Option 6

4 SPS Physical Description ..……….……………………………………. 7

4.1 SPS Module ………….…………………..……………….………………. 7

4.2 LCD Remote Control/Status Panel ….………………………...…. 8

5 Installation ..………………………….…………………………………… 9

5.1 Tools Needed for Installation ..…………………………….………. 9

5.2 System Components ..………………………………….……………... 9

5.3 Mounting the SPS ….…………………………………………………… 9

5.3.1 Chassis Bonding Lug .……………………………………..… 9

5.3.2 Temperature Compensation Sense Probe …………….. 9

5.3.3 Connecting the LCD Remote Control/Status Panel . 9

6 SPS Wiring …………..……….……………………………………………. 11

6.1 DC Wiring …………………………………………………………….……. 11

6.1.1 Inverter Cable .…………………….………………………….. 11

6.1.2 Charge Cable ..……………………….……..……………..…. 11

6.1.3 Connecting the DC Wires ………..…………………..……. 12

6.1.4 Deep Cycle Batteries .…………………………………..…… 12

6.2 AC Wiring …………………………………………….…………….…..…. 13

6.2.1 AC Output …..…………………………….……………………. 13

6.2.2 AC Input ……..…………………………….……..……………. 13

6.3 DC Wiring Diagram ..…………………………………………………… 14

6.4 AC Wiring Diagram ….………………………….……………………… 15

7 Operation and Troubleshooting ..………………………………....…. 16

7.1 Operation …..……………………………………………………………… 16

7.1.1 Setting the Battery Size and Type ..….…………….….. 16

7.1.2 Turning the SPS On ………….…………..……………..….. 16

7.1.3 Battery Charger Draw – Set Input ……………………... 17

7.1.4 LCD Remote Control/Status Panel Display Messages 17

7.2 Troubleshooting ……………..………………..………………..….….. 19

7.2.1 Troubleshooting Chart ……….….…….……………….….. 19

7.2.2 System Flow Chart …………………………………………… 21

8 Warranty ………………………………………..…………………….…… 23

Dimensions Unlimited 3

Safety Instructions

Important: Read this manual before installation, it contains important safety,

installation, and operating instructions. Save this manual and keep it in a safe place.

1.1 Warning and Danger Symbols:

To reduce the risk of electrical shock and to ensure the safe operation of your

Dimensions power inverter, the following symbols are used throughout the manual.

ATTENTION:

Important operating instructions.

Follow them closely.

DANGER:

Risk of personal harm and/or

electrocution exists in this area.

Use extreme caution.

SAFETY CERTIFICATION:

This is a UL and CUL Certified product that complies with all the safety

standards required in the USA and Canada for land vehicle inverters.

1.2 Standby Power System Precautions:

• Standby Power Systems produce hazardous voltages. To avoid risk of harm or fire,

the unit must be properly installed.

• There are no user serviceable parts inside, do not remove the cover.

• The Standby Power Systems should not be mounted in a location that may be

exposed to rain or spray.

• The Standby Power Systems should not be installed in a zero clearance enclosure.

• Damage to the Standby Power Systems will occur if correct polarity is not observed

when installing the DC input cables.

• Damage to the Standby Power Systems will occur if an external AC power source is

applied to the inverter’s AC hardwire output.

• The Standby Power Systems contains a circuit breaker and capacitor that may

produce a spark. Do not mount in a confined battery or gas compartment.

• Be sure the Standby Power Systems is turned OFF during installation.

1.3 Battery Precautions:

• Working in the vicinity of lead-acid batteries is dangerous. There is a risk of acid

exposure.

• Batteries generate explosive gases during operation.

• There is risk of high current discharge from shorting a battery that can cause fire

and explosion. Use insulated tools during installation.

• Remove all rings, watches, jewelry or other conductive items before working near

the batteries.

• Inspect the batteries once a year for cracks, leaks or swelling.

• Dispose of the batteries according to local regulations. Do not incinerate batteries;

risk of explosion exists.

Dimensions Unlimited 4

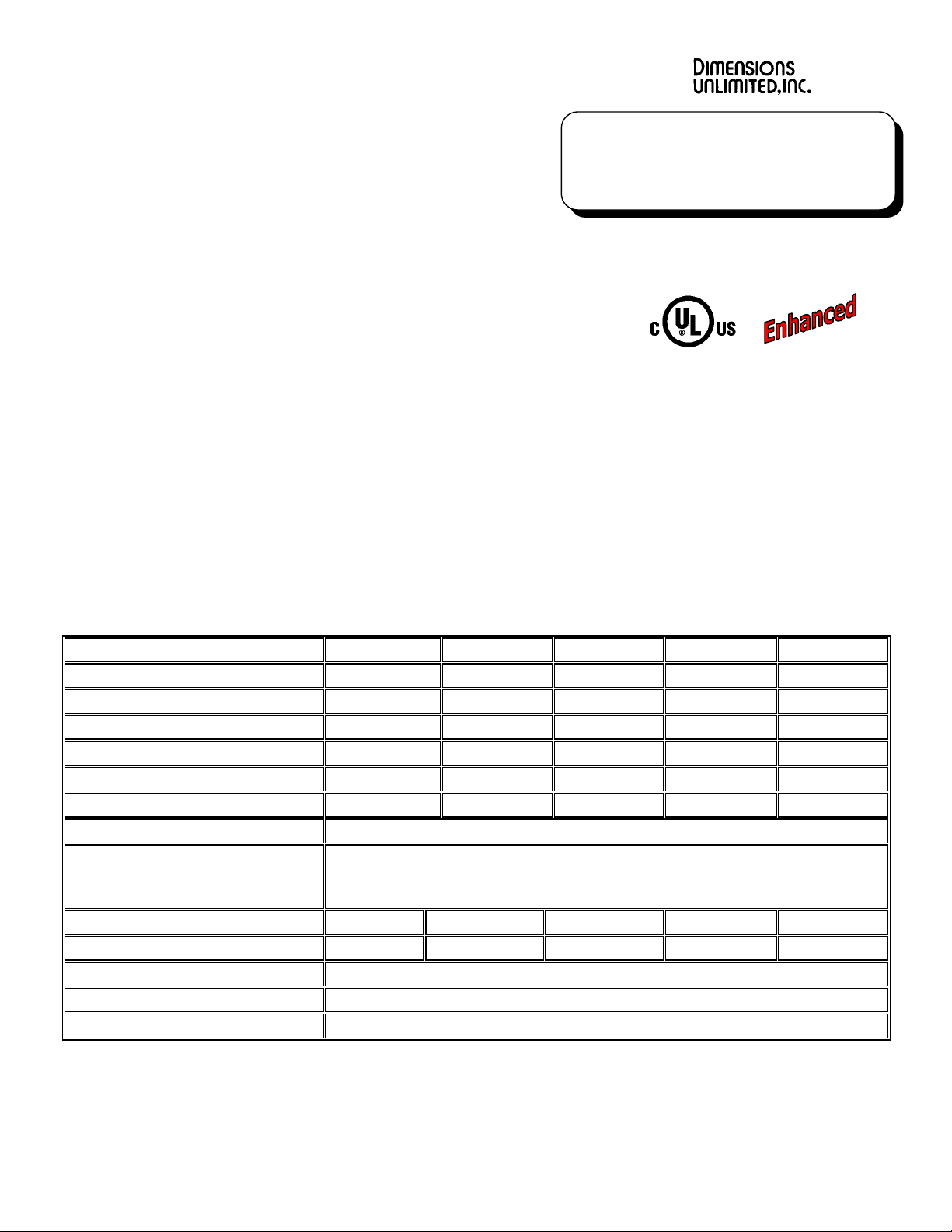

Specifications

Millennium Series

Standby Power Systems

12X16B3R4T, 12X20B3R4T,

12X25B3R4T, 12X30B3R4T,

12X36B3R4T

Environmentally Friendly,

Quiet, Reliable, AC Power

MODEL NUMBER 12X16 12X20 12X25 12X30 12X36

Output Power (Watts Cont.) 1,600 2,000 2,500 3,000 3,600

Output Current (Amps AC) Up to 13 Up to 17 Up to 21 Up to 25 Up to 30

Peak Output (Amps AC) 55 70 80 90 90

Output Rating: (hp) 1/3 ½ ¾ 1 1½

Input Current (Amps DC) Up to 160 Up to 200 Up to 250 Up to 300 Up to 360

Weight (lbs.) 40 44 49 53 58

Dimensions LxWxH (Inches) 15¾ x 11½ x 7¾

BATTERY CHARGER “B3” 3 step charger with automatic conditioning; Temperature compensated

output voltage; selectable between wet and sealed lead acid batteries;

selectable between small and large battery banks

Output Current (Amps DC) 75 100 130 140 140

Input Current (Amps AC) Up to 16 Up to 21 Up to 26 Up to 28 Up to 28

TRANSFER RELAY “T” Fail-safe shore power Transfer Relay

Current Rating (Amps AC) 30

Transfer Time (milliseconds) Less than 16 typical

Output Voltage (VAC) 120 RMS ±5%

Output Frequency: 60 Hz ± 0.05%

Output Waveform: Quasi-sine wave, with waveform stabilizer

Input Voltage: (VDC) 11 to 14

Operating Temperature: -20° to 40° C (0° to 104° F)

Efficiency: Up to 93%

Other Design Features:

• Thermally controlled cooling fan.

• Enclosed AC and DC cable connections with strain relief.

• Built-in battery charger “B3” and transfer relay “T”

Remote Control Panel – “R4”:

• LCD Display – Blue background, 16 white characters by

two lines with user-friendly messages.

• Dimensions – W x H x D: 5.75” x 3.75” x 1.25”

• Optional DC master disconnect switch control wire with

assembly panel 141315-1 only

Unit Protection:

• Automatic electronic short

circuit/overload protection

• Automatic high temperature

shutdown

• Output circuit breakers

Battery Protection:

• Automatic low battery shutdown

at 10.5 VDC (with in-rush delay)

• Usage: Any 120 VAC, 60 Hz single-phase products within the standby power system’s rating that does

not require a pure sine waveform.

Dimensions Unlimited 5

Technical Description

3.1 Standby Power System:

A Standby Power System is a DC to AC power inverter with a battery charger “B3” and

an automatic fast transfer switch “T”.

Note: In this manual, we will use the acronym SPS when referring to a Standby Power

System.

A remote LCD control/status panel controls the SPS and provides system status by

displaying user-friendly screen messages.

The system has two operational modes: Inverter power mode and external power mode.

3.1.1 Inverter Power Mode: The SPS converts DC power from batteries to usable

120 VAC, 60 Hz power. The direct current (DC) that enters the SPS is filtered by a large

input capacitor and switched “On” and “Off” by the Metal Oxide Silicon Field Effect

Transistors (MOSFET) at a rate of 60 cycles per second, and directed into the

transformer which steps the voltage up to 120 volts. The unit has a Digital System

Processor (DSP) to control the output voltage and frequency as the DC input voltage

and/or output load varies. The signal output waveform shape is not sinusoidal; it has a

total harmonic distortion of 31% and a maximum single harmonic distortion of 25%.

3.1.2 External Power Mode: 120 VAC, 60 Hz external power can be applied

directly to the SPS by hardwire connections to the AC input wire leads provided in the

field-wiring compartment. When external power is present, the internal transfer switch

cannot be defeated; it automatically turns the DC to AC inverter OFF and activates the

three-step battery charger. At this time the loads attached to the SPS output will

operate directly from the external power line even if the SPS was turned OFF manually.

The internal transfer relay automatically switches the SPS back to “inverter power” mode

in the absence of external power whenever the SPS was previously set to ON.

Dimensions Unlimited 6

3.2 Features

3.2.1 Battery Charger – “B3” Option: External power 120 VAC, 60 Hz is applied

as explained in section 3.1.2 The internal transfer switch automatically turns the DC to

AC inverter OFF and turns the three-step built-in battery charger ON. The battery

charger cannot be defeated at this time and will engage even if the inverter has been

set OFF manually. SPSs with the three-step battery charger feature require the transfer

switch “T” option to operate.

The 3-steps of the charging process are as follows:

Bulk mode: Charging current is passed through the batteries until a factory set

acceptance voltage limit is reached. The charger’s maximum output and/or the state of

charge of the batteries determine the amount of current.

Acceptance mode: Charging continues with the voltage held at the accept voltage

until current flow decreases to the factory set end value or the factory set acceptance

mode time limit is reached.

Float mode: Battery voltage is held at a factory set value, which will neither charge nor

discharge the batteries.

Condition mode occurs every 10th charge cycle between Acceptance mode and Float

mode to ensure full restoration of active materials in all the plates of the battery cells.

The SPS has an automatic power sharing feature that automatically decreases the

battery charger output so that the total AC input current draw by the SPS for both the

AC loads and the battery charger does not exceed 30 amps AC. If the loads exceed 30

amps the charger will be at zero amp draw and the AC input circuit breaker will trip. The

battery charger draw will automatically increase when the external loads are reduced if

the batteries will accept more current.

3.2.2 LCD Remote Control/Status Panel – “R4”: The SPS can only be

controlled by the remote control/status panel which is connected to the SPS module by

a gray flat 8-conductor wire. There are three push buttons and a red LED that when lit

indicates a trouble condition. The remote control/status panel provides system status

through a 16-character by 2 line LCD display.

3.2.3 Transfer Switch – “T” Option: The transfer switch automatically switches

between “Inverter mode” and “External power mode” depending of the external power

line availability. External power 120 VAC, 60 Hz can be applied directly to the SPS AC

input as explained in section 3.1.2.

3.3 Options

3.2.1 LCD Remote Control/Status Panel – “R1” Option: This option is the

same as “R4” except the LCD Remote Control/Status Panel – “R1” part number 141315-

1 includes a 1-foot control wire extending from the back for DC master disconnect if

available in the coach.

Dimensions Unlimited 7

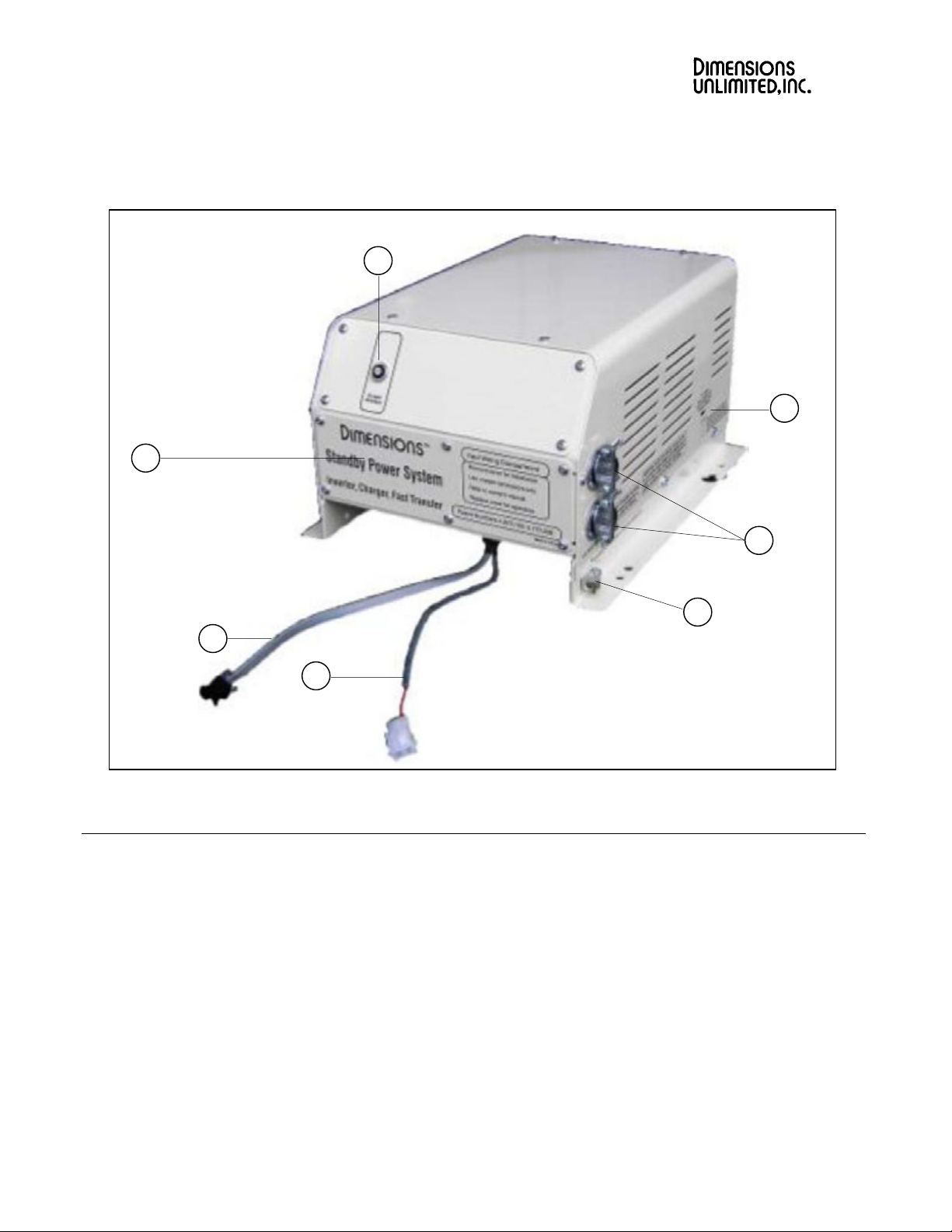

SPS Physical Description

4.1 SPS Module

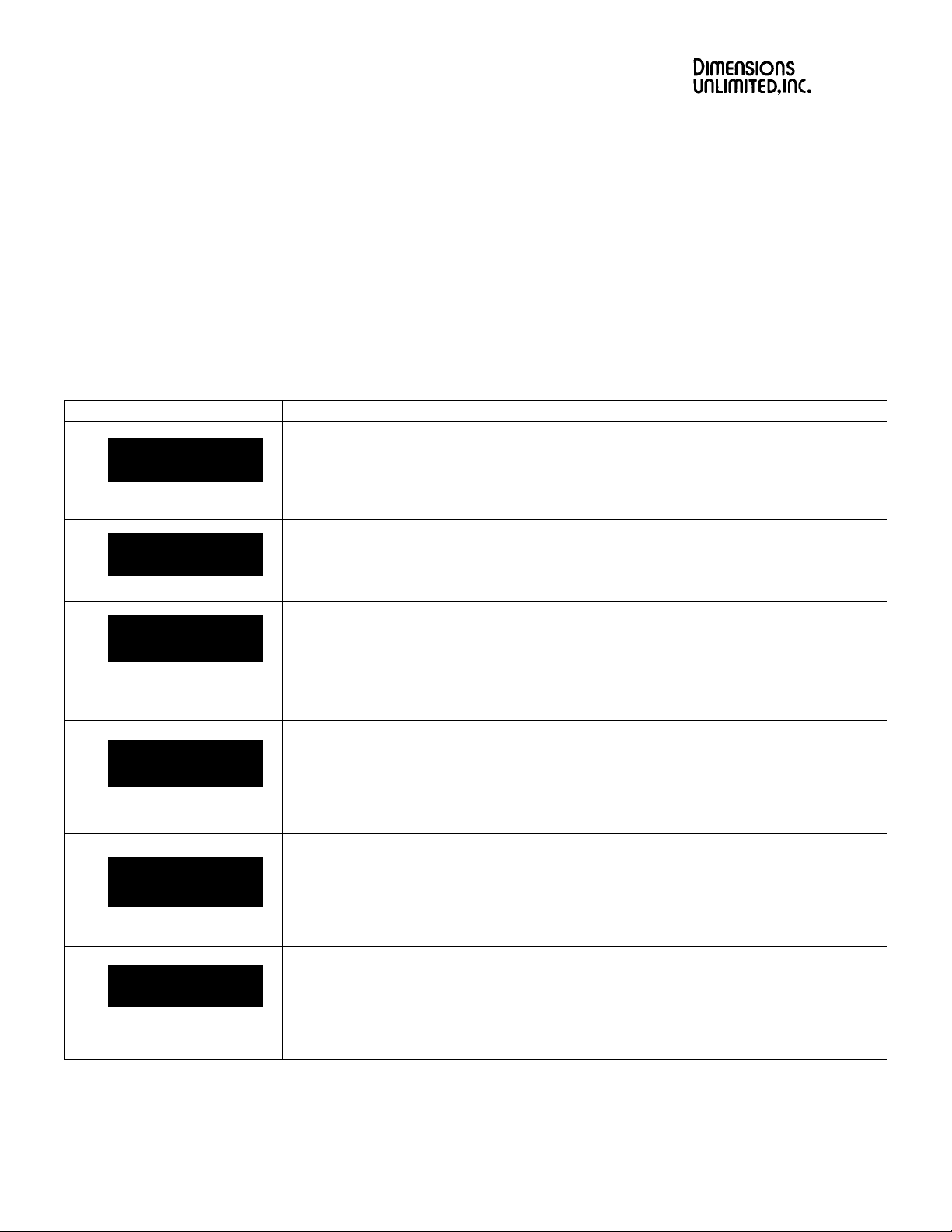

FIGURE 1: SPS physical description

Item # Description Function

1 Output Breaker – 30A Trips to protect the SPS from hardwire AC output

short circuit or overload.

2 Field Wiring Compartment Cover Remove the faceplate to access the AC Input/Output

lead wires and DC field-wiring compartment.

3 Remote Control Panel Connector Connects to the LCD Remote Control/Status Panel

4 Temperature Compensation Sensor

Connector

Connects to the remote temperature sense probe.

5 Bonding Lug Connects to the ground system.

6 DC input entry opening Allows the DC cables to reach the DC input terminal

connector.

7 Battery Capacity Selector Switch Sets the correct battery type and the capacity of the

battery bank for proper charging.

1

2

3

4

5

6

7

Dimensions Unlimited 8

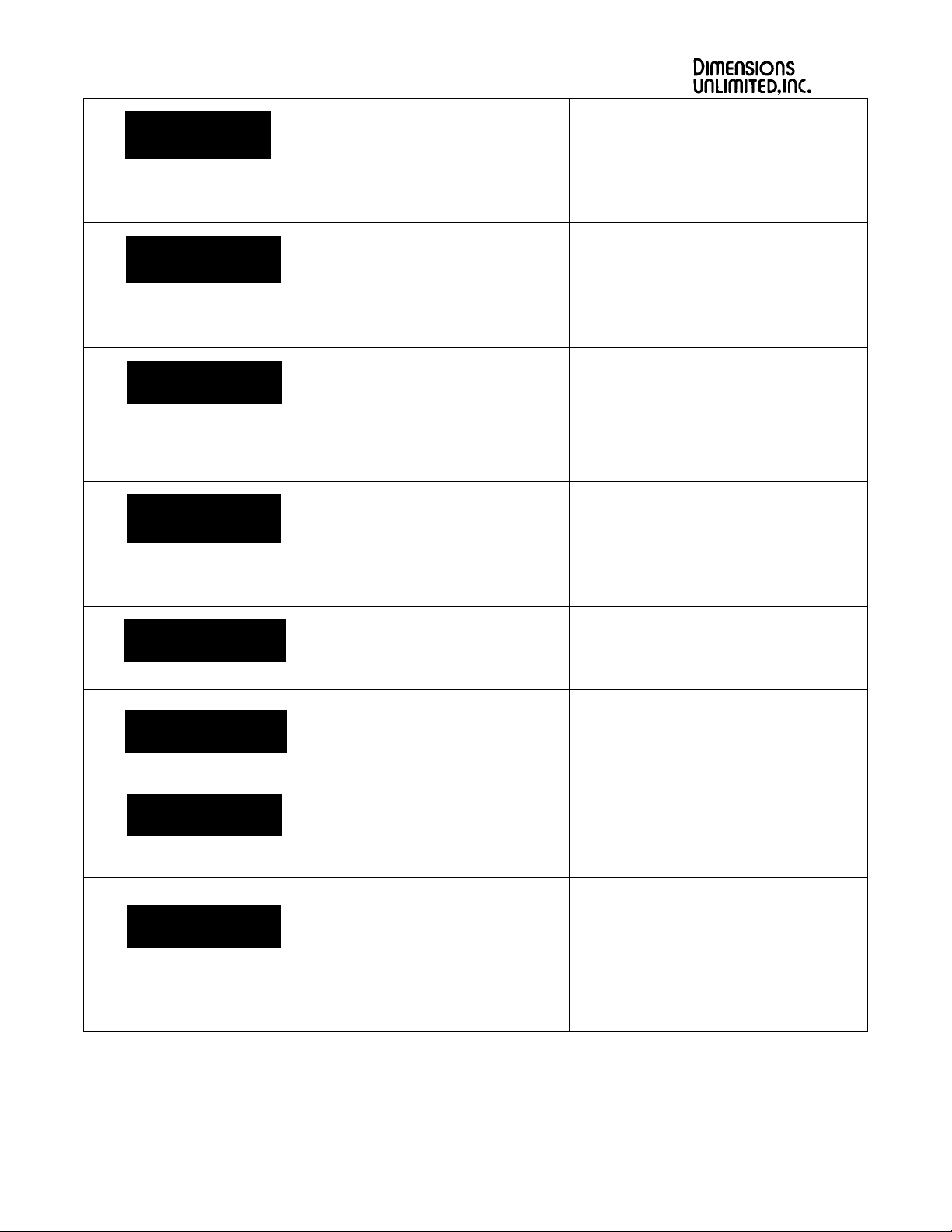

4.2 LCD Remote Control/Status Panel

FIGURE 2: LCD Remote Control/Status Panel

1 Read Display: The red LED indicator will light when the SPS is in a warning

condition.

2 Display – On/Off: Turns the LCD screen backlighting ON or OFF.

3 Inverter & Reset – On/Off: Turns the SPS ON or OFF and resets any error

message.

4 Charger draw – Set Input: This button limits the input AC current for the battery

charger.

5 LCD Display: Shows system status, battery voltage, and electrical current in both

inverter and external power mode as well as shut down conditions.

6 DC Master Disconnect switch control wire – “R1” Option: Available with the

LCD Remote Control/Status Panel – R1 assembly 141315-1. A 1-foot, red wire

extends from the back of the panel and connects to the “DC master disconnect

switch” which is found in most recreational vehicles.

7 Flat cable connector jack: Connects the 8-conductor flat gray signal cable coming

from the SPS.

INVERT 1250 WATT

BATT 12.4 VOLTS

1

2 3

4

7

6 141315-1

Front view

Rear view

5

Dimensions Unlimited 9

Installation

5.1 Tools for Installation:

Tools required for installation: 3/8” Allen Wrench and socket wrench, connectors (butt

type and insulated), drill, Crimpers (for insulated and non-insulated connectors), #2

Phillips screwdriver, wire cutters, wire strippers, cable ties, tape measure.

5.2 System Components:

Picture Model and Description Qty.

12X16B3R4T, 12X20B3R4T, 12X25B3R4T, 12X30B3R4T,

12X36B3R4T

1

LCD Remote Control/Status Panel assembly 141255-2 or

141315-1

1

LCD Remote Control/Status Panel flat cable, 611446-XX; XX:

Length of the cable in feet.

1

Temp. Comp. Cable 611440-XX; XX: Length of the cable in feet.

1

5.3 Mounting the SPS:

The SPS mounting location should provide adequate ventilation and clearance

to maintain room temperature during operation. At least 1/2 inch of clearance

is required on all sides.

• Locate a suitable, secure vertical or horizontal mounting surface as close to the

batteries as possible without being in the same airtight compartment.

• If mounting the SPS on a vertical surface, it is recommended that the front panel be

pointing down whenever possible.

• Locate the mounting holes on the chassis flanges and fasten them using ¼ inch

diameter screws to secure the inverter. See figure 3, page 10.

5.3.1 Chassis Bonding Lug: Connect the bonding lug located at the right side of

the SPS chassis to the earth grounding system using an 8-gauge copper wire.

5.3.2 Temperature Compensated Wire Sense: Connect the two-conductor

gray wire to the negative post of the battery bank. Failure to connect the remote

temperature sense probe correctly will result in high output voltage that will cause

severe damage and exploding batteries and fire.

5.3.3 Connecting the LCD Remote Control/Status Panel: Mount the panel

last in a convenient, visible and accessible location. Connect the flat cable connector

extending from the SPS module to the receptacle at the rear of the panel. 141315-1

assembly panels must connect the red wire extending from the back of the panel to the

output of the DC master disconnect switch. See wiring connections on figure 6, page 14.

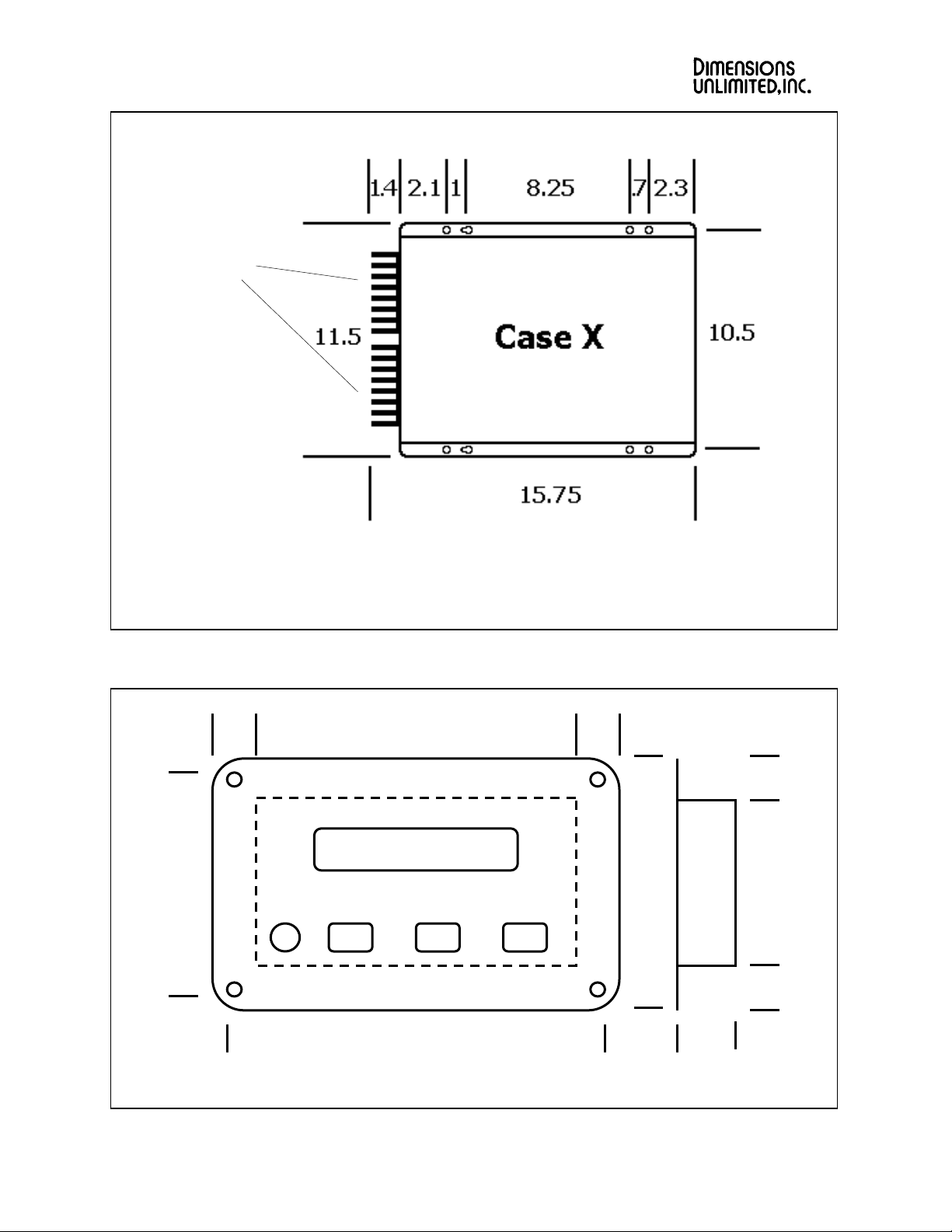

Dimensions Unlimited 10

Figure 3: SPS footprint

• All dimensions are in inches

• Heatsinks are available with the “U” option only or any 3600-watt inverter.

• Front of the unit is to the right

Heatsinks

Figure 4: LCD Control panel footprint

–

Assemblies 141255-2 or 141315-1

5.25

3.25

1.22

0.50

4.75

3.75

• All dimensions are in inches

0.50

0.500.50

Dimensions Unlimited 11

SPS Wiring:

6.1 DC Wiring:

1 It is recommended in all cases to use stranded copper wires.

2 Use SGX cross-linked polyurethane insulation type that complies with the high

temperature insulation requirements (125°C.) of SAE J-1127 and vehicle

manufacturer requirements.

3 Wire gauge recommendations are minimum. For higher temperature applications

inside engine spaces or large motor loads and other applications with high surge

currents use wire gauge 1 to 2 sizes larger than shown on table I.

4 Keep the wire runs between battery and SPS as short as possible.

5 Use Bussmann fuse type ANN-XXX and fuseblock # 3576 where XXX is the size of

the fuse.

6.1.1 Inverter Cable: This is the cable that runs from the SPS to the batteries.

Estimate the “inverter cable” length and locate your SPS model on table I, cross-

reference the wire gauge and fuse size.

Table I: Wire and Fusing Guide for 12VDC systems at 5% Voltage Drop at Full Output

Figure 5: Inverter cable assembly

6.1.2 Charge Cable: This is the cable that runs from the batteries to vehicle

alternator or OEM engine battery. Use 2-gauge cables and 250A fuse for small OEM

alternators and 1/0-gauge and 350A for heavy-duty alternators.

SPS to battery estimated cable length in feet

SPS

Model

Full Load

(Amps DC) 1’ – 10’ 11’ – 15’ 16’ – 20’

12X16B3R4T 160 2-gauge, 250A fuse 1-gauge, 300A fuse 1/0-gauge, 350A fuse

12X20B3R4T 200 2-gauge, 250A fuse 1/0-gauge, 350A fuse 2/0-gauge, 400A fuse

12X25B3R4T 250 1/0-gauge, 350A fuse 2/0-gauge, 400A fuse 3/0-gauge, 500A fuse

12X30B3R4T 300 2/0-gauge, 400A fuse 3/0-gauge, 500A fuse 4/0-gauge, 600A fuse

12X36B3R4T 360 4/0-gauge, 600A fuse 4/0-gauge, 600A fuse Not Recommended

To inverter

DC input

To

batteries Fuse-holde

r

Black wire (-)

A

20 feet maximum

B

18” max.

Red wire (+)

A

B

Fuse B terminal: 5/16” Ring

A

terminal:

3/8” Ring

Dimensions Unlimited 12

6.1.3 Connecting the DC cables

Damage to the SPS not covered under warranty will occur if correct polarity is

not observed when installing the DC input cables.

• Refer to Figure 6: DC wiring diagram.

• Open the SPS field-wiring compartment to access the DC input lugs.

• Unscrew the DC input lug POS (+) and NEG (-) 3/8” Allen screws.

• Remove the fuse from the fuseholder for cable installation.

• Remove 1 inch of insulation from the un-terminated ends of the red and black

cables.

• Insert the stripped end of the red wire into the DC input lug labeled POS (+) and the

stripped end of the black wire into the DC input lug labeled NEG (-). Tighten the

3/8” Allen screws to 23 Ft. Lbs.

• Tighten the cover DC cable strain relief screws to 1 Ft. Lb.

• Connect the end of the short red cable to a POS (+) battery post.

• Connect the terminated end of the black cable (neg. return cable) directly to a

battery NEG (-) post (DO NOT connect to the chassis).

• Install the in-line fuse in the fuseholder that is within 18” of the positive post of the

battery bank (a one-time spark will occur when this final DC connection is made). To

determine the fuse size, refer to section 6.1.1.

6.1.3 Deep Cycle Batteries:

Do not use vehicle-starting batteries; deep discharge cycles typical with

inverter applications can shorten the life of this type of batteries.

• Install at least one auxiliary deep cycle battery to feed the SPS directly.

• Depending on the application running time more batteries could be added if

necessary. The vehicle alternator will recharge the batteries.

• It is recommended to mount the battery bank close to the SPS.

• The maximum recommended distance between the SPS and the battery bank is 20

feet.

• The battery compartment must be vapor-tight to the interior of the vehicle and

vented directly to the exterior.

• Install several vent-plugs within one inch of the top of the battery compartment to

allow for ventilation. Install a ventilation assembly as needed.

• Allow space around the battery and especially above the battery for inspection, and

maintenance purposes.

• The battery should not be able to move more than 1 inch in any direction.

Install the LCD Remote Control/Status Panel last, after the batteries, DC wires

and AC wires been installed.

Dimensions Unlimited 13

6.2 AC Wiring:

Remove the SPS field-wiring compartment cover plate to access the 120VAC, 60Hz input

and output hardwire leads and follow the color code connections: Hot - Black wire,

Neutral - White wire, Ground - Green wire.

6.2.1 AC Output: The 120 VAC, 60 Hz current produced by the SPS is presented

behind the wiring compartment panel with direct hardwire leads.

• The hardwire leads are not GFCI protected and must require the installation of

remote GFCI outlets. The GFCI outlets model recommended is Hubbell # GFR

5352XX (20A) or GFR 5252XX (15A).

Do not connect another source of AC power directly to the output of the SPS.

This will result in damage to the SPS that is not covered under warranty.

6.2.2 AC Input: The transfer switch “T” has AC input hardwire leads which can be

connected to an external power line 120VAC, 60Hz outlet. The cable clamp strain relief

should be used to secure the field wires. The input circuit should have a maximum 30

amps circuit protection from the distribution panel. If the input cable to the unit is 14-

gauge, then a 15 amps circuit protection is required.

Install the LCD Remote Control/Status Panel last, after the batteries, DC wires

and AC wires been installed.

Dimensions Unlimited 14

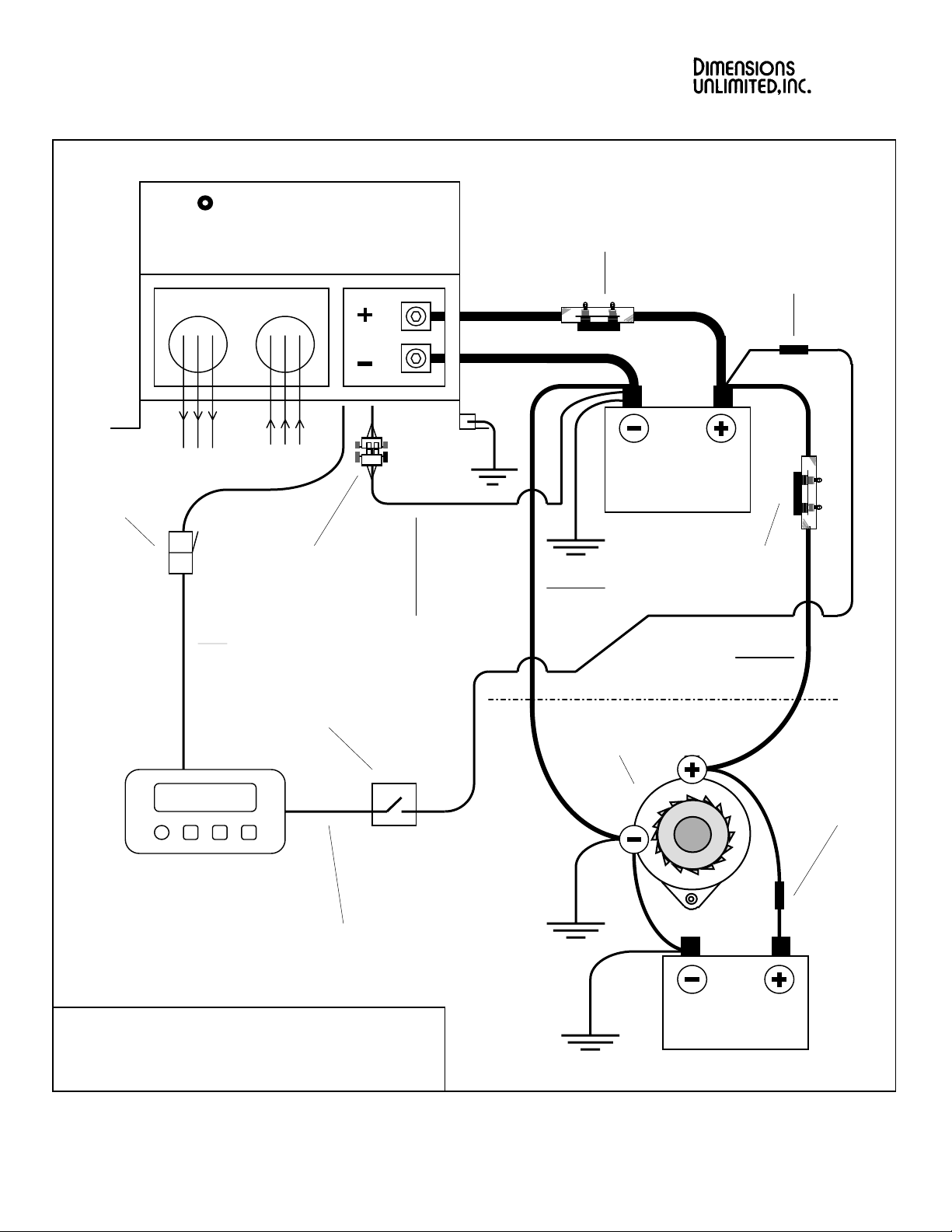

6.3 DC Wiring Diagram

Figure 6: DC wiring diagram

- +

Aux.

12 Volts

Battery

Fuse

Charge Cable

Black (-)

Vehicle Alternator

OEM

12 Volts

Batter

y

Fuse

Fuse

AC Output AC Input

Under the hood

Remote Temp. Sense

Red (+)

Black (-)

Charge Cable

Red (+)

•

Connect the charging cables directly to th

e

vehicle alternator whenever possible or t

o

the OEM starting engine battery.

2-pin

Connector

Remote Control Panel

141255-2 or 141315-1

Flat Cable

Adapter

DC master disconnect switch

(customer supplied)

This feature (red wire) is available with

the 141315-1 assembly panel only

Fuse

Dimensions Unlimited 15

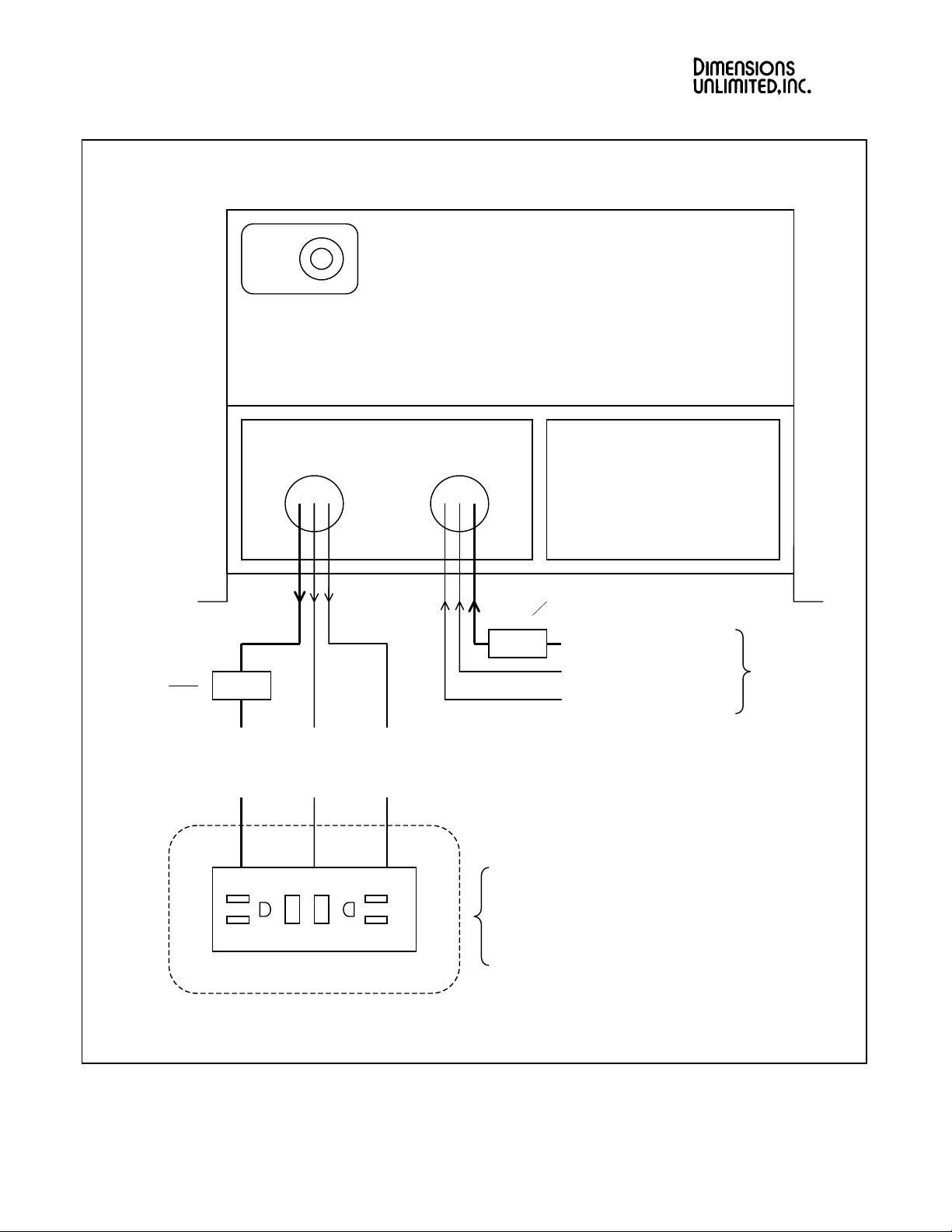

6.4 AC Wiring Diagram

Figure 7: AC wiring diagram

30

Output

Breaker

AC Output AC Input

30A

20A

Black wire – Hot

White wire – Neutral

Green wire - Ground

Black White Green

Wire Wire Wire

H

o

t Neutral Gr

o

und

Install GFCI outlets Hubbell # GFR 5352X

X

(20A) or Hubbell # GFR 5252XX (15A)

120VAC 60Hz Output

AC Input

Fuse (maximum)

Remote GFCI outlet

Fuse

Dimensions Unlimited 16

Operation and Troubleshooting

7.1 Operation

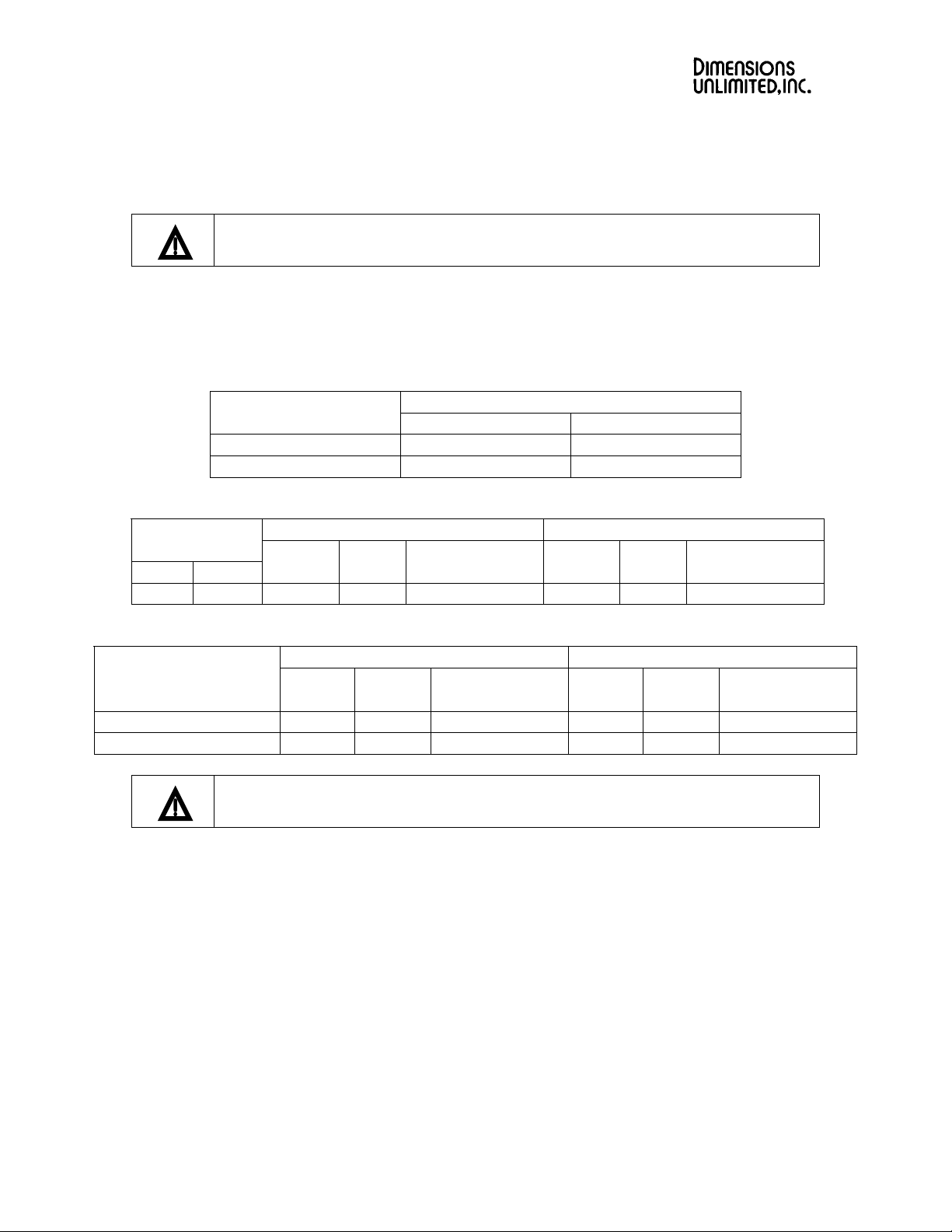

The battery voltage must be higher than 9 volts for the SPS to operate.

7.1.1 Setting the Battery Size and Type: The battery selector switch located at

the right side of the chassis must be set according to the type and size of the battery

bank the SPS is connected to as shown in table II below.

TABLE II: BATTERY SELECTOR SWITCH POSITION

DEEP CYCLE BATTERY TYPE

BATTERY BANK SIZE

(Amp-Hour) SEALED LEAD ACID WET LEAD ACID

More than 400 A C

Less than 400 B D

TABLE III: BATTERY CHARGER VOLTAGES

WET CELL BATTERIES SEALED BATERIES

BATTERY

TEMPERATURE

°F °C

ACCEPT

(Volts)

FLOAT

(Volts)

CONDITIONING

(Volts)

ACCEPT

(Volts)

FLOAT

(Volts)

CONDITIONING

(Volts)

78 25 14.6 13.2 14.9 to 15 max. 14.2 13.2 14.4 to 15 max.

TABLE IV: BATTERY CHARGER TIME PERIODS

WET CELL TYPE BATTERIES SEALED TYPE BATTERIES

BATTERY BANK SIZE

(Amp-Hour) BULK

(max.)

ACCEPT

(max.)

CONDITIONING

(max.)

BULK

(max.)

ACCEPT

(max.)

CONDITIONING

(max.)

Less than 400 6-hrs. 2-hrs. 3-hrs. 6-hrs. 2-hrs. 3-hrs.

Greater than 400 8-hrs. 3-hrs. 6-hrs. 8-hrs. 3-hrs. 4-hrs.

If the bulk mode times-out the charging process will go to the float mode

immediately bypassing the acceptance mode.

7.1.2 Turning the SPS ON: After correct installation, the built-in transfer relay

automatically switches the SPS to “external power” mode activating the battery charger

any time a proper external AC voltage source is present. Setting the charger current

draw to zero with the LCD Remote Control/Status Panel can turn off the battery charger.

See figure 2, item (4) page 8.

The “inverter mode” can only be activated when there is no proper voltage external AC

power source. The inverter is turned ON or OFF by the LCD Remote Control/Status

Panel. See figure 2, item (3) page 8. The inverter can be left ON and the SPS will

automatically cycle back and forth between the battery charger and inverter. However,

there is a one to two amps draw on the batteries when the inverter is ON and there are

no AC loads which could discharge the battery(s).

Dimensions Unlimited 17

Pressing any button enables the panel. This first button activation shows the status. To

change, press the button again.

7.1.3 Battery Charger Draw - Set Input: The SPS automatically limits the

battery charger AC current draw to a maximum of 25 Amps and the SPS also has the

automatic power share feature (see section 2.3.3 page 12). The user may want to

further limit the charger’s maximum AC current draw because of a limited capacity

“shore” power source (ie: 15 Amps rather than 30 or 50 Amps).

Decrease the input AC charge current limit in increments of 5 Amps by pressing the

“CHARGER DRAW – SET INPUT” button on the Inverter/Charger Control Panel (see

figure 2, item 4, page 7).

7.1.4 LCD Remote Control/Status Panel Display Messages:

MESSAGE MESSAGE EXPLANATION

a)

This indicates that the SPS is in “inverter mode”. The panel displays the

wattage of the load and the voltage of the batteries. The “inverter mode”

will activate only if there is no external AC power connected to the SPS.

b)

This indicates that the battery charger is OFF because there is no external AC

power connected to the SPS. The inverter is also turned OFF.

c)

When external AC power is connected to the SPS the three-stage battery

charger may be activated. This indicates that the charge current limit has

been set to 0 amps (see section 7.1.3 on this page). The battery charger is

not active.

d)

This indicates that the three-stage charger is in the bulk mode. The bulk

mode is the first stage of the battery charging process. The display also

indicates the battery voltage and the amount of DC charge current flowing

into the batteries. See tables II & III on page 15 for more information.

e)

This indicates that the charger is in the acceptance mode, the second stage

of the battery charging process. The display also indicates the battery voltage

and the amount of DC charge current flowing into the batteries. See tables II

& III on page 15 for more information.

f)

This indicates that the charger is in the float mode, the third stage of the

battery charging process. The display also indicates the battery voltage and

the amount of DC charge current flowing into the batteries. See tables II &

III on page 15 for more information.

INVERTER xxxx WATT

BATT xx.x VOLTs

CHGR-OFF NO INPT

INVERTER-OFF

CHGR-OFF

0 AMP LIMIT SET

CHGR-BULK MODE

xx.x VOLT, xxx AMP

CHGR-ACCEPT MODE

xx.x VOLT, xxx AMP

CHGR-FLOAT MODE

xx.x VOLT

,

xxx AMP

Dimensions Unlimited 18

g)

This indicates that the charger is in the conditioning mode. Battery

conditioning is automatically performed every 10th complete charge cycles.

The display also indicates the battery voltage and the amount of DC charge

current flowing into the batteries. See tables II & III on page 15 for more

information.

h)

This message is displayed when you press the “

Inverter & Reset – On/Off”

button while the SPS is in the external power mode and the battery charger

is activated. It indicates that the inverter is OFF and will not automatically

turn ON when external power is removed. Pressing the button again will

result in message (j) below. This message will be displayed for ten seconds.

i)

This message is displayed when you press the

“Inverter & Reset – On/Off”

button while the inverter is OFF and there is no external power connected

to the SPS. Pressing this button again will turn the inverter ON and

message (a) will appear.

j)

This message is displayed when you press the “

Inverter & Reset – On/Off”

button while the SPS is in the external power mode and the battery charger

is activated. It indicates that the inverter will automatically turn ON when the

external power is removed. Pressing this button again will result in message

(h) above. This message will be displayed for ten seconds.

k)

This message is displayed when you press the

“Charger Draw – Set Input”

button. It indicates the battery charger input current limit setting. Pressing

this button again will decrease the current limit. This is explained in more

detail in section 7.1.3, page 16. This message will be displayed for ten

seconds.

INVERTER-OFF

PUSH FOR STANDBY

INVERT-STANDBY

OVERRIDE BY CHGR

CHGR- COND MODE

xx.x VOLT

,

xxx AMP

CHGR POWER DRAW

LIMIT xx AMP AC

INVERTER – OFF

PUSH FOR ON

Dimensions Unlimited 19

7.2 Troubleshooting

Call or e-mail Customer Service Department for free consultation during business hours

(central time zone) at: 1-800-553-6418 or 1-651-653-7000; fax: 1-651-653-7600;

e-mail: [email protected]

A TRUE RMS voltmeter is required for accurate AC output voltage readings on

quasi-sine inverters. Other voltmeters that use averaging circuitry will give a

false reading.

• The LCD Remote Control/Status Panel “Read Panel” Red LED warning indicator will

light to indicate a problem either with the inverter or battery charger. Press the

“Panel – On/Off” button to turn the display ON.

• A problem with the transfer relay is indicated when it fails to switch between battery

power “inverter mode” and “external power mode” or when appliances do not

operate when the inverter is in “external power mode”.

• Unplug all loads and connect a 100-watt light bulb to the inverter output. Observe

the LCD Remote Control/Status Panel then check the troubleshooting table.

7.2.1 Troubleshooting Chart

MESSAGE PROBLEM POSSIBLE CAUSE

1

The SPS is not connected to

the batteries or the battery

voltage is below 9 volts DC.

Check the in-line fuses for continuity.

Make sure the DC wires are clean

and tight. Check the DC voltage at

the inverter DC input.

2

Indicates immediately that the

SPS is operating in a low

battery voltage condition.

Fault in the battery wiring, battery

capacity and voltage or the in-line

fuse. This message will automatically

clear or the screen will go to

message 3.

3

Indicates that the inverter has

shut off due to a low battery

condition. Press the

“inverter &

reset – On/Off”

button three

times to turn the inverter back

ON.

The same screen message coming

on again indicates a fault in the

battery wiring, battery capacity and

voltage or the in-line fuse. If the

condition persists, call Dimensions.

4

Indicates immediately that the

SPS is operating in an overload

condition.

SPS output wiring is shorting or

loads that exceed rating. This

message will automatically clear or

the screen will go to message 5.

INVERT LOW BATT

BATT xx.x VOLTS

INVERTER-OFF

LOW BATTERY

INVERTER OVERLOAD

BATT xx.x VOLTS

Dimensions Unlimited 20

5

Indicates that the SPS has shut

off due to an overload

condition.

Remove the short circuit or excessive

load from the output, and then press

the

“inverter & Reset On/Off”

button

three times to turn the inverter back

ON. If the condition persists, call

Dimensions.

6

Indicates that the inverter has

shut off due to high internal

temperature. The unit will

automatically turn back on

when it has cooled to 40°C

(104°F)

Verify that the SPS is not in a closed

compartment and that the fan is not

blocked. High ambient temperatures

combined with a poor ventilation

condition may also contribute to the

shut down of the SPS.

7

Indicates that the inverter has

shut off due to high battery

voltage. The unit will

automatically turn back on

when the condition is

removed.

Check battery wiring or remove

other source of battery charging,

such as the vehicle alternator.

8

Indicates that the charger has

shut off due to high internal

temperature. The unit will

automatically turn back on

when it has cooled to 40°C

(104°F)

Shorted or defective battery. Make

sure that the DC cable connections

are tight and clean and not shorted,

and that the proper wire gauge is

used.

9

Indicates that the charger has

shut off due to high battery

temperature 47°C – 50°C

(117°F - 122°F).

Battery compartment is too hot and

needs to cool down. The charger will

automatically turn back on when it

has cooled down to 40°C (104°F)

10

Indicates that the charger has

shut off due to short or open

temperature compensating

sensor cable.

Temperature compensation sensor

cable needs to be replaced.

11

Indicates that the charger is

operating in a low DC output

voltage condition.

Shorted or defective battery. Make

sure that the DC cable connections

are tight and clean and not shorted,

and that the proper wire gauge is

used.

12

Indicates that the charger is

operating in a high DC output

voltage condition.

There is another source of battery

charging or there is a defective

battery charger. Disconnect and

reconnect the external AC power to

restart the battery charger. If

condition persists, call Dimensions.

INVERTER - OFF

HIGH TEMP

CHARGER - OFF

HIGH TEMP

CHGR-OFF HI-VOLT

RESET OR SERVICE

CHGR-ON LO-VOLT

CHECK BATTERIES

INVERTER - OFF

HIGH BATTERY

INVERTER - OFF

OVERLOAD

CHARGER - OFF

BATT HIGH TEMP

CHARGER - OFF

CHECK BATT PROBE

This manual suits for next models

4

Table of contents