Disc-Go-Tech disc-go-roboto User manual

»Fu l l y Au t o m A t e d di s c Re p A i R sy s t e m

Setting the Standard in Disc Repair

DISC-GO-ROBOTO

Disc Repair Machine Manual

in t R o d u c t i o n

Thank you for purchasing the DISC-GO-ROBOTO Automated Optical Disc

Repair Machine. Please take a few minutes to read through this manual

to become familiar with your new machine and achieve the best results.

If you have questions concerning the operation or maintenance of this

machine, please visit our website at www.discgotech.com or if within Canada

or the USA, contact our Customer Service Department at 1-866-237-3724.

Important Safeguards

Please read through this entire manual and retain it for future reference. To prevent

personal injury or equipment damage, the following precautions should be observed:

1. Do not use this equipment for other than its intended purpose. The use of attachments,

supplies or accessory equipment not recommended or sold by Disc Go Technologies may cause

equipment damage and/or personal injury and will void the warranty for the unit.

2. Install the DISC-GO-ROBOTO on a at level surface at least 24” x 24” (61cm x 61cm).

3. Ensure the DISC-GO-ROBOTO has its own grounded electrical circuit. Do not run the power

cord where it may be subject to wear or abuse. Do not allow anything to rest on or roll over the

power cord which may damage it.

4. To protect against the risk of electrical shock, do not put cord, plug or machine where they

may be exposed to water or moisture.

5. Do not use with a damaged cord or plug. If the DISC-GO-ROBOTO is not working as it should,

has been dropped, damaged, or exposed or dropped into water, call DISC-GO-TECH

Support or your DISC-GO-TECH distributor’s customer service department for service.

6. Turn off the DISC-GO-ROBOTO from the outlet when not in use and before changing

supplies (cartridge, pads).

7. Do not install or operate the DISC-GO-ROBOTO in or near ammable or explosive gas.

8. Do not insert objects through the fan grating or other exterior openings.

9. Use close supervision if this machine is to be operated near children.

10. To prevent damage or injury, do not move the DISC-GO-ROBOTO while the lid is open.

11. Do not move the DISC-GO-ROBOTO with a cartridge installed! If the machine is

inadvertently tipped, polish may leak from the cartridge.

12. Avoid coming in contact with any moving parts while the machine is in operation.

Vers. 2.0 DISC-GO-ROBOTO User’s Manual 1

Machine Description

Supplied Components

Machine Familiarization

2

2

2

Setup Instructions

Optimum Environmental Conditions

Unpack the DISC-GO-ROBOTO

Basic Setup Checklist

Assembling and Installing the DISC-GO-ROBOTO Arm

Conguring the DISC-GO-ROBOTO Arm

The Disc Repair cartridge

Installing Disc Repair cartridge

Start-Up Check

Lid Locking Mechanism

3

3

4

5

5

7

11

11

12

13

Machine Operation

Before you Start / Getting Started

Disc Repair Modes - Light, Medium, and Heavy

BluRay Disc Repair

Mixed Mode Disc Repair

End of Repair Session

Post Repair

14

14

15

16

16

18

19

Machine Maintenance

Daily Cleaning

Regular Cleaning

Switching DISC-GO-ROBOTO back into Disc Repair Mode

Replacing the Polishing Pads

19

19

20

21

22

Getting to Your Options Menu 24

Options

Machine Diagnostics

25

25

Advanced Options

Machine Conguration

Arm Diagnostics

Arm Conguration

Systems Menu

27

27

29

30

31

Troubleshooting 33

Warranty Information 39

Customer Service / Disc Repair Supplies 40

tA b l e o F

co n t e n t s

2

mA c h i n e de s c R i p t i o n

Supplied Components

1 DISC-GO-ROBOTO Machine

1 DISC-GO-ROBOTO Arm

2 Input / Output Disc Spindles

1 Bypass Spindle

1 Disc Repair cartridge

1 Machine Cleaning cartridge

2 Polishing Pads

1 Power Cord

1 Quick Reference Guide

1 User’s Manual

Machine Familiarization

The DISC-GO-ROBOTO is comprised of two pieces: the DISC-GO-ROBOTO

machine and the DISC-GO-ROBOTO Arm. After you have unpacked them, we

recommend that you retain the packaging in case your DISC-GO-ROBOTO needs to

be transported. Refer to Figure 1 below to better acquaint yourself with the machine

and its parts and to help you set up, operate, and troubleshoot the machine.

1Keypad and Display Screen 6Lid Latch (on each side of Lid)

2Vacuum Pickup Head 7Turntable / Tray

3Output Spindle 8Cartridge Latch

4

5

Bypass Spindle

Input Spindle

9

10

Cartridge Compartment

Arm Tab Lock (on each side of Arm)

2

3

1

Figure 1: DISC-GO-ROBOTO with Arm

4

5

7

8

6

9

10

MACHINE DESCRIPTION

Vers. 2.0 DISC-GO-ROBOTO User’s Manual 3

se t u p in s t R u c t i o n s

Optimum Environmental Conditions

Surface Preparation:

Before you unpack and set up your DISC-GO-ROBOTO, please ensure you have a

at, level surface at least 24” wide by 24” deep (61 cm by 61 cm) on which to unpack,

situate and operate the machine. Allow adequate space on the right-hand side of the

machine for cartridge insertion and removal.

Environmental Conditions:

Do not use the DISC-GO-ROBOTO in areas subject to direct sunlight or in

locations where liquids, foreign matter, or corrosive gases may enter the interior of

the product. Please adhere to the following temperature and humidity guidelines

when operating, transporting, or storing the DISC-GO-ROBOTO.

T• Operate machine in 10˚C to 32˚C / 50˚F to 90˚F.

• Transport machine in 5˚C to 40˚C / 41˚F to 104˚F.

• Store machine in 2˚C to 45˚C / 36˚F to 113˚F.

S• Operate in 10% - 80% relative humidity.

• Transport in 5% - 100% relative humidity (non-condensing). 1

• Storage in 5% - 80% relative humidity.2

(1) Should this device or its cartridges be exposed to condensing humidity it may be unsafe to operate. In

this case, the device and/or cartridge(s) must be relocated to adequate operating conditions and remain

unplugged for at least 3 hours past the point of full evaporation.

(2) This device and the associated cartridges operate with water based solvents and polishing

compounds. If the device is exposed to temperatures below 2ºC (36ºF) for a prolonged period, please

contact DISC-GO-TECH technical support (at 1-866-237-3724) prior to operation.

Power Input Specications:

Input Voltage: (congured to region)

a) 90-132VAC

b) 180-264VAC

Input Frequency: 47-63 Hz

Nominal Power Requirements: 300 Watts

Max Inrush Current 15A @ 110VAC or 20A @ 220VAC

4

Unpack the DISC-GO-ROBOTO

1. Using two people, lift up the machine

out of the box using the packing straps.

2. Set the machine down on a at

surface and remove the straps.

3. Lay the machine back so the display

screen faces up. With the machine

rmly supported, remove the bottom

foam packing material.

4. Carefully return machine back to

upright position. Remove top and back

foam packing and bag from machine.

Step 5: Unpack Arm Box

5. Unpack the Arm box. The materials in the box includes the machine Arm, the

Arm Deck, 3 spindles and 1 screwdriver.

Note: Store packing box and foams if you plan to transport or ship the machine.

SETUP INSTRUCTIONS

Step 1: Lift machine out of box Step 2: Set machine down

Step 3: Lay machine back Step 4: Remove packaging

Vers. 2.0 DISC-GO-ROBOTO User’s Manual 5

Basic Setup Checklist

This checklist is to be performed the rst time you set up your DISC-GO-ROBOTO

or when you re-locate the machine.

Assemble and Install the DISC-GO-ROBOTO Arm – (See this page)

Congure the DISC-GO-ROBOTO Arm – (See pages 7-10)

Perform a Sensor Calibration – (See page 10)

Install Disc Repair cartridge and check pads – (See page 11)

Perform a Start-Up Check – (See page 12)

Have questions while setting up your DISC-GO-ROBOTO? Call us at 1-866-237-3724 or contact your

DISC-GO-TECH Distributor. Enjoy your new DISC-GO-ROBOTO!

Assembling and Installing the DISC-GO-ROBOTO Arm

1. Attach the machine Arm to the deck

by lining up the contact leads on the

underside of the Arm to the connector

plug on the Arm Deck.

2. Use the screwdriver to tighten 3

screws around the bottom of the Arm

to secure it to the deck.

Step 1: Connect Arm Step 2: Tighten Arm to Deck

Important! Ensure the Arm

and DISC-GO-ROBOTO decks are level with one

another for optimum operation!

6

Assembling and Installing the DISC-GO-ROBOTO Arm

(Continued)

3. Locate the two leveling feet underneath the front of the Arm Deck. Turn them

counter-clockwise until the deck is sitting level and stable on the surface, with no

front or back end tilt.

4. Place the Input and Output Spindles (the two tall spindles) on the Input (right) and

Output (left) Spindle positioning guides on the Arm deck by aligning the two holes in

the spindle bases with the screws in the guides. Place the shorter Bypass Spindle on

the rear positioning guide.

Step 4: Place Spindles

Positioning Guides Adjustment Holes

Step 3: Adjust Arm Deck feet

Leveling FootArm Deck Underside

SETUP INSTRUCTIONS

Note: Discs stuck together on the Input Spindle will be rejected during the repair process

to avoid damage to the machine or the discs. Stuck discs are placed on the Bypass Spindle

while the remainder of discs on the Input Spindle will continue to be repaired normally.

Vers. 2.0 DISC-GO-ROBOTO User’s Manual 7

6. Slide Arm back onto the hooks so

that it is ush with the front of the

DISC-GO-ROBOTO. The Power /

Control Socket and Plug will t into

place when the Arm is properly seated

onto machine. Push down tab locks on

either side of the Arm.

7. On the backside of your assembled

DISC-GO-ROBOTO, insert the power

cord into the power socket. Be sure to

plug machine into a properly grounded

outlet. Turn on machine by ipping the

rocker switch next to the power socket

to the right.

Conguring the DISC-GO-ROBOTO Arm

To access the “Arm Conguration” menu that allows you to congure the Arm and

the sensor, you must enter through the OPTIONS Menu.

To enter the OPTIONS MENU, press and Hold the STOP button AND press the

CYCLE SELECT button, then release both the STOP button and the CYCLE SELECT

button at the same time. The screen below is what you will see on the display. (For

more information on the OPTIONS Menu and its Sub-Menu choices see page 24-32.)

Step 6: Plug in machine

On / Off Switch Electrical Plug

Figure 2: Initial Options Display Screen

OPTIONS

MACHINE DIAGNOSTICS

Step 5: Slide Arm onto Machine

Connection HooksArm Tab Lock

Arm Connection Slot

8

Arm Conguration

Press the CYCLE SELECT button until you see the “Arm Conguration” Option.

This Sub-Menu allows you to adjust the position of the Arm over each of the three

spindles as well as the Center Tray. Press the START Button to enter the “Arm

Conguration” Sub-Menu. You will see the screen (See Figure 3). “Press the CYCLE

SELECT button to scroll through the following options, then press START to enter

each option:”

a. Center Tray

The tray will eject and

the Arm will rotate

until it is directly over

the turntable.

The following adjustments should only be made if Vacuum

Pickup Head is not centered on the Turntable:

» If the Vacuum Pickup Head is:

- too far right, press the EJECT button to adjust the Arm’s

position counter clockwise or move Arm manually.

- too far left, press the CYCLE SELECT button to adjust

the Arm’s position clockwise or move the Arm manually.

- too far forward or too far back from the Turntable

Center, loosen the four screws, two on each side of metal

section of arm and one screw on the top of the Vacuum

Pickup Head and manually adjust it in relation to the

Turntable Centering Knob.

- Press START to save changes, then CYCLE SELECT to

progress to the next menu option.

Figure 3: DISC-GO-ROBOTO Arm Conguration Screen

Arm Conguration

Center Tray

SETUP INSTRUCTIONS

Vers. 2.0 DISC-GO-ROBOTO User’s Manual 9

b. Input Spindle

The Arm will rotate

until it is directly over

the Input Spindle.

The following adjustments should only be made if Vacuum

Pickup Head is not centered on the Input Spindle:

» If the Vacuum Pickup Head is:

- too far right, press the EJECT button to adjust the Arm’s

position counter clockwise or move Arm manually.

- too far left, press the CYCLE SELECT button to adjust

Arm’s position clockwise or move Arm manually.

- too far in or too far out from the Input Spindle, loosen

the two screws under its base to move it in or out until

centered under the Vacuum Pickup Head.

- Press START to save changes, then CYCLE SELECT to

progress to the next menu option.

c. Output Spindle

The Arm will rotate

until it is directly over

the Output Spindle.

The following adjustments should only be made if Vacuum

Pickup Head is not centered on the Output Spindle:

» If the Vacuum Pickup Head is:

- too far right, press the EJECT button to adjust the Arm’s

position counter clockwise or move Arm manually.

- too far left, press the CYCLE SELECT button to adjust

the Arm’s position clockwise or move Arm manually.

- too far in or too far out from the Output Spindle, loosen

the two screws under its base to move it in or out until

centered under the Vacuum Pickup Head.

- Press START to save changes, then CYCLE SELECT to

progress to the next menu option.

d. Bypass Spindle

The Arm will rotate

until it is directly over

the Bypass Spindle.

The following adjustments should only be made if Vacuum

Pickup Head is not centered on the Bypass Spindle:

» If the Vacuum Pickup Head is:

- too far right, press the EJECT button to adjust the Arm’s

position counter clockwise or move Arm manually.

- too far left, press the CYCLE SELECT button to adjust

the Arm’s position clockwise or move Arm manually.

- too far in or too far out from the Bypass Spindle, loosen

the two screws under the its base to move it in or out

until centered under the Vacuum Pickup Head.

- Press START to save changes, then CYCLE SELECT to

progress to the next menu option.

10

e. Input Spindle

Depth

Arm will rotate over

the Input Spindle and

descend until it contacts

the disc surface. It will

not pick up the disc.

The machine will prompt you to put a disc on

the Input Spindle. The function calibrates the

Input Spindle Depth setting.

Press CYCLE SELECT to progress to the nal

menu option.

f. Center Tray

Depth

Arm will rotate over the

Turntable and descend

until it contacts the

Turntable surface.

This function does not require a disc to be

placed on the Turntable. The function

calibrates the Center Tray Depth setting.

Once this step is complete, press STOP once

to return to the Options/Arm Conguration

menu.

Sensor Calibration

This Sub-Menu allows you to calibrate the Disc Sensor which enables the

DISC-GO-ROBOTO to detect one disc, two discs and no discs on the turntable.

1. From Options menu, press Cycle Select and you will see the Machine

Conguration Sub-Menu. Press Start. Press Cycle Select to get to Sensor

Callibration Sub-Menu. Press Start. he turntable tray will eject and the display

will prompt you to place a disc on the turntable, as shown in Figure 4.

2. Place a standard disc on the turntable LABEL SIDE DOWN and press the

START button to activate the Sensor Calibration. The turntable tray will retract

and the display will indicate calibration progress.

3. When done, the screen will briey display “Calibration Complete” and return

to Options Menu.

Figure 4: DISC-GO-ROBOTO Sensor Calibration Screen

Place Disc On Tray

Press Start To Continue

SETUP INSTRUCTIONS

Vers. 2.0 DISC-GO-ROBOTO User’s Manual 11

The Disc Repair cartridge with HydraShine Technology

The quality of the disc repair process is dependent on the quality of the supplies it

uses (Disc Repair cartridge and polishing pads). These items have a xed usage life and

need to be replaced to ensure optimum disc repair quality. To determine when the

cartridge needs to be replaced, an embedded SmartChip records the number and

type of disc repairs performed and updates a percentage readout on the LCD screen,

informing you when the repair supplies require changing. The polishing pads should be

replaced at the appropriate prompts (twice / cartridge).

Cycle Standard Repair Time Discs Repaired

Light 2 minutes 250

Medium 5 minutes 125

Heavy 8 minutes 80

The total number of discs that can be repaired with one cartridge depends on the

types of repairs and the number of each. Table 1 shows the repair count per repair

cycle, assuming only light or only medium or only heavy repair cycles are performed.

Any proportional combination of repair cycles can also be performed. For example, if

30 Heavy Cycle repairs have been completed (50% of the maximum), an additional

50 Medium Cycle or 80 Light Cycle repairs may subsequently be performed before

the cartridge and pads will need to be replaced.

Installing Disc Repair cartridge with HydraShine Technology

1. Remove the shipping tape and the anti-static foam covering the SmartChip on the

Disc Repair cartridge. IMPORTANT! - Do not touch the metal contacts on the cartridge.

2. Shake the cartridge well (agitate approximately 30 to 45 seconds).

3. Remove the red cartridge stopper and set it aside to reseal the cartridge after use.

DO NOT tilt the cartridge without the stopper in place as the polish can very easily

spill out.

Table 1: Repair Count Per Cycle

Caution!

DO NOT TOUCH the METAL CONTACTS

on the top of the polish cartridge. Static

discharge can permanently damage the

onboard SmartChip!

12

Caution: Do not remove the stopper from the cartridge until you are ready to install it. Without the

stopper, liquid will easily spill out of the cartridge if it is tilted. If a small amount of uid (less than 20 ml)

is spilled, wipe it up with paper towel or cloth. If a larger amount is spilled, do not install the cartridge.

4. Insert the cartridge into the cartridge compartment located on the right hand side

of the machine. When fully inserted, the cartridge latch will audibly ‘click’ and lock

the cartridge into position (see Fig. 5).

Start-Up Check

1. Connect the Power Cord into the Power Socket at the right rear panel of the

DISC-GO-ROBOTO. Plug it into a properly grounded and fused protected outlet or

surge protected powerbar.

2. Turn the ON/OFF switch at the right rear of the machine (next to Power Socket) to

ON. DISC-GO-ROBOTO will initialize and the screen will be displayed (see Fig. 7).

3. Press the EJECT button to extend the Turntable Tray.

4. Verify that the center hole in the Arm Pickup head is centered over the Turntable

Centering Knob (see Fig. 6). If it is not, turn the power off then on and repeat steps 1

through 3. If still not centered, refer to the Arm Conguration section on pages 8-10.

5. Press the EJECT button to retract Turntable Tray.

Figure 5: Inserting a Cartridge Figure 6: Verify Arm centered over Turntable

Cartridge Latch

Cartridge Compartment

Figure 7: DISC-GO-ROBOTO Start Up Screen

DISC-GO-ROBOTO LIGHT 100%

Turntable Center Knob

SETUP INSTRUCTIONS

Pick-Up Head

Vers. 2.0 DISC-GO-ROBOTO User’s Manual 13

Lid Locking Mechanism

The DISC-GO-ROBOTO features a two

stage lid locking mechanism that ensures it

can only be operated when the lid is closed

and locked. There are some maintenance

situations that require you to disengage

the locking mechanism to open the lid (i.e.

Changing polishing pads, inspecting the turn-

table, cleaning and overall maintenance, etc.).

To Open Lid (2 ways):

1. Press and hold the FUNCTION button. The “HOLD TILL LID OPEN” will be

displayed on the screen.

At the same time pull both lid release latches (located on left and right side of machine

lid) forward and lift lid fully open until lid catch clicks and holds lid securely open.

2. Alternatively, press the EJECT button to eject the tray. Pull both lid release latches

(located on left and right side of machine lid) forward and lift lid fully open until lid catch

clicks and holds lid securely open.

To Close Lid:

1. Pull back lid slightly with one hand. Using

other hand, gently press Lid Catch (located at

the bottom of right lid hinge) inward and

carefully lower lid.

Figure 9: Lid Catch

Lid Catch

No Pressure!

Do not force the DISC-GO-ROBOTO lid

down! Doing so could damage the

machine! Please follow the instructions

above to learn how to close the lid properly.

Figure 8: Lid Locking Mechanism

FUNCTION ButtonEJECT Button

Lid Latches

14

mA c h i n e op e R A t i o n

Before you Start...

Quick checklist before beginning your repair:

Ensure a Disc Repair cartridge is inserted properly and Polishing Pads are

installed (refer to Polishing Pad Installation on page 23).

Ensure the turntable does not have a disc in it. Press the EJECT button or open

the lid (see previous page) to inspect the turntable.

Perform a Start-Up Check to ensure Center Hole in the Arm Pickup Head is

centered over the Turntable Centering Knob (refer to “Start-Up Check” section,

page 12).

Ensure the area around the DISC-GO-ROBOTO, and especially around the

Arm, is free of obstacles that might interfere with machine movement.

Getting Started - To begin disc repair:

1. Load the Input Spindle with up to 100 discs, placed label side DOWN.

Note: The number of discs that can be repaired with one cartridge will vary based on the repair

cycle(s) selected. Refer to the “The Disc Repair Cartridge” section on Page 11.

2. Select the desired repair cycle (LIGHT, MEDIUM, HEAVY, BLURAY or MIXED

MODE) using the CYCLE SELECT button. For mixed disc repair cycles or BluRay

disc repair cycle, refer to pages 16-18.

3. Press the START button. The machine will begin repairing discs, selecting

them one at a time from the Input Spindle, and will stop once all discs have been

processed and deposited on the Output Spindle.

Figure 10: DISC-GO-ROBOTO START and CYCLE SELECT Buttons

DISC-GO-ROBOTO LIGHT 100%

MACHINE OPERATION

Vers. 2.0 DISC-GO-ROBOTO User’s Manual 15

Disc Repair Modes - Light, Medium, and Heavy

Light Damage Discs

Light damage is characterized by small,

hairline scratches. It can also comprise

light scuffs, marks and deposits such as

food or glue residue. This type of damage

cannot normally be felt when running

your ngernail across the scratch.

Medium Damage Discs

Medium damage typically comprises larger

scratches than those in the Light category.

Medium scratches can be felt by run-

ning your ngernail across the scratch;

however, your nail should not stop in the

scratch. More extensively damaged discs

with many surface scratches will typically

have several that fall into the Medium

damage category.

Heavy Damage Discs

Heavy damage is the deep knife or

screwdriver type of damage that, when

you run your ngernail across the scratch,

will stop your ngernail in the scratch.

This type of damage can be very severe.

Occasionally it may be necessary to

process a heavily damaged disc through a

Heavy Cycle more than once.

Figure 11: Light Damage Disc

Figure 12: Medium Damage Disc

Figure 13: Heavy Damage Discs

16

Blu-Ray Disc Repair Mode

The DISC-GO-ROBOTO can repair Blu-Ray, but it must be specically selected as a

repair mode using the CYCLE SELECT button.

To get started in Blu-Ray Repair Mode:

1. Load the Input Spindle with your Blu-Ray disc(s).

2. Press the CYCLE SELECT button until the CYCLE screen display reads “BLURAY.”

3. Press the START button. This will begin the Blu-Ray disc repair. Each Blu-Ray disc

repair takes 5 minutes to complete.

Note: Each Blu-Ray mode repaired disc will need nal spray and wipe before returning

into inventory.

Note: Run a Machine Cleaning Cycle after a Blu-Ray disc repair before returning to

LIGHT, MEDIUM, or HEAVY modes.

Mixed Mode Repair

Mixed Mode allows the user to program a customized batch repair of discs with

varying levels of damage. To use Mixed Mode, the user sorts and counts discs into

their appropriate damage levels: Light, Medium, and Heavy damage. Each batch is then

entered into the machine, in the order described.

In Mixed Mode, the maximum number of discs which can be repaired is automatically

calculated based on:

• Percentage of Disc Repair cartridge life left;

• Damage level and number of discs in the previous batch; and

• Damage level of discs in current batch.

Figure 14: DISC-GO-ROBOTO BLURAY Mode Screen

DISC-GO-ROBOTO BLURAY 100%

Vers. 2.0 DISC-GO-ROBOTO User’s Manual 17

To get started in Mixed Repair Mode:

1. Press the CYCLE SELECT button until the CYCLE screen display reads “MIXED.”

2. Press and release the STOP button. This will initiate the Mixed Mode and the

following screen will appear.

3. Press the START button to begin setting up the damage mode.

4. Press the CYCLE SELECT button to enter in the numbers of damaged disc types in

your batch. The screen will initially display the maximum number of repairs

available in the mode displayed (in this case, Light mode). This number is based on how

many repairs the cartridge is able to do. The value will then change to zero, at which

point you can use the CYCLE SELECT button to add in discs incrementally. Hold the

CYCLE SELECT button down for 3 seconds to rapidly add in disc quantities.

5. Press the START button to accept your entered value. The screen of Figure 15 will

be displayed again.

6. Press the CYCLE SELECT button to go to next damage mode. Repeat steps 3-5.

7. Once all damage modes have been programmed with your disc quantities, press the

STOP button. You will briey see the screen displayed below.

Figure 15: DISC-GO-ROBOTO Mixed Mode Setup Screen

Mixed Mode Setup

Qty Light Discs 000

Figure 16: DISC-GO-ROBOTO Disc Loading Instructions

Place discs on spindle,

Light Bottom, Heavy Top

18

MACHINE OPERATION

8. Load your LIGHT damage discs on the Input Spindle rst, followed by all MEDIUM,

then HEAVY damage discs. REMEMBER - All discs must be loaded label side down!

9. Press the START button when you have loaded the discs onto the Input Spindle to

begin the repair process. Figure 17 is an example of a Mixed Mode repair screen.

End of Repair Session

Once all discs have been processed, the screen of Figure 18 will be displayed.

Figure 17: DISC-GO-ROBOTO Mixed Mode Screen

DISC-GO-ROBOTO

L:030 M:040 H:30 Mixed 100%

L:30 refers to 30

Light Damage discs.

M:40 refers to 40

Medium Damage discs.

H:30 refers to 30

Heavy Damage discs.

DISC-GO-ROBOTO

Input Stack Empty

Figure 18: DISC-GO-ROBOTO End of Repair Session Message

Stack it in order!

In Mixed Mode repairs, please load Light

damage discs rst on the spindle, followed

by Medium then Heavy damage discs. And

always load discs LABEL SIDE DOWN!

Table of contents

Popular Tools manuals by other brands

BEA

BEA 554 DCC Spare parts list/service instructions

Utility Solutions

Utility Solutions BREAK-SAFE 600 FIELD INSPECTION PROCEDURE

Clam

Clam 109935 quick start guide

Toro

Toro 110-0069 Operator's manual

Clarke

Clarke CHT706 Instructions for use

Parkside

Parkside PAMFW 12 C3 Translation of the original instructions

Parkside

Parkside PDST 10 B3 Translation of the original instructions

GreenWorks

GreenWorks MTG305 Operator's manual

WilTec

WilTec 61488 Operation manual

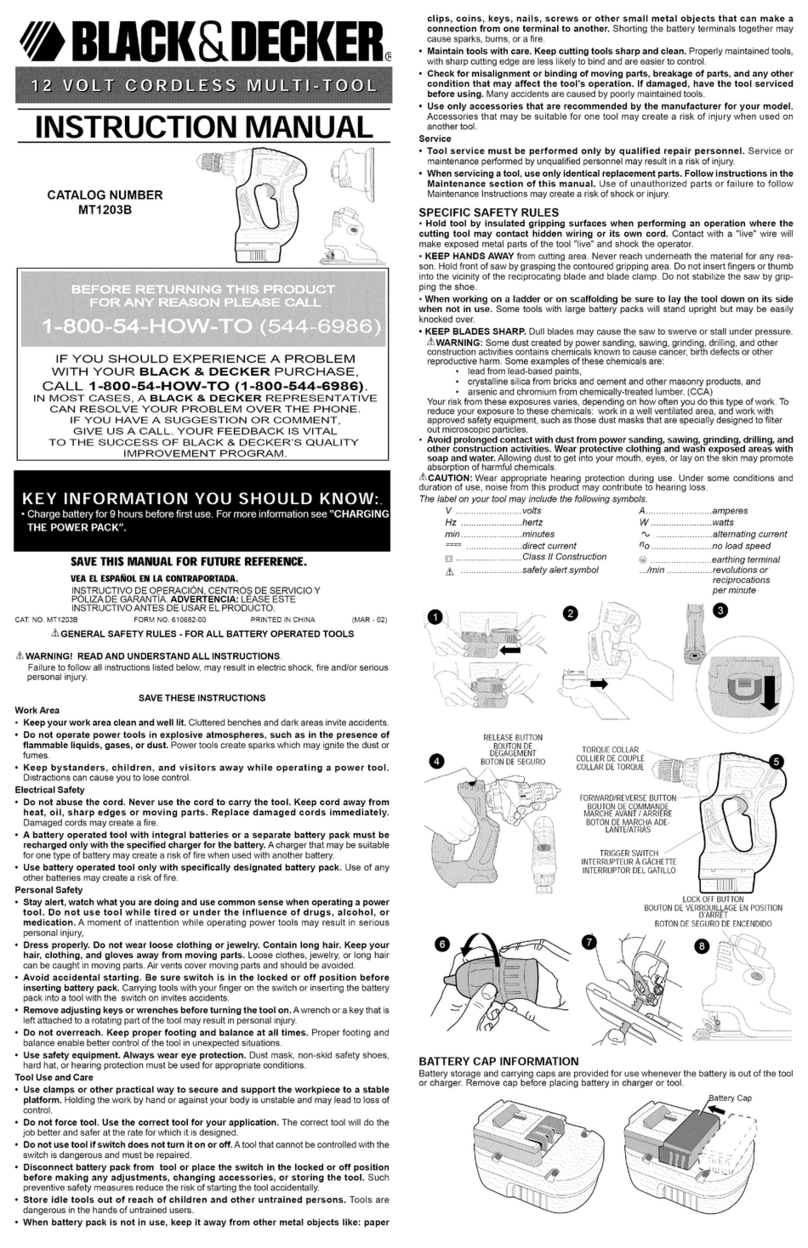

Black & Decker

Black & Decker MT1203B instruction manual

Triton

Triton Maxi ETA300 Operating and safety instructions

Harbor Freight Tools

Harbor Freight Tools 42606 Assembly & operating instructions