Most accidents occur because of a component

rupture. Be certain that any and all system

components will withstand the pressures being

developed. Never exceed the pressure rating of any

component installed in the system.

Weak, worn or damaged hoses are also a hazard.

Before each use check hose for signs of wear, leaks or

loose fittings. Tighten all fluid connections regularly

and replace weak or damaged hose. Your personal

safety and well being are at stake.

Before attempting any repairs or maintenance of this

product disconnect air supply and release oil line

pressure by squeezing hand piece/gun trigger.

Never allow any part of the human body to come

in front of or in direct contact with a material

outlet. Never point the nozzle of the gun at yourself or

anyone else.

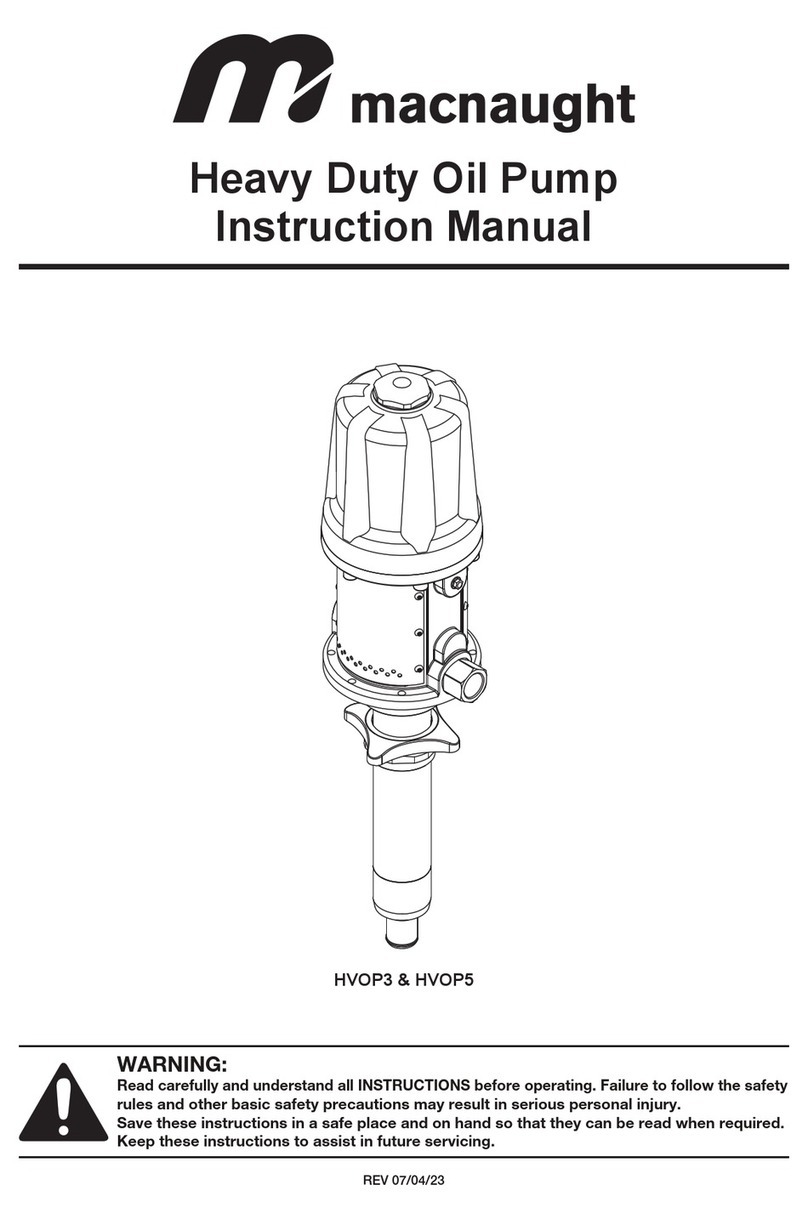

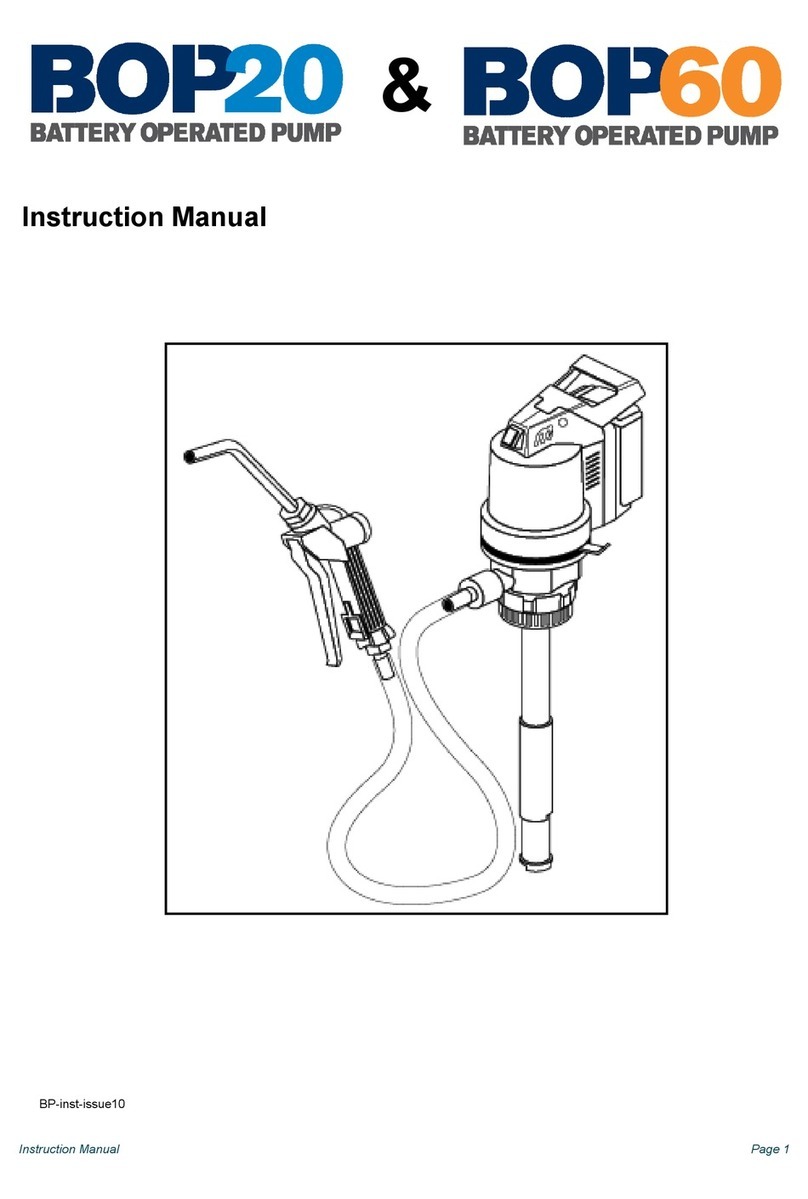

ASSEMBLY

1) Measure the depth of the drum/tank and attach

appropriate length of 1” BSP (1” NPT USA/Canada)

threaded pipe to the inlet of the pump (or use a

Macnaught suction tube kit TB25s).

2) Remove the bung adaptor assembly from the pump

and screw into drum/tank opening. Carefully lower

the pump through bung adaptor and tighten the clamp

screw located at the clamp sleeve.

Note: There is a wire mesh strainer located in the brass

air inlet. It is recommended that a micro-fine (5 micron)

in-line air filter is fitted to the air inlet to ensure maximum

efficiency of this pump.

3) Before connecting the air supply, the user should add

a ‘stop’ compressed air cock.

Note: The air cock must be a ¼ turn type (allowing quick

closure ) and should be located close to the body of the

pump and be easily recognised.

OPERATION

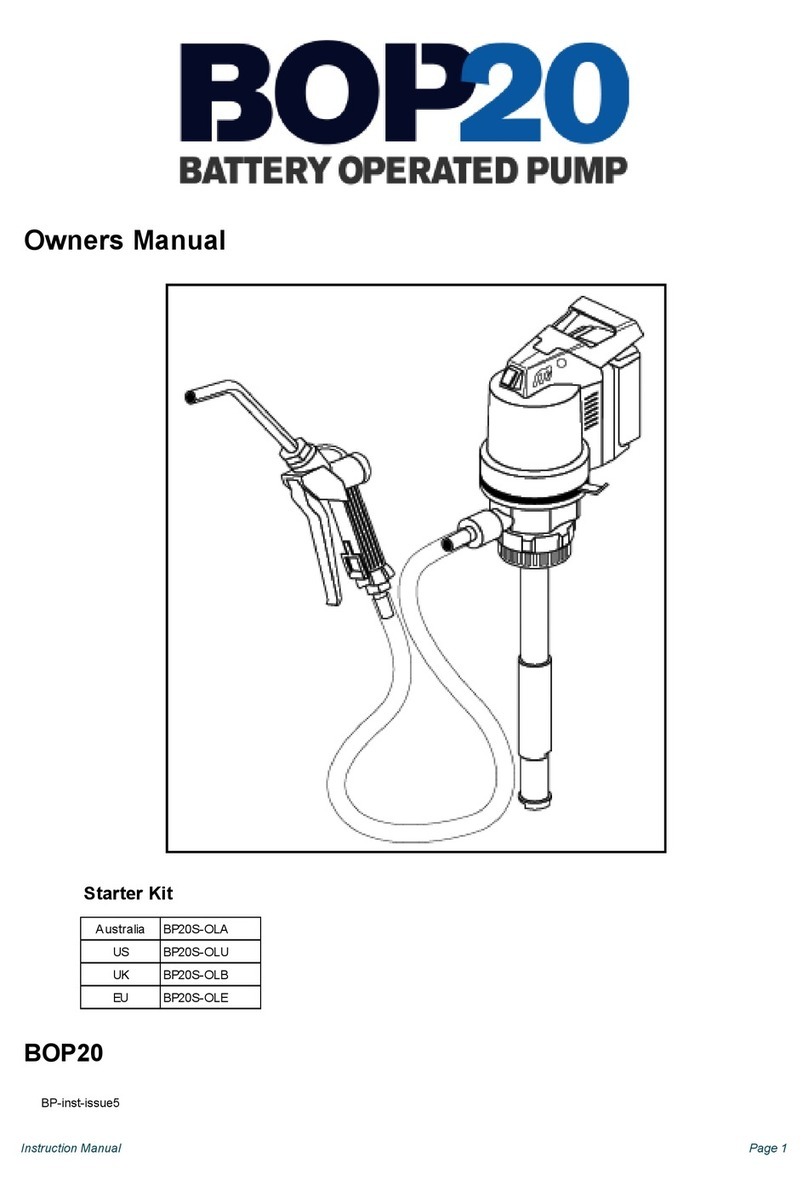

1) Ensure that the drum or tank is ‘vented’.

2) Partially open the on/off air valve. The pump will

prime automatically.

3) Open the oil delivery outlet/nozzle. The pump will

automatically start.

4) Adjust on/off air valve to regulate the flow. Close

delivery outlet/nozzle to stop flow.

Caution! Do not run the pump dry. Remember to switch

air supply off if not using the pump for an extended period

e.g. at the end of each working day.

MAINTENANCE

Before carrying out any maintenance disconnect the air

supply and release the fluid pressure in the system.

Inspect your oil pump weekly for any signs of damage.

Replace any suspect or damaged parts/components as

required.

Every 2 weeks (or sooner if the pump is used every day)

apply a few drops of light oil to the air inlet of the pump.

(Sewing machine oil is ideal).

PUMP DISASSEMBLY

1) Remove oil hose from the pump unit.

2) Withdraw pump from the oil drum/tank. Use a clean

bench to carry out maintenance.

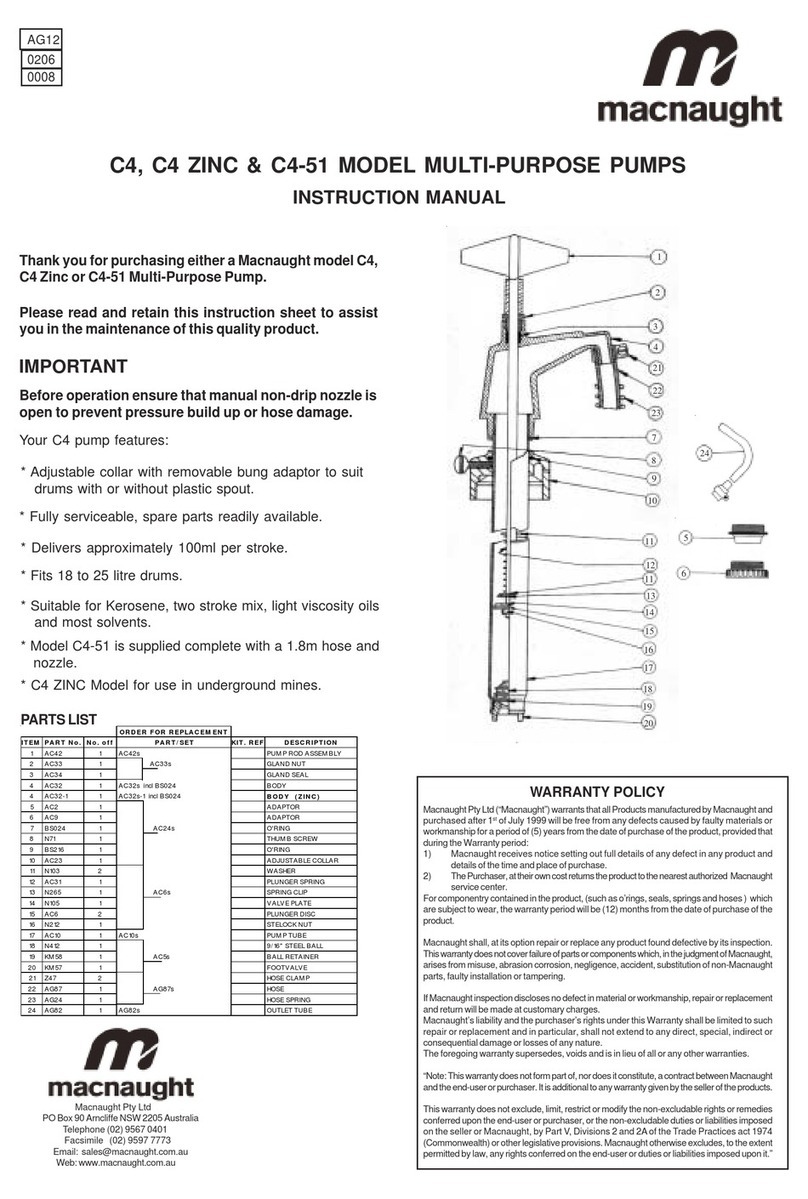

3) Remove the 4 screws (19) holding cylinder (7) to base

(14). Lever the cylinder off the base. There is a slot in

the base near the valve body (31).

4) Remove the cover screw (6) and valve body cover

(33).

5) Remove the 6 screws (35) holding the valve body (31)

to the cylinder (7). Remove the valve body assembly

and valve gasket (29).

6) Pull out the 2 brass pins (34) from the valve body.

Lever out the valve plugs (30) and (39).

7) Gently push the spool (36) out of the valve body. Be

careful when removing the O-Rings (5) and (38).

8) Remove top (long) poppet valve assembly (2), (3), (4)

and O-Rings (1), (5) and the bottom (short) poppet

valve assembly (28), (32) (3) and O’Rings (1) (5).

9) Hold hex section foot valve (27) horizontally in a vice.

Hold air piston firmly and unscrew allen head screw

(8). Remove screw and piston from piston rod.

10) Carefully unscrew the foot valve and pump cylinder

assembly (24), (25), (26) (27) from cylinder base

(14).

11) Withdraw the piston and piston road assembly from

the cylinder base.

12) Clean and inspect all parts. Replace any suspect or

worn or damaged parts.

PUMP REASSEMBLY

1) Ensure that all parts have the correct orientation. If

parts are assembled upside down, the pump will not

work. Check the parts diagram for correct orientation.

2) Apply thread sealant (Loctite or similar) to pump

cylinder thread (24) when reassembling the unit.

3) Assembly of the pump is a reversal of the disassembly

procedure.

4) Ensure that all O-Rings, particular in the valve body

(31) and poppet valve (2), (28) areas sit square.

5)Apply light grease (eg Petroleum Jelly) to O-Rings (17),

(43) and piston seals (11) before fitting cylinder (7) to

base (14).

6) Fit the pump to your oil drum/tank and reconnect

the oil hose and air supply. Open dispensing nozzle

to ensure correct operation.

WARNING