Dinel RFLS-53N User manual

Read carefully the instructions published in this manual before the rst use of the sensor. Keep the manual

at a safe place. The manufacturer reserves the right to implement changes without prior notice.

INSTRUCTION MANUAL

High frequency level switch

RFLS-53N

CONTENT

1 . Basic description ..................................................................................................................... 4

2 . Range of application ................................................................................................................ 4

3 . Dimensional drawing ................................................................................................................ 5

4 . Installation and putting into operation ...................................................................................... 5

5 . Installation instructions ............................................................................................................. 6

6 . Electrical connection ................................................................................................................ 7

6.1. Connection through valve connector ............................................................................... 8

6.2. Connection through connector M12 ................................................................................ 8

6.3. Connection via standard cable gland or gland for protective hoses ................................ 9

7 . Setting ................................................................................................................................... 10

8 . Order code ............................................................................................................................. 11

9 . Accessories ........................................................................................................................... 11

10 . Safety, protection and compatibility ..................................................................................... 12

11 . Use, manipulation, and maintenance .................................................................................. 12

12 . Technical specications ...................................................................................................... 13

13 . Making of labels .................................................................................................................. 14

RFLS–53 © Dinel, s.r.o.

4

The RFLS-53 sensor uses the principle of the capacity measurement on high frequency.

This means that the sensor reacts to the mass of material and ignores the deposits and

remnants of material that remain on the measuring part - the active surface of the sensor.

Thus, the sensor can be used in demanding applications to indicate powder, dust and

hygroscopic materials and can replace mechanical rotary level switches or standard capacitive

level switches.

The sensor is manufactured in several versions with extra low (24 V DC) or low supply voltage

(230 V DC). With dierent types of outputs (PNP, relay, SSR) and electrical connection (M 12,

valve connectors, cable).

RFLS-53 fully replaces the older CLS-53, but its electrical connection of the 230 VAC version is

dierent (3 wires).

All operations described in this instruction manual have to be carried out by trained

personnel or by an accredited person only. Warranty and post warranty service must

be exclusively carried out by the manufacturer.

Improper use, installation or set-up of the sensor can lead to crashes in the ap-

plication.

The manufacturer is not responsible for improper use, loss of work caused by either

direct or indirect damage, and for expenses incurred at the time of installation or

during the period of use of the level sensors.

To ensure maximum safety of control processes, we have dened the following safety instruc-

tions and information. Each instruction is labelled with the appropriate pictogram.

Alert, warning, danger

This symbol informs you about particularly important instructions for installation and

operation of equipment or dangerous situations that may occur during the installation

and operation. Not observing these instructions may cause disturbance, damage or de-

struction of equipment or may cause injury.

Information

This symbol indicates particularly important characteristics of the device.

Note

This symbol indicates helpful additional information.

Used symbols

safety

1 . basic description

5

© Dinel, s.r.o. RFLS–53

2 . range of application

Detection of various kinds of bulk-solid materials (pellets, wood chips, sawdust, granulates,

cereals, sand, gravel, ...) and other powder materials (our, cement, ne mineral powders,

metallic powders, ...) in hoppers, containers, silos, etc.

The sensor is not intended to be used for liquids or pasty media.

The sensor cannot be used in explosive atmospheres.

3 . dimensional drawing

G1 1/2

26 13 34

102

6

RFLS–35N Performance„G“

with valve connector

Performance„C“

with connector M12 Performance „B“ with

plastic cable gland Performance „H“with cable

gland for protective hose

RFLS–53 © Dinel, s.r.o.

6

4 . installation and pUtting into operation

This procedure has the following three steps:

• installation - chapter 5

• electrical connection -chapter 6

• settings -chapter 7

• The sensor should be mounted to a slant

or vertical wall of the hopper using a weld-

on tting with G1 ½'' thread or appropriate

xing nut (PUM-G1,5). The front (active

surface) of the sensor should remain 2-5

mm in front of the inner wall (inwards) or

in front of the xing nut – Fig. 1a, 1b.

• Although the inuence of the build-ups

is strongly eliminated, thick sediments

might cause false activation (blocking) of

the sensor (see Fig. 2). The function of the

sensor is safe with a maximum sediment

thickness of ca. 5 - 10 mm depending on

the dielectric properties of the material.

• The sensor must not be installed in places

with direct solar radiation and must be

protected against weather conditions. In

case the installation at places with direct

solar radiation is inevitable, it is necessary

to mount a shielding cover above the

sensor (Fig. 3).

• If possible, mount the cable from the

sensor down and let there a draining loop

to avoid intrusion of humidity (Fig. 4). The

cable gland as well as the connector's

safety screw have to be tightened

suciently.

• The placement of the sensor must be

carried out in such a way that the material

ow from the lling point does not

interfere with the sensor's scanning eld.

Othrewise false activation (blocking) of the

sensor could occur (Fig. 5).

5 . installation instrUctions

Fig. 1a: Installation of the sensor using

a fastening nut

Fig. 1b: Installation of the sensor using

a weld-on tting

FIG. 2: The height of the sediment

can be a maximum of 5-10 mm

5

14

5~ *

1,7~

1,7~

18

5

6~ *

max.

5-10 mm

5

14

5~ *

1,7~

1,7~

18

5

6

~

*

max.

5-10 mm

5

14

5~ * 1,7~

1,7~

18

5

6~ *

max.

5-10 mm

5

14

5~ * 1,7~

1,7~

18

5

6~ *

max.

5-10 mm

!

7

© Dinel, s.r.o. RFLS–53

2 - 5

max. 5-10 mm

Fig. 3: Shielding cover

against direct solar

radiation

2 - 5

max. 5-10 mm

2 - 5

max. 5-10 mm

2 - 5

max. 5-10 mm

Fig. 4: Prevention to avoid

intrusion of humidity

Fig. 5: Position of the sensor related

with the lling point

6 . electrical connection

Electrical connection can only be made in a voltage - free state!

In the event that the level meter (sensor) is installed in an outdoor environment at a distance

greater than 20 m from the outdoor switchboard, or from an enclosed building, it is necessary

to supplement the electrical cable leading to the level meater (sensor) with suitable overvoltage

protection.

Inthe eventofstrong ambientelectromagnetic interference,parallelingof conductorswith power

distribution, or for distribution to distances over 30 m, we recommend using a shielded cable.

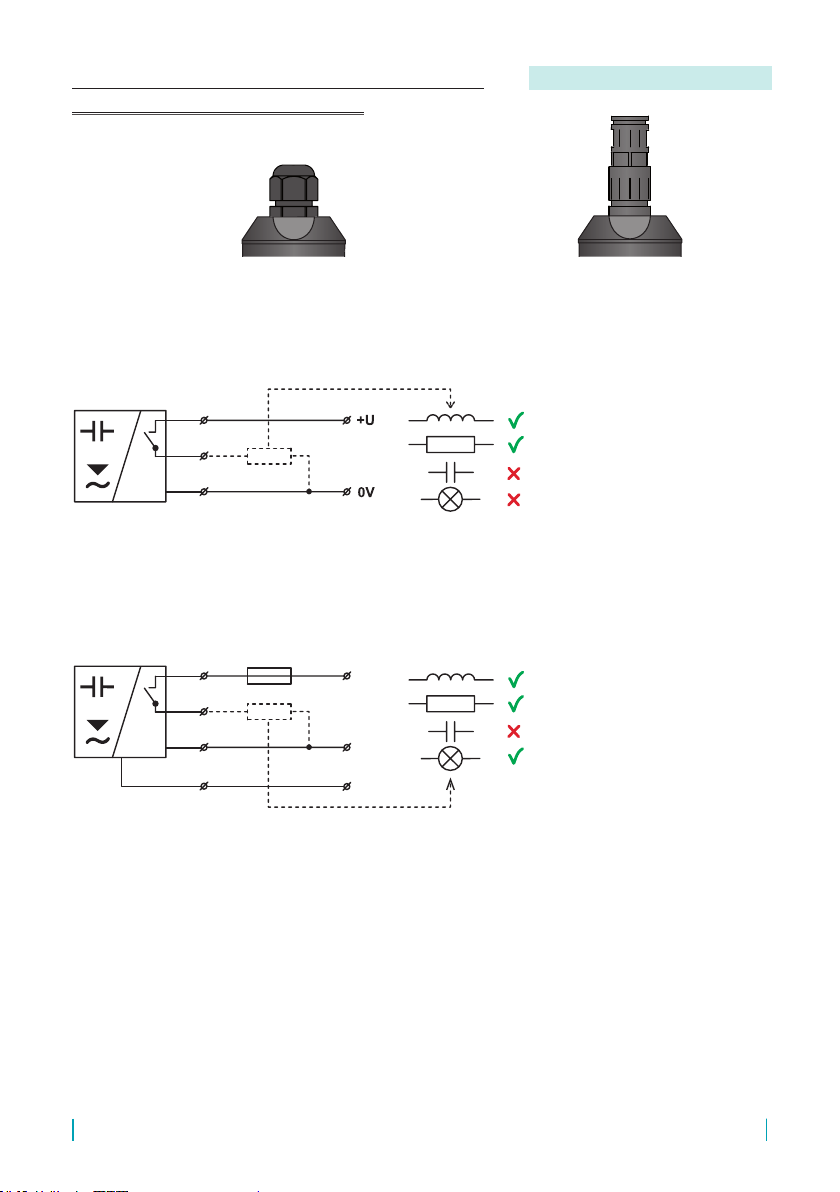

RFLS-53N-_-P-_

The source of the power voltage must comprise of a stabilised safe low power source with

galvanic separation. In the event that a switch-mode power supply is used, it is essential

that its construction effectively suppresses common mode interference on the secondary

side. In the event that the switch-mode power supply is equipped with a PE safety terminal,

it must be unconditionally grounded!

RFLS-53N-_-RE(SSR)-_

The device may only be connected to the power supply via an easy to reach switch with marked

turnedoff /onpositions and must be protectedby afuse orcircuit breaker withavalueofmax.6 A!

The switch or circuit breaker used as the disconnect device must be in accordance with the

IEC60947-1 and IEC60947-3, must be marked and must not be in the network inlet.

RFLS-53N-_-RE(SSR)-_

The output wire of the device is not separated from hazardous circuits. It must not be connected

to secondary accessible safety circuits.

RFLS–53 © Dinel, s.r.o.

8

RFLS-53N-_-RE-G

RFLS-53N-_-SSR-G

RFLS-53N-_-P-G

RFLS-53N-_-P-C

L

N

L

N

L

N

4

0 V

+U

output

N

L

output

Top view of the

connector

Top view of the

connector

Top view of the

connector

fuse max.6A

6.1. Connection through valve connector

6.2. Connection through connector M12

Valid for: RFLS-53_-_-_- G

Valid for: RFLS-53_-_-_- C

Performance„G“

with valve connector

Performance„C“

with connector M12

1

3

4

0 V (3)

+U (1)

Uout (4)

9

© Dinel, s.r.o. RFLS–53

Performance „B“ with short

cable gland Performance „H“with cable

gland for protective hose

RFLS-53N-_-RE-B

RFLS-53N-_-RE-H

RFLS-53N-_-SSR-B

RFLS-53N-_-SSR-H

* Grey wire with blue wire ferrule.

RFLS-53N-_-P-B

RFLS-53N-_-P-H

L

N

(PE)

BN

BK

BU

BN

BK

GY *

GNYE

L

N

(PE)

BN

BK

BU

BN

BK

GY *

GNYE

fuse max.6A

6.3. Connection via standard cable gland

or gland for protective hoses

Valid for: RFLS-53_-_-_- B(H)

RFLS–53 © Dinel, s.r.o.

10

Fig. 6: Full view of capacitive level switch

7 . setting

Setting-up can be performed with a "MP–8" magnetic pen that is a part of of the delivery.

Settings are performed by touching a magnetic pen on sensitive spot indicated as or

located beside the connector or cable gland.

1) Setting the Normally Open or Normally Closed switching mode:

Factory default mode is Normally Open. If the setting mode satises, you can skip next steps.

Setting the sensor to Normally Closed mode:

1. Disconnect the sensor from the power source (e.g. by disconnecting the connector).

2. Place the magnetic pen on spot in the voltage-free state and hold it.

3. Connect the power supply. Green and Orange LED lights up.

4. Take the magnetic pen away.

• Other settings of the sensor remain unchanged.

• Repeating this procedure will set the switching mode Normally Open again.

2) Adjusting sensitivity by short touch of magnetic pen (approx. 0,5 sec) to:

1. spot: increase sensitivity (every step is conrmed by 3-times ashing green LED)

2. spot: decrease sensitivity (every step is conrmed by 3-times ashing green LED)

• When the end of sensitivity range is reached (min or max sensitivity), the frequency of

green LED ashing slows down.

• Verify the function by activation of the sensor and watch the sensor behavior.

• The sensor is factory default set to basic sensitivity.

3) Factory default mode:

factory mode is Normally Open, setting of sensitivity is for materials about εr= 2.

1. Disconnect the sensor from the power source (e.g. by disconnecting the connector).

2. Place the magnetic pen on spot in the voltage-free state and hold it.

3. Connect the power supply. Green and Orange LED lights up.

4. Take the magnetic pen away.

5. Now is Factory default mode set.

spot marked

LED indicators

Valve connector

Safety screw

spot marked

Cable gland

11

© Dinel, s.r.o. RFLS–53

For safety reasons, for scanning min. level, we recommend you to use the "O" mode setting (sensor closes when

submerged). A faulty sensor or wiring will take eect here in the same way as level emergency conditions by opening

the sensor. Analogously for the max. level, we recommend you to set the "C" mode (sensor opens when submerged).

level state mode output state Orange LED

maximum level sensing

COPEN

(dark)

CCLOSED

(shining)

level state mode output state Orange LED

minimum level sensing

OCLOSED

(shining)

OOPEN

(dark)

Setting modes

The sensor can be set to normally closed "O-mode" or to normally open "C-mode" switch types.

RFLS–53 © Dinel, s.r.o.

12

8 . order code

PRODUCT

RFLS-53

MECHANICAL PERFORMANCE

Nfor non-explosive areas

TYPE OF DESIGN

1at face

OUTPUT TYPE

PPNP (open collector)

RE relay contact

SSR solid state relay

ELECTRICAL CONNECTION

Gvalve connector DIN 43 650, form A

Cconnector M12, cannot be selected for output type RE, SSR

Bstandard cable gland

Hcable gland for protective hose

CABLE

Kcable length in m, only for variants with connection type "B"

and "H"

RFLS-53 N-1 RE BK 2 POSSIBLE PRODUCT VARIANT

standard – included in the price of the sensor

• 1 pcs. MP–8 magnetic pen

• 1 pcs. Seal

• 1 pcs. Connector with IP67 coverage (for version with valve connector)

9 . accessories

13

© Dinel, s.r.o. RFLS–53

RFLS-53N-_-P-_

Protection against dangerous contact is provided by low safety voltage according to

ČSN 33 2000–4–41 and degree of coverage IP 65.

RFLS-53N-_-RE(SSR)-_

Equipment of protection class II. Protection against dangerous contact with live parts is en-

sured by the degree of protection IP 65. Electrical safety is ensured in accordance with the

requirements of the standard EN 61010-1.

The operator of the equipment must be demonstrably acquainted with the operation and

maintenance of the equipment.

Electromagnetic compatibility is provided by conformity with standards:

EN 55 011 (A), EN 61326-1, EN 61000-4-2 (A, 8 kV),

EN 61000-4-3 (A, 10 V), EN 61000-4-4 (A, 2 kV),

EN 61000-4-5 (A, 1 kV), EN 61000-4-6 (A, 10 V),

EN 61000-4-8 (A, 30 A), EN 61000-4-11 (A, B)

The sensor is equipped with protection against polarity reversal of the supply voltage and

voltage peaks. RFLS-53N -_- RE (SSR) -_ sensors are not equipped with current overload pro-

tection! RFLS-53N -_- P-_ sensors are equipped with overload and short circuit protection

at the output.

10 . safety, protection and compatibility

The sensor does not require any personnel for its operation.

Maintenance of this equipment consists in verication of sensor's and supply cable's integrity.

In case any visible defects are discovered, the manufacturer or reseller of this equipment must

be contacted immediately.

Any changes or interventions without the permission of the manufacturer are

forbidden to be performed on the RFLS-53 level sensor. Any repairs must be

carried out only at the manufacturer site or by a service organization authorized

by the manufacturer. The assembly, installation, commissioning, operation, and

maintenance of the RFLS-53 level sensor must be performed following this manual

and must comply with the provisions of the applicable standards for the installation

of electrical equipment.

11 . Use, manipUlation and maintenance

RFLS–53 © Dinel, s.r.o.

14

12 . Technical specifications

Technical specification

Supply voltage

RFLS-53N-_-P-_

RFLS-53N-_-RE-_

RFLS-53N-_-SSR-_

7 ... 34 V DC

95 ... 230 V AC (± 10 %) / 50 ... 60 Hz

95 ... 230 V AC (± 10 %) / 50 ... 60 Hz

Supply current

RFLS-53N-_-P-_

RFLS-53N-_-RE-_

RFLS-53N-_-SSR-_

≤ 10 mA DC

≤ 60 mA AC

≤ 60 mA AC

Output

RFLS-53N-_-P-_

RFLS-53N-_-RE-_

RFLS-53N-_-SSR-_

open collector PNP output, max. 300 mA

relay contact 1 A / 250 V / 250 VA AC

solid state relay, max. 130 mA / 250 V AC

Tightening torque

of cable gland RFLS-53N-1-_-G 1 ... 2 Nm

Recommended cable RFLS-53N-1-_-G external dimension

RFLS-53N-1-_-G wire size

Ø 4 ... 9 mm

3x 1,5 mm2 max.

Cable

RFLS-53N-_-P-B (H)

RFLS-53N-_-RE-B (H)

RFLS-53N-_-SSR-B (H)

3x 0,5 mm2, PVC

4x 0,75 mm2, PVC

4x 0,75 mm2, PVC

Max. remanent voltage

(ON state) RFLS-53N-_-P-_ max. 1,5 V

Max. switching frequency 0.5 Hz

Min. relative permittivity 1,3 εr

Ambient temperature range -20 ... +60° C

Protection class IP65

Housing material PP and PVC-U

Weight approx. 0,13 kg

15

© Dinel, s.r.o. RFLS–53

Štítek pro RFLS-53N-_-RE-G

Ser. No.: ______

RFLS-53N-_-RE-G

www.dinel.cz

Made i n Czech R epublic

Dinel

t = -20 ... +60 °C

a

I < 1 A

out

I = 60 mA

U = 95 ... 230 V

50 ... 60 Hz

175x20

Štítek pro RFLS-53N-_-RE-B

Ser. No.: ______

RFLS-53N-_-RE-B

www.dinel.cz

Made i n Czech R epublic

Dinel

t = -20 ... +60 °C

a

I < 1 A

out

I = 60 mA

U = 95 ... 230 V

50 ... 60 Hz

Cable: __ m

Štítek pro RFLS-53N-_-RE-H

Ser. No.: ______

RFLS-53N-_-RE-H

www.dinel.cz

Made i n Czech R epublic

Dinel

t = -20 ... +60 °C

a

I < 1 A

out

I = 60 mA

U = 95 ... 230 V

50 ... 60 Hz

Cable: __ m

L

N

1

3

2

L

N

BN

BK

GY

(PE)

GN YE

L

N

BN

BK

GY

(PE)

GN YE

IP65

IK06

IP65

IK06

IP65

IK06

Label for device of the type RFLS–53N

Symbol of producer: logo Dinel®

Internet address: www.dinel.cz, Country of origin: Made in Czech Republic

Connection scheme and labelling of wires:

Cable length: Cable: _ _ m

Serial number: Ser. No.: ______ – (from the left: production year, serial production number)

Supply voltage: U= ... V

Supply current: I= ... mA

Maximum switching current: Iout=... mA (A)

Ambient temperature range: ta= ... °C

Impact rating: IK06

Protection class: IP6_

The character of double insulation (device of protection class II):

Compliance mark:

Electro-waste take-back system mark:

13 . Marking of labels

Dinel, s. r. o.

U Tescomy 249

760 01 Zlín

Czech Republic

phone: +420 577 002 002

e-mail: [email protected]

www.dinel.cz

industrial electronics

Find the updated version at www.dinel.cz

version: 08/2017

08/2021

Table of contents

Other Dinel Laser Level manuals