Osmo FloorXcenter User manual

Osmo Holz und Color GmbH & Co. KG

Affhüppen Esch 12, 48231 Warendorf

- 1 -

Holzimport

Industriehobelwerke

Farbenwerk

www.osmo.de

FloorXcenter

Floor cleaning machine

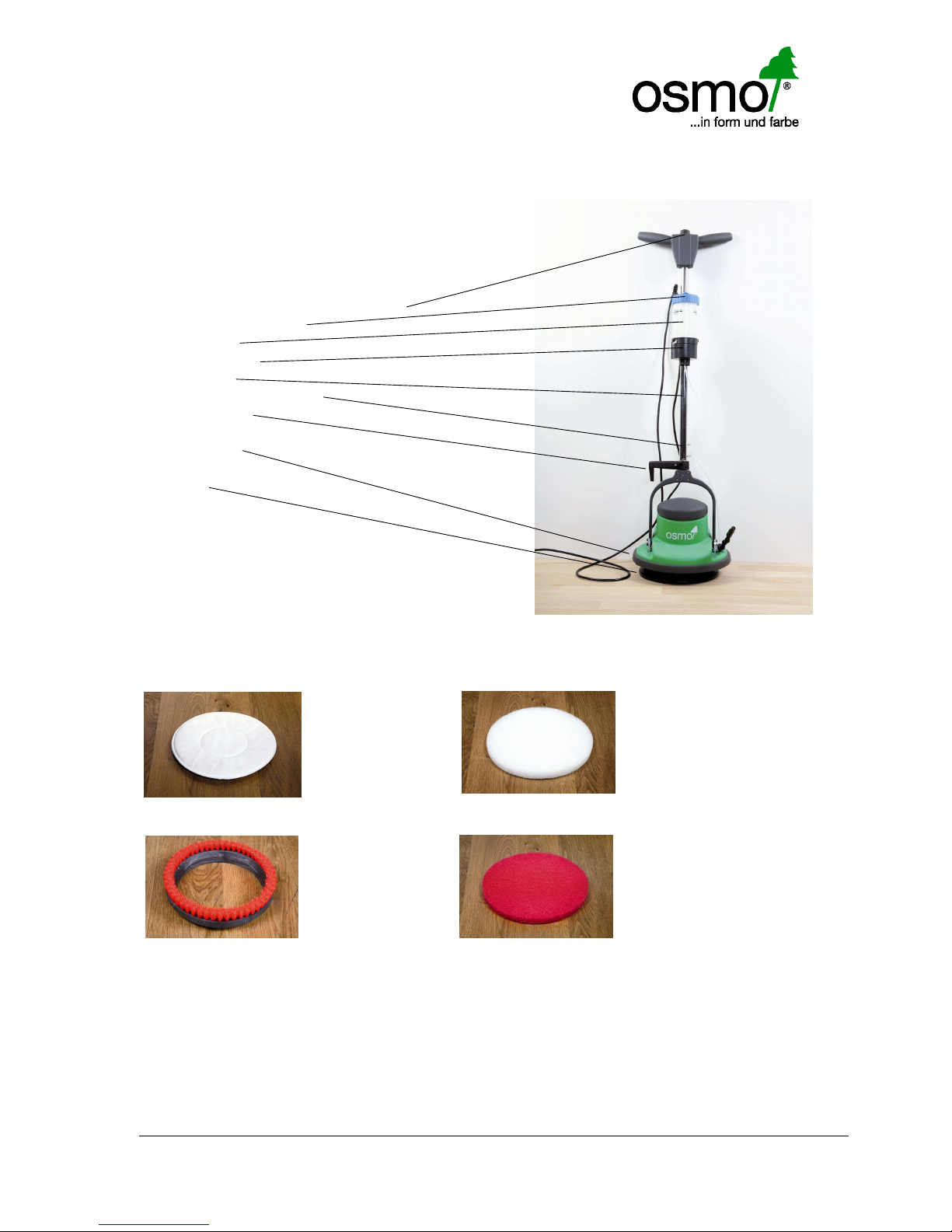

Basic layout:

1 x FloorXcenter with Lye bottle and Driving disk plate

1 x White Pad

1 x Micro-fibre Pad

Read these instructions imperatively before operating the machine.

Operation Instructions

Content:

1. Safety regulation

2. Equipment configuration

3. Accessories

4. Basic cleaning, extreme dirt

5. Refreshing of oiled surfaces with

Osmo Liquid Wax Cleaner

6. Maintenance and re-oiling of

surfaces

7. Staining with Wood Wax Finishes

and Polyx Professional Color Oil

8. Service

9. Maintenance

10. Technical data

Osmo Holz und Color GmbH & Co. KG

Affhüppen Esch 12, 48231 Warendorf

- 2 -

Holzimport

Industriehobelwerke

Farbenwerk

www.osmo.de

These operating instructions are intended for operating personnel.

1. Please make yourself familiar with the notes and recommendations of these operating

instructions before assembly, starting and maintenance of the machine.

2. By doing so, you will control the machine in a safe manner and enhance its performance.

Servicing and maintenance as per these operating instructions improve your safety and

maintain the machine’s value.

3. The manufacturer accepts no liability for personal injury and damage to property

arising from improper use of the machine!

1. Safety regulations

For your safety

Before starting the floor cleaning machine, it is imperative to read these operating instructions

and always keep them ready at hand.

The floor cleaning machine must not be used by persons which are not instructed in its use and

expressly charged with its operation.

Attention! The FloorXcenter is not suited for the treatment of surfaces from which dusts and

liquids hazardous to health are being detached. Do not cross steps!

Caution!

Never cross over the electric cable with the machine. Danger of electric shock!

General

The operation of the FloorXcenter is subject to the current national regulations.

Besides the operating instructions and the current and binding regulations concerning accident

prevention in the country of use, the approved technical rules for safe and professional working

have to be adhered to also. Any operation method which can be deemed as critical or dangerous,

in terms of safety must be refrained from. The use of the appliance on public ways and streets is

not allowed.

Use of the machine in accordance with regulations

• The FloorXcenter is exclusively intended for internal use in buildings.

• Any further use is not deemed to be in accordance with the regulations. The manufacturer will

not be liable for any damage arising from such use; such risks and the results thereof are

solely the liability of the user.

• To use the machine in accordance with the regulations also means to observe the provisions

concerning operation, maintenance and servicing specified by the manufacturer.

• The pertinent rules and regulations concerning accident prevention as well as all other

generally approved safety and working regulations have to be adhered to.

• Unauthorized modifications of the machine will void all guarantees and the liability of the

manufacturer for any resulting damage.

• Before using the machine, floor coverings have to be tested for their suitability for this cleaning

method!

• Mind the surface pressure with point-elastic floors, e.g. in gyms, use with caution and test

appropriately before use!

• The manufacturer is not liable for any damage caused to surfaces upon incorrect use of the

machine or its accessories.

Osmo Holz und Color GmbH & Co. KG

Affhüppen Esch 12, 48231 Warendorf

- 3 -

Holzimport

Industriehobelwerke

Farbenwerk

www.osmo.de

Product liability

It is expressly pointed out to the operator, that the machines may only be used in accordance

with all relevant regulations. The user will bear all responsibility if the appliances are not used in

accordance with the regulations. Thereby, any liability of the manufacturer is excluded.

Safety hazards

• At standstill of the machine the brush unit / head of machine has to be shut off immediately to

prevent the floor covering from being damaged.

• For transport in lifts please remember that all safety regulations - particularly in terms of load

capacity - have to be adhered to.

Operating position

The operating position is behind the machine.

Admitted maintenance personnel

The floor cleaning machine must not be maintained or serviced by persons which are not

qualified to do so.

Cleaning agents

• For the use of cleaning agents and care products it is required to observe the hazard

indications of the manufacturer; wear safety goggles and protective clothing if appropriate.

• Use only low-foam, non-combustible cleaning agents containing no substances which are

generally hazardous to health.

Please note carefully the risks of using substances which are highly inflammable,

combustible, toxic, hazardous to health, caustic or irritating.

First starting

• The delivery, instruction on safety regulations, operation and maintenance as well as the first

starting are accompanied, as a rule, by an authorized expert.

If this should not be the case, the operating company will be responsible for the instruction of the

operators.

Osmo Holz und Color GmbH & Co. KG

Affhüppen Esch 12, 48231 Warendorf

- 4 -

Holzimport

Industriehobelwerke

Farbenwerk

www.osmo.de

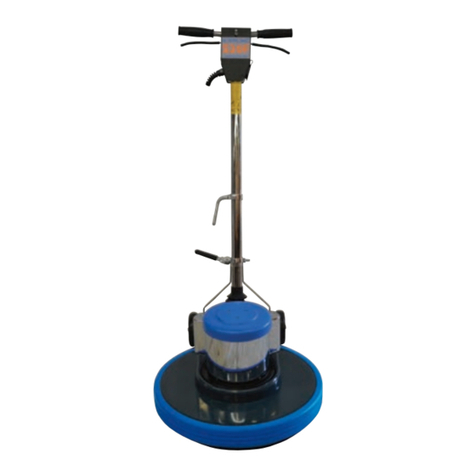

2. Application layout

1. Control device for cleaning agent

2. Lid with lock button

3. Lye bottle

4. Bottle holder

5. Rod duct

6. Bottle-pressure valve

7. Cable hook

8. Rebounding

protection

9. Driving disc

plate

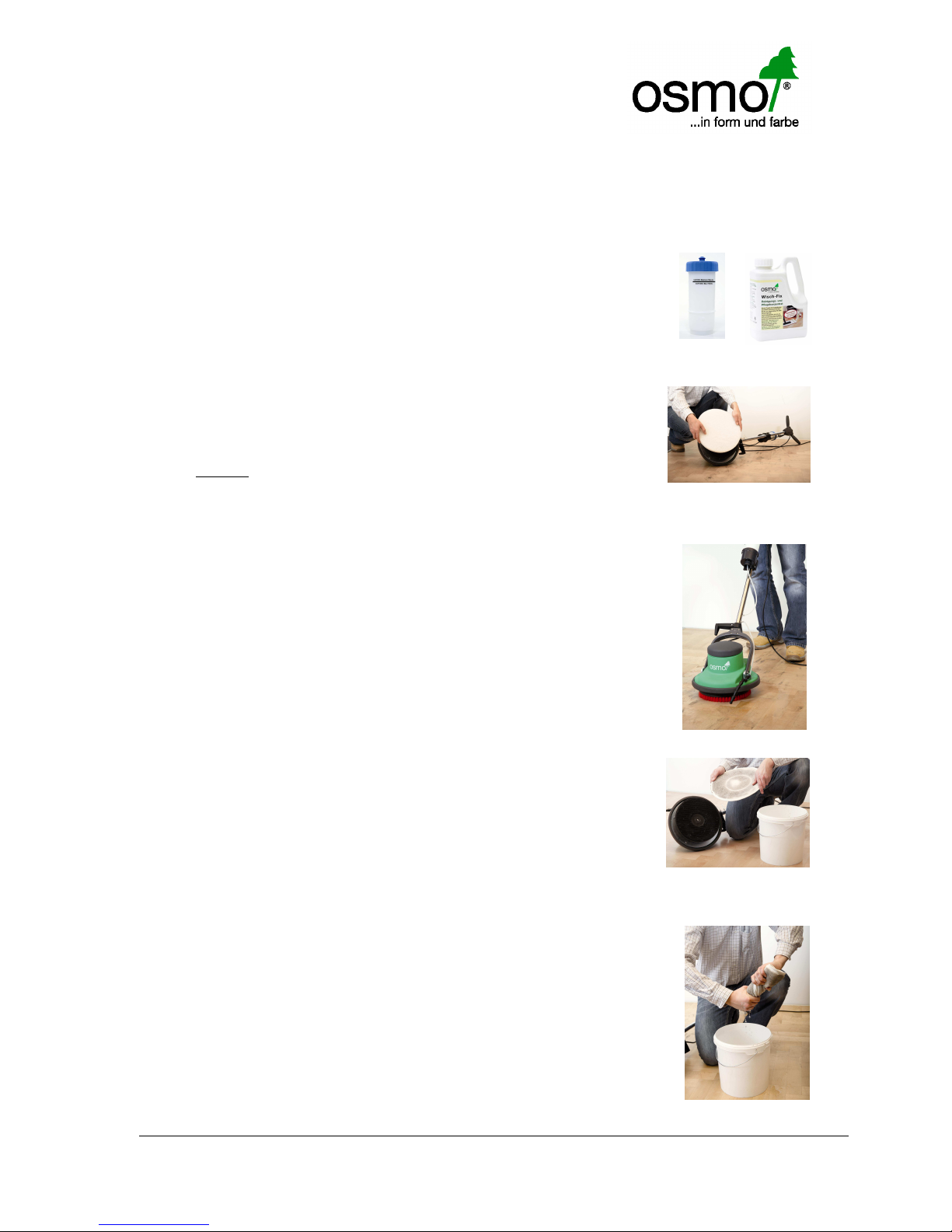

3. Accessories

Following accessories are available:

Micro-fibre pad (Ø 33 cm)

Cleaning Pad white (Ø 33 cm)

Brushing ring Cleaning Pad red (Ø 33 cm)

Advice:

Never leave the FloorXcenter standing on a Cleaning Pad, Micro-fibre Pad or Brushing ring after

use. The weight of the machine will squeeze out any remaining fluid, smooth and even

application / working can no longer be achieved. If this occurs, the pad / brushing ring has to be

replaced.

Lifting the machine allows the pad / brushing ring and the driving disc plate to be separated easily

from the machine.

Osmo Holz und Color GmbH & Co. KG

Affhüppen Esch 12, 48231 Warendorf

- 5 -

Holzimport

Industriehobelwerke

Farbenwerk

www.osmo.de

4. Basic cleaning, extreme dirt

Cleaning with Brushing ring - white pad

• Fill lye bottle (left picture) with Osmo Wash & Care and

water (Dosage 1:1)

• Put lye bottle in the bottle holder

• Put brushing ring / white pad on the driving disc plate

(Use brushing ring on structured surfaces.)

• Pull lock button of the lid upwards

• Push control device as long as first drops come onto the floor

Advice: push control device only for a short time. Too much liquid

may penetrate into the wood and lead to irreparable damages.

• Move the FloorXcenter onto the dirty surface and begin work

Advice: work on approx. 10 m². Otherwise loosened dirt can

dry again. If FloorXcenter is laid on the floor close the lid

in order to avoid the liquid to leak.

• When lifting the machine, the driving disc plate together

with brushing ring / white pad can

easily be removed

from the machine

• Put Micro-fibre pad under the driving disc plate

• Absorb the loosened dirt with the Micro-fibre pad

• Clean, wring out and use again

• Micro-fibre pad can be washed at 95°C

(washing machine + dryer)

Osmo Holz und Color GmbH & Co. KG

Affhüppen Esch 12, 48231 Warendorf

- 6 -

Holzimport

Industriehobelwerke

Farbenwerk

www.osmo.de

5. Refreshing of oiled surfaces

with Osmo Liquid Wax Cleaner

• Clean the surface (see point 4.)

• After complete drying, apply Osmo Liquid Wax Cleaner

(or in the sprayable form) directly on the wooden floor

(approx 1 tablespoon for 1 m²).

Advice: Do not fill Osmo Liquid Wax Cleaner in the lye bottle (danger of blockage)

• Put white pad under the driving disc plate

• Polish with white pad

Advice: There is too much material on the surface when you can see driving rings

on the surface. Turn the pad around or dry the pad on an untreated surface.

• In order to get a shiny result polish up the surface after drying (ca. 30 minutes) with a new

white pad

6. Maintenance and re-oiling of surfaces

• At first clean the surface (see point 4.)

• With stubborn dirt use a red pad if necessary

• Re-oil extremely worn out surfaces with Osmo Polyx

®

Oil

• Apply a very thin layer of Osmo Polyx

®

Oil with either the Osmo Double Blade Scraper or

the Osmo Professional Scraper and then polish with a white pad.

Advice: There is too much material on the surface when you can see rings on the surface.

Turn the pad around or dry the pad on an untreated surface.

Osmo Holz und Color GmbH & Co. KG

Affhüppen Esch 12, 48231 Warendorf

- 7 -

Holzimport

Industriehobelwerke

Farbenwerk

www.osmo.de

7. Staining with Wood Wax Finishes and Polyx

®

Professional Color-Oil

• First apply Wood Wax Finishes or Color-Oils with

Osmo Double Blade or Professional Scraper

• Disperse and polish with FloorXcenter and white pad

Advice: There is too much material on the surface when you can see rings on the surface.

Turn the pad around or dry the pad on an untreated surface.

Clear finish:

In order to protect the pigments 1 coat of a clear Osmo Polyx

®

Oil is necessary.

Please find more information in our Osmo catalogue „Top-quality treatments for wooden

flooring“ or on our homepage www.osmo.com /Help and Tips / Product Information Color.

8. Service

• If the machine requires repairing, please contact your specialized wholesale dealer or one of

the service stations.

• Attention! This machine is only intended for use on surfaces with a maximal gradient of 2%.

• Attention! The use of this machine on public ways and streets is not allowed.

9. Maintenance - it is imperative to observe the following notes

• For cleaning and maintenance of the machine, the replacement of parts, or switching to

another function the motor has to be shut off and the mains connection must be unplugged.

• The mains lead must not be injured or damaged by either crossing, squeezing, straining or

anything similar.

• The mains lead has to be checked regularly for indications of damage.

• The machine must not be used if the mains lead is not in perfect condition.

• For the use or replacement of mains leads or cord sets the notes given by the manufacturer

must be strictly observed.

• For the replacement of couplings of mains leads or cord sets, splash protection and

mechanical strength have to remain ensured.

Osmo Holz und Color GmbH & Co. KG

Affhüppen Esch 12, 48231 Warendorf

- 8 -

Holzimport

Industriehobelwerke

Farbenwerk

www.osmo.de

• For transport in lifts the handle/pole of the machine is to be placed upright to prevent it from

getting stuck on the hoistway walls.

• Sprays and cleaning agents which are not suited for the intended purpose of the appliance

must not be used.

• Never use substances which are highly inflammable, combustible, toxic, hazardous to

health, caustic or irritating.

•

Corrective maintenance inclusive of the integration of spray leads and hoses may only be

carried out by approved after-sales service points or competent qualified personnel being

familiar with all relevant safety regulations.

10. Technical Data:

A.C. motor 230 V; 50 Hz

Rated power 290 W; 1.9 A

Oscillation speed 1.450 1/min.

Brush 330 mm

Working height 250 mm

Working weight 12,5 kg

Protection class I

Cable length 7.5 m

Subject to changes within the framework of technical progress.

The above information is given to the best of our knowledge but without liability.

(dated 01/2009)

Table of contents

Popular Floor Machine manuals by other brands

Crommelins

Crommelins CFGKUB Operation & instruction manual

SCANMASKIN

SCANMASKIN Scan Combiflex 500i manual

PowerBoss

PowerBoss PHOENIX 30 user manual

Tieppo

Tieppo 4-75 Operating and maintenance handbook

Superabrasive

Superabrasive LAVINA ELITE Series user manual

Jungheinrich

Jungheinrich EZS 350 XL operating instructions