Dirty hand 103879 User manual

SNOW THROWER

is safety alert symbol identies important safety messages in

this manual. Failure to follow this important safety information

may result in serious injury or death.

MODELS # 103879 & 103880

Operation Manual

!

Part # 104459 Rev B

1100 W 120th Ave, Suite 600

Westminster, CO 80234 • 720-287-5182

For Service or Questions

Call 1-877-487-8275

720-287-5182

www.dirtyhandtools.com

Dirty Hand Tools® is a brand of

Table of Contents

Important Safety Information .....................................................4

Unpacking and Setup .....................................................................7

Assembly ........................................................................................8

Filling with Gasoline and Oil.......................................................10

Operation Precautions..................................................................11

Operation Controls ......................................................................13

Operation .....................................................................................14

Maintenance.................................................................................16

Troubleshooting ...........................................................................24

Storage .........................................................................................27

Warranty and Specifications.......................................... Back Cover

3

Important Safety Information

WARNING: Read and thoroughly understand all instructions

and safety information before operating this Snow thrower. Failure

to do so may cause serious injury or death. Do not allow anyone

to operate this Snow thrower who has not read this manual. As

with all power equipment, a snow thrower can be dangerous if used

improperly. Do not operate this snow thrower if you have doubts or

questions concerning safe operation.

Call our customer service department at 720-287-5182,

1-877-487-8275, or visit www.dirtyhandtools.com if you have any

questions or concerns about the safe operation of this equipment.

Intended Use

Do Not Use the Snow thrower for any purpose other than for

which it was designed. Any other use is unauthorized and may

result in serious injury or death.

Personal Protective Equipment

Wear ANSI-approved safety goggles, heavy-duty work boots

and gloves during set up and operation. While this snow thrower

operates at a relatively low noise level, about 74dB, you may want

to wear ear plugs or noise deafening headphones.

A SNOW THROWER IS CAPABLE OF AMPUTATING

HANDS AND FEET AND THROWING OBJECTS.

FAILURE TO OBSERVE THE SAFETY INSTRUCTIONS

COULD RESULT IN SERIOUS INJURY OR DEATH.

4

!

WARNING

!

DANGER

!

DANGER

5

Important Safety Information

General Safety

Failure to follow warnings, cautions, assembly and operation

instructions in the Operation Manual may result in serious injury

or death.

READ THE OPERATION MANUAL BEFORE

OPERATION.

• Do not permit children to operate this equipment at any time. Do

not permit others that have not read and understood the complete

Operation Manual to operate this equipment.

• Do not operate the snow thrower when under the influence of

alcohol, drugs or medication.

• Do not allow a person who is tired or otherwise impaired or not

completely alert to operate the snow thrower.

NEVER place ngers, hands, or body near the snow thrower

when it is running. Do not lean or reach over the snow thrower.

Do not aim the discharge at a person or animal.

• Keep all safety guards in place and in proper working order.

• Keep all people (except the operator) a minimum of 25 feet from

the snow thrower during operation.

• Do not transport the snow thrower with the engine running.

• Do not tilt the machine while the engine is running.

• Do not leave the snow thrower unattended when it is running.

Turn off the engine before leaving the area.

• Never run the engine in an enclosed area or without proper

ventilation as the exhaust from the engine contains carbon

monoxide, which is an odorless, tasteless, and deadly poisonous.

• Fill the gasoline tank outdoors with the engine off and allow the

engine to cool completely.

• Do not operate the engine with the air cleaner or cover over the

carburetor air-intake removed, except for adjustment. Removal of

such parts could create a fire hazard.

• e muer and engine become very hot with use and can cause

a severe burn; do not touch. Allow the engine to cool before

refueling, doing maintenance, or making adjustments.

!

DANGER

!

DANGER

6

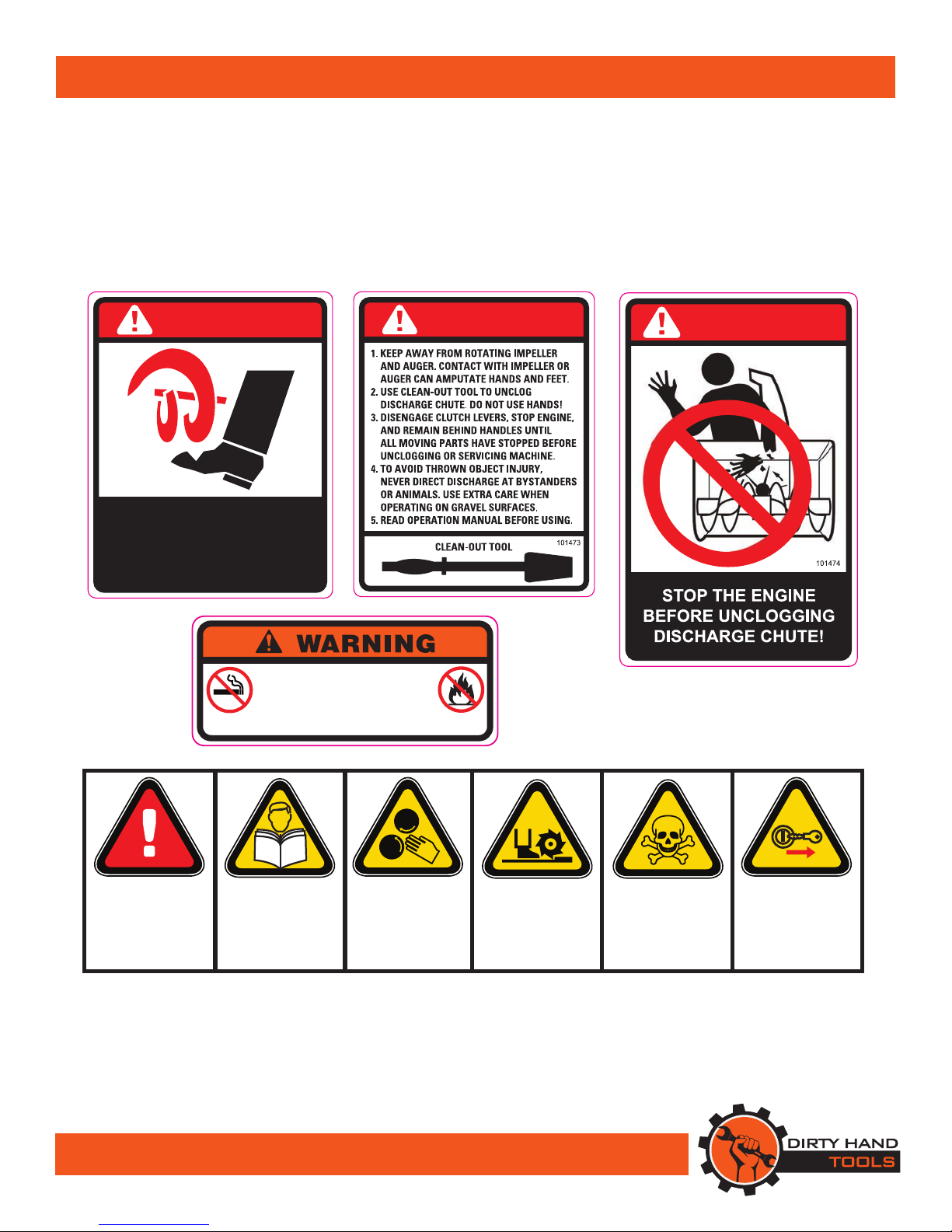

Important Safety Information

Safety Decals

Safety labels on the snow thrower are to remind you of

important information while you are operating the unit.

Make sure all safety warning decals are attached and in

readable condition. Replace missing or defaced decals. Contact

Dirty Hand Tools at 1-877-487-8275 for replacement decals.

DANGER

AVOID INJURY FROM

ROTATING AUGER!

KEEP HANDS, FEET

AND CLOTHING AWAY!

101471

DANGER

DANGER

To prevent serious injury and fire:

1. Do not add fuel while the engine is running

or when the engine is hot.

2. Do not smoke while filling with fuel.

3. Do not overfill.

Use only fresh gasoline. Empty fuel before storage. 101068

READ

OPERATION

MANUAL

BEFORE USE

REMOVE

KEY

BEFORE

ADJUSTING

DO NOT USE

HANDS TO

UNCLOG

SNOW

WARNING

USE CAUTION

WHEN

OPERATING

KEEP HANDS

AND FEET

AWAY

DANGER

CO2POISON

DO NOT USE

INDOORS

7

Unpacking and Setup

Your snow thrower requires some assembly. Save the packing

materials and box for future use as a storage container.

COMPLETELY READ AND UNDERSTAND THE

OPERATOR’S MANUAL BEFORE ATTEMPTING TO

OPERATE THE SNOW THROWER.

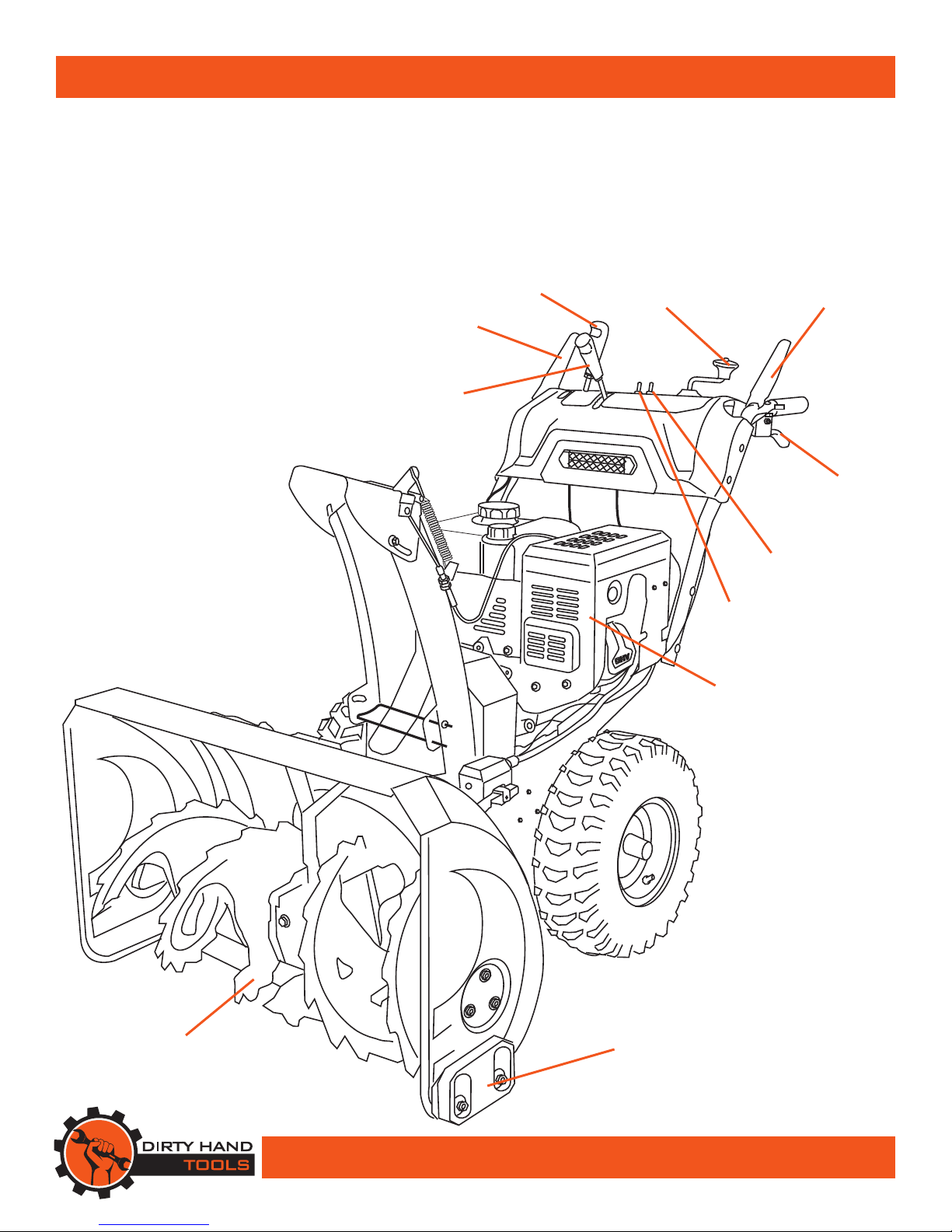

DRIVE

CONTROL

LEVER

AUGER

CONTROL

LEVER

CHUTE TILT

CONTROL

CHUTE

DIRECTION

CONTROL

ADJUSTABLE

SKID

SHOE

SHIFT

LEVER

AUGER

MUFFLER

LIGHT

SWITCH

HEATED HANDLE

SWITCH

DIFFERENTIAL

LEVER

8

Assembly

Handlebar and Shift Contol Assembly

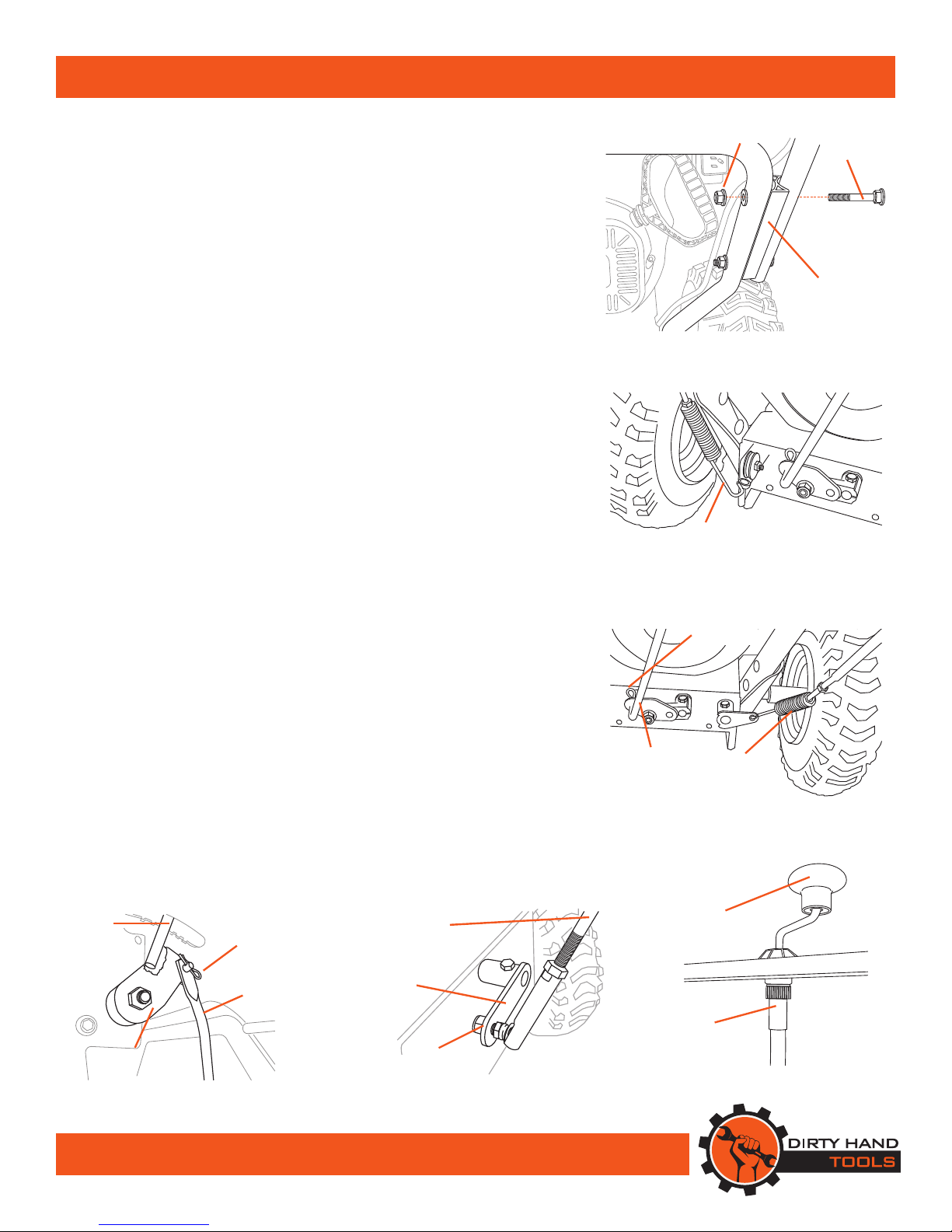

1. Hex bolts and nylon lock nuts have been provided in a hardware

package. Align the two holes in the handlebar connector block with

the two holes in the upper and lower handlebars assemblies on the

snow thrower. Push hex bolts through from the outside and secure

with a nylon lock nut on the interior in two places on both sides of

the snow thrower. Tighten securely (see Figure 1).

2. Attach the drive wire on the le side of the snow thrower (see Figure

2). Remove the R-Clip that connects the drive wire to the control

lever on the handlebars, then slip the wire o. Attach the other end

of the drive wire with the spring mechanism to the connection ring

and reattach the drive wire to the control lever reinserting the R-clip.

Aer connecting the wire adjust the tension. e wire should be

taught when connected. (See Control Wire Adjustment, page 23).

3. Attach the auger wire on the right side of the snow thrower (see

Figure 3). Remove the R-clip that connects the auger wire to the

control lever on the handlebars, then slip the wire o. Attach

the other end of the auger wire with the spring mechanism to

the connection and reattach the auger wire to the control lever

reinserting the R-clip. Aer connecting the wire adjust the tension.

e wire should be taught when connected. (See Control Wire

Adjustment, page 23).

4. Attach the gear shi rod to the rocker arm on the under side of the

contol panel and secure with a cotter pin (see Figure 4).

5. Attach the other end of the gear shi control rod to the rocker arm

on the rear of the snow thrower (see Figure 5). Pass the attachment

bolt on the control rod through the hole in the rocker arm and secure

with a nylon lock nut.

Attaching the Chute Direction Control Cable

1. Attach the chute direction control cable to the chute direction

handle by threading onto the recptacle underneath the control panel

(see Figure 6).

Attaching the Shift Lever Handles

1. read the shift lever handles on to the shift lever rods, one for the

speed shift and one for the tilt control.

HEX

BOLT

Figure 1

NYLON

LOCK NUT

HANDLEBAR

CONNECTING

BLOCK

ROCKER

ARM

Figure 4

COTTER

PIN

GEAR

SHIFT

CONTROL

ROD

Figure 5

CONTROL

ROD

ROCKER

ARM

NYLON

LOCK NUT Figure 6

CONTROL

CABLE

CHUTE

DIRECTION

CONTROL

HANDLE

DRIVE

WIRE

Figure 2

AUGER

WIRE

Figure 3

SPEED

SHIFT ROD

R-CLIP

9

Assembly

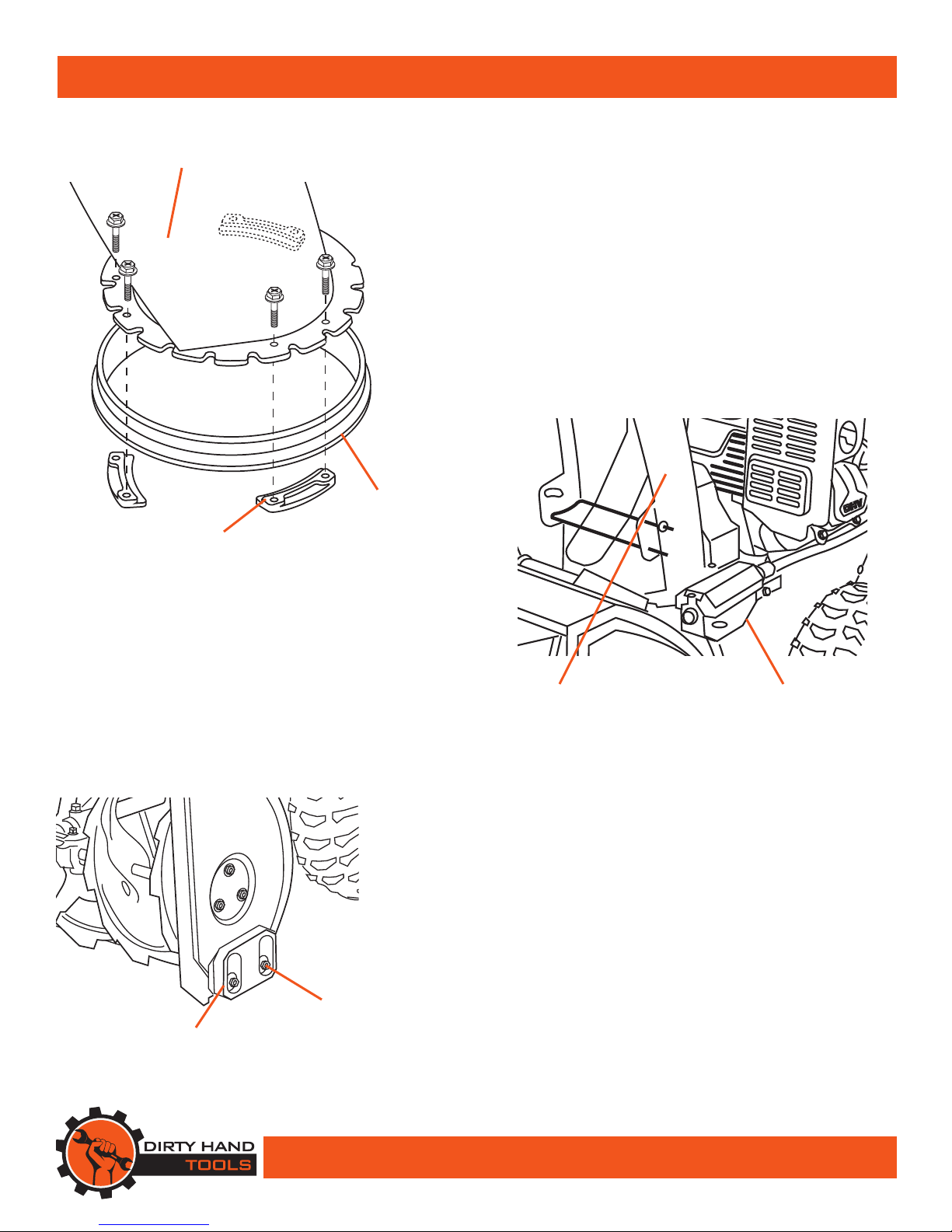

Attaching the Discharge Chute

1. Attach the discharge chute to the snow thrower by placing

it on the chute seat on the snow thrower. Position the flange

keeper beneath the chute seat lip. Align the two holes in the

chute and two holes in the flange keeper and secure with two

bolts from the top side (see Figure 7). Repeat in three locations

to attach the discharge chute to the snow thrower.

2. Attach the chute crank bracket aligning the chute notches with

the spiral end of the chute directional control assembly (see

Figure 8). Lubricate both ends of the chute directional control

crank with petroleum jelly, paraffin wax, or light machine oil.

SKID

SHOE

HEX NUT

(2 PLACES)

Adjusting the Skid Shoes

1. Position the skid shoes based on surface conditions. Adjust

upward for hard-packed snow. Adjust downward when

operating on gravel or crushed rock surfaces. Loosen the two

hex nuts that retain the skid shoe in place and move up or

down as desired, then retighten the lock nuts (see Figure 9).

Repeat for the opposite side of the snow thrower.

Figure 9

CHUTE

SEAT

DISCHARGE

CHUTE

Figure 7

FLANGE

KEEPER

CHUTE DIRECTIONAL

CONTROL

DISCHARGE

CHUTE

Figure 8

10

Filling with Gasoline and Oil

FUEL IS HIGHLY FLAMMABLE AND POISONOUS

ALWAYS FILL THE TANK WITH

ENGINE OFF AND COOL.

ALWAYS CHECK THE FUEL LEVEL

BEFORE OPERATING.

Allow the engine to cool for at least two minutes before

removing the fuel cap.

1. Place the snow thrower on a level surface outdoors to fuel.

2. e fuel tank holds approximately 1.1 gallons of fuel. 87+

octane unleaded gasoline is recommended. Do not fill above

the top of the fuel filter. Replace the fuel cap securely and wipe

any excess from the fuel tank before starting the snow thrower.

DO NOT REFUEL INDOORS OR NEAR ANY SOURCE

OF POSSIBLE COMBUSTION.

DO NOT SMOKE WHILE FUELING.

DO NOT OVERFILL.

THE SNOW THROWER IS SHIPPED WITHOUT

FLUIDS. YOU MUST ADD OIL BEFORE STARTING

THE ENGINE.

3. Add engine oil to the upper level of the oil filler hole. SAE

10/30 motor oil is recommended for most environmental

conditions. e oil capacity is 1 quart (0.95L).

Note: Do not thread the dipstick in when checking the oil level.

!

WARNING

!

WARNING

WARNING

GASOLINE

FUEL ONLY!

DO NOT USE

DIESEL FUEL 101120

101071

101127

To prevent serious injury and fire:

1. Do not add fuel while the engine

is hot or running.

2. Do not smoke while filling with fuel.

3. Do not overfill.

Empty fuel before storage.

11

Operation Precautions

COMPLETELY READ AND UNDERSTAND THIS

MANUAL BEFORE ATTEMPTING TO OPERATE

THE SNOW THROWER

1. Keep all safety guards in place and in proper working order at

all times.

2. NEVER place fingers, hands, or body near the snow thrower

when it is running. Do not lean or reach over the snow thrower

when the machine is running.

STOP THE ENGINE TO UNCLOG THE DISCHARGE

CHUTE. NEVER USE YOUR HAND TO CLEAN OUT

THE DISCHARGE CHUTE OR AUGERS.

3. Always stop the engine to dislodge snow from the discharge

chute or from the augers. Wait ten seconds for the augers to

stop rotating. Never use your hands to clear out the augers or

discharge chute. Always use the clear-out tool provided or a

similar tool.

4. Keep all people (except the operator) a minimum of 25 feet

from the snow thrower during operation.

5. Always aim the discharge chute away from people and animals.

6. Do not leave the snow thrower unattended when it is running.

Turn off the engine before leaving the area.

7. Do not use this piece of equipment while tired or under the

influence of drugs, alcohol or medication.

8. Parts, especially exhaust system components, get very hot

during use. Stay clear of hot parts.

9. Use extra caution when operating on gravel or other loose

material.

!

DANGER

!

DANGER

12

Operation Precautions

DISENGAGE ALL CONTROL LEVERS AND

STOP THE ENGINE BEFORE YOU LEAVE THE

OPERATING POSITION.

Wait until the auger/impeller comes to a complete stop

before unclogging the chute assembly, making any

adjustments, or inspections.

1. Exercise caution to avoid slipping or falling, especially

when operating in reverse.

2. oroughly inspect the area where the equipment is to be

used. Remove all foreign objects, which could be tripped

over or thrown by the auger/impeller.

3. Always wear safety glasses or eye shields during operation

and while performing an adjustment or repair to protect

your eyes.rown objects which ricochet can cause serious

injury to the eyes.

4. Operate the equipment with appropriate footware, gloves

and clothing. Avoid loose fitting clothing that can get

caught in moving parts.

5. After striking a foreign object, stop the engine, remove

the wire from the spark plug, thoroughly inspect the snow

thrower for any damage, and repair the damage before

restarting and operating the snow thrower.

6. e auger and drive controls must be depressed to operate.

Do not override this safety feature. Both control levers

must operate easily and automatically return to the

disengaged position when released.

7. Do not overload the snow thrower by attempting to clear

snow too quickly.

8. Do not operate at high speed on icy or slippery surfaces.

9. Always be sure of your footing especially when driving in

reverse.

10. If the snow thrower should vibrate abnormally, stop the

engine immediately, disconnect the spark plug and inspect

for damage

!

CAUTION

13

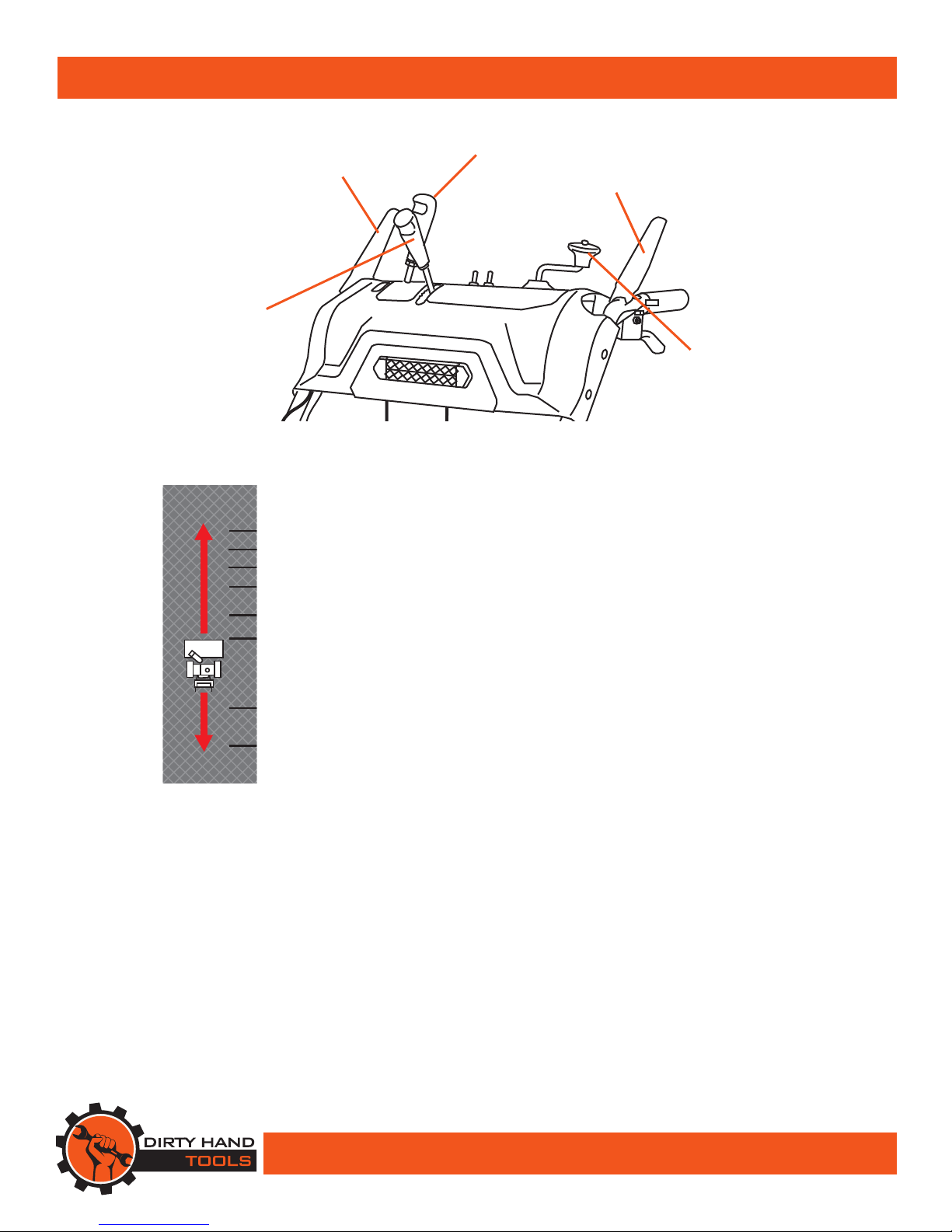

Operation Control

Shift Lever

e shift lever controls the direction of travel and ground speed.

ere are six forward speeds. Position one (1) is the slowest and

position six (6) is the fastest. ere are two reverse (R) speeds.

Drive Control Lever

e drive control is located on the left handle. e drive control

engages the transmission and propels the snow thrower forwards

or backwards. Select forward or reverse and the speed before

depressing the drive control. Squeeze the control grip against the

handle to engage the wheel drive. Release to stop.

Auger Control Lever

e auger control is located on the right handle. e auger control

engages the rotating auger and pushes snow upwards through the

discharge chute. Squeeze the control grip against the handle to

engage the augers and start snow throwing. Release to stop.

Chute Direction Control

Rotate the discharge chute control to the direction that snow will

be thrown.

Chute Tilt Control

e chute tilt control can be moved backwards to throw snow

farther away from the machine or forwards to throw snow closer.

SHIFT

LEVER

AUGER

CONTROL

LEVER

DRIVE

CONTROL

LEVER

Figure 10

LIGHTS HEAT

6

5

4

3

2

1

R1

R2

READ

OPERATION

MANUAL

BEFORE USE

REMOVE

KEY

BEFORE

ADJUSTING

DO NOT USE

HANDS TO

UNCLOG

SNOW

WARNING

USE CAUTION

WHEN

OPERATING

KEEP HANDS

AND FEET

AWAY

DANGER

CO2POISON

DO NOT USE

INDOORS

CHUTE

TILT

FORWARD

REVERSE

CHUTE

DIRECTION

103895

CHUTE TILT

CONTROL CHUTE

DIRECTION

CONTROL

ere are six forward speeds

and two reverse speeds. Release the

drive control lever when changing

speeds or direction.

14

Operation

FILL WITH OIL BEFORE STARTING

Make sure the auger control and drive control are in the

disengaged (released) position.

Recoil Starter

1. To start a cold engine, move the choke to the CHOKE

position (to the left). To restart a warm engine, leave the

Choke in the RUN position (to the right). (See Figure 11).

2. Push the ignition key all the way in. Push the primer two or

three times for cold engine start, making sure to cover vent

hole in the center of the primer when pushing. DO NOT

use primer to restart a warm engine after a short shutdown.

Additional priming maybe necessary if the temperature is

below 15° Fahrenheit.

3. Open the fuel valve by moving to the ON position.

4. Slide the throttle 1/3 of the way to the right.

5. Grip the recoil starter handle and pull slowly several times

to allow the gasoline to flow into the engine’s carburetor.

en pull the recoil starter handle gently until resistance

is felt. Allow cable to retract fully and then pull it quickly.

Repeat until the engine starts.

6. Allow the engine to run for several seconds. e engine

will not develop full power until it reaches the operating

temperature.en move the choke lever slowly to its RUN

position (to the right). Moving the choke lever too fast

could stall the engine.

7. Adjust the throttle as needed (see Figure 12).

Electric Starter

1. Connect extension cord to the starter outlet on the engine

and into a 120V AC outlet (see Figure 13).

2. Push the ignition key all the way in.

3. Slide the choke lever to the CHOKE position (left).

4. Slide the throttle 1/3 of the way to the right.

5. Push the electric starter button and hold for no more than

10 seconds at a time, until the engine runs.

6. Move the choke lever to the RUN position (right).

7. Adjust the throttle as needed.

!

CAUTION

Figure 11

CHOKE THROTTLE

FUEL

VALVE

Figure 13

ELECTRIC

STARTER

BUTTON

PRIMER

BUTTON IGNITION

KEY

RECOIL

STARTER

Figure 12

STARTER

OUTLET

THROTTLE

FUEL

VALVE

15

Operation

Engaging the Drive and Auger Controls

1. With the throttle control in the fast position, move shift lever

into one of the six forward (F) or two reverse (R) positions.

Select a speed appropriate for the snow conditions and a pace

you’re comfortable with. When selecting a drive speed, use

slower speeds until you are familiar with the operation of the

snow thrower.

2. Squeeze the auger control against the handle and the auger

will turn. Release it and the augers will stop.

3. Squeeze the drive control against the handle and snow

thrower will move. Release it and drive motion will stop.

Do not reposition the shift lever

(change speeds or direction of travel)

without rst releasing the drive control

and bringing the snow thrower to a complete stop.

Shifting between speeds or directions while the drive control is

is engaged will result in premature wear

to the snow thrower’s drive system.

4. Release both the auger control and the drive control to

redirect the discharge chute.

5. To move from forward to reverse, release the drive control

and the auger control and allow the rotating augers to stop

before moving the shift lever to a new position.

6. ALWAYS release the auger and drive control and turn the

engine off before dislodging snow accumulation from the

augers or unclogging the discharge chute. ALWAYS use the

clean-out tool provided. NEVER use your hands at any time

to dislodge snow form the augers or unclog the discharge

chute.

Dierential Traction Control (Model 103880)

For easy turning when using the snow thrower, use the red

differential lever (see Figure 14). Engaging the differential lever

releases the right traction wheel, but allows the left wheel to

continue driving. Releasing the differential lever automatically

engages both drive wheels for full traction.

NOTE: e differential lever will be more difficult to activate

under a heavy load. Activate the lever before beginning a turn.

!

CAUTION

Depress

Differential Lever

for Turning

Figure 14

16

Maintenance

BEFORE PERFORMING ANY MAINTENANCE

PROCEDURE STOP THE ENGINE, WAIT FIVE 5

MINUTES TO ALLOW ALL PARTS TO COOL.

Disconnect the spark plug wire,

keeping it away from the spark plug.

Regular maintenance is the way to ensure the best performance

and long life of your machine. Please refer to this manual and the

engine manufacturer’s owner’s manual for maintenance procedures.

!

WARNING

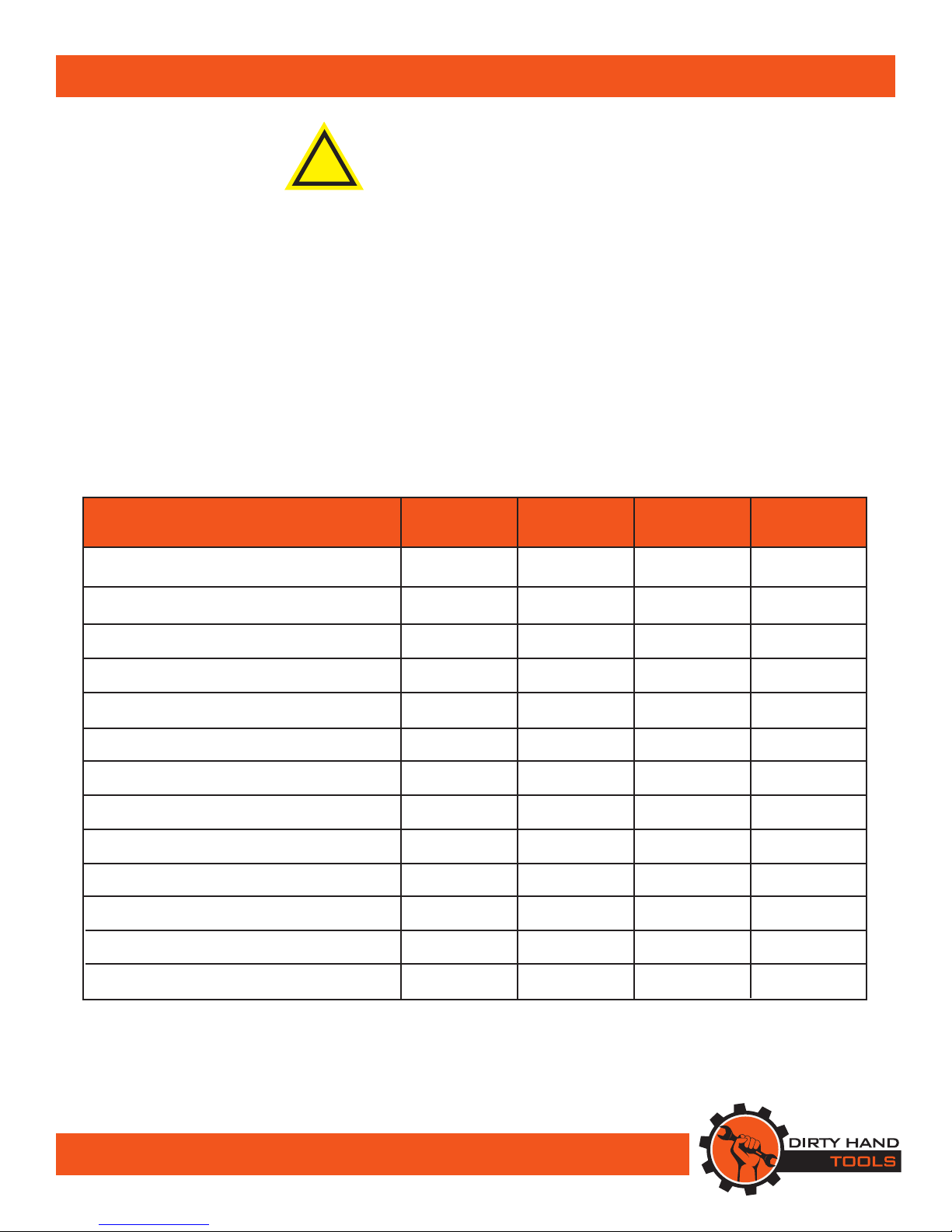

Maintenance Before Monthly/ Every 6 Mo./ Annually/

Procedure Each Use 20 Hours 100 Hours 300 Hours

Check Engine Fuel Level X X X X

Check General Equipment Condition X

Lubricate Gear Shaft & Auger Shaft X X X

Lubricate Wheels & Discharge Chute X

Check Air Cleaner X X X

Check Fuel Strainer X X X

Clean/Replace Air Filter X X X

Check/Clean Spark Plug X X

Check/Adjust Idle Speed X X

Check/Adjust Valve Clearance X X

Clean Fuel Tank, Strainer & Carburetor X X

Clean Combustion Chamber* X

Replace Fuel Lines* X

Maintenance Checklist

* Service performed by qualified technician

17

Maintenance

TO PREVENT SERIOUS INJURY FROM

ACCIDENTAL STARTING TURN THE POWER

SWITCH OF THE ENGINE TO ITS “OFF” POSITION.

Wait for the engine to cool, and remove the spark plug wire

before performing any inspection, maintenance, or cleaning

procedures.

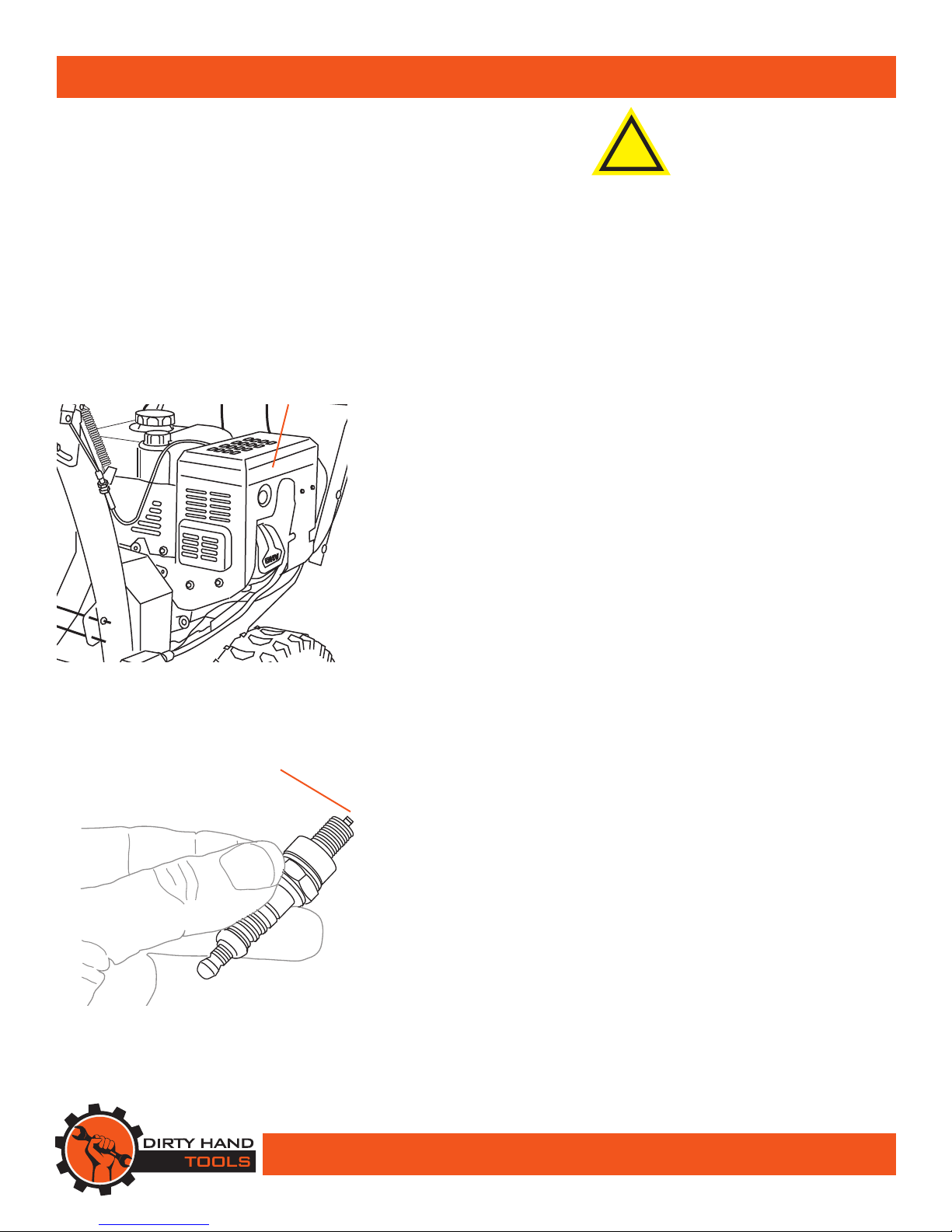

Changing /Cleaning the Air Filter

1. Wipe off the air cleaner cover. Loosen the knob at the bottom

of the air cleaner housing (see Figure 15).

2. Remove the air cleaner filter.

3. Wash the air filter in warm water and mild detergent several

times. Rinse. Squeeze out excess water and allow it to dry

completely. Soak the filter in lightweight oil briefly, then

squeeze out the excess oil.

4. Install a new air filter or reinstall the cleaned air filter. Secure

the air cleaner cover before use.

Spark Plug Maintenance:

1. Disconnect spark plug wire from end of plug. Clean out debris

from around the spark plug.

2. Using the spark plug wrench provided, remove the spark plug.

Inspect the spark plug. If the electrode is oily, clean it using

a clean, dry rag. If the electrode has deposits on it, polish it

using emery paper. If the white insulator is cracked or chipped,

replace the spark plug.

3. When installing a new spark plug, adjust the plug’s gap to the

specication on the technical specication chart. Do not pry

against the electrode or the insulator, the spark plug can be

damaged (see Figure 16).

4. Install the new spark plug or the cleaned spark plug into the

engine. Gasket style spark plugs should be nger-tightened

until the gasket contacts the cylinder head, then turned about

1/2 to 2/3 more rotation. Non-gasket-style spark plugs should

be nger-tightened until the plug contacts the head, then

about 1/16 turn more.

!

WARNING

Figure 15

AIR

CLEANER

COVER

Figure 16

Spark Plug Gap

0.028”~ 0.031”

18

Maintenance

OIL IS VERY HOT DURING OPERATION AND CAN

CAUSE BURNS. WAIT FOR ENGINE TO COOL

BEFORE CHANGING OIL.

Wait for the engine to cool, and remove the spark plug wire

before performing any inspection, maintenance, or cleaning

procedures.

Changing the engine oil

1. Make sure the engine is stopped and is level.

2. Close the fuel valve.

3. Place a drain pan underneath the crankcase’s drain plug.

4. Remove the drain plug and, if possible, tilt the crankcase

slightly to help drain the oil out.

5. Replace the drain plug and tighten it.

6. Clean the top of the dipstick and the area around it. Remove

the dipstick by threading it counterclockwise, and wipe it off

with a clean lint free rag.

Note: Do not thread the dipstick in when checking the oil level.

7. Add the appropriate type of oil until the oil level is at the full

level. SAE 10W-30 oil is recommended for general use for

temperatures above 32°F. Use SAE 5W-30 for temperatures

consistently below 32°F.

8. read the dipstick back in clockwise.

DO NOT RUN THE ENGINE WITH TOO LITTLE

OIL. THE ENGINE WILL BE PERMANENTLY

DAMAGED.

!

WARNING

!

WARNING

SAE VISCOSITY GRADES

AVERAGE OUTSIDE TEMPERATURE

30W

10W - 30W

5W - 30W

-20 0 20 40 60 80 100°F

19

Maintenance

LUBRICATION

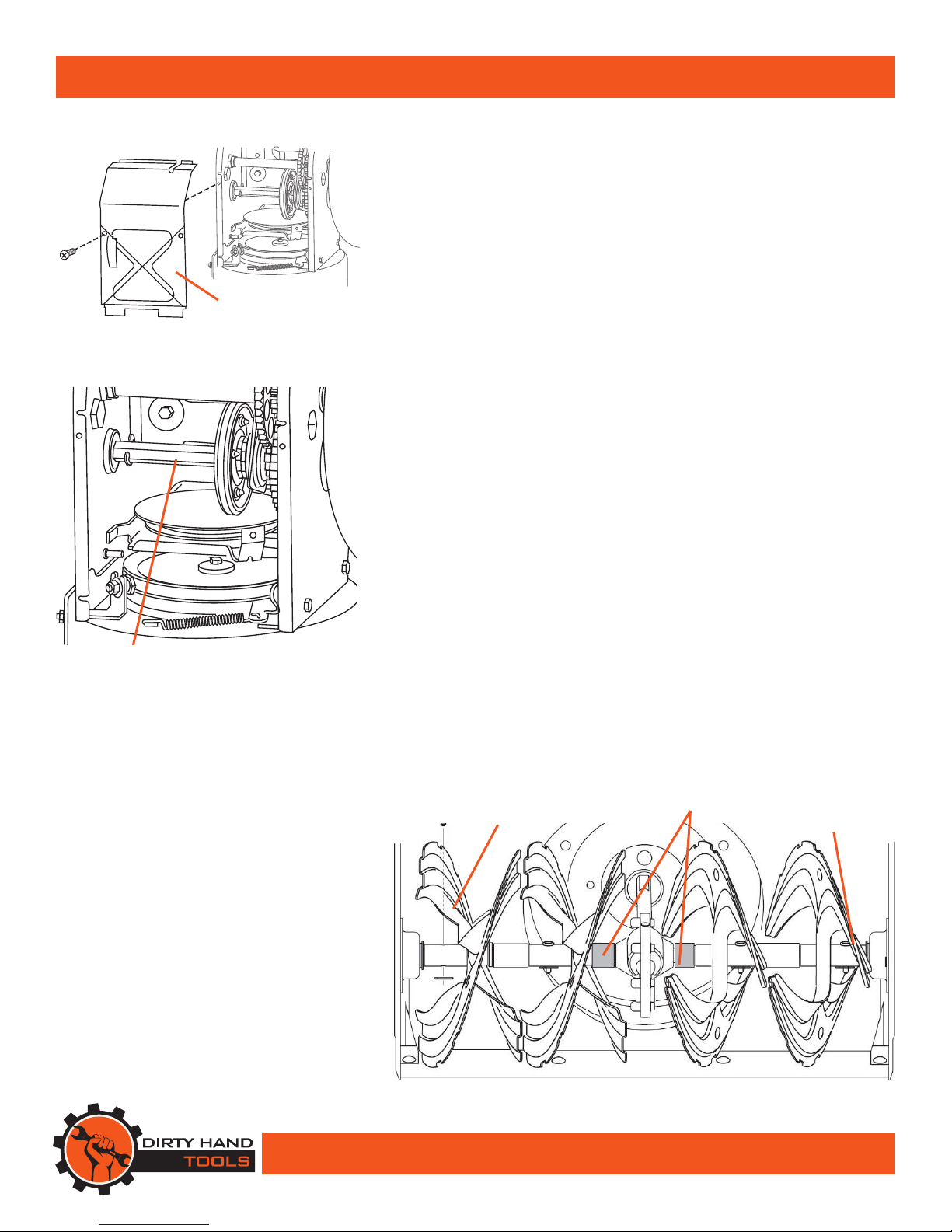

Gear Shaft

e gear (hex) shaft should be lubricated at least once a season or

after every 20 hours of operation.

1. Remove the lower frame cover by removing the two screws

which secure it (see Figure 17).

2. Apply a light coating of an all-weather multi-purpose grease to

the hex shaft (see Figure 18).

Wheels

At least once a season, remove both wheels. Clean and coat the

axles with a multipurpose automotive grease then reinstall.

Auger Shaft

At least once a season, remove the shear pins on the auger shaft

(see Figure 19). Spray lubricant inside shaft, around the spacers.

Also lubricate the flange bearings found at either end of the shaft.

Gear Case

e auger gear case has been filled with grease and sealed at

the factory. If disassembled from any reason, lubricate with two

ounces of new grease.

NOTE: Do not over fill the gear case. Damage to the seals could

result. Be sure the vent plug is free of grease in order to relieve

pressure.

Chute Directional Control

Once annually, lubricate both ends of the chute directional control

crank with petroleum jelly, paraffin wax, or light machine oil.

Figure 18

GEAR (HEX)

SHAFT

Figure 19

SHEAR

PIN SPACERS BEARING

FRAME

COVER

Figure 17

20

Maintenance

Shear Pin Replacement

e auger is attached to the spiral shaft with shear pins

secured with cotter pins. If the auger should strike a foreign

object or ice jam, the snow thrower is designed to shear off

those pins (see Figure 20). If the auger will not rotate, check if

the pins have been sheared. When replacing shear pins, spray

an oil lubricant into the shaft before inserting new pins.

Shave Plate and Skid Shoes

e shave plate and skid shoes on the bottom of the

snow thrower are subject to wear. ey should be checked

periodically and replaced when necessary.

To remove skid shoes:

1. Remove the four carriage bolts and hex flange nuts which

secure them to the snow thrower (see Figure 21).

2. Reassemble new skid shoes with the four carriage bolts

(two on each side) and hex flange nuts.

To remove shave plate:

1. Remove the carriage bolts and hex nuts which attach it to

the snow thrower housing (see Figure 21).

2. Reassemble new shave plate, making sure heads of carriage

bolts are to the inside of housing.Tighten securely.

Figure 21

SKID

SHOE

SHAVE

PLATE

Figure 20

SHEAR

PIN

COTTER

PIN

This manual suits for next models

1

Table of contents

Other Dirty hand Snow Blower manuals