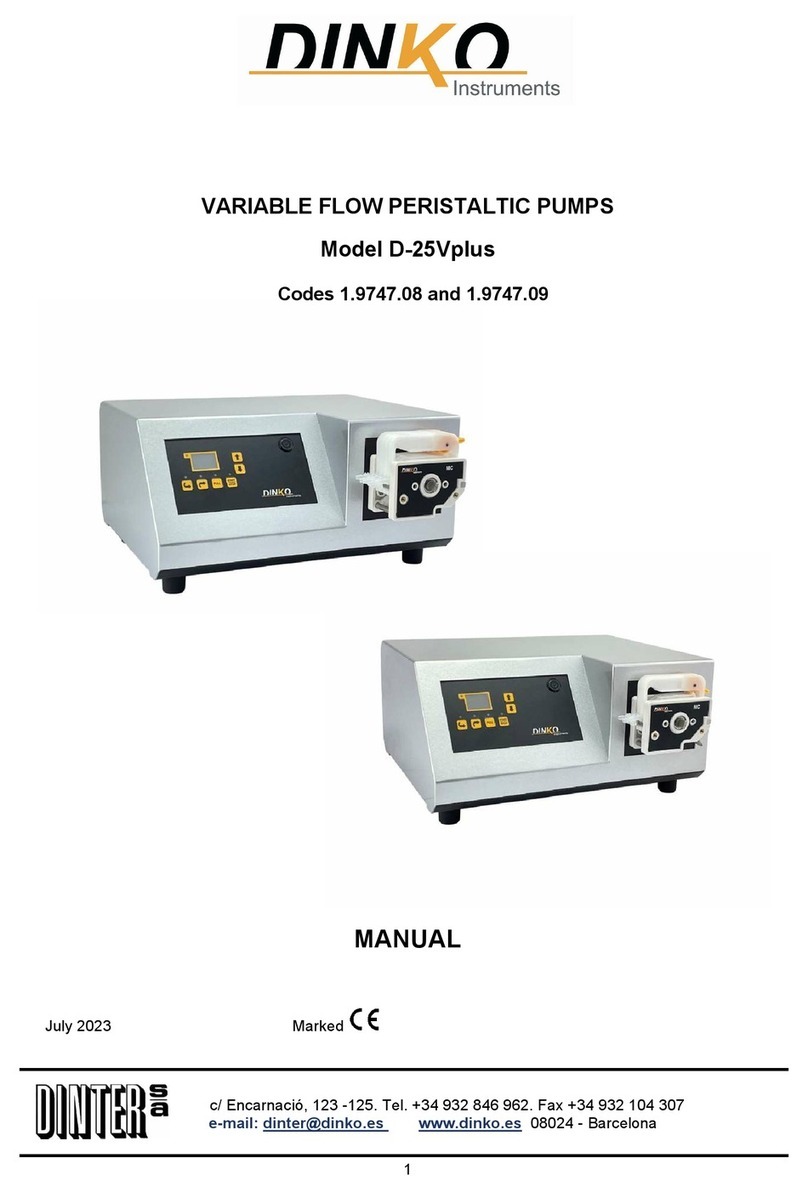

DINKO Instruments D-25VXi User manual

1

INSTRUCTION MANUAL

PERISTALTIC PUMPS

MULTIHEADS

Model

D-25VXi and D-25VTXi

June 2019

Marked

c/ Encarnació, 123 -125. Phone +34 93 284 69 62. Fax +34 93 210 43

07

E-mail: dinter@dinko.es www.dinko.es 08024 – BARCELONA

2

GENERAL INTRODUCTION

The following considerations have as purpose to guarantee a correct reception and use the apparatus, like the security of

the user. We recommend to read this manual detailed before proceeding to unpack the apparatus and later use.

-This manual should be conserved permanently within reach of the user.

- To unpack the apparatus carefully. Check that the content coincides with the packing list. Notify any eventuality

immediately.

- For the correct conservation of the apparatus it is necessary to avoid their installation in areas with corrosive atmospheres

or exposed liquid splashes.

- To avoid the use of the apparatus when the possibility exists to generate mixtures of explosive and inflammable gases.

-The European norm for use 89/655/CEE it exempts the maker all responsibility when it lacks an appropriate maintenance

or there is alteration or change of some component.

-The apparatuses that are sent to the Technical DINKO Instruments Service they will be perfectly clean and desinfected.

Otherwise it will be rejected and returned with freight in charge of the owner.

PAKING LIST

Description Code Quantity

Peristaltic Pumps D-25VXi /D25VTXi 1.9733.04-05 / 1.9738.00-01-121-17-24-25 / 1.9734.04-05/1.9739.00-01 1

Set tubing and connectors 1

Cable plug 1

Instruction Manual 1

DESCRIPTION

Unitized instruments contains a peristaltic pump, speed control and on-of switch for each head pump in a single case.

The peristaltic pumps D-25VXi has heads that facilitates the extraction of the tube when it should substitute or for

sterilisation. In the pumps with 50-2r head type retires the cover extracting the three screws. The head pump CF-3r and CF-

4r is for easy change tube

Each pump admits four or six tube sizes giving the interval flows ranges in the table.

Pumps regulated for sign 0-10V incorporate their connector.

Other multi-heads pumps are available on demand.

PUMP HEAD 50

Back plate

Screws Connectors

Rotor axis (rotor not showed)

Housing

Tube

Opening the CF pump head

1- Tube clamp setting (only CF-3r)

2- Tube wall thickness indication.

3- Set for tube bore size ( only CF-3r)

3

Tube loading, CF pump head

X- Not well installed tube

V- Well installed tube

Pump head 1500

Cover fixing screws

Pump head 5000 -Description and adjustment.

1 Lock 5 Flexible rotor lid 9 Roller

2 Protection lid 6 Hose guide roller 10 Tube clamp

3 Track 7 Rotor 11 Tube clamp

4 Clutch button lid 8 Support roller 12 Protection gasket

13 Drain

Remove rotor.

◊Open protection lid and remove pump head hoses.

◊Open flexible black lid located on the rotor center.

◊With a Phillips screwdriver to remove the central screw positioning.

◊Pull the rotor hub off its axis.

◊Between the hub and the shaft is a split collet. If the collet is retained by the shaft, pull it off, loosening, if necessary, using

light strokes. Do no t try to remove it by prying with a screwdriver. If the collet is retained within the bucket, remove, if

necessary, slightly loosen the screw reinserting central locating and tapping the screw head.

Rotor replacement.

4

◊Reassemble the split collet on the shaft, rotating it until it is fully inserted. Fit the body of the

rotor drive shaft as a unit.

◊Open the flexible black cover of the center rotor. With a Phillips screwdriver to tighten the

screw positioning a pair of 3 Nm to prevent the collet slipping during work. If the assembly

is correct, the guide rollers of the hose should be aligned with the outer surface of the track.

Close the flexible lid rotor.

◊Close the cover and make sure the rotor is separated from it, watching the first rotation of the rotor.

Placing the tubes (hoses

)

The 5000 pump heads are factory set to accommodate tubes from 1.6 mm wall. Pumping performance may be adversely

affected if the tubes are not used right.

◊Check hose length 225 mm. to be placed inside the head. Please

note, if you put more than 225 mm can be seen shortened tube life.

◊Open the bottom clamp (spring) and put the hose to the first mark

of 225 mm. aligned with the inside of the bracket that has the dock.

Loosen the clamp.

◊Disengage the rotor clutch fully depressed the yellow button on the side of the rotor

hub and rotor turning the hub a few degrees, while maintaining the button. Now the

rotor can give a complete revolution independently of the gearbox and engine.

If the clutch re-engages before the hose is fully assembled, press the button again and

turn the rotor a few degrees.

◊Place the tubing around the track head, turning the rotor properly. Make sure the hose is not twisted or pinched between

the guide rollers and track. Check that the second mark of the 225 mm. is located along the inner edge of the upper

clamp.

◊Open the upper hose clamp with spring and place the hose, making sure the hose does not twist and is supported

centrally between the guide rollers of the hose. Loosen the clamp

◊Hose clamps, with spring, holding the hose must be strong enough to keep it from

Moving in or out of the pump head, but should not be tightened too much or choke the

passage of fluid. The clamps have a yellow slide that can be placed in two

positions

while the clamps are open. The external position allows tightly hold the hose clamps,

while the inner position leaves him weaker . Adjust the sliders to prevent tube

movement during a test a few turns the rotor.

◊Close the cover by pushing it fully until the latch engages

◊Remember that it is appropriate, after 30 minutes of operation, tighten the hose back,

which can lengthen as it accommodates.

Tighten the hose so that the 225 mm. hose are located between the parts of the hose

clamp that carry spring.

PREVIOUS OPERATING

1. - Select the tube diameter. Remove the plastic cover of the pump head. Installing the tube with their terminals of

fixation. When you settle the new tube, should remain centred on the rollers in order to avoid the rotor to pinch the tube.

Place the cover again. With each pump the sizes of tube are giving. The feeding and discharge tubes could have any

thickness of wall. But the tube that settles in the pump head should have 1.6 mm calibrated thickness of wall, with the

exception of pump head 1500 pump which uses tube 2.4 mm wall thickness.

2. - Insert feeding and discharge tubes in the terminals of the pump head.

Because the friction of the tubes with the rollers increases with the tube diameter, the adjustable minimum speed increases

as much as big is the tube.

5

Starting from the tube of 4,8 mm the necessary minimum speed is the following one: Tube 4,8 mm / 5%. Tube 6,4 mm/10%.

tube 8 mm/15%. It is convenient to lubricate the tubes lightly with silicone grease to use smaller speed and increase the life

tube.

It is not convenient to use very smaller speed although the motor starts up since in any moment it can stop and to cause a

excessive heating of the regulation circuit that could be damaged if it remains in this situation for a lot of time.

When you use two CF pump head simultaneously, the inside tube diameter could be limited up to 4.8 mm. ,

especially with t

high hardness tubes

Consult the table of dosages. Install the appropriate tube (see maintenance section).

Put ON the pump using the power switch located at the rear panel.

Control range flow by pump head and tube diameter. Pump heads 50 and CF-4r

Code rpm 0,5mm 0,8mm 1,6mm 3,2mm 4,0mm 4,8mm 6,4mm Tube Ø

1.9733.05/1.9734.05 30 0,1-0,8 0,3-2,0 1,5-9 4,3-30 6,8-48 10-67 15-100

Flow

ml/min

1.9738.00 80 0,4-2,5 1,1-6,3 4,2-30 13-94 20-147 25-210 36-250

1.9738.01/1.9738.17

1.9739.07

240

240

1,0-5,5

1,0-5,5

2,6-14

2,6-14

8-70

8-70

26-240

26-240

41-337

41-337

70-556

70-556

88-700

88-700

1.9733.04/1.9734.04 80 0,15-1,8 0,4-4,5 1-15 4-40 0,7-57

Control range flow by pump head and tube diameter. Pump heads CF-3r, 1500-2r and 5000-2r

Code rpm

0,5mm

0,8mm

mmm

1,6mm 3,2mm 4,0mm 4,8mm 6,4mm 8,0mm 9,6mm Tube Ø

1.9738.12

270

0,5-7,0 1,3-18 7,5-79 20-257 32-404 75-600 130-900 200-1300

Flow

ml/min

1.9738.24 270 - - - - - -

-

400-2000

1.9738.25 270 0,12-1,8 3-28 14-112 43-449 68-705 100-999 165-1725 240-2760 348-4025

Code Pumps-Specifications

Code

Model

Pump

Head

Timer

Motor

rpm

Weigh

Size cm

Article

1.9733.05 D25V2i 50-2r NO 30 5 32x26x14 Pump, 2 Pump Heads

↓1.9738.00 D25V2i 50-2r NO 80 5 32x26x14

1.9738.01 D25V2i 50-2r NO 240 5 32x26x14

1.9738.17 D25VT2i 50-3r YES 240 5 32x26x14

1.9738.12 D25V2i CF-3r NO 270 6 32x26x14

1.9738.24 D25V2i 1500-2r NO 270 6 26x34x27

1.9738.25 D25V2i 5000-2r NO 270 6 26x34x27

1.9734.05 D25V4i 50-2r NO 30 6 26x34x27 Pump, 4 Pump Heads

↓1.9739.00 D25V4i 50-2r NO 80 6 26x34x27

1.9739.01 D25V4i 50-2r NO 240 6 26x34x27

1.9733.04 D25VT2i CF-4r YES 80 5 32X26X14 Pump, 2 Pump Heads

1.9734.04 D25VT4i CF-4r YES 80 6 26X34X27 Pump, 4 Pump Heads

1.9739.07 D25VT6i 50-3r YES 240 8 53x40x23 Pump, 6 Pump Heads

The flows are approximate and refer to liquids of similar viscosity to the water.

Power: 100…240V 50/60Hz.

PUMPS D25VTXi with integrated digital cyclic timer and users of the Cyclic timer code 1.8119.00

DESCRIPTION OF DIGITAL TIMER

•

Memory EEPROM, without battery, free of maintenance.

•

With or without memorization of lapsed cycle.

•

Display LCD backlight.

•

Multimodes, 8 ways of work.

•

Multiranges 0.01 seconds ta 99.9 hours or 999.9 hours according mode.

•

Front Protection IP65.

6

GENERAL TECHNICAL CHARACTERISTICS

PHYSICAL CHARACTERISTICS

Display: L.C.D backlight of 8 digits.

Box: grey colour manufactured in UL 94 - V-0 Polycarbonate

Fixation in panel: With support by pressure.

Format: 48mm x 48 mm.

Weight: 170gr.

Hole in panel: 45 mm x 45 mm.

Protection: Frontal IP65.

Connector: UNDECAL.

MODES

Memory: EEPROM (without maintenance).

Inpout : 3 inpout optocoupled.

Modes of work : 4 modes of 1 time and 2 modes of 2

times for asymmetric cycle

.

Ranges: 8 selected by screen.

Output: contact relay commuted.

ENVIRONMENTAL CONDITIONS

Temperature of work:-10 ºC +55 º C

Relative humidity:< 85 %

OPERATION

Operation: 230 VAC, 110 VAC, 48VAC, 24 VAC.

24 VDC, 12 VDC.

Power: 2.3 VA.

Intensity of the realy contact:

AC1: 5A, 250V, AC15: 3A, 24V.

DC1: 5A, 24V, DC13: 2A, 24V

NORMATIVE

Conformity with CE rules: LVD 33/23/CEE.

EMC 89/336/CEE

PROGRAMMING OF THE SCALE( Range).

Push simultaneously SCALE and SET keys for enter to a programming screen in which you can select the scale and the

decimal comma.

If the first scale indicator has intermittence, indicates that it can modify. To select another scale (hours, minutes, seconds) it

is necessary to use the keys↑↓ and next with the key →the range is selected (units, tenth, hundredth). With F on screen

you can program the scale for the time of operation. Pulsing ESCALE appears L on screen and you will be able to program

the scale of the stop time.

To leave programming and to memorize, to pulse SET.

PROGRAMMING OF OPERATION AND REST TIMES

When pulsing ESCALE and SET keys simultaneously, we will be able to modify the value of the times. If the first digit this in

intermittence, indicates that it can modify. For selecting another digit it is necessary to use the keys with the indication →

and next to increase or to decrement with the keys↑↓.

With F on screen the time of operation can be programmed. Pulsing TIME you have on screen L and will be able to program

the rest period. To leave programming and to memorize data to push SET key.

MODE OF OPERATION

ASYMMETRIC OVERTURNED CYCLE

The apparatus, begins the first time activating the exit, when connecting the outburst contact or, this being connected when

giving tension.

When reaching the scheduled value (Ta) the exit is disabled and the apparatus begins the second time. When it reaches the

scheduled value (Tb) active the exit and the cycle begins again. If the operation is carried out with memory, when failing

tension the cycle it continued from the position in that the tension lack took place.

CHANGE TUBES

Press OF switch.

Pump head 50: remove the three screws. (page 2)

Pump head 1500: remove the two screws (page 3)

To take out the tube together with their terminals of fixation.

The new tube should be centered on the rollers to avoid that the rotor breaks it.

To take advantage of the slow turn of the rotor to introduce the new tube. It is avoided this way to force the motor-axis when

one tries to place the tube with the stopped rotor. Be careful not to pinch your fingers.

In general, new tubes can be stretched for the first 30 minutes of operation. If this occurs, tighten again to avoid

unexpected breakage. In order to detect the elongation or insufficient attachment of the tube to the pump head it is

useful to mark the tube with a pen.

OU TPUT REL AY

Ap proved b y

VD E

ÖV E

+

FI

48 14,5 63,5

88

10

2,5

48

44,7

7

Place again the cover.

Pump head CF, see “Description section”.

Pump head 5000, see “Description section”.

The supply and discharge tubes can have any thickness wall, but the tube that settles in the pump head should have a

calibrated thickness wall of 1,6 mm. and 2,4 mm for the pump head 1500.

All the pumps are supplied with medical /alimentary degree silicone tube according to FDA norms and USP. It can sterilise.

Range of use until 250ºC and half duration.

Other available materials are:

NORPREN: great resistance to acids and caustics.

FARMED: of long duration, FDA degree. Appropriate for discharges pressures.

FARMAPURE: Farmed with inside Teflon® coated. Full chemical compatibility.

TYGON: great resistance to the chemical inorganic products. Not toxic.

VITON: appropriate for acids, solvents. It supports 300 ºC.

PVC: resistant to the chemical products. Not toxic.

TYGON F-4040-A: resistant to petroleum products.

Codes for calibrated tube of 1.6 mm thickness wall, 1 meter.

Tube Ø 0,5 mm 0,8 mm 1,6 mm 3,2 mm 4,0 mm 4,8 mm 6,4 mm

Farmapure 1.8711.08 1.8711.16 1.8711.32 1.8711.48 1.8711.64

Farmed 1.8710.05 1.8710.08 1.8710.16 1.8710.32 1.8710.48 1.8710.64

Neoprene 1.8730.08 1.8730.16 1.8730.32 1.8730.48 1.8730.64

Norprene F 1.8740.16 1.8740.32 1.8740.48 1.8740.64

Norprene G 1.8750.16 1.8750.32 1.8750.48 1.8750.64

Silicon 1.8760.05 1.8760.08 1.8760.16 1.8760.32 1.8760.40 1.8760.48 1.8760.64

Tygon L 1.8770.16 1.8770.32 1.8770.48 1.8770.64

Tygon 4040 1.8780.32 1.8780.48

Viton 1.8790.16 1.8790.32 1.8790.48 1.8790.64

Codes for tubes and connectors. Pk of 5 units.

Tube Ø 0,5 mm+ 0,8 mm+ 1,6 mm 3,2 mm 4,0 mm 4,8 mm 6,4 mm

Farmapure 1.8717.08 1.8717.16 1.8717.32 1.8717.48 1.8717.64

Farmed 1.8715.05 1.8715.08 1.8715.16 1.8715.32 1.8715.48

Neoprene 1.8735.08 1.8735.16 1.8735.32 1.8735.48 1.8735.64

Norprene F 1.8745.16 1.8745.32 1.8745.48 1.8745.64

Norprene G 1.8755.16 1.8755.32 1.8755.48 1.8755.64

Silicon 1.8765.05 1.8765.08 1.8765.16 1.8765.32 1.8765.40 1.8765.48 1.8765.64

Tygon L 1.8775.16 1.8775.32 1.8775.48 1.8775.64

Tygon 4040 1.8785.32 1.8785.48

Viton 1.8795.16 1.8795.32 1.8795.48 1.8795.64

+Packs of 0,5 mm. and 0,8 mm. only for 3 units.

Connector codes with 1meter tube and 2 stainless steel capillaries for CF-3r or CF-4r heads

Tube, inside Ø 0,5mm 0,8mm

Farmed 1.8711.05 1.8711.08

Silicon 1.8761.05 1.8761.08

For connectors of CF-4r heads with 0,5 mm and 0,8 mm Ø tubes longer than 1meter acquire the tubes, see table, and the

capillaries code 1.0077.23, bag of 10 units, if required.

In the case of needing tubes with diameters greater than 0.8mm , see the tube table and acquire the tube and the white PP

connectors that are required:

White PP connector for Ø tubes between 1,6 and 4,0 mm Ø. Code 1.0077.22 in bag of 10 units

White PP connector for Ø tubes between 4,8 and 6,4 mm Ø. Code 1.0077.15 in bag of 10 units

Outside Tubes

Silicone, 3 x 5 mm., 1 meter. Cod: 1.8737.00 / Silicone, 5 x 10 mm. , 1 meter. Code 1.8738.00

8

IMPORTANT: The tubings for the pump head should be greased lightly with silicone grease

Fig. nr. 1

Figure nr. 1 shows from left to right the head cover(housing) 50 with tube

installed, a connection / tube representing all tubes from 1,6 to 6,4mm

diameter and a connection / tube corresponding to 0,5 and 0,8mm diameter

tubes provided of loading / unloading capillaries of stainless steel

MAINTENANCE / SPARES

Before proceeding to any exam or repair it is necessary to disconnect of the mains.

All initiative should be made by qualified personnel to avoid bigger wrongs.

Trust their apparatus to a technical service authorized by DINKO Instruments.

The motor and block of the dispenser pump don't require lubrication for what they don't have maintenance. It is convenient

to lubricate the rollers lightly with silicone grease.

The tubes should be replaced periodically to avoid the break.

Back plate 50. Code 1.0077.04 Press switch. Code 1.0015.09

Dial of potentiometer. Code 1.0062.07 Potentiometer 10 turns. Code 1.0062.06

Fan. Code 1.0042.01 Power board 4,5A. Code 1.8093.21

Foot switch. Code 1.9740.01 Power supply 75-24. Code 1.8093.17

Foot switch for T models Code 1.9740.02 Power supply 50-24. Code 1.8093.16

Housing 50. Code 1.0077.03 Pump head “CF” complementary. Code 1.0078.02

Motor 50,240 rpm. Code: 1.0077.01 Pump head CF-4r. Code 1.0078.22

Motor 50,80 rpm. Code 1.0077.10 Pump head “CF”. Code 1.0078.01

Motor 50,30 rpm. Code 1.0077.24 Pump head 5000.Code 1.0078.10

Motor CF-4r,80 rpm. Code 1.0079.02 Pump head with motor 1500. Code 1.0080.10

Motor CF/5000/1500, 270rpm. Code 1.0080.01 Rotor 50-3r. Code 1.0077.02

Rotor 50-2r. Code 1.0077.11

Tube for pump code 1.9748.15 with 1500 pump head (2.4 mm wall thickness)

Farmed tube 8,0mm inside diameter, wall thickness 2,4 mm. Code 1.8710.82

Important: Tubings for the pump head should be greased lightly with silicone grease

CHANGE FUSE

The fuse box is part of the supply base located at the rear of the pump. See figure.

Base

Fusible

Interruptor

I O

Base/Fuse /Switch ON-OFF

Prying with a screwdriver between the central part of the box holder and the top of the supply base to remove the fuse box.

The box is subject not removed completely. There are two fuses

Press the box inward to restore its original position.

Note

Disposal of Waste Electrical and Electronic Equipment by users in private households in the

the European Union.

This symbol on the product or on the packing indicates that this cannot be disposed of as household waste. You must

dispose of your waste equipment by handling it over to the applicable take-back scheme for the recycling of electrical and

electronic equipment. For more information about recycling of this equipment please contact your city office, the shop where

you purchased the equipment or your household waste disposal service. The recycling of materials will help to conserve

natural resources and ensure that it is recycled in a manner that protects human health and environment

9

WARRANTY

WHAT IS COVERED:

This product is guaranteed to be free of defect in workmanship and materials under normal use for a period of one year from

the date of purchase by the consumer. During the warranty period, the manufacturer will repair or, at their option, replace at

no charge a product that proves to be defective, provided you return the product, shipping prepaid, to an authorized service

center.

WHAT IS NOT COVERED:

Instruments subjected to misuse, buse, neglect or unauthorized repair or modifications will be excluded from this warranty.

Also excludes expendables, consumables. The liability of Dinko is limited to repair or replacement and in no event shall

Dinko be liable for any collateral or consequential damagages or loss

“CE” DECLARATION OF CONFORMITY

DINTER S. A. DINKO Instruments, c/ Encarnació, 123-125 / 08024-Barcelona

Declare that the products mentioned in attached list, to which this declaration relates, comply with the essential safety

requirements of the relevant European Directive.

- Low Voltage Directive D2006/95/CEE, of December 12, 2006

-Essential requirements of Annex I of Directive for Machinery 2006/42/CEE, of May 17, 2006

- Electromagnetic compatibility (EC), relative to the Directive for electromagnetic compatibility 2004/108/CEE, of

December 15, 2004

-Safety for electrical devices of measurement, control and laboratory use. Requirements concerning to CEM. EN 61326

-Safety rules for the electric devices of measurement, control and laboratory use. Part I. General requirements EN 61010-1

Mounting and connecting instructions defined in catalogues and technical data sheets must be respected by the user

Name: Joan A. Bravo Josep X. Sensada

Position: Technical Manager Quality Manager

Signature:

Peristaltic Pumps D-25VXi/D-25VTXi

10

OTHER DINKO APPARATUS

- Colorimeters

- Extractor for mince analysis

- Heater Metallic Blocks

- Heater Plates

- Infrared Ovens

- Kits for Water Analysis

- Magnetic Stirrers.

- Muffle Furnaces to 1200ºC

- Nephelometers

- Orbital Shakers

- Peristaltic Pumps

- Photometers

-Respirometers

- Rod Stirrers

- Rotary Stirrers

- Sand Baths

- Spectrophotometers

- Temperature Controllers

- Timers

-Trichinoscope

- Turbidimeters

- Turn Dishes

- Vacuum Pumps

DINKO

Instruments

c/ Encarnació,123 -125. 08024- Barcelona. Phone: + 34 93 284 69 62 / Fax +34 93 210 43 07

E-mail:

dinter@dinko.es www.dinko.es

Other manuals for D-25VXi

1

This manual suits for next models

1

Table of contents

Other DINKO Instruments Water Pump manuals

DINKO Instruments

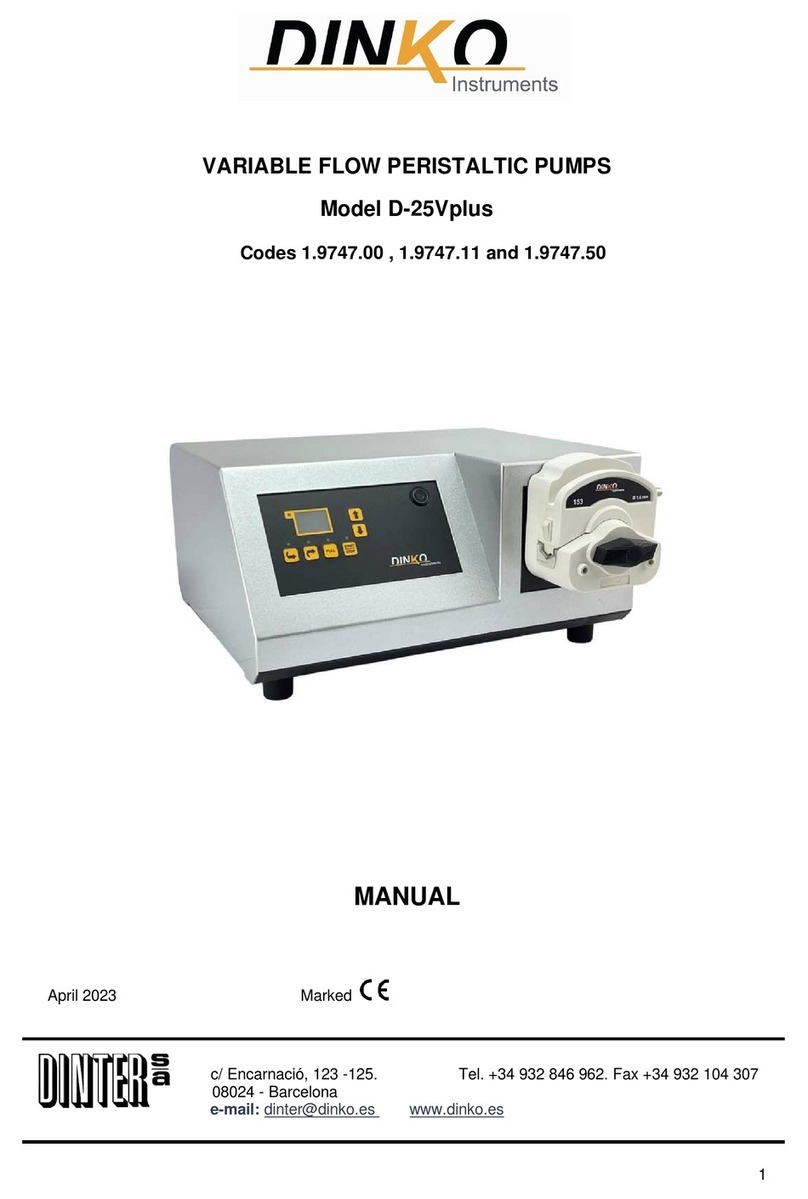

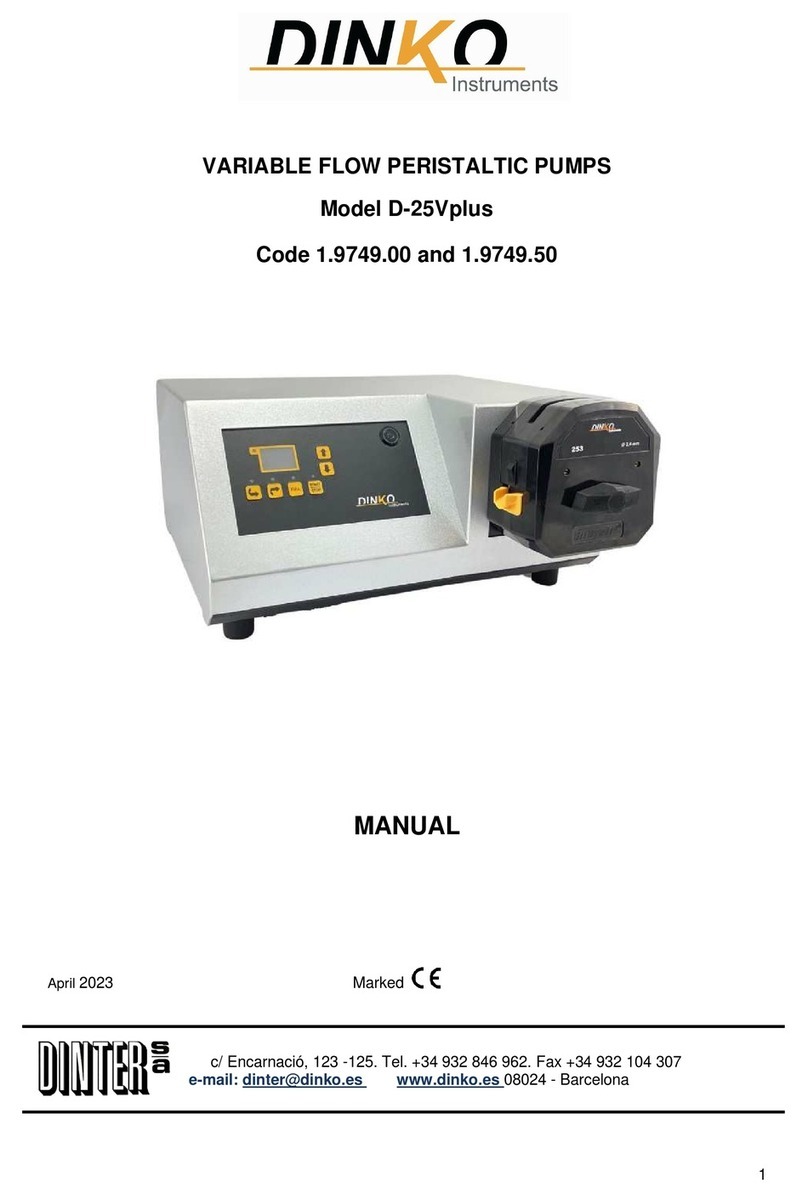

DINKO Instruments D-25Vplus 1.9747.00 User manual

DINKO Instruments

DINKO Instruments D-25VT User manual

DINKO Instruments

DINKO Instruments D-25Vplus 1.9747.00 User manual

DINKO Instruments

DINKO Instruments D-25Vplus 1.9747.00 User manual

DINKO Instruments

DINKO Instruments A-60-F User manual

DINKO Instruments

DINKO Instruments D-25VXi User manual