Discount Equipment CD-5 User manual

Instructions nd Parts List Manual

Printed in USA

©2001

Go to Discount-Equipment.com to order your parts

Discount-Equipment.com is your online resource for quality parts & equipment.

Florida: 561-964-4949 Outside Florida TOLL FREE: 877-690-3101

Need parts?

Click on this link: http://www.discount-equipment.com/category/5443-parts/ and

choose one of the options to help get the right parts and equipment you are looking

for. Please have the machine model and serial number available in order to help us

get you the correct parts. If you don’t find the part on the website or on one of the

online manuals, please fill out the request form and one of our experienced staff

members will get back to you with a quote for the right part that your machine needs.

We sell worldwide for the brands: Genie, Terex, JLG, MultiQuip, Mikasa, Essick, Whiteman,

Mayco, Toro Stone, Diamond Products, Generac Magnum, Airman, Haulotte, Barreto,

Power Blanket, Nifty Lift, Atlas Copco, Chicago Pneumatic, Allmand, Miller Curber, Skyjack,

Lull, Skytrak, Tsurumi, Husquvarna Target, Stow, Wacker, Sakai, Mi-T-M, Sullair, Basic,

Dynapac, MBW, Weber, Bartell, Bennar Newman, Haulotte, Ditch Runner, Menegotti,

Morrison, Contec, Buddy, Crown, Edco, Wyco, Bomag, Laymor, EZ Trench, Bil-Jax, F.S.

Curtis, Gehl Pavers, Heli, Honda, ICS/PowerGrit, IHI, Partner, Imer, Clipper, MMD, Koshin,

Rice, CH&E, General Equipment ,Amida, Coleman, NAC, Gradall, Square Shooter, Kent,

Stanley, Tamco, Toku, Hatz, Kohler, Robin, Wisconsin, Northrock, Oztec, Toker TK, Rol-Air,

APT, Wylie, Ingersoll Rand / Doosan, Innovatech, Con X, Ammann, Mecalac, Makinex, Smith

Surface Prep,Small Line, Wanco, Yanmar

E-CDS-IP-6/98

READ

AND

UNDERSTAND THE INSTRUCTIONS

THOROUGHLY

BEFORE

ATTEMPTING TO OPERATE THIS EQUIPMENT.

Death orserious injury could occur if the machine

is

used improperly.

A safety instruction

that

advises

that

death

or

serious

injury will result if instructions

are

not

followed

and

caution exercised.

A safety instruction

that

advises

that

death

or

serious

injury

can

result if instructions

are

not

followed

and

caution exercised

A safety instruction

that

advises

that

injury

could

re-

sult if instructions

are

not

followed.

This

equipment

will

create

dust

from

the

material

being

removed.

That

dust

may

contain a chemical

known

to

the

State

of

California

to

cause cancer

and/or

birth

defects

or

other

reproductive

harm.

As

an

example,

paints

and

concrete

contain

chemicals

known

to

the

State

of

California

to

cause cancer

and/or birth defects

or

other reproductive harm. Check the chemical

properties

of

the

material

to

be

removed

and

take

appropriate precautions.

It

is

the

operator's responsibility

to

keep

other

people

(workers,

pedestrians,

bystanders, etc.)

away

during operation. Block off

the

work

area

in

all

directions

with

roping,

safety

netting,

etc.

for

a

safe

distance.

Failure

to

do

so

may

result

in

others

being

injured

by

flying

debris

or

exposing

them

to

harmful

dust

and

noise.

Maintain

a

safe

operating

distance

from

flammable

materials.

Sparks

from

the

cutting-action of this

machine

can

ignite

flammable

materials

or

vapors.

GENERAL

INSTRUCTIONS

MACHINE PRECAUTIONS

Eye and ear protection must be worn

at

all

times when the

machine

is

in

use.

During normal

operation, sound levels

may

exceed

92

dB(A).

Wear appropriate clothing, footwear, and safety attire when

operating this machinery. Steel toe safety shoes, padded

gloves, non-fogging vented safety goggles or face screen,

dust respirator (when dry cutting), hard hat (when

appropriate for the job), and safety vest should

be

worn.

Do

not wear loose clothing that

can

get tangled

in

moving

parts.

Wear

an

approved dust/particle respirator

when removing hazardous material or when

operating dry.

8

~

Maintain a safe operating distance to other personnel

This equipment

is

designed for preparation of horizontal

concrete or asphalt surfaces using Tungsten Carbide

Bits.

It

is

controlled

by

a single operator from the

rear

of the

machine.

Read and follow

all

safety decals.

Avoid deck inserts, pipes, columns, openings, electrical

outlets, or any objects protruding from slab surface.

Stay

alert;

use common sense, and avoid unsafe conditions.

OWNER RESPONSIBILITIES:

Never allow anyone to operate the machine

in

an

impaired

physical or mental state.

Provide

all

instruction manuals for the operator to fully

read

and understand.

Provide proper training and instruction to the operator.

Maintain safety decals

on

the machine.

Maintain the machine

in

safe operating condition with

all

guards securely

in

place,

all

mechanical fasteners tight, all

controls

in

working order, and the machine configured for

the job application.

Maintain a copy of the equipment's operators manual with

the machine for reference at

all

times.

OPERATOR RESPONSIBILITIES:

Be familiar with

all

aspects of the machine's operation and

controls before applying power to the equipment.

Use the correct accessory for the job being performed and

material being removed. Make sure accessories are

mounted correctly.

Never operate this machine while under the influence of

drugs or alcohol, while taking medications that impair the

senses or reactions, or when excessively tired or under

stress.

Follow the instructions

in

the operators manual and exercise

caution.

Never leave the machine running unattended.

Comply with

all

local safety and health regulations

as

well

as

EPA and OSHA regulations.

TABLE

OF

CONTENTS

1-

Safety

&

General

Instructions

2 -

EDCO

Model

C0-5

"CHIP-DEK"

Scabbier,

Machine

Layout

3-

Instructions

for

EDCO

Model

CD-5

"CHIP-DEK"

Scabbier

4-

Maintenance,

Trouble

Shooting

Guide

5-

Illustration

1:

Main

Assembly

6-

Parts

Listing

-

Illustration

1:

Main

Assembly

7-

Illustration

2:

Filter

and

Lubricator

Assembly

8-

Parts

Listing

-

Illustration

2:

Filter

and

Lubricator

Assembly

9-

Parts

Listing/Illustration

3:

Piston

&

Cylinder

Assembly

10

-

Tungsten

Carbide

Bits

(Back

Cover)

-

Limited

Equipment

Warranty,

Ordering

replacement

parts

Page

1

Go to Discount-Equipment.com to order your parts

E-CDS-IP-6/98

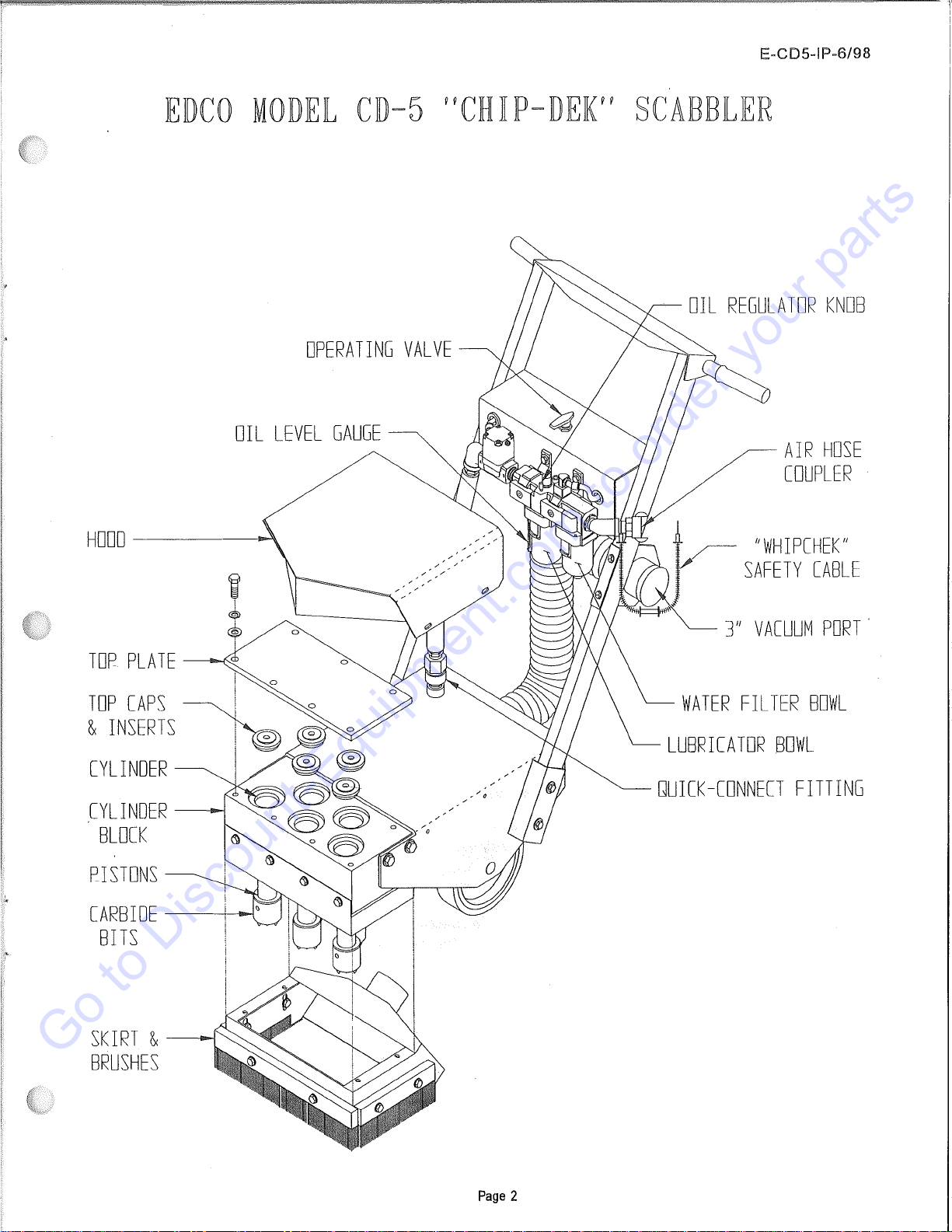

EDCO

MODEJL

CD-5

HCHKP-DE!C'

SCABBJLER

OPERA

TING

VAL

VE

DI

L

LEVEL

GAUGE

HODO

------l-

TOR

PLATE

_..-Ne

CYLI

NOER

---

BLOCK

PJSTONS

CARBIDE-----+--

BITS

SKIRT

&

---

BRUSHES

Page

2

OIL

REGULATOR

KNOB

AIR

HOSE

COUPLER

"WHIPCHEK"

SAFETY

CABLE

3"

VACUUM

PORT

.

WATER

FILTER

BOWL

LUBRICATOR

BOWL

QUICK-CONNECT

FITTING

Go to Discount-Equipment.com to order your parts

E-CD5-IP-6/98

INSTRUCTIONS FOR EDCO MODEL CD-5 "CHIP-DEK" SCABBLER

BEFORE STARTING OPERATION:

For efficient operation of the CD-5, be sure to use a compressor with adequate output. A compressor

output of150 CFM @ 90 PSI or larger

is

recommended.

Before operating the machine check to make sure, the water bowl

of

the filter

is

empty. There

is

a

manual drain valve at the bottom of the bowl.

Also, check the level

of

the lubricator. The proper oil to use is one with a viscosity

of

32

centi-stokes

(IS0-32). For example, Citgo AW-32 hydraulic oil or Lubriplate

H0-32

hydraulic oil.

Tilt machine backwards and check the condition and secureness of the five carbide bits.

If the

job

requires dust free operation, hook-up the EDCO VAC-150 Industrial dust control vacuum

system, or equivalent, to the 3 inch vacuum port

(a

2"

reducing adapter

is

also available) located

directly underthe handle bar assembly.

Determine if the slab

is

structurally sound and safe. While the CD-5 delivers a measured

impact and should not damage the base, care should be taken that the slab is strong

enough to withstand the impact of repeated hammering. A

slab

less

than

4

inches

thick

may

crack

under

repeated

hammering.

OPERATING MACHINE:

Before starting, this machine be sure to read and understand this entire operators manual. Hook air

hose (3/4" minimum) from a regulated air supply to the coupler on the handle

of

the CD-5 and do not

exceed 60 feet

of

3/4" hose.

Be sure to use a "whipchek" safety cable at this joint. Failure to do so could result in

serious bodily injury or death. Before supplying the air hose with air, ensure that the

operating valve on the console of the CD-5

is

in

the "OFF" position.

To start operation of the CD-5, grasp handle bars and turn operating valve to the "ON" position and

pistons will start pounding the pavement. The CD-5 will feel as though the front head is floating.

It

will

be necessary to move the machine so that it will not pound pockets into the slab. The CD-5 should be

moved slowly

in

a side to side sweeping motion to ensure a consistently uniform removal

of

material.

As the machine

is

operating, it may become necessary to adjust the hammering action of the CD-5.

The addition of an air pressure regulator between the machine and your compressor will allow for this

adjustment. The air pressure flowing to the pistons

in

the cylinder head may be adjusted from OPSI,

minimum, to 90 PSI, maximum.

The air pressure should be regulated between 40 PSI and the maximum of 90-PSI depending

on

how

aggressive the machine needs to be to accomplish the job. During the operation of the CD-5, it will be

necessary to periodically stop the machine and visually inspect the level of condensation (water) that

might accumulate

in

the water filter bo1

wl

located on the bottom of the air filter. If the accumulation

of

water exceeds the maximum level as marked on the water filter bowl, it will be necessary to drain the

water filter bowl. To drain the water filter bowl, loosen the drain valve knob located on the bottom of the

water filter bowl, let it completely drain then retighten.

Page 3

Go to Discount-Equipment.com to order your parts

In addition, during the operation of the CD-5 it will

be

necessary to maintain the correct amount of oil in

the lubricator. This oil

in

the lubricator

is

essential to the operating life of the components

in

the

cylinder head. The proper oil

in

the airflow reaching the pistons and cylinders will help flush away any

contaminants

as

well

as

lubricate the close tolerance components and will leave a non-corrosive

film

to-

eliminate rusting ofthe surfaces. The adjustment knob

on

top of the lubricator controls the oil drip rate.

Adjustment should only be made under normal steady flow condition. Turning the adjustment knob

counter-clockwise will increase the oil drip rate and turning adjustment knob clockwise will decrease the

oil drip rate. The knob

is

set

at

the factory

all

the way counter-clockwise to the maximum (+) position.

Each piston should

be

receiving lubrication and have a light film of oil

on

the surface, just enough to

"feel"

it.

If oil starts to appear on the surface, then decrease the

oil

drip rate. Excess

oil

will stain the

concrete, Insufficient oil will result

in

damage to the equipment.

When work

is

complete, close air compressor outlet valve then turn CD-5 operating valve to the "ON"

position to empty the high pressure air from the hose before disconnecting the machine from

compressor. Be

sure

to

disconnect

the

CD-5

from

the

air

source

when

not

in use.

MAINTENANCE:

If the CD-5 is to be stored or not used

for

a

prolonged

length

of

time

it is recommended that the

following suggestions be followed:

(1) Drain moisture from water filter.

(2) Fill lubricator bowl with proper grade of oil.

(3) Remove top plate from cylinder block, remove top caps, and generously apply the proper

oil

to top

of pistons. Manually move the pistons up and down through their cycle several times to ensure all

surfaces are coated with oil. Generously oil the top of the cylinders. Reassemble the machine·

taking care to ensure that the o-ring seals on the cylinder top caps are not damaged.

Table: 1

TR©UEU.E

Sl+l©©TIN@

@l..JIIDE

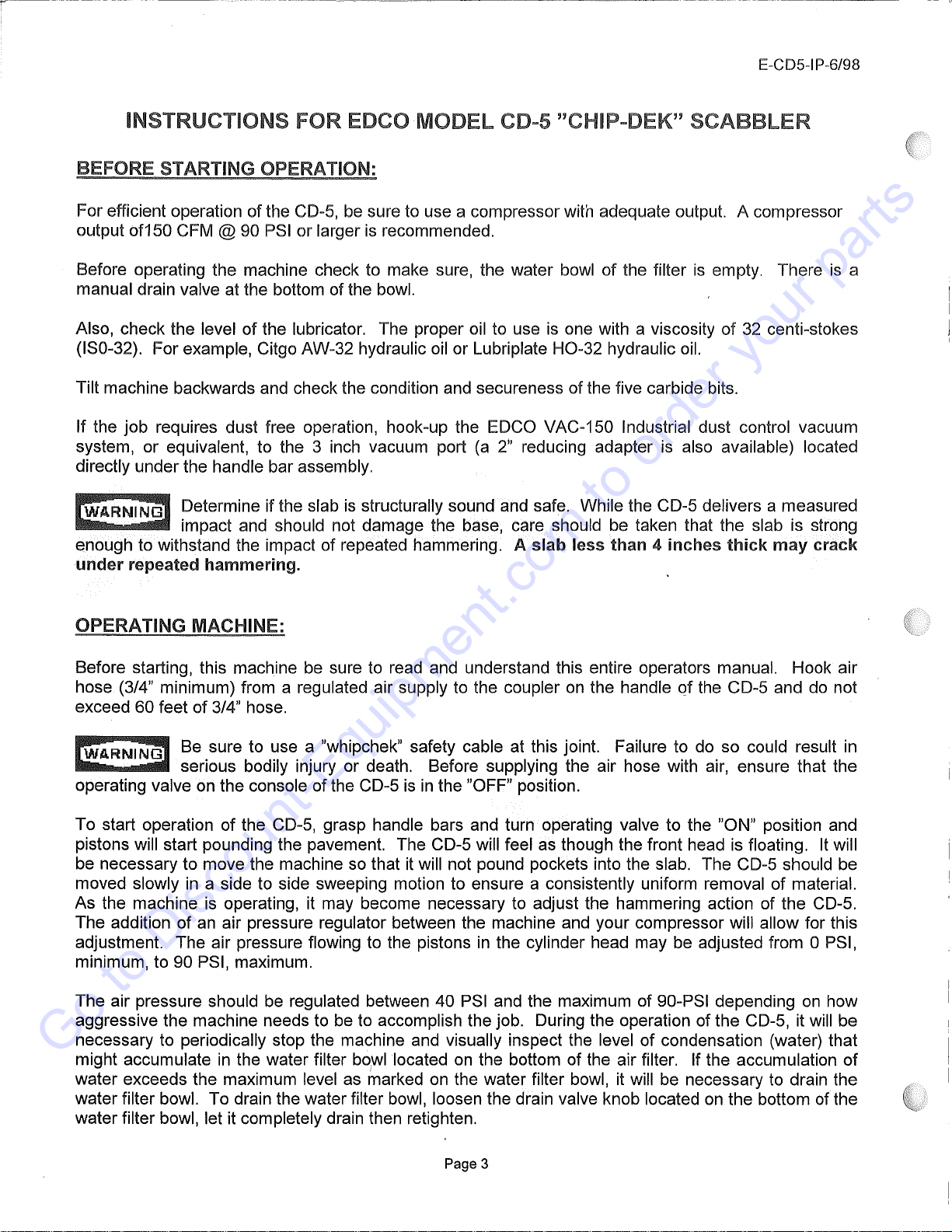

FAULT

POSSIBLE REMEDIES

Machine will

not

012.erate.

Cylinders or valves clogged with dirt. Strip and clean.

Insufficient air supply. Check compressor output.

Valve not turned on. Turn

on

valve.

Low oil level. Add proper amount and qrade of oil.

Finish

of

work is unsatisfactorx,. Incorrect or worn bits. Replace with new or correct bits.

Dust

level is unacce12table. Operating environment. Moisten area to be machined with

water

or

utilize an industrial vacuum

svstem.

Work rate is too low. Insufficient air supply. Check compressor output.

Worn bits. Check hose size.

Check clearance between piston,

cylinder and liner -(.006" Max.)

Page4

Go to Discount-Equipment.com to order your parts

t

--

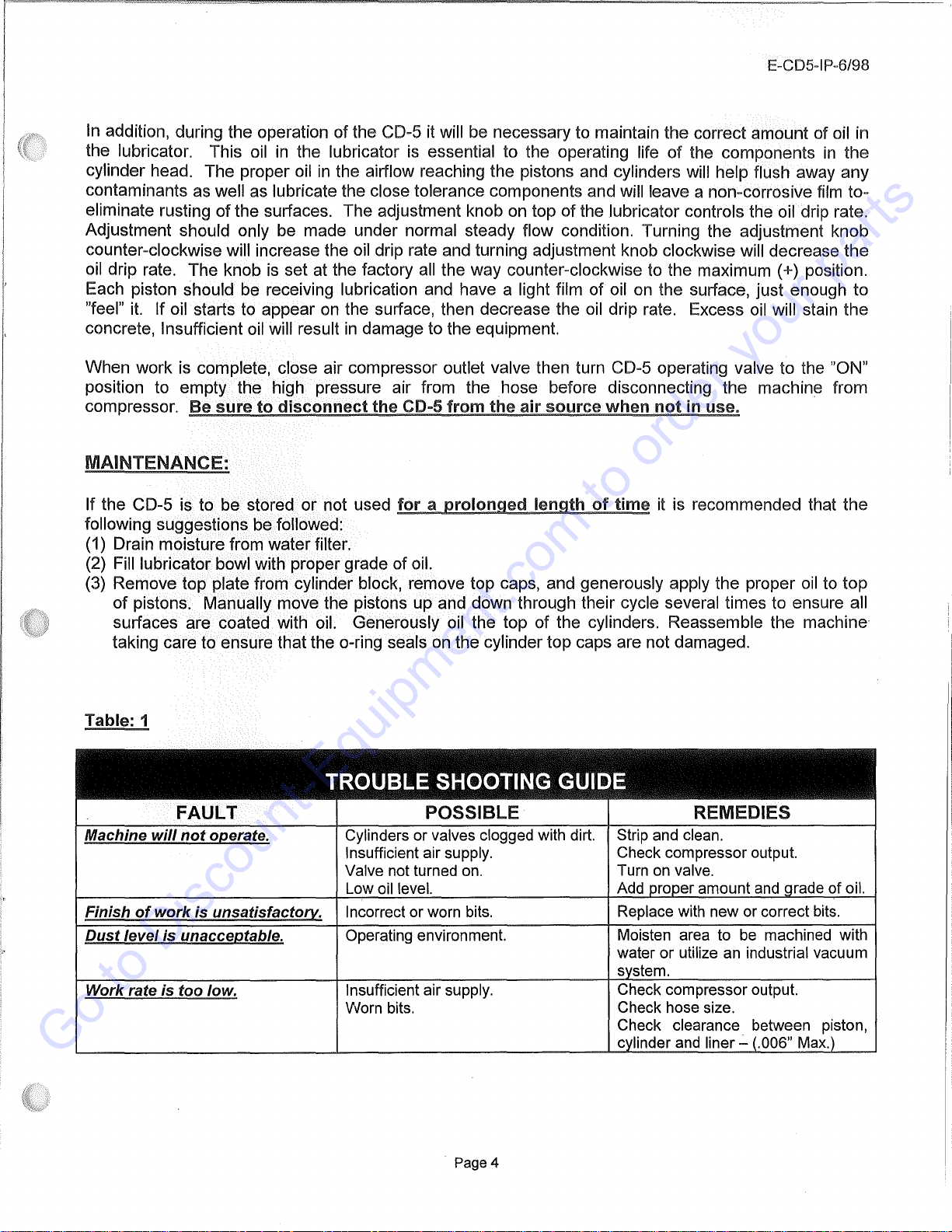

ILLUSTRATION

l:

MAIN

ASSEMBLY

32--------W

33---

34

37

-------J

44

SI

48

49

5

29

30

31

\\1

20

26

27

45

46

Page

5

E-CDS-IP-6/98

6~

13

12

28

NOTES:

I.

REFER

TD

ILLUSTRATION

2

FDR

BREAKDOWN

OF

FILTER

AND

LUBRICATOR

ASSEMBLY.

2.

REFER

TD

ILLUSTRATION

3

FDR

BREAKDOWN

OF

ITEM

36,

PISTON

AND

CYLINDER

ASSEMBLY.

Go to Discount-Equipment.com to order your parts

E-CDS-IP-6/98

PARTS

LISTING·

ILLUSTRATION

1:

MAIN

ASSEMBLY

Item#

Part#

Description Qty.

1 63115 Hood 1

2 10018 Screw, Cap 1/4-20 x 3/4 4

3 10038 Washer, Lock 1/4 4

4 10602 Washer, Flat 1

/4

4

5 63101 Main Frame 1

6 10608 Grip, Hand,

1"

Model

AT

2

7 63104 Handle Bar 1

8 63106 Bushing, Rubber 1-1/4

x5/8

x 1-1/2 4

9 63107 Tube, Bushing Center 5/8 x 3/8 x 1-9/16 4

10

63105 Bracket, Handle Bar Mounting 2

11

10025 Washer, Flat 3/8 4

12

10815 Screw, Cap 3/8-24 x2-3/4 4

13 10004 Nut, Lock 3/8-24 4

14 64030 Plug, Cap

3"

1

15 63112 Bracket, Vacuum Hose 3" 1

16 10455 Washer, Lock,

Ext.

Tooth #10 2

17 10846 Screw, Self-Tap Hex

Washer

1/4-20 X 1/2 2

18 10849 Clamp, Hose, Size 52, Adj.

To

3-3/4" 2

19 63117 Hose, Flex

3"1D

x26"L 1

20 63118 Hose, Flex

3"1D

x 15"L 1

21

63065 Fitting, Quick-Connect Male Plug 3/4 NPT 1

I 22 10727 Elbow, Street 3/4NPT x 90 (Black) 1

23 63047 Barb,

1"

Hose x3/4MPT 1

24 10784 Clamp, Hose, Size 20, Adj.

To

1-3/4" 2

25 63119 Hose,

,Ajr

1"

ID

x 12"L 1

26 63053

Axle

Shaft

1"

Rd.

x 15"L 1

27 10427 Collar, Locking 1"

ID

2

28 63050 Wheel 8 X 1-15/16 X 1"Brg., Poly Thread 2

29 10356 Screw, Cap 1/2-13 X 1-1/2 4

30 10045 Washer, Lock 1/2 4

31

10312 Washer, Flat 1/2 4

32 10356 Screw, Cap 1/2-13 X 1-1/2 7

33 10045 Washer, Lock 1/2 7

34 10312 Washer, Flat 1/2 7

35 63023 Plate, Cylinder Block Top 1

36 63010 Piston & Cylinder Assembly(Refer

to

Illus. 3 for Breakdown) 5

37 63024 Block, Cylinder 1

38 63026 Sealing Strips, Exhaust Box

(2

each) 1

1/2"

Wx

3/8" Thk xT' L

1/2"

Wx3/8"

Thkx

13-1/2" L

39 10025 Washer, Flat 3/8 7

40 10811 Washer, Lock 3/8 7

41

10907 Screw, Cap 3/8-16 x 3/4 7

42 63102 Exhaust Box 1

43 63110 Grommet2-1/2"1D x 1/16"Grvx2-3/4"GD 5

44 63103 Skirt,

3"

Vacuum 1

45 10602 Washer, Flat 1/4 4

46 10038 Washer, Lock 1/4 4

47 11573 Screw,

Skt.

Hd. Cap 1/4-20 X 3/4 4

48 63114 Brush, Wooden 2" H x

8-1

/2" L 2

49 63113 Brush, Wooden 2" H x 16" L 1

50 10029 Screw, Cap 3/8-24 x 1-3/4" 6

51

10025 Washer, Flat 3/8 18

52 10004 Nut, Lock 3/8-24 6

Page

6

Go to Discount-Equipment.com to order your parts

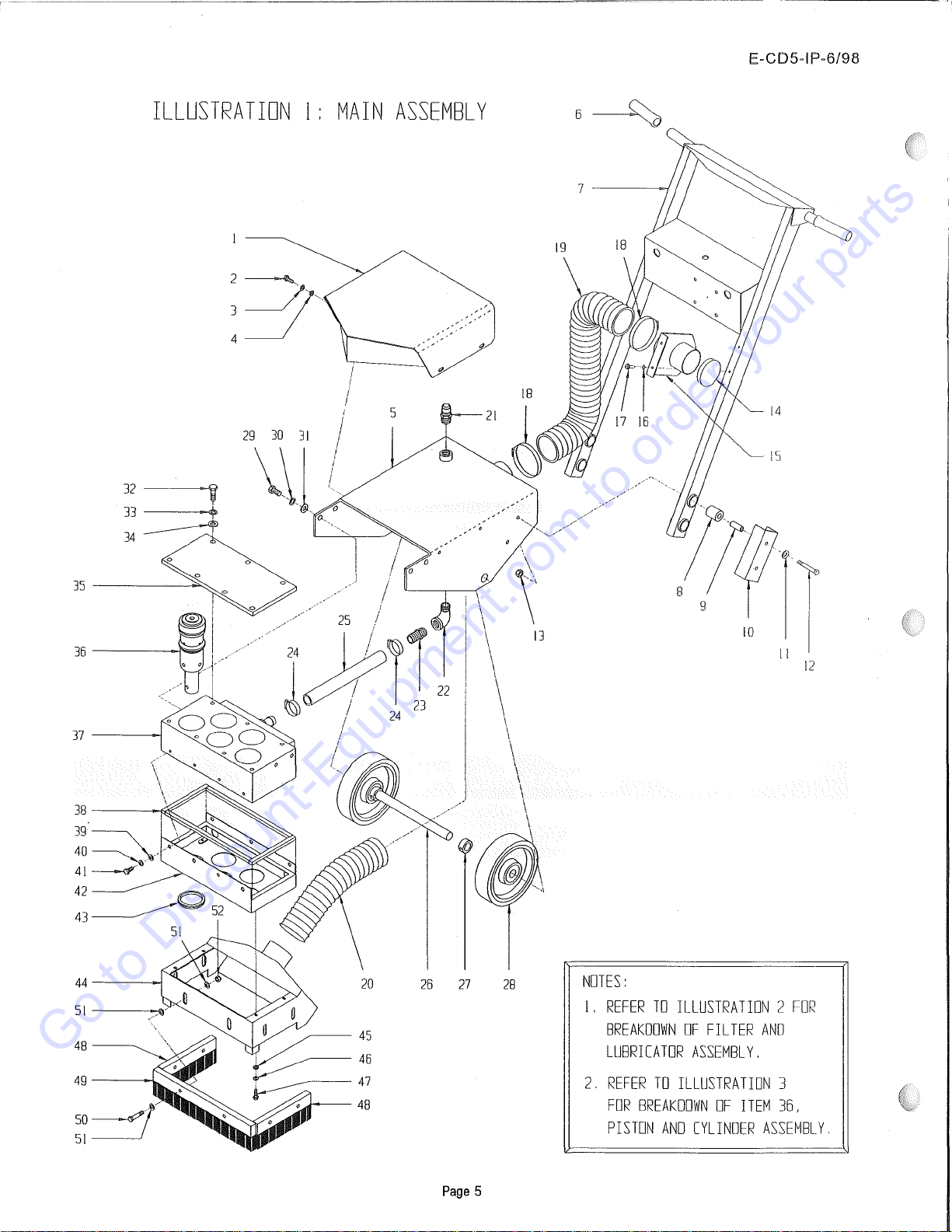

(

18)

-------.------~

J!..,J

~.

.

20

i .

l.

·'~17

*SEE

ABOVE

INSET

FOR

DETAILS.

21

18

29~

I

28

i

I

JI~

NOTE:

CONNECTS

TO

MALE

PLUG

(

ILLUS.

l -

ITEM

#21

)

17*

19

Page

7

ILLUSTRATION

2:

FILTER

&

LUBRICATOR

ASSEMBLY

18

9 7 6 7 9

-

-e--~3

4

s

'?"r-+-

INLET

SIDE

INDICATED

AS

SHDl'/N.

12

13

11

lO

Go to Discount-Equipment.com to order your parts

E-CD5-IP-6/98

PARTS

LISTING-

ILLUSTRATION 2: FILTER AND LUBRICATOR

ASSEMBLY

ITEM # PART DESCRIPTION QTY.

1 63104 Handle Bar (Refer to Illus. 1 -

Item#

7) 1

2 63116 Panel, Console Rear 1

3 10877 Screw, Self-Tap Hex Washer 10-24 x ½ 4

.........

4

..................

1.0455

.......

washer,

...

Lock,

..

Ext

...

Tooth

..

#1.o

...........................................................................................................................

1

........

..

5 63111 Grommet 3/4"

ID

x 1/8" Grv. x

I"

GD 2

.........

6

..................

63004

....

.Yalve,

..

Ba.11

..

W/.Vent

..

1/4"

..

Fem.-

...

NPT

...........................................................................................................

!

..........

.

.........

7

..................

63034

.......

Fitting,

..

straight

..

5/1.6"Tube.

X..1/4

..

M.PT

..................................................................................................

?.

........

..

.........

~

...................

63057

.......

Fitting,

..

Swivel

..

45°,

..

5/1.6"Tu.be

..

X

..

1/8

...

B.SPT

..................................................................................

:!

.........

..

.........

9

..................

63121

.....

Jubing,

...

Nylon

..

5/1.6"

..

0D

..

x

..

1.0"

..

L

.......................................................................................................................

?.

........

..

.......

1.

0

................

63067

.......

cou

pier,

..

Air.Hose'

..

3/4"

..

M.PT

..........................................................................................................................

.......

!

..........

.

.......

1

..

1

.................

63040

.......

cable,

..

"Whipchek"

..

Safety

..

1/8"

..

x

..

20-1/4

.............................................................................................

1

..........

..

12 10740 Conduit Lock Nut 3/4" NP 2

......................................

,

...

,

.........................................................................................................................................................................................................................

,

...................................

,.

........

~

..

~

.................

50086

.......

Elbow,

...

Street

..

3/4"

..

N.PT

..

X..45°

..

(Black)

.....................................................................................................

!

..........

.

........

~.1

.................

631.23

.......

Filter,

..

3/4

..

N.PT.(NAF4000-N06-2),,,

..............................................................................................................

!

.........

..

........

~

..

~

.................

1.0730

.......

El.bow,

...

street

..

1/4

..

NPT.X

..

90

..

(Brass)

........................................................................................................

!

..........

.

16 63034 Fitting, Straight 5/16" Tube x 1/4" MPT 1

17 63124 Bracket, T-Type, Y51T-N02 (Includes 2

0-rings

Item #18) 1

........

~

..

~

.................

~~.~.~

8

ri~·~~$~~~~~.:.,;;:t~;~;.I.~f.qf

...

~

..

~~~.~.::

...

~.~

.....................................................................................

~

........

..

.......

1.9

................

63122.

......

Lub.ricator,

..

3/4

..

N.PT.(NAL4000-N06-8)

................................................................................................

1

..........

.

20 63064 Bracket, T-Type Adapter, NE50T-N06

............................................................

(1.ncludes

..

1

...

0-Ring,

..

ltem

..

#1.8)

............................................................................................................................

!

..........

.

21

10213 Washer, Flat 5/16" 4

.....................................................................................................................................................................................................

,

...................................................................................................

.

22 10801 Washer, Lock 5/16" 4

..........................................................................................................................................................................................................................................................................................................

23 10806 Screw, Cap 5/16-18 x

1"

4

...........................................................................................................................................................................................................................................................................................................

.......

?.1

.................

1.

0577

.......

Pipe

..

N.ipple

..

3/4NPT

..

X

...

1-.1./2

..

(Black)

..................................................................................................

.......

!

..........

.

.......

?..~

.................

63.1.25

....

.Yalve,

..

Process,

..

3/4

..

N.PT,

..

VNA301.A-20A

.......................................................................................

!

.........

..

.......

?.?

.................

63.1.26

.......

Pipe

..

Plug

...

1/8

...

BSPT

......................................................................................................................................................

.......

!

.........

..

.......

?..!..

................

1.0727

.......

El.bow

'

...

street

..

3/4"

..

NPT

..

x

..

90

..

(Black)

........................................................................................................

1

..........

.

.......

?.~

.................

63047

.......

Barb,

...

1."

..

H.ose

..

x

..

3/4"

..

MPT

.........................................................................................................................................

?.

........

..

.......

?..~

.................

1.0784

.......

clamp,

..

H.ose,

..

S.ize

..

20,

..

Adj

...

To

...

1.-3/4"

...................................................................................................

?.

........

..

.......

~9

.................

63.120

.......

Hose,

..

Air

..

1."

...

1.D

..

x

...

1.5-.1/2"

..

L

........................................................................................................................................

!

..........

.

31

63066 Fitting, Quick-Connect Fem. Coupler 3/4" 1

Page 8

Go to Discount-Equipment.com to order your parts

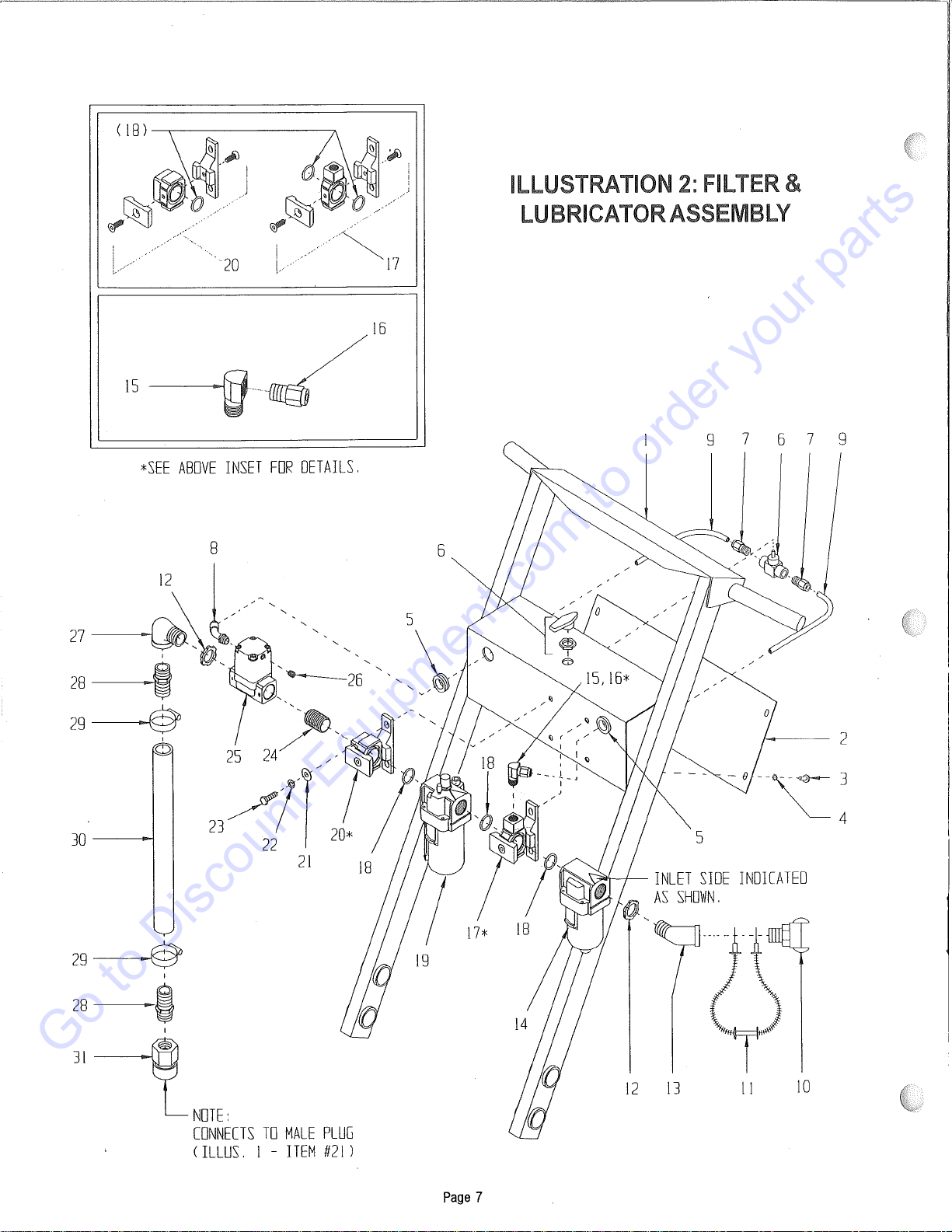

Addendum

to

Parts

List

-

Replaces

p.9

in

EDCO

Document

No.

E-CD5-IP-6/98

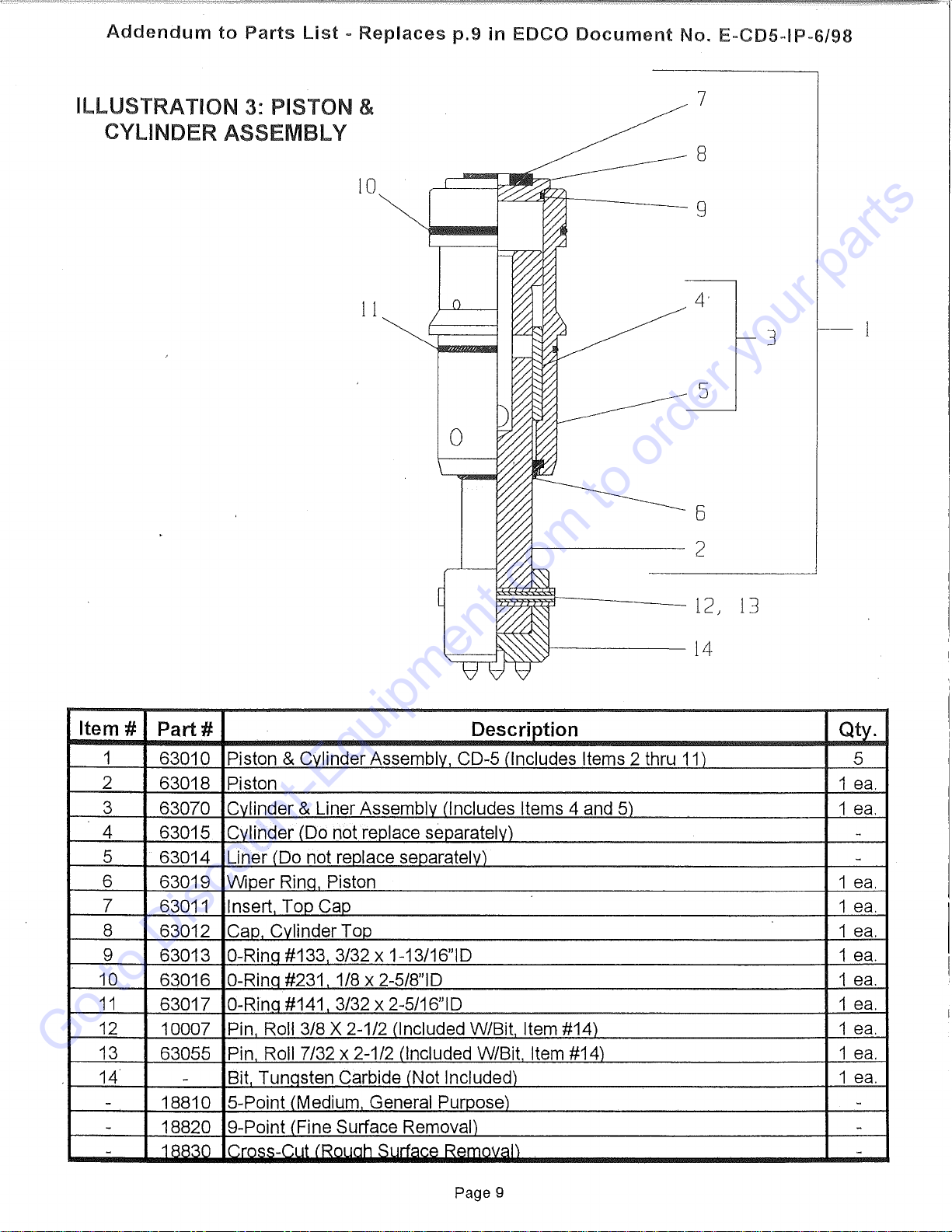

ILLUSTRATION

3:

PISTON &

CYLINDER ASSEMBLY

7

8

10

g

11

s

~~--

12

/

13

.!-------

14

Item#

Part#

Description

1 63010 Piston & Cvlinder Assembly CD-5 (Includes Items 2 thru

11)

2 63018 Piston

3 63070 Cvlinder & Liner Assemblv (Includes Items 4 and 5)

4 63015 Cvlinder (Do not replace separately)

5 63014 Liner (Do not reolace seoarately)

6 63019 Winer Rina Piston

7 63011 Insert Too Cao

8 63012 Cao Cvlinder Too

9 63013 0-Rina #133 3/32 x 1-13/16"1D

10

63016 0-Rina #231 1/8 x 2-5/S"ID

11

63017 0-Rina #141 3/32 x 2-5/16"1D

12

10007 Pin Roll 3/8 X 2-1/2 (Included W/Bit Item #14)

13 63055 Pin Roll 7/32 x 2-1/2 (Included W/Bit Item #14)

14 -Bit Tunasten Carbide (Not Included)

-18810 5-Point (Medium General Puroose)

-18820 9-Point

<Fine

Surface Removal)

-1RR30

lr.rn<::::.c:::-C:11t

(Rouah Surface Removal)

Page 9

3

Qty.

5

1

ea.

1

ea.

-

-

1

ea.

1

ea.

1

ea.

1

ea.

1

ea.

1

ea.

1

ea.

1

ea.

1

ea.

-

-

-

Go to Discount-Equipment.com to order your parts

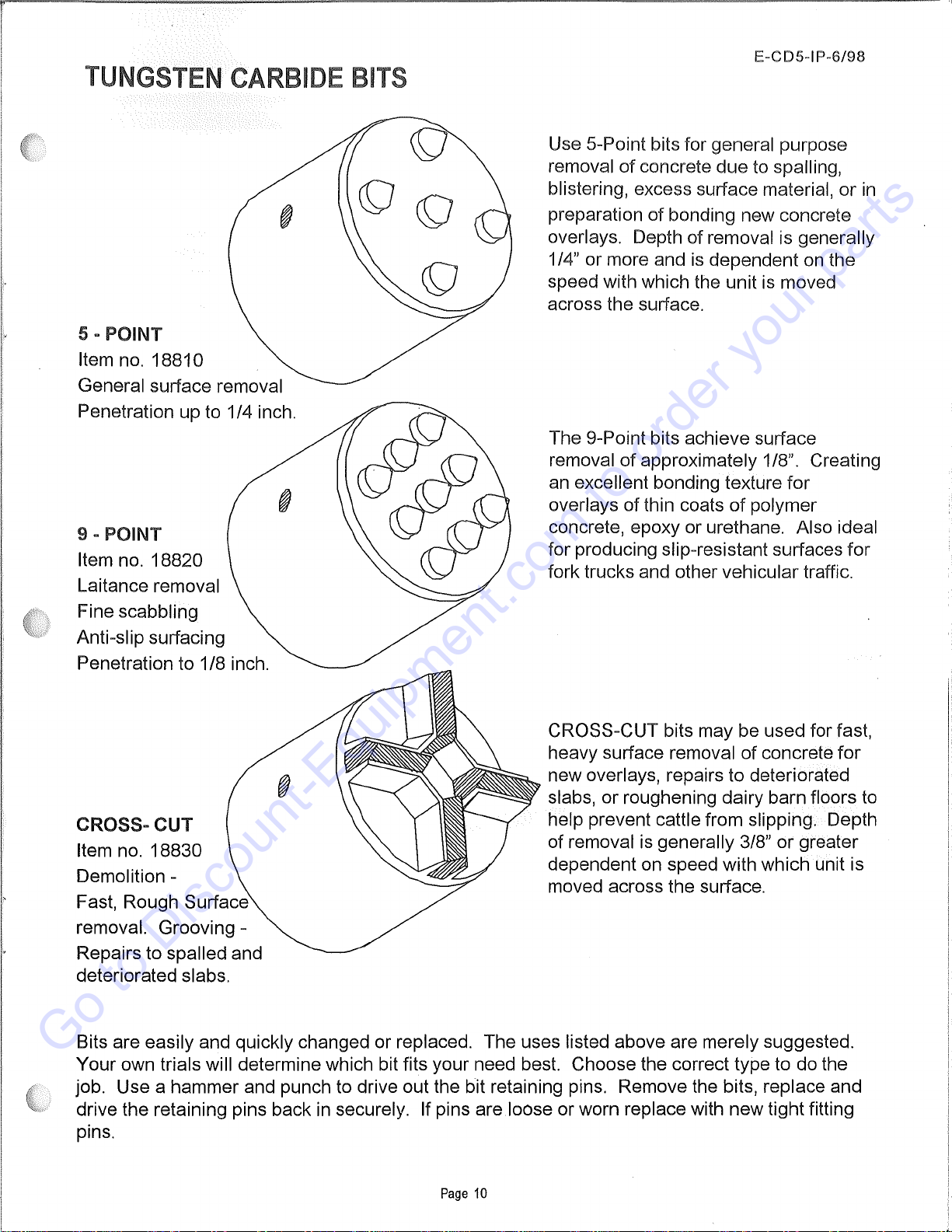

TUNGSTEN

CARBIDE

BITS

5 - POINT

Item no.

18810

General surface removal

Penetration up to 1/4 inch.

9 - POINT

Item no. 18820

Laitance removal

Fine scabbling

Anti-slip surfacing

Penetration to 1/8 inch.

CROSS-CUT

Item no.

18830

Demolition -

Fast, Rough Surface

removal. Grooving -

Repairs to spalled and

deteriorated slabs.

E-CDS-IP-6/98

Use 5-Point bits for general purpose

removal

of

concrete

due

to spalling,

blistering, excess surface material,

or

in

preparation

of

bonding new concrete

overlays. Depth

of

removal is generally

1/4" or more and

is

dependent on the

speed with which the unit is moved

across the surface.

The 9-Point bits achieve surface

removal

of

approximately 1/8". Creating

an excellent bonding texture

for

overlays

of

thin coats

of

polymer

concrete, epoxy or urethane. Also ideal

for producing slip-resistant surfaces

for

fork trucks and other vehicular traffic.

CROSS-CUT bits may be used for fast,

heavy surface removal

of

concrete

for

new overlays, repairs to deteriorated

='-'.,..""'"""

slabs,

or

roughening dairy barn floors to

help prevent cattle from slipping. Depth

of removal is generally 3/8"

or

greater

dependent on speed with which unit is

moved across the surface.

Bits are easily and quickly changed or replaced. The uses listed above are merely suggested.

Your

own trials will determine which bit fits your need best. Choose the correct type to do the

job. Use a hammer and punch to drive out the bit retaining pins. Remove the bits, replace and

drive the retaining pins back in securely. If pins are loose

or

worn replace with

new

tight fitting

pins.

Page

10

Go to Discount-Equipment.com to order your parts

Discount-Equipment.com is your online resource for quality parts & equipment.

Florida: 561-964-4949 Outside Florida TOLL FREE: 877-690-3101

Need parts?

Click on this link: http://www.discount-equipment.com/category/5443-parts/ and

choose one of the options to help get the right parts and equipment you are looking

for. Please have the machine model and serial number available in order to help us

get you the correct parts. If you don’t find the part on the website or on one of the

online manuals, please fill out the request form and one of our experienced staff

members will get back to you with a quote for the right part that your machine needs.

We sell worldwide for the brands: Genie, Terex, JLG, MultiQuip, Mikasa, Essick, Whiteman,

Mayco, Toro Stone, Diamond Products, Generac Magnum, Airman, Haulotte, Barreto,

Power Blanket, Nifty Lift, Atlas Copco, Chicago Pneumatic, Allmand, Miller Curber, Skyjack,

Lull, Skytrak, Tsurumi, Husquvarna Target, Stow, Wacker, Sakai, Mi-T-M, Sullair, Basic,

Dynapac, MBW, Weber, Bartell, Bennar Newman, Haulotte, Ditch Runner, Menegotti,

Morrison, Contec, Buddy, Crown, Edco, Wyco, Bomag, Laymor, EZ Trench, Bil-Jax, F.S.

Curtis, Gehl Pavers, Heli, Honda, ICS/PowerGrit, IHI, Partner, Imer, Clipper, MMD, Koshin,

Rice, CH&E, General Equipment ,Amida, Coleman, NAC, Gradall, Square Shooter, Kent,

Stanley, Tamco, Toku, Hatz, Kohler, Robin, Wisconsin, Northrock, Oztec, Toker TK, Rol-Air,

APT, Wylie, Ingersoll Rand / Doosan, Innovatech, Con X, Ammann, Mecalac, Makinex, Smith

Surface Prep,Small Line, Wanco, Yanmar

Table of contents

Other Discount Equipment Floor Machine manuals

Popular Floor Machine manuals by other brands

Mercury Floor Machines

Mercury Floor Machines 1.5 HP 1170 Safety, operation and maintenance manual with parts list

Tornado

Tornado MARATHON 2000 Operation & service manual

Edco

Edco SEC-NG Operator's instruction manual

Tennant

Tennant SweepSmart S20 ELECTRIC Instruction bulletin

NSS

NSS WRANGLER 20 E manual

Advance acoustic

Advance acoustic SC2000 9087361020 Instructions for use