DISCO DAG810 User manual

2016-06

INSTALLATION MANUAL

Automatic Surface Grinder

DAG810

Software Version: JUM0001***

Copyright of this document is owned by DISCO CORPORATION

("DISCO"). No part of this document may be copied or reproduced

in any form or by any means, without the express written permission

of DISCO. Also, this document may not be disclosed or transferred

to third parties.

UJUSNE*003F

This document is printed on recyclable Lint-Free Paper.

- The blue paper is recyclable as used paper just like plain paper.

- The cover paper and adhesive portions are non-recyclable.

(Remove the cover and adhesive portions before recycling.

Recycle the blue paper only.)

READ CAREFULLY BEFORE USING THIS

MANUAL

Introduction

This machine grinds silicon wafers (hereinafter called wafers) and, therefore, has rotary sections which

rotate at high speed, high-voltage sections which present electric shock hazard and drive sections which

may catch operating personnel’s body and clothing.

If the machine is not properly operated, safety hazards that could result in serious injury or death may

occur.

Read before using the machine

In using this machine, thoroughly read this manual and follow the instructions set forth in it.

To assure safety in operating and maintaining the machine, it is important that you know the locations of

the potential safety hazards. It is difficult for DISCO to predict each and every potential hazard.

However, this manual carries various precautionary notes and warnings wherever the presence of any

safety hazard is foreseeable. For increased safety assurance, therefore, it is essential that you observe all

the precautions and other relevant instructions set forth in this manual.

If you modify the machine without prior consent of DISCO or repair it in a manner not stated in this

manual, the safety assurance features of the machine may be seriously affected.

Never attempt to modify or repair the machine in a manner not approved by DISCO.

Scope of responsibility

DISCO shall not be responsible for any accident due to any of the following events:

・Any parts other than the genuine DISCO brand are mounted onto the machine.

・Any parts other than periodic replacement or consumable parts are replaced without prior consent

of DISCO.

・Any parts designed by the customer are mounted onto the machine without prior consent of

DISCO.

・Equipment of another manufacturer is added to the machine.

・The machine or part of the machine is transported, reused, resold or modified.

If the customer refuses to disclose the names and contents of the process materials or piping parts used for

the machine as trade secret or confidential commercial information, DISCO may not be able to carry out

repair or maintenance on the machine for protection of the safety and health of our technical personnel.

Parts replacement

When you replace any parts other than periodic replacement or consumable parts described below, consult

your nearest DISCO office. If they are replaced without consulting DISCO, DISCO shall assume no

liability for the consequences arising therefrom.

・Operation Manual

・Maintenance Manual

・When specified in a separate document (e.g., Technical news letter, Operation guide)

Hazard level

The safety precautions set forth in this document are classified into DANGER, WARNING and

CAUTION categories which represent three degrees of hazards latent in the machine.

These categories are defined as detailed below in accordance with the seriousness and probability level of

the hazard. In addition to the above three safety precaution levels, CAUTION without the safety alert

symbol (

) and NOTICE are used to give safety usage instructions to the user.

Before using the machine, be sure to read and understand all the associated safety precautions set forth in

the manual.

The classified hazard levels are defined as follows:

DANGER

If you cannot avoid the incident in question, a critical situation in which

either critical injury or death is very likely to result.

This symbol is used for the incident in which the injury is critical and there

is high probability of occurrence.

WARNING

If you cannot avoid the incident in question, a serious situation in which

either critical injury or death may result.

This symbol is used for the incident in which the injury is serious but there is

not high probability of occurrence.

CAUTION

If you cannot avoid the incident in question, a medium or slight injury may

result.

This symbol is used for the incident in which the injury is slight and there is

not high probability of occurrence.

CAUTION

If you cannot avoid the incident in question, an accident of property damage

may occur.

NOTICE

Indicates the safe way of using the machine as well as precautions to avoid

accidents resulting in damage to property.

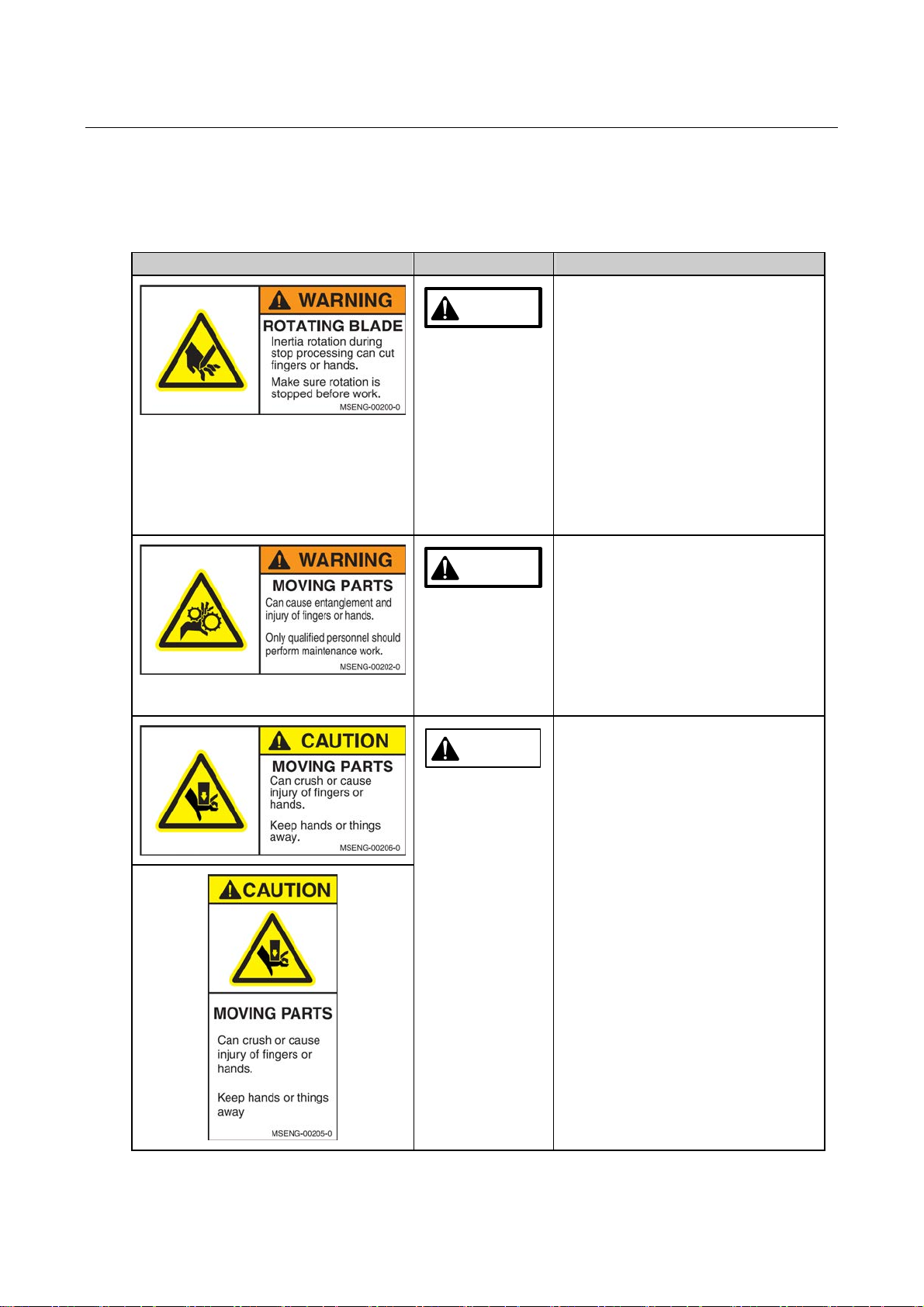

Safety labels

Safety labels are affixed to the potentially hazardous sections of this machine. Before using this machine,

verify the label positions and thoroughly understand the hazard levels and hazard descriptions.

・The language used for the safety labels affixed to the machine outer covers can be requested by

customers. The language used for the safety labels affixed to the machine interior is only either

Japanese or English.

Label Hazard Level Hazard Descriptions

WARNING There is a danger that your fingers or

hands may be cut by the rotating blade.

・Do not place your fingers or hands

near the blade or flange until the

spindle comes to a complete stop.

・Do not open the grinding section

side cover until the spindle comes to

a complete stop.

・It takes approximately 70 seconds

for the spindle to stop completely

after the stop process is executed

(including in case of EMO and a

power failure).

WARNING There is a danger that your fingers,

hands or clothes may be caught up, cut

and injured by the drive sections.

・Do not position your hands or

fingers in the drive sections.

・The maintenance work of the

machine should be done only by

operators with the maintenance

qualification.

CAUTION There is a possibility that your fingers

or hands may get caught and injured in

the drive sections.

・Do not position your fingers or

hands in the drive sections.

・Do not place tools or other irrelevant

items near them.

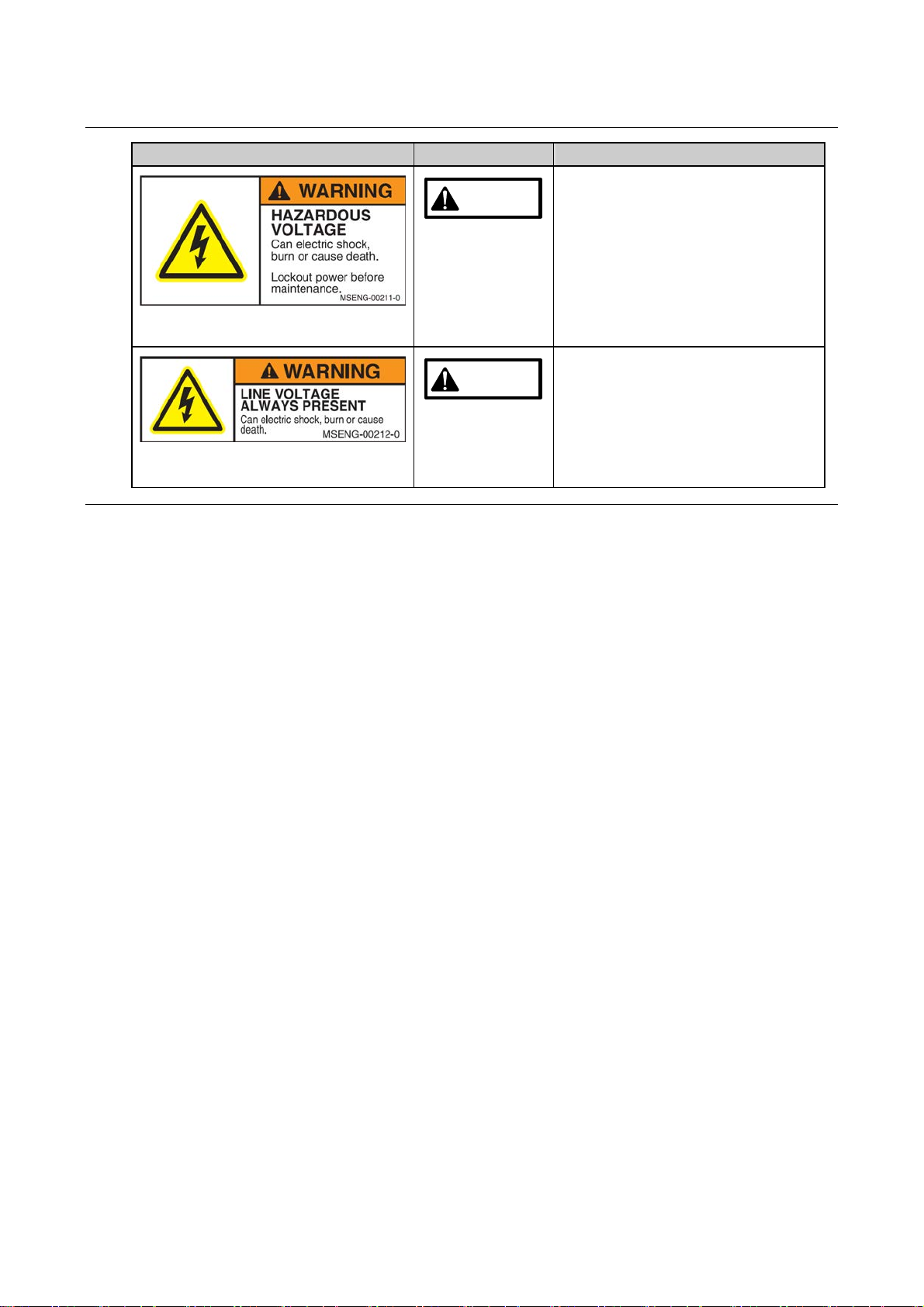

Safety labels (Continued)

Label Hazard Level Hazard Descriptions

WARNING There is a danger that you may die or

get seriously injured from electric

shocks.

・Do not touch the electrically charged

sections.

・Before performing maintenance

work, make sure to shut off the

machine power, and lock out the

breaker.

WARNING Even if the power circuit breaker of the

machine is turned off, the primary side

of the breaker remains energized.

There is a danger that you may die or

get seriously injured from electric

shocks.

・Do not touch the energized sections.

Introduction-1

INTRODUCTION

About this manual

This manual describes the installation procedures of Automatic Surface Grinder Model DAG810.

To ensure safety

To ensure safety, be sure to thoroughly read and understand the contents of this manual before installing

and adjusting the machine.

Note that this manual is based on the software of version JUM0001***.

In installing and adjusting the machine, which must be performed by qualified maintenance personnel

(hereinafter referred to as maintenance personnel) who have completed DISCO's maintenance training,

make sure that the procedures set forth in this manual are followed.

This manual is the 'Original instructions'.

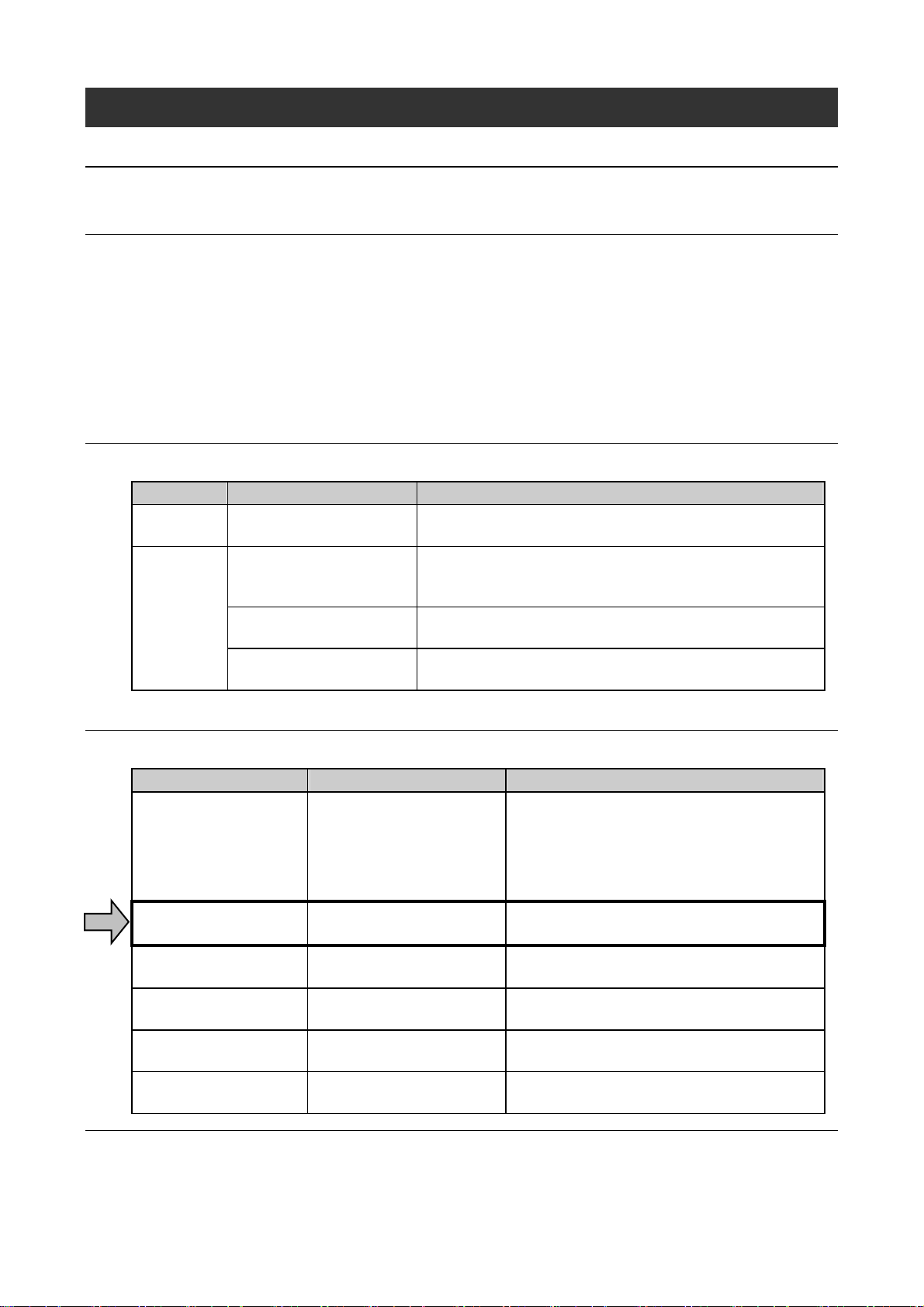

Definition of a manager and an operator

This manual defines a manager and an operator of the machine as follows:

Category Applicable Personnel Job and Responsibility

Manager Management

representative Engages in overall management of the machine and its

operators.

Maintenance personnel Qualified person who has completed DISCO's machine

maintenance training to engage in maintenance of the

machine.

Data maintenance

personnel Qualified person to manage the software data of the

machine.

Operator

Machine operator Engages in operation of the machine for processing

workpieces.

Documentation for this machine

This manual is the Installation Manual in the list below indicated by an arrow.

Manual Who should read Contents

Safety Manual ・Management

representative

・Data maintenance

personnel

・Maintenance personnel

Information for ensuring safety during

machine operation, installation and

maintenance

Installation Manual Maintenance personnel Machine installation and adjustment

procedures

Operation Manual Machine operator Operational procedures to be performed by the

machine operator

Data Maintenance

Manual Data maintenance personnel Screen contents for data entry and machine

operation data setting procedures

Maintenance Manual Maintenance personnel Servicing, inspection and adjustment

procedures to be performed by the customer

Technical Reference Maintenance personnel Machine specifications/

Circuit diagrams/Illustrations/Part list

Introduction-2

Unit notation

International System of Unit is adopted to express any unit. Also, all the pressure values are expressed in

gauge pressure.

Notation of part number

In this document, the part numbers are shown as follows.

XXXX-XXXXXX-X (YYYYYYYY--Y)

New style part no. Former style part no.

Contents-1

CONTENTS

READ CAREFULLY BEFORE USING THIS MANUAL

INTRODUCTION..............................................Introduction-1

CONTENTS..........................................................Contents-1

A. SPECIFICATIONS AND ENVIRONMENTAL

REQUIREMENTS OF THE MACHINE.........................A-1

1. Machine Specifications................................................................................................A-2

2. Dimensions and Mass of Machine on Delivery............................................................A-4

3. Environmental Conditions............................................................................................A-5

3-1. Installation Space..........................................................................................................................A-6

3-2. Environmental Conditions for Installation......................................................................................A-8

3-3. Environmental Conditions for Storage and Transportation .........................................................A-10

4. Piping and Wiring Diagram........................................................................................ A-11

4-1. Rear Panel Connection Ports......................................................................................................A-12

4-2. Piping and Wiring Diagram .........................................................................................................A-14

B. INSTALLATION AND RELOCATION OF MACHINE ....B-1

1. Machine Installation.....................................................................................................B-2

1-1. Hoisting and Lowering the Machine..............................................................................................B-4

1-2. Transferring the Machine ..............................................................................................................B-9

1-3. Leveling the Machine..................................................................................................................B-12

1-4. Installation of Machine Anchors [Optional Accessory] ................................................................B-14

1-5. Piping Connection.......................................................................................................................B-15

1-5-1. Drain and Exhaust Duct Piping Connection.....................................................................B-19

1-5-2. Utility Piping Connection ..................................................................................................B-21

1-6. Power Cable Connection ............................................................................................................B-23

1-6-1. Power Cable Installation to Machine Main Body..............................................................B-25

1-6-2. Connection of Power Cable of Vacuum Unit [Optional Accessory]..................................B-29

1-6-3. Connection of Power Cable of Booster Pump Unit [Optional Accessory]........................B-30

1-6-4. Connection of Power Cable of Duct Unit [Optional Accessory] .......................................B-31

1-6-5. Connection of Power Cable of Coolant Unit [Optional Accessory] ..................................B-32

1-6-6. Connection of Signal Cables of Water Temperature Control Unit (DTU152)...................B-33

Contents-2

CONTENTS

1-7. Connection of Power Cables of Uninterruptible Power Supply Unit [Optional Accessory].........B-34

1-8. Removal of Retainers Used for Machine Transportation............................................................B-36

1-8-1. Removal of Z-axis Retainer Jig........................................................................................B-36

1-8-2. Removal of Y-axis Retainer Jig ........................................................................................B-37

1-9. Installation of Machine Outer Covers..........................................................................................B-38

1-10. Air Supply..................................................................................................................................B-40

1-11. Wheel Coolant and Spindle Coolant Water Supply...................................................................B-41

1-12. Power Supply............................................................................................................................B-41

1-13. Application of Power to Machine...............................................................................................B-42

1-14. SupplyAir Pressure Check .......................................................................................................B-44

1-15. Wheel Coolant Flow Check.......................................................................................................B-45

1-15-1. Air Purge.........................................................................................................................B-46

1-15-2. Wheel Coolant Supply Condition Check........................................................................B-49

1-16. Spindle Coolant Flow Check.....................................................................................................B-50

2. Machine Relocation ................................................................................................... B-51

2-1. Terminating Machine Operation ..................................................................................................B-53

2-2. Water Purge (by DISCO Customer Engineers)...........................................................................B-53

2-3. Removal of Machine Outer Covers.............................................................................................B-54

2-4. Installation of Retainers for Machine Transportation...................................................................B-56

2-4-1. Installation of Y-axis Retainer Jig .....................................................................................B-57

2-4-2. Installation of Z-axis Retainer Jig.....................................................................................B-58

2-5. Piping and Wiring Disconnection ................................................................................................B-59

2-6. Machine Transfer ........................................................................................................................B-59

INDEX ....................................................................... Index-1

WHOM TO CONTACT IN AN EMERGENCY

IN THE EVENT OF AN ACCIDENT

A-1

A. SPECIFICATIONS AND ENVIRONMENTAL

REQUIREMENTS OF THE MACHINE

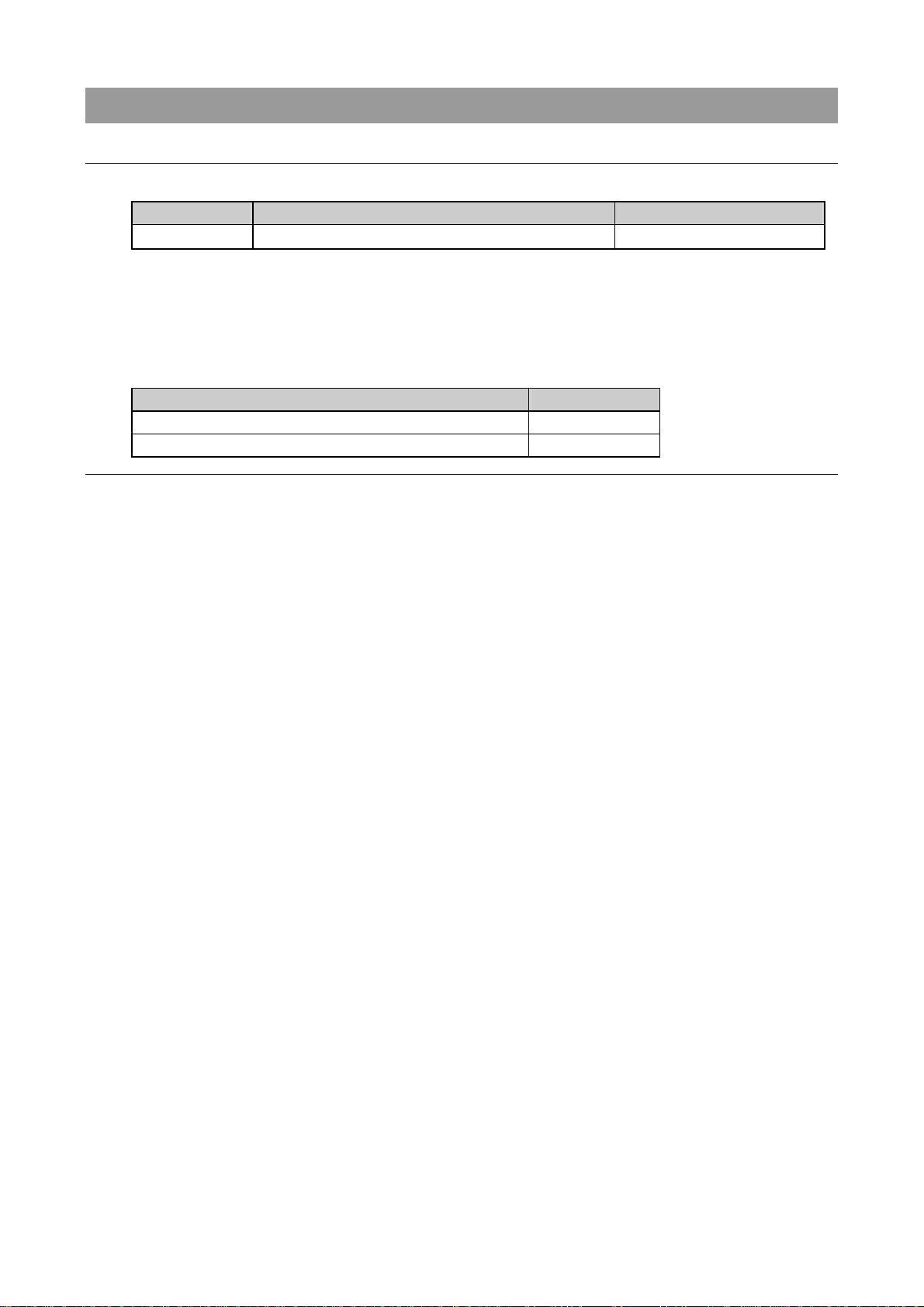

Summary of this chapter

Section No. Title Contents

1 Machine Specifications ・Specifications of DAG810

2 Dimensions and Mass of

Machine on Delivery ・Dimensions and mass of the machine upon

delivery

3 Environmental Conditions

・Environmental requirements for installing the

machine

4 Piping and Wiring Diagram ・Connection points of the hoses and wires of the

machine

A-2

1. Machine Specifications

Machine specifications

Supply power 200 VAC, 3-phase, 50/60 Hz

Voltage variation : ±10 %

Power

consumption ・during warming up : 0.65 kW

・during grinding : 2.4 kW

(The above values are the reference values. They may vary

depending on the operating conditions used.)

Maximum

consumption 12 kVA

Noise Do not use the machine in electrically noisy environments. A

noise test has been conducted on the machine in compliance with

the standard below.

Standards

IEC: 61000-4-4

Electrical fast transient/burst immunity test

(JIS: C61000-4-4

Electrical fast transient/burst immunity test)

・Charge voltage used for noise testing: ±2.0 kV

Ground Facility-side ground connection must be made according to the

local regulations.

Power

requirements

The leakage

current 15 mA or less

(If you use an earth leakage protective breaker at the plant facility

side, choose one ready for higher harmonic waves and whose

sensed current is 30 mA or higher.)

Pressure 0.5 to 0.8 MPa

Pressure

variation 0.03 MPa or less

Flow rate 150 L/min or higher

Dew point -15 °C or lower

Dry air

Residual oil

content 0.1 ppm

(For wheel coolant and cleaning use)

Water used Deionized water (Consult DISCO if you want to use water other

than deionized water)

Pressure 0.2 to 0.3 MPa

Flow rate 20 L/min or higher

Wheel coolant water MAX 5 L/min

External nozzle MAX 5 L/min

Chuck table blow MAX 5 L/min

Height gauge coolant water MAX 5 L/min

[optional accessory]

* When using an optional accessory other than the one stated

above and the water temperature control unit, please contact

DISCO sales representatives.

Water

Water

temperature Room temperature + 2 °C

(the maximum permissible hourly temperature variation is 1 °C)

A-3

Machine specifications (Continued)

(for spindle coolant use)

Water used If the chlorine, iron, copper or sodium content or electrical

conductivity is high, mechanical parts corrosion or hose clogging

may be caused.

Pressure 0.2 to 0.3 MPa

Flow rate 2 L/min or higher

Water

(Continued)

Water

temperature 20 to 25°C (the maximum permissible hourly temperature

variation is 2 °C)

Displacement 4 to 6 m3/min

(at the duct hose connection port of the machine main body

when the static pressure is as below indicated)

Exhaust

Static pressure 0.4 kPa

(at the duct hose connection port of the machine main body)

Machine

dimensions Main body 600 (W) ×1,700 (D) ×1,780 (H) mm

(excluding the status indicator (345 mm) and other protrusions)

Machine dry

mass Main body Approx. 1,300 kg

Paint color Munsell No. 2.5 GY 8.0/0.5 and N2.4

A-4

2. Dimensions and Mass of Machine on Delivery

Dimensions and mass of the machine

Dimensions and mass of the machine upon delivery are as follows.

Dimensions (mm) Mass(kg)

Main body 600 (W) ×1,700 (D) ×1,780 (H) Approx. 1,300

・In transferring, secure enough space so that the machine will pass safely through the selected route.

(Information:At least a space of approximately 610 mm wide is necessary for a person to work sitting.)

・The status indicator (335 mm) and other protrusions are not included in the above dimensions.

・If you select the transformer unit for use outside Japan or uninterruptible power supply, the mass of

these equipment would be added to the machine's mass.

Optional Accessory Mass (kg)

Transformer unit for use outside Japan Approx. 45

Uninterruptible power supply Approx. 50

A-5

3. Environmental Conditions

Summary of this section

Section No. Title Contents

3-1 Installation Space ・Installation drawing of the machine with

required space indications

3-2 Environmental Conditions for

Installation ・Environmental conditions required for

installing the machine

3-3 Environmental Conditions for

Storage and Transportation ・Conditions in which the machine is stored or

transported

A-6

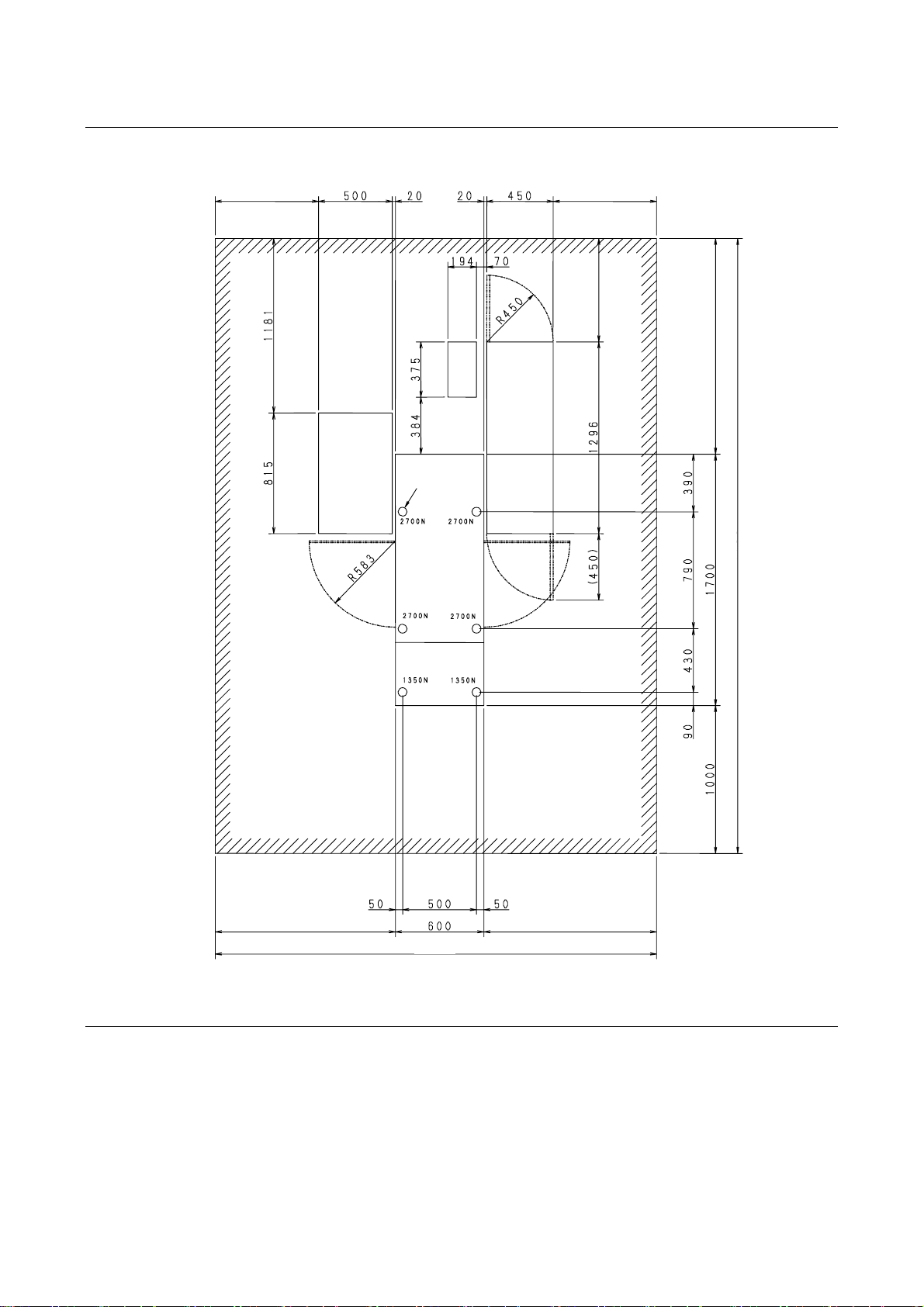

3-1. Installation Space

Considerations in selecting installation site

・Secure enough space taking operational and maintenance ease into account.

・Avoid places where temperature greatly changes.

・Maintenance space for spindle replacement requires at least 2,700 mm from the floor to the ceiling.

・The maintenance area is described with the recommended values that are based on SEMI S8.

Installation diagram (standard specification)

Installation diagram of DAG810 (standard specification) is described here.

Unit : mm

Operation /

Maintenance area

Adjuster feet (6)

690690

690

3390

1980

A-7

Installation diagram when the optional accessory are used

The installation diagram of DAG810 when the vacuum unit, water temperature control unit and UPS

(optional accessories) are used is shown.

UPS water

temperature

control unit

vacuum

unit

Unit:mm

(*1): The booster pump [optional accessory] is incorporated into the vacuum unit.

(*2): The duct unit [optional accessory] is installed on the vacuum unit.

Operation

Maintenance

area

Adjuster feet (6)

690690

690

1449

4149

11601210 2970

A-8

3-2. Environmental Conditions for Installation

Environmental conditions required for installing the machine

Accuracy of the machine is greatly affected by the environmental conditions in which it is installed. Make

sure to use the machine in the following operating condition ranges.

Ambient temperature

(room temperature) 20 to 25 °C (variation: ±1 °C max.)

Ambient humidity 55 ±15 % (non condensing)

Treatment for

waterproof and

drainage

If water leakage should occur, the floor surface and downstairs might be

damaged. Therefore, provide the floor surface with an appropriate treatment

for waterproof and drainage.

(The water leakage detection system by adding the drain pan will be available

soon. Please contact DISCO office or DISCO service office for the detailed

specification.)

Wheel coolant

temperature Room temperature + 2 °C (hourly temperature variation: 1 °C max.)

Wheel coolant water

quality Consult your DISCO sales representative in the following cases:

・When using except for deionized water

・When using water including impurities that may have harmful effects on

the machine

Spindle coolant

temperature 20 to 25°C (hourly temperature variation: 2°C max.)

Spindle coolant water

quality If water used is high in chlorine (Cl), iron (Fe), copper (Cu) or sodium (Na)

content or has high electrical conductivity, mechanical parts corrosion or

piping system clogging may occur.

Air Filtration efficiency: 0.00001 mm/99.5 % or better

Residual oil content: Less than 0.1 ppm

Dew point: -15 °C or lower

Power requirements 200 VAC ±10 %, 3-phase

・Leakage current: 15 mA or less.

If you use an earth leakage protective breaker at the plant facility side,

choose one ready for higher harmonic waves and whose sensed current is

30 mA or higher.

・Significant voltage fluctuation must be avoided.

・A momentary power failure must not occur with the employed power

source.

・Do not use the machine in electrically noisy environments.A noise test has

been conducted on this machine in accordance with the standard below.

IEC: 61000-4-4

Electrical fast transient/burst immunity test (JIS: C61000-4-4

Electrical fast transient/burst immunity test)

Charge voltage used for noise testing: ±2.0 kV

Vibration Amplitude: 5 μm max. (10 Hz or lower)

Acceleration: 0.02 m/s2(2 Gal) max (10 Hz or higher)

Ground Facility-side ground connection must be made according to the local

regulations.

Altitude Altitude of 1000 m or lower

・When the altitude of the site is higher than 1000 m, consult your nearest

DISCO.

A-9

Environmental conditions required for installing the machine (Continued)

Others ・Make sure that the air, water, and power sources and the water drain ports

are positioned near the machine.

・Install valves which can be locked out for both the air and water supplies at

the facility-side. These should be prepared by the customer.

・Ensure that the insides of the employed hoses are free of dirt.

・Install the machine on the floor of adequate strength (refer to Section 3-1

[Installation Space] of this chapter for the required load-carrying capacity

of the floor).

・Do not install the machine in places where noise, vibration, heat, or oil mist

is generated or near fans and ventilation openings.

・If the machine is used or kept in the environment where dirt and dust float

around, precision parts of the machine may be worn out or get dirty

quickly, which could shorten the part life or adversely affect processing

and part quality.

If you need to use or keep the machine in the environment where dirt and

dust float around, please consult DISCO sales representatives.

・Machine anchors are optionally available. They are designed to provide

human/equipment protection in the event of an earthquake or other disaster.

It is recommended that the installed machine be secured with these

anchors.

・Do not use this machine at any place other than an industrial or commercial

facility.

This machine is designed for industrial use and its EMC performance has

been evaluated as EN55011, Group 1, Class A.

Therefore, there is a possibility that electromagnetic noise may exceed the

limit defined by standards for residential environments.

A-10

3-3. Environmental Conditions for Storage and

Transportation

Environmental conditions for storage and transportation

The conditions in which the machine is stored or transported greatly affect the machine's accuracy when it

is operated again after such processes.

Ambient temperature

(room temperature) 5 to 40°C

Ambient relative

humidity 35 to 70% (no condensation)

Machine anchors are optionally available. They are designed to provide human/equipment protection in

the event of an earthquake or other disaster. It is recommended that the machine is secured with these

anchors.

Avoid places where noise, vibration, heat or oil mist is generated, or near the fans and ventilation

openings.

Drain water from the machine before storing or transporting the machine.

Before starting operation of the machine after storage or transport, make sure to grease its driving axes.

If the machine is used or kept in the environment where dirt and dust float around, precision parts of the

machine may be worn out or get dirty quickly, which could shorten the part life or adversely affect

processing and part quality.

If you need to use or keep the machine in the environment where dirt and dust float around, please

consult DISCO sales representatives.

A-11

4. Piping and Wiring Diagram

Summary of this section

Section No. Title Contents

4-1 Rear Panel Connection Ports ・Piping and wiring connections on the machine

rear panel

4-2 Piping and Wiring Diagram ・Piping and wiring diagram of the machine

Table of contents

Other DISCO Grinder manuals