Discount Equipment MAYCO ST-70 User manual

PARTS AND OPERATION MANUAL

Revision #4 (05/29/07)

MODEL ST-70

Structural Concrete Pump

(Hatz Diesel Engine)

THIS MANUAL MUST ACCOMPANYTHE EQUIPMENT AT ALLTIMES.

Go to Discount-Equipment.com to order your parts

Discount-Equipment.com is your online resource for quality parts & equipment.

Florida: 561-964-4949 Outside Florida TOLL FREE: 877-690-3101

Need parts?

Click on this link: http://www.discount-equipment.com/category/5443-parts/ and

choose one of the options to help get the right parts and equipment you are looking

for. Please have the machine model and serial number available in order to help us

get you the correct parts. If you don’t find the part on the website or on one of the

online manuals, please fill out the request form and one of our experienced staff

members will get back to you with a quote for the right part that your machine needs.

We sell worldwide for the brands: Genie, Terex, JLG, MultiQuip, Mikasa, Essick, Whiteman,

Mayco, Toro Stone, Diamond Products, Generac Magnum, Airman, Haulotte, Barreto,

Power Blanket, Nifty Lift, Atlas Copco, Chicago Pneumatic, Allmand, Miller Curber, Skyjack,

Lull, Skytrak, Tsurumi, Husquvarna Target, Stow, Wacker, Sakai, Mi-T-M, Sullair, Basic,

Dynapac, MBW, Weber, Bartell, Bennar Newman, Haulotte, Ditch Runner, Menegotti,

Morrison, Contec, Buddy, Crown, Edco, Wyco, Bomag, Laymor, EZ Trench, Bil-Jax, F.S.

Curtis, Gehl Pavers, Heli, Honda, ICS/PowerGrit, IHI, Partner, Imer, Clipper, MMD, Koshin,

Rice, CH&E, General Equipment ,Amida, Coleman, NAC, Gradall, Square Shooter, Kent,

Stanley, Tamco, Toku, Hatz, Kohler, Robin, Wisconsin, Northrock, Oztec, Toker TK, Rol-Air,

APT, Wylie, Ingersoll Rand / Doosan, Innovatech, Con X, Ammann, Mecalac, Makinex, Smith

Surface Prep,Small Line, Wanco, Yanmar

PAGE 2 — ST-70 — PARTS & OPERATION MANUAL — REV. #4 (05/29/07)

Diesel engine exhaust and some of

Go to Discount-Equipment.com to order your parts

PAGE 4 — ST-70 — PARTS & OPERATION MANUAL — REV. #4 (05/29/07)

Here's How To Get Help.......................................... 3

Table Of Contents ...................................................4

Parts Ordering Procedures ..................................... 5

ST-70

Specifications .......................................................... 6

Pump Warranty ....................................................... 7

Safety Instructions ............................................. 8-10

Important Hand Signals ........................................ 11

General Information......................................... 12-13

Concrete Mix Information ................................ 14-17

Slump Test Procedure........................................... 18

Operation (How it Works)...................................... 19

Initial Start-up Procedure................................. 22-25

Operating Procedures...................................... 26-30

Towing Information........................................... 31-33

Explanation Of Codes In Remarks Column .......... 34

Suggested Spare Parts......................................... 35

Decals Safety ................................................... 36-37

Component Illustrations

Control Panel Installation.................................38-39

Control Panel Front..........................................40-41

Control Panel Interior.......................................42-44

Main Drive Pumps ...........................................46-47

Manifold (Control) ............................................48-49

Accumulator.....................................................50-51

Hydraulic/Concrete Cylinders..........................52-53

Shuttle Tube Assy ............................................54-55

Hopper Assy ....................................................56-57

Remixer Control Assy ......................................58-59

Throttle Assy....................................................60-61

Engine and Frame ...........................................62-63

Oil Cooler Assy ................................................64-65

Fuel and Hydraulic Tank ..................................66-67

Battery,Tail Lights,Water Separator,Gauges ...68-69

Axle and Brakes...............................................70-71

Hydarulic Surge Brake and Hitch.....................72-73

TABLE OF CONTENTS

NOTE: Specification and part number

are subject to change without notice.

Service Information

Wiring Schematic:

1) Interior Control Panel (Inside Door)............... 74

2) Schematic Electrical Control Box .............. 75-76

3) Interconnect Electrical Control Box ................ 77

Hydraulic Diagram ........................................... 78-79

Optional Radio Control.......................................... 80

Safety Service Procedures ................................... 81

Maintenance Check Schedule ......................... 82-83

Pressure Setting Sequence .................................. 84

Accumulator Circuit............................................... 85

Hydraulic System Troubleshooting........................ 86

Electrical System................................................... 87

Changing Concrete Cylinder Piston Cups ............ 88

Changing the Wear Plate and Ring ...................... 89

Wheel Bearings..................................................... 90

Terms and Conditions Of Sale — Parts .................91

Go to Discount-Equipment.com to order your parts

PAGE 6 — ST-70 — PARTS & OPERATION MANUAL — REV. #4 (05/29/07)

ST-70 SPECIFICATIONS

PERFORMANCE U.S. METRIC

PumpingRate—VolumeOutput 70yd/hr.* (54m/hr)*

MaximumAggregateSize 11/2" minus (38mm)

Verticle PumpingHeight .................................................300 ft.*..................................................................... (91m)*

HorizontalPumping Distance .........................................1200ft.*................................................................... (366m)*

Engine— Diesel.............................................................HATZ 4M40L:80HP(59.68KW)

HopperCapacity 10cu.ft. capacitywithoptionalforward/reversere-mixer

Line Size ........................................................................3",4"or 5"dia.

ElectricalSystem ............................................................12 vD.C.

Hydraulic OilSystem ......................................................58 gal.

FuelTank Capacity .........................................................20 gal.

Weight (withfluids) .........................................................4700 lb.................................................................... (2132kg)

Tire Size .........................................................................7.35 - 14, 8 ply

Brakes ............................................................................12" dia.Hydraulic Surge

All SteelTrailer Frame

DIMENSIONS

L x W x H ........................................................................149"X67" X55"...................................................... (356X170X140cm)

Weight(Shipping)...........................................................4,700lbs. ................................................................ (2132kg)

*Thesefigures willvary with Pump Model, concrete mix design, line size,job site conditions and engine option.

Maycoreserves the right to change and modifythe abovespecifications ordesign without notice or obligation.

Go to Discount-Equipment.com to order your parts

ST-70 — PARTS & OPERATION MANUAL — REV. #4 (05/29/07) — PAGE 7

MAYCO PUMP WARRANTY

Mechanical Drive Models

MAYCO PUMP, hereinafter referred to as “Manufacturer’,

warrants each new Mayco Pump sold by the manufacturer to

be free from defects in material and workmanship, under

normaluse andservice, fora period of one year after the date

ofdelivery to the original retail purchaser.Manufacturer will, at

its option, replace or repair at a point designated by the

Manufacturer any part or parts which shall appear to the

satisfactionof the Manufacturer upon inspection at such point

to have been defective in material or workmanship. This

warranty does not obligate the Manufacturer to bear any

transportation charges or labor charges in connection with

the replacement or repair the of the defective parts.

This warranty does not apply to any pump if attempts have

been made to pump concrete materials which have

separated, to any pump which has been repaired with other

than Genuine Mayco Parts, nor to any pump which has been

altered,repairedorused in such mannerasto adversely affect

itsperformance,nortonormalserviceormaintenance orwhere

blockages have developed within the pump manifold or

placing line or which has been operated in any other manner

not recommended by the Manufacturer. Due to the abrasive

nature of concrete, Mayco does not cover natural component

wear.

THIS WARRANTY AND MANUFACTURER’S OBLIGATION

HEREUNDER, IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESS, IMPLIED OR STATUTORY AND ALL OTHER

OBLIGATIONS OR LIABILITIES INCLUDING SPECIAL OR

CONSEQUENTIALDAMAGESORCONTINGENTLIABILITIES

ARISING OUT OF THE FAILURE OF ANY PUMP OR PART

TO OPERATEPROPERLY,INCLUDING ANYWARRANTIES

OFMERCHANTABILITYOR FITNESSFOR APARTICULAR

PURPOSE.

Hydraulic Drive Models

MAYCO PUMP, hereinafter referred to as “Manufacturer”,

warrants each new Mayco Pump sold by the manufacturer to

be free from defects in material and workmanship, under

normaluseand service, fora period ofone year or2000 hours

after the date of delivery to the original retail purchaser.The

Manufacturer will, at its option, replace or repair at a point

designated by Manufacturer any part or parts which shall

appear to the satisfaction of Manufacturer upon inspection at

suchpoint to havebeen defective inmaterialor workmanship.

This warranty does not obligate Manufacturer to bear any

transportation charges or labor charges in connection with

the replacement or repair of the defective parts.

This warranty does not apply to any pump if attempts have

been made to pump concrete materials which have

separated, to any pump which has been repaired with other

than Genuine Mayco Parts, nor to any pump which has been

altered,repairedorused in such mannerasto adversely affect

it’s performance, nor to normal service or maintenance or

where blockages have developed within the pump manifold

orplacinglineorwhichhasbeenoperatedinanyother manner

not recommended by the Manufacturer. Due to the abrasive

nature of concrete, Mayco does not cover natural component

wear.

THIS WARRANTY AND MANUFACTURER’S OBLIGATION

HEREUNDER, IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESS, IMPLIED OR STATUTORY AND ALL OTHER

OBLIGATIONS OR LIABILITIES INCLUDING SPECIAL OR

CONSEQUENTIALDAMAGESORCONTINGENTLIABILITIES

ARISING OUT OF THE FAILURE OF ANY PUMP OR PART

TO OPERATEPROPERLY,INCLUDING ANYWARRANTIES

OFMERCHANTABILITYOR FITNESSFOR APARTICULAR

PURPOSE.

Go to Discount-Equipment.com to order your parts

PAGE 8 — ST-70 — PARTS & OPERATION MANUAL — REV. #4 (05/29/07)

READ THIS PARTS AND OPERATION MANUAL

THOROUGHLYBEFOREUSINGTHISMACHINE.Itdescribes

the safe, proper and most efficient way to operate it. KNOW

YOURMACHINE!

Whenoperating concrete pumpsthe safety regulations of

theresponsibleemployers’liabilityinsurancecompanymust

beobserved.The observationof these regulations shall be

theresponsibilityof the contractorandoperator.

Thefollowing are somesupplementary recommendations:

Allsafety devices andprovisions against accidentssuch as

warninglabelsand information signs,coverings, etc. must

beinplace. Do notremove or tamperwiththem. If theyare

missing,replacethem.

Check the operational reliability of the machine each time

before it is put into operation. Any defects found must be

repairedimmediately.

Allowthemachinetobeoperatedandmaintainedbyqualified

personnelonly.

Beforeleaving the machine, protect it fromunauthorizeduse

andunintentionalmovements.

Unauthorizedpresenceintheimmediateareaoftheconcrete

pumpisnotallowed.Warnpersonswhoareintheimmediate

area.Stopworkifpersonsdonotleavethearea after having

beenwarned.

Wear personal protective equipment when operating the

machine.

WW

WW

WARNING! DANGER OF AMPUTARNING! DANGER OF AMPUT

ARNING! DANGER OF AMPUTARNING! DANGER OF AMPUT

ARNING! DANGER OF AMPUTAA

AA

ATION!TION!

TION!TION!

TION!

Neverplaceyourhandsoranypartofyourbodyinthehopper

orallow anyoneelse to do so while the engine is runningor

whenthereisaccumulatorhydraulicpressureorseriesinjury

couldresult.

ST-70 — SAFETY INSTRUCTIONS

TRAVEL AND TRANSPORTATION

The machine must not be moved with extended outriggers.

Before traveling, check the transportation safety devices of

the outriggers, the tire pressure and the functioning of the

brakes.

Usehoistingunitswith transport devicescomplyingwith safety

requirements.

Hoisting cables or equipment are to be applied only at the

lifting points provided.

TOWING:

1. Read the Atwood Hydraulic Surge Brake Installation

Instructions.

2. The pump should not be towed in excess of 55 MPH (less

depending on road conditions). It can be towed with any

truck rated to pull a 5000 lb.load.

3. Before towing, check with local and state laws for proper

compliance.(Referto page 31)

a. Secure the hitch on the ball and attach the breakaway

cable and safety chain to the towing vehicle.

b. Raise all stand pipes and secure.

4. Use only a 2” one-piece, all-steel, machined or forged ball

ratedat 5000lbs.minimumcapacity.

5. Do not tow the pump with concrete in the hopper.

6. Do not tow the pump with the concrete reducers attached.

7. Checkallwheellugboltsforpropertightnesspriortotowing.

Go to Discount-Equipment.com to order your parts

ST-70 — PARTS & OPERATION MANUAL — REV. #4 (05/29/07) — PAGE 9

ST-70 — SAFETY INSTRUCTIONS

STABILIZER JACK

Priorto jackingcheckthe soil conditions.Ifnecessary,enlarge

thesupport foot areaby placingsquare timbers underneath.

Keepasufficientdistancefromexcavations;slopescouldbreak

awaybecauseof support pressures.

On inclines and slopes place chocks behind the wheels.

Jackthe pump insuch a manner that itis in ahorizontal (level)

position.Check the positionof thepump frequently.

CONCRETEPUMP

To avoid splashes due to suction of air, the agitator hopper

mustalways be filledwith concreteup to the mixing shaft.

DONOTOPERATEANYCONCRETEPUMP

WITHOUTTHEHOPPER GRILLFIRMLY IN

PLACE.

NEVER ALLOW ANY HANDS NEAR THE

SHUTTLE CRANK VALVE OR IN THE

AGITATORHOPPERWHILETHE MACHINE

ISRUNNING.

WARNING! DANGER OFWARNING! DANGER OF

WARNING! DANGER OFWARNING! DANGER OF

WARNING! DANGER OF

AMPUTAMPUT

AMPUTAMPUT

AMPUTAA

AA

ATION!TION!

TION!TION!

TION!

Never place your hands or any part of your

bodyinthehopper or allow anyoneelsetodo

so while the engine is running or when there

is accumulator hydraulic pressure or series

injurycouldresult.

Referto Operation sectionof thismanual for more details.

PIPELINES

PIPELINES AND CLAMPS MUST BE OF SUFFICIENT SIZE

FORTHEPUMP’S CAPACITY.

The pipeline connections must not be opened under working

pressure. Before the pipeline is opened, pressure must be

relieved by sucking back the concrete. Secure the couplings

afterthe assembly ofthe pipeline.

Whenlayingpipelineuse as fewbendsaspossible. Horizontal

pipelines must be adequately supported. When installing a

vertical pipeline, the best method is to use upright struts that

can be anchored to the building.

Itis preferable to install pipelineswithin thebuilding whenever

possible. See Operator’s Manual and “Pumping Concrete”

bookletsfor more information on pipeline installations.

MAINTENANCE AND REPAIR

TURN OFF THE ENGINE AND

DISCONNECT THE BATTERY CABLES

BEFORE PERFORMING ANY

MAINTENANCEOR REPAIRS.

MAKESURETHATTHEACCUMULATORPRESSUREGAUGE

READS ZERO BEFORE ALLOWING ANYBODY TO PUT

THEIRHANDSINTO HOPPERORSHUTTLE AREA.

Referto maintenance sectionof this manualfor moredetails.

CAUTION: If the hoses or lines are blocked for any

reason, or if the lines are kinked when

starting up or during the pumping cycle, the

pump pressure could straighten out the kink

or force out the blockage.This rapid surge of

materialcouldcausethelinestowhipormoveinsuchamanner

that it could cause injury to anyone working near the hosses

or lines.

When moving hoses from one site application to another, it is

important to walk the entire system and visually inspect for

anykinksor sharp bendsin thehose.Youmustand straighten

them before starting or resuming the pumping operation.

Inspect the lines at all times to prevent the above conditions.

Go to Discount-Equipment.com to order your parts

PAGE 10 — ST-70 — PARTS & OPERATION MANUAL — REV. #4 (05/29/07)

MODEL ST-70

THEOPERATORISINCOMPLETECHARGEOFTHEPUMP

ANDDELIVERY SYSTEM ANDIS RESPONSIBLEFOR HIS/

HEROWNSAFETYANDTOWARNANDKEEPALLOTHERS

OUT OF DANGER.

Do not attempt to operate this equipment without a

thorough understanding of this Parts and Operation

Manual:

1. To preventdamage to equipment orinjury to personnel,the

followinginstruction must befollowed carefully:

A. A copy of this manual and all others shall accompany the

pumpat all times.

B. This equipment shall be operated only by experienced

operators or students under the direct supervision of an

experienced operator.

C. No unauthorized persons shall be permitted to assist or

remain in the vicinity of the unit while it is in operation, or

duringthe, inspection,cleaningorrepairforthemake-ready

operation.

D. Thisequipmentshallnotbetowedoroperatedbyindividuals

who cannot read and understand the signs, decals or

operatinginstructions.

E. This equipment shallnot be operated by individuals under

the influence of alcohol or drugs.

F. Before towing, check the hitch and secure the breakaway

cable and safety chain to the towing vehicle.

G. Tow only with a vehicle and hitch rated to pull a 5000 lb.

load.

H. Use only a 2" one-piece, all-steel machined or forged ball

rated for a minimum of 5000 lbs.

I. Before start-up, check the hopper and remove all

obstructions.

J. Keep hands, feet and human body parts out of the hopper

when the engine is running.

K. The engine must be turned off before performing any

service operations. The engine is remote controlled and

may start pumping any time the engine is running.

L. Do not use worn hoses or hose couplings – inspect daily.

M. Replace any worn or damaged hoses, or couplings,

immediately.

N. Do not disconnect the hose couplings or nozzles while

under pressure.

ST-70 — SAFETY INSTRUCTIONS

O. Never fill the fuel tank while the engine is running or hot.

Avoid the possibility of spilled fuel which may cause a fire.

P. Always carry a fire extinguisher of adequate size and a

firstaid kit.

Q. Always wear a safety helmet and safety glasses when on

a job site pumping.

R. Always have the hopper grate securely in place when

pumping.

S. Pumpin reverse when the shuttlevalve ordelivery system

is plugged.

T. Guards, grates, covers, etc. MUST NOT be removed or

altered.

U. If a failure ormalfunction occurs,stop thepump and make

all necessary repairs immediately.

V. Electrical and manual controls must always be in working

order.

W. NEVER stand on the hopper grate.

X. Alwayspositionthepumponsafe,solid,levelground, using

the jack stands.

Go to Discount-Equipment.com to order your parts

ST-70 — PARTS & OPERATION MANUAL — REV. #4 (05/29/07) — PAGE 11

IMPORTANT HAND SIGNALS

Go to Discount-Equipment.com to order your parts

PAGE 12 — ST-70 — PARTS & OPERATION MANUAL — REV. #4 (05/29/07)

ST-70 — GENERAL INFORMATION

CONCRETE MIX DESIGN

Mixdesignismostimportant to achievemaximum pumpability.

Pumpability is affected by, among other factors, the type and

gradationofaggregateused.Naturalaggregatesmakea more

workablemix andpumpmorereadilythancrushedaggregates.

A blend of natural and crushed aggregates will produce a

workablemix.The typeand gradationof aggregates is equally

importantfor workabilityas thesize andpercentage ofcoarse

aggregatesin the mix.

Theterm“aggregates”describesallofthe solid materials, from

the largest rock to the smallest grain of sand, contained in the

concrete mix.

Concrete mixes with a consistency as dry as one-inch slump

and as wet as ten-inch slump have been pumped; but for

maximumefficiency from the pump,a slump ranging from two

to six inches will produce a more workable mix than one that

contains more or less water.

Aslumpratingshouldbe used with discretion;itisnotalways a

realindication ofthe pumpabilityof themix.The concrete may

be workable in the sense that it will readily flow into place, but

the same mix may not respond to pressure. Overly wet mixes

tendto separate.Inadditiontoaffectingthestrength andquality

oftheconcrete,thedeliverysystemwillnottolerateseparation.

Overlydrymixesaresimilarlyunsatisfactoryiftheylackplasticity

andtendtobecrumbly.Tobeproperlypumped,themixmustbe

abletocontinuouslycoatthe inside of thelinewithalubricating

sealof mortar.

Theprincipleof concrete pumpingis based onself-lubrication.

As it moves through the transfer line, the concrete takes the

shapeof aplastic cylinder.It isforcedthrough the transferline

on a film of mortar that is self-troweled to the service of the

transfer line around its full periphery by the slug of concrete

itself.

There are four ways in which this seal can be lost:

1. By pumping excessively wet mixes which do not have

enoughcohesion to hold together.

2. Bypumpingharshundersandedconcretewithpoorlygraded

aggregates which can jam together when the pressure

becomes too great for the insufficient amount of sand to

holdthe aggregates apart.

3. By getting a rock pocket, such as mixer tailings, into the

pumpvalve.Thisrockpocketwill haveaninsufficientcoating

ofmortarand the mixwillnot be plasticenoughto allow the

valveto operateor themix to move in the line.

4. Through excessive bleeding.If the mixisshort or fines,but

the sand is otherwise fairly well graded, bleeding will not

normallycreateanyproblemsaslongasthepumpcontinues

operation.But, if the pump isshutdown,bleedingcanresult

in a loss of lubrication and blocked erratic flow.

The above are bad concrete practices, regardless of how the

mix is to be placed. But, these points do show that special

mixes are not always needed, within limits, for pumping

concrete. Good aggregate gradation is most important to

pump concrete the maximum distance.

The use of admixtures can have a beneficial effect on

pumpability. Most of the dispersing agents will fatten, retard

bleeding,and increase workability.Thus,the averageconcrete

canbepumpedforappreciablylongerdistances.Airentraining

agents will also improve workability, although they cannot be

used as a substitute for good gradation of the aggregate.

Pumping will not appreciably affect the final air content of the

mix.High-earlycement tendstogive amorereadily pumpable

mix with superior water retaining qualities.However, if delays

are likely to occur, extra care must be exercised due to the

fastersettingtimeover regular cement.

The Mayco Model ST-70 will pump a wide variety of concrete

pump mixes. But, there are guidelines that must be followed.

Usethisinformation in conjunctionwith “The DeliverySystem”

on page 32, Sections 18 thru 18.10.

Go to Discount-Equipment.com to order your parts

ST-70 — PARTS & OPERATION MANUAL — REV. #4 (05/29/07) — PAGE 13

ST-70 — GENERAL INFORMATION

REGIONAL DIFFERENCES

Concrete is made by mixing locally available rock and sand

with cement and water. For this reason there are great

differences in the pumpability of concrete from one region of

the country to another.

Itis impossible to define a specific mixfor eachregion thatthe

ModelST-70 be will workingin.Therefore,the mixeson pages

14 through 17 will provide a basic guideline for establishing

the proper mix design for your area.

Usethis information to specify yourrequirements to your local

ready-mixbatchplant,contractorandcivilengineer.It maytake

minor adjustments to make a mix pumpable, so you should

explainyour needs.

The elements that have to be controlled and consistently

maintainedby the batch plant are:

1. The sizing and mix percentage of rocks, gap graded from

thelargest down throughthe smallest sizes.

2. Sandwith a sieve analysis that has the proper percentage

offines,ASTMC33 spec.

3. Sufficient cement to produce the required design strength

of the concrete and provide the lubricating binder to pump

theconcretethrough the delivery system.

Use a minimum of:

500 lbs.of cement/cu yd for 2500 p.s.i. concrete

after 28 days.

530 lbs.of cement/cu yd for 3000 p.s.i. concrete

after 28 days.

600 lbs.of cement/cu yd for 4000 p.s.i. concrete

after 28 days.

4. Admixture pump-aid if necessary.

5. The proper amount of water to make a workable slump

and plasticize the mix.

Inaddition,theMaycoStructural Concrete ST-70Pumpcanbe

usedto pumpa largeaggregate hard rock as follows:

1. Pea rock (1/2" minus) pump with mixes being as low as

30% rock and 70% sand. (See page 30, for comments on

cleaning the pump.)

2. Shortening pea rock when used with an air compressor

and nozzle. (See back pages for recommended set-up.)

3. “Mud Jacking”, high pressure grouting.

Go to Discount-Equipment.com to order your parts

PAGE 14 — ST-70 — PARTS & OPERATION MANUAL — REV. #4 (05/29/07)

ST-70 — CONCRETE MIX INFORMATION

JobIdentification* _______________________________________ Date* ______________________________________

Architect* ______________________________________________ GeneralContractor* ___________________________

StructuralEngineer*______________________________________ Concreteby* ________________________________

THEPROPORTIONSSHOWNHEREARE A RECOMMENDATION BASEDONTESTSOFSAMPLESRECEIVED BYTHE

LABORATORY.TESTS PERFORMED BY SUPPLIERS OR MANUFACTURERS OR ON PRIOR KNOWLEDGE OF THE

MATERIALSINVOLVED ANDISLIMITEDTOINFORMATIONDERIVEDFROMTHESE SAMPLESTESTSBYOTHERS OR

TOTHAT PRIOR KNOWLEDGE.

IT IS UNDERSTOOD THAT THE CHEMICAL AND/OR PHYSICAL CHARACTERISTICS OF THESE MATERIALS ARE

SUBJECTTOVARIATIONSTHATMAY ADVERSELYAFFECTTHEFINISHEDPRODUCTANDTHATTHISMIXDESIGNIS

NOT TO BE USED EXCEPT AT THE USERS OWN RISK UNLESS THESE VARIATIONS ARE DETERMINED AND

COMPENSATED FOR INAMANNER APPROVEDBYTHELABORATORYINWRITING.

Specificationsrequirements: 2500P.S.I. in 28 DAYS 3"SLUMP PUMPMIX 4"DIALINE

SIEVEANALYSIS PER CENT PASSINGU.S.STANDARD SIEVE

MATERIAL .........11/2............1...............3/4..................................................................................................................

FAIWCS.......................................................................100 ........97............84 ........... 70....... 45 ........25..... 10 ....... 97.5

FA2...................................................................................................................................................................................

CA1#4-3/8" ..............................................100.............95 ..........13............3 ............................................................... 90.5

CA2#3-1 ................................100...........96...............61 ..........6..............1 ............................................................... 91.0

CA3 ..................................................................................................................................................................................

...............................................100...........98...............85 ..........50............40 ........... 33....... 21 ........12..... 4 .........

Sourceof Coarse& FineAggregates -* Cement–Type* MixNo*

CementSks/Cu.Yd. ................................................................ 5.3

Cement–Lbs. ........................................................................ 500

Sand,Lbs.W.C.S. ................................................................... 1550

No.4Gravel (3/8"),Lbs. .......................................................... 500

No.3Gravel(1"), Lbs.............................................................. 1220

No.2Gravel(1-1/2"),Lbs........................................................

Water,Lbs............................................................................... 290

Total Weight........................................................................... 4060

Water,gal.peryd. ................................................................... 34.8

Water,gal./Sk.per yd. ............................................................. 6.5

Slump,calculated ................................................................... 3"

Admixture ............................................................................... 3fl. oz. POZZOLITH 300N/100 *OF CEMENT

Max.WaterAllowable ............................................................. *

*THIS INFORMATION PROVIDED BY ENGINEER OR BATCH PLANT

THE ABOVE MIX DESIGN IS TYPICAL OF A PUMPABLE MIX.TO BE USED AS A GUIDELINE ONLY. REFERTO LOCAL

AGENCY FOR JOB SPECIFICATION.

3-5

Go to Discount-Equipment.com to order your parts

ST-70 — PARTS & OPERATION MANUAL — REV. #4 (05/29/07) — PAGE 15

ST-70 — CONCRETE MIX INFORMATION

Job Identification* _______________________________________ Date* ______________________________________

Architect* ______________________________________________ General Contractor*___________________________

StructuralEngineer* _____________________________________ Concrete by* ________________________________

THEPROPORTIONSSHOWNHEREARE A RECOMMENDATION BASEDONTESTSOFSAMPLESRECEIVED BYTHE

LABORATORY.TESTS PERFORMED BY SUPPLIERS OR MANUFACTURERS OR ON PRIOR KNOWLEDGE OF THE

MATERIALSINVOLVED ANDISLIMITEDTOINFORMATIONDERIVEDFROMTHESE SAMPLESTESTSBYOTHERS OR

TOTHAT PRIOR KNOWLEDGE.

IT IS UNDERSTOOD THAT THE CHEMICAL AND/OR PHYSICAL CHARACTERISTICS OF THESE MATERIALS ARE

SUBJECTTOVARIATIONSTHATMAYADVERSELYAFFECTTHEFINISHEDPRODUCTANDTHATTHISMIXDESIGNIS

NOT TO BE USED EXCEPT AT THE USERS OWN RISK UNLESS THESE VARIATIONS ARE DETERMINED AND

COMPENSATEDFORIN A MANNERAPPROVED BYTHELABORATORYINWRITING.

Specificationsrequirements: 3000P.S.I. in 28 DAYS 4" SLUMP PUMPMIX 4"DIALINE

SIEVEANALYSIS PER CENT PASSING U.S.STANDARDSIEVE

MATERIAL .........11/2............1...............3/4..................................................................................................................

FAIWCS.......................................................................100 ........98............86 ........... 70....... 48 ........24..... 8 ......... 97.5

FA2...................................................................................................................................................................................

CA1#4-3/8" ..............................................100.............94 ..........16............4 ............................................................... 90.5

CA2#3-1 ................................100...........93...............57 ..........6..............1 ............................................................... 91.0

CA3 ..................................................................................................................................................................................

...............................................100...........97...............83 ..........51............41 ........... 33....... 23 ........11..... 4 .........

Sourceof Coarse& FineAggregates -* Cement–Type* MixNo*

CementSks/Cu.Yd. ................................................................ 5.

Cement–Lbs. ........................................................................ 525

Sand,Lbs.W.C.S. ................................................................... 1520

No.4Gravel (3/8"),Lbs. .......................................................... 480

No.3Gravel(1"), Lbs.............................................................. 1230

No.2Gravel(1-1/2"),Lbs........................................................

Water,Lbs............................................................................... 295

Total Weight.................................................................... 4050

Water,gal.peryd. ................................................................... 35.4

Water,gal./Sk.per yd. ............................................................. 6.3

Slump,calculated ................................................................... 4"

Admixture ............................................................................... 3fl. oz. POZZOLITH 300N/100 *OF CEMENT

Max.WaterAllowable ............................................................. *

*THIS INFORMATION PROVIDED BY ENGINEER OR BATCH PLANT

THE ABOVE MIX DESIGN ISTYPICAL OF A PUMPABLE MIX. TO BE USED AS A GUIDELINE ONLY. REFERTO LOCAL

AGENCY FOR JOB SPECIFICATION.

Go to Discount-Equipment.com to order your parts

PAGE 16 — ST-70 — PARTS & OPERATION MANUAL — REV. #4 (05/29/07)

ST-70 — CONCRETE MIX INFORMATION

Job Identification* _______________________________________ Date* ______________________________________

Architect* ______________________________________________ General Contractor*___________________________

StructuralEngineer* _____________________________________ Concrete by* ________________________________

THEPROPORTIONSSHOWNHEREARE A RECOMMENDATION BASEDONTESTSOFSAMPLESRECEIVED BYTHE

LABORATORY.TESTS PERFORMED BY SUPPLIERS OR MANUFACTURERS OR ON PRIOR KNOWLEDGE OF THE

MATERIALSINVOLVED ANDISLIMITEDTOINFORMATIONDERIVEDFROMTHESE SAMPLESTESTSBYOTHERS OR

TOTHAT PRIOR KNOWLEDGE.

IT IS UNDERSTOOD THAT THE CHEMICAL AND/OR PHYSICAL CHARACTERISTICS OF THESE MATERIALS ARE

SUBJECTTOVARIATIONSTHATMAY ADVERSELYAFFECTTHEFINISHEDPRODUCTANDTHATTHISMIXDESIGNIS

NOT TO BE USED EXCEPT AT THE USERS OWN RISK UNLESS THESE VARIATIONS ARE DETERMINED AND

COMPENSATED FOR INAMANNER APPROVEDBYTHELABORATORYINWRITING.

Specificationsrequirements: 4000P.S.I. in 28 DAYS 4"SLUMP PUMPMIX 5"DIALINE

SIEVEANALYSIS PER CENT PASSINGU.S.STANDARD SIEVE

MATERIAL .........11/2............1...............3/4..................................................................................................................

FAIWCS.......................................................................100 ........97............84 ........... 56....... 36 ........22..... 8 ......... 97.5

FA2...................................................................................................................................................................................

CA1#4-3/8" ..............................................100.............95 ..........13............3 ............................................................... 90.5

CA2#3-1 ................................100...........95...............64 ..........8..............1 ............................................................... 91.0

CA3 ................... 100 .............93.............64...............18 ..........2................................................................................. 90.0

..........................100 .............98.............90...............73 ..........49............40 ........... 26....... 17 ........10..... 4 .........

Sourceof Coarse& FineAggregates -* Cement–Type* MixNo*

CementSks/Cu.Yd. ................................................................ 6.4

Cement–Lbs. ........................................................................ 600

Sand,Lbs.W.C.S. ................................................................... 1480

No.4Gravel (3/8"),Lbs. .......................................................... 400

No.3Gravel(1"), Lbs.............................................................. 470

No.2Gravel(1-1/2"),Lbs........................................................ 800

Water,Lbs............................................................................... 300

Total Weight.................................................................... 4050

Water,gal.peryd. ................................................................... 36

Water,gal./Sk.per yd. ............................................................. 5.6

Slump,calculated ................................................................... 4"

Admixture ............................................................................... 3fl. oz. POZZOLITH 300N/100 *OF CEMENT

Max.WaterAllowable ............................................................. *

*THIS INFORMATION PROVIDED BY ENGINEER OR BATCH PLANT

THE ABOVE MIX DESIGN ISTYPICAL OF A PUMPABLE MIX. TO BE USED AS A GUIDELINE ONLY. REFERTO LOCAL

AGENCY FOR JOB SPECIFICATION.

Go to Discount-Equipment.com to order your parts

ST-70 — PARTS & OPERATION MANUAL — REV. #4 (05/29/07) — PAGE 17

ST-70 — CONCRETE MIX INFORMATION

Thesand content of pumpable concrete is very important. It is

one of the two major ingredients that change due to regional

location(the other is the rockor gravel).

Above is a typical sieve analysis of washed concrete sand

(W.C.S.)toA.S.T.M.C33specifications.

The total of the “Accumulated % Retained” is the Fineness

Modulus(F.M.).TheidealF.M.isbetween2.50and2.75,butthe

correctF.M.doesnotguaranteepumpability.Besideshavinga

correctF.M.thepercentageofsandbyweightthatpassesthrough

the No. 50 sieve must be between 15 and 30 and through the

No.100sieve5and10.The total of #50 and 100 mesh particles

mustbe between 25 and 35 percent.

This fine material plus the cement will provide the necessary

filmoflubricationtomovetheconcreteinsidethedeliverysystem.

DNASETERCNOC—SISYLANAEVEIS

EZISEVEIS 33CMTSA SCEPS SSAP% MUCCA 1#ELPMAS %VIDNI TER

4# 001-59 89 2 2

8 001-08 98 11 9

61 58-05 17 92 81

03 06-52 74 35 42

05 03-01 32 77 42

001 01-2 7 39 61

002

56.2=.M.FsuludoMsseneniF 56.2

Go to Discount-Equipment.com to order your parts

PAGE 18 — ST-70 — PARTS & OPERATION MANUAL — REV. #4 (05/29/07)

1.To obtain a representative sample, take samples at three or

more regular intervals throughout the discharge of the mixer

or truck.DO NOT take samples at the beginning or end of the

discharge.

2. Dampen the inside of the cone and place it on a smooth,

moist, nonabsorbent, level surface large enough to

accommodateboththeslumpedconcreteand the slump cone.

Stand on the “foot pieces” throughout the test procedure to

hold the cone firmly in place.

3.Fillthe cone

!/3

fullbyvolume and rod25times with a1/2"

dia x 24" lg. bullet-pointed steel rod. (This is a specific

requirement which will produce non-standard results unless

followedexactly.) Distributeroddingevenlyovertheentirecross

section of the sample. (See figure A.)

4.Fill cone another

!/3

which will makethe cone

@/3

fullby

volume.Rod thissecondlayer25timeswiththe rodpenetrating

into, but not through, the first layer. Distribute rodding evenly

over the entire cross section of the layer.(See figure B.)

5. Fill cone to overflowing. Rod this layer 25 times with rod

penetrating into but not through, the second layer. Distribute

rodding evenly over the entire cross section of this layer.(See

figureC.)

6.Removetheexcess concrete from thetopofthe cone, using

the tamping rod as a screed.(See figure D.)

7. Lift the cone vertically with a slow even motion. Do not jar

the concrete or tilt the cone during this process. (See figure

E.) Invert the withdrawn cone, and place it next to, but not

touching the slumped concrete.

8. Lay a straight edge across the top of the slumped cone.

Measure the amount of slump in inches from the bottom of

the straight edge to the top of the slumped concrete at a point

over the original center of the base (See Figure F).The slump

operation must be complete in a maximum elapsed time of 1-

½ minutes.Discard the concrete.DO NOT use it in any other

tests.

SLUMPTEST PROCEDURE

Go to Discount-Equipment.com to order your parts

ST-70 — PARTS & OPERATION MANUAL — REV. #4 (05/29/07) — PAGE 19

ST-70 — OPERATION (How itWorks)

The following is a brief explanation of

how the concrete cylinders, hydraulic

cylinders, shuttle tube, valves and

hopper work in sequence to pump

concrete.

The hydraulic pressure is generated by

a variable volume, pressure

compensated, axial piston pump that is

driven by a diesel engine.The hydraulic

pressure is applied to one of the two

hydraulic cylinders causing the

hydraulic piston, which is connected to

the concrete piston, to discharge

concrete into the delivery line.The rod

sides of the drive cylinders are

hydraulically connected together

creatinga“slavecircuit.”Asone cylinder

isdischargingconcrete, the hydraulicoil

from the rod side of the drive cylinders

is being transferred through the slave

circuit causing the opposite cylinder to

move back on the suction stroke filling

the cylinder with concrete. This

operation is made possible by the

shuttle tube located in the hopper and

is sequenced to operate in conjunction

with the cycling of the drive cylinders.

The ST-70 cycling sequence is initiated

by an electrical signal generated by two

proximity switches located in the drive

cylinder. The proximity switches are

normallyopen,magneticallysensingthe

movement ofthe maindrivecylinder.As

the drive cylinder piston head passes

theproximity switch, an electrical signal

is sent to the solenoid operated pilot

valve which in turn directs pilot oil to the

fourvalves controllingthe drive cylinder

and the shuttle cylinder.

A one-gallon accumulator assists the

movementoftheshuttletube.This circuit

assures that the shuttle tube will throw

with the same intensity of each stroke

regardless of how fast the main drive

cylinders are cycling.

TO TANK HIGH PRESSURE

OIL FROM PUMP TO TANK

HYDRAULIC

CYLINDERS

PISTON

CUP

CONCRETE

CYLINDERS

SLAVE

OIL

SLAVE

OIL

AA

BB

Figure 1

CYLINDER A — INTAKE STROKE

CYLINDER B — DISCHARGE STROKE CYLINDER A — DISCHARGE STROKE

CYLINDER B — INTAKE STROKE

Figure 2

PROXIMITY SWITCH

PROXIMITY

SWITCH

SHUTTLE TUBE

Go to Discount-Equipment.com to order your parts

PAGE 20 — ST-70 — PARTS & OPERATION MANUAL — REV. #4 (05/29/07)

This section is intended to assist the operator with the initial

start-up of the MAYCO ST-70 Concrete Pump.It is extremely

important that this section be read carefully beforeattempting

to use the pump in the field.

DO NOT proceed to the Operating Procedures (field use) of

this manual until this section is thoroughly understood.

NOTE:

Failure to understand the operation of the MAYCO ST-70

Concrete pump could result in severe damage to the pump or

personalinjury.

Figure1 illustratesthe basicoperating controlsand indicators

on the MAYCO ST-70 Concrete pump. Each of the items

referenced will bediscussed.Thesequencewill beas follows:

1. Engine Oil

2. Hydraulic Oil

3. Fuel

4. Rear Stabilizer Stands

5. Emergency Stop Switch

6. Ignition Switch

7. Status Indicators

8. Control Switch, EngineThrottle Control

9. Volume Control

10. Engine Speed, Cooling Fan

11. PressureTest

12. Hopper RemixerControl Lever

13. Manual and Radio Control

14. Cylinder Lubrication

INITIAL START-UP PROCEDURE

Figure 1. MAYCO ST–70

Controls and Indicators

Go to Discount-Equipment.com to order your parts

ST-70 — PARTS & OPERATION MANUAL — REV. #4 (05/29/07) — PAGE 21

Engine Oil

1. Pull the engine oil dipstick from the engine side panel as

shown in Figure 2.

Determineif engineoil islow.Ifoil level is low, addcorrect

amount of engine oil to bring oil level to a normal safe

operating level. See Figure 3.

If the hydraulic oil level is low, remove the cap just above

the oil level sight glass and add the correct amount of

hydraulic oil to bring the hydraulic oil level to a normal

safe operating level.(Use Shell oilTellus 68 or Mobil oil

DFE26)

FUEL

3. Determine if engine fuel is low (Figure 5). If fuel level is

low, remove the fuel filler cap and fill with diesel fuel.

Figure 3.

Engine Oil Dipstick

MAX

MIN

ADD ENGINE OIL

SAFE OPERATING

OIL LEVEL

OIL DIPSTICK

Figure 4.

Hydraulic Oil Sight Glass

150

200

250

150

100

50

0

F

H

L

I

O

G

W

H

HYDRAULIC

OIL LEVEL

SIGHT GLASS

NORMAL LEVEL

LOW LEVEL

ADD OIL

HYDRAULIC OIL

TEMPERATURE

GAUGE

OIL DIPSTICK

OIL FILTER

THROTTLE

CABLE

SOLENOID

ENGINE

SIDE PANEL

RED (POSITIVE)

WHITE (NEGATIVE

Figure 2.

Engine Oil

INITIAL START-UP PROCEDURE

Hydraulic Oil

2. Determine if the hydraulic oil levelis low by observing the

level of the oil in the Hydraulic Oil Sight Glass (Figure 4).

REAR STABILIZER STAND

ToreduceexcessivevibrationandrockingoftheST-70Concrete

Pumpset the rearstabilizer as follows:

4. Locate both left and right rear stabilizerstands (Figure6).

Figure 6.

Rear Stabilizer Stand

COTTER PIN

BOLT EYE

REAR STABILIZER STAND

HANDLE TEE BOLT

STABILIZER FOOT PAD

A. Remove the

cotter pin

from the handle tee bolt eye, and

then

pull

the handle tee to release the stabilizer stand.

B. Positionbothrearstabilizersstandsonfirm(notloose)

level

ground.

C. Align the hole on the stabilizer stand with the hole on the

framebody and

insert

handle teebolt.

Figure 5.

Fuel Sight Tube

Go to Discount-Equipment.com to order your parts

Table of contents

Popular Water Pump manuals by other brands

EINHELL

EINHELL GH-SP 2768 Original operating instructions

Crane

Crane Barnes SPRINT III Series Installation and operation manual

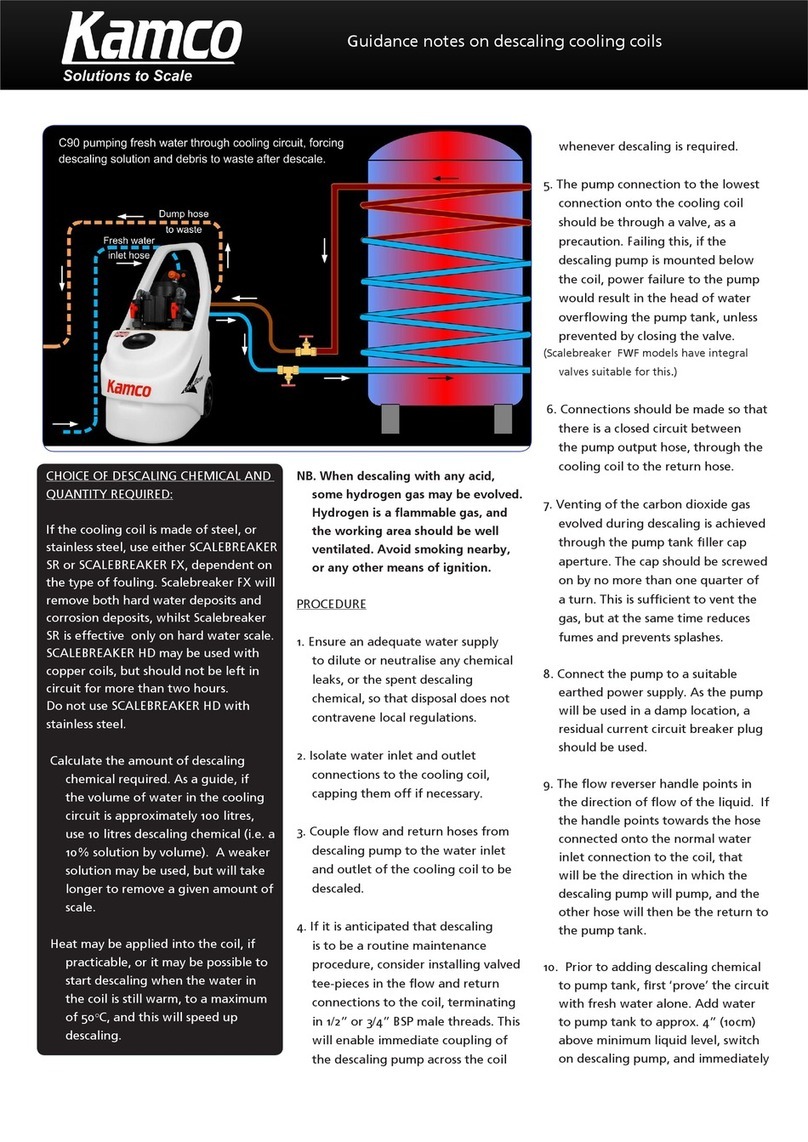

Kamco

Kamco C90 Guidance notes

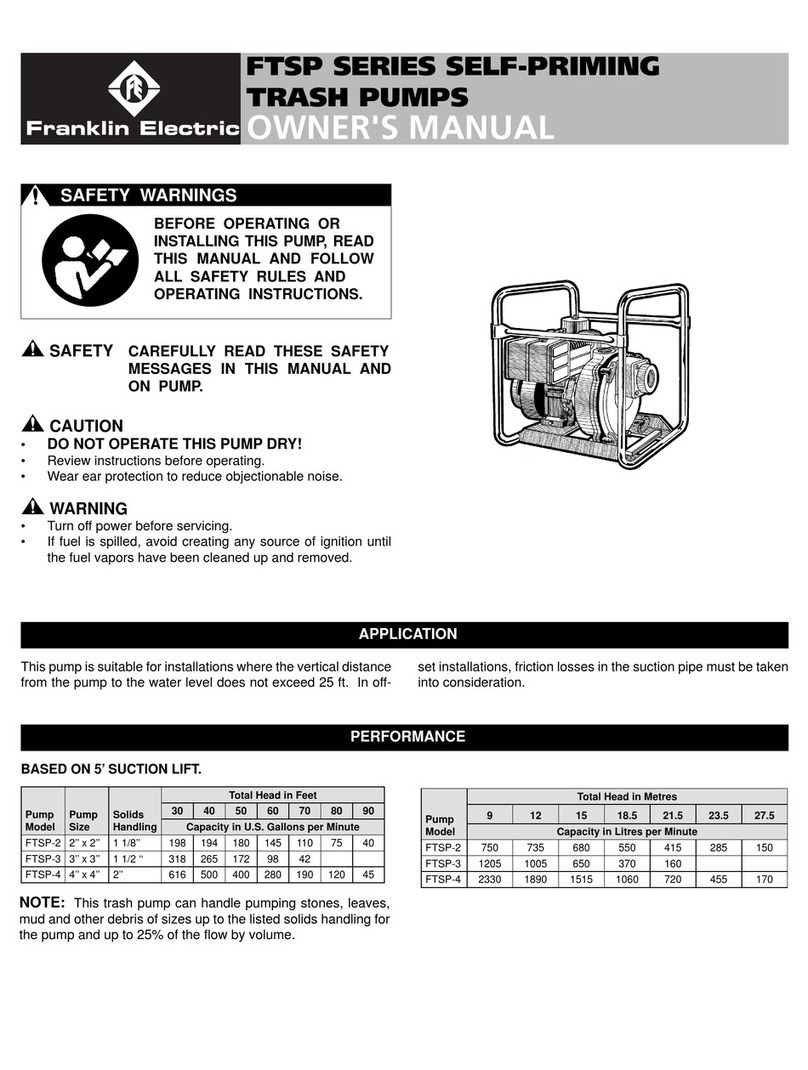

Franklin Electric

Franklin Electric FTSP Series owner's manual

EINHELL

EINHELL GC-DP 5225 N operating instructions

Hyundai power products

Hyundai power products HFP750 Original instructions

Milwaukee

Milwaukee M18 Operator's manual

Liberty Pumps

Liberty Pumps LEH150-E Series owner's manual

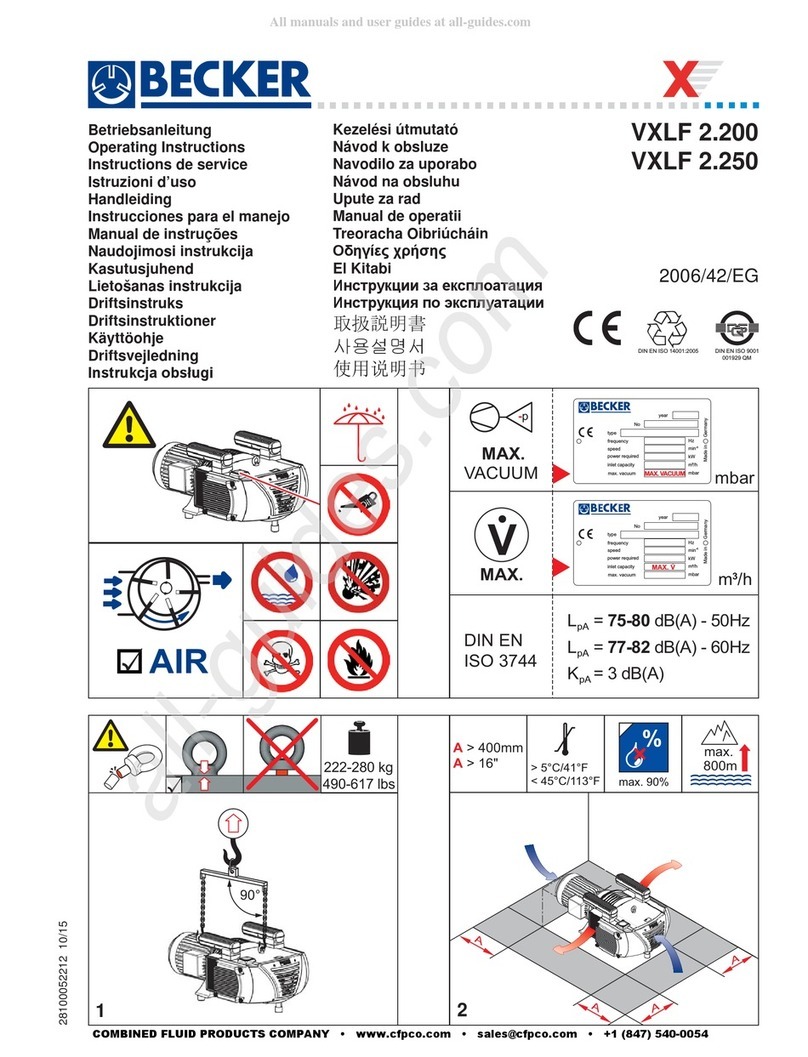

Becker

Becker VXLF 2.200 operating instructions

Ingersoll-Rand

Ingersoll-Rand PD05P series Operator's manual

Makita

Makita DVP181ZK instruction manual

salmson

salmson Mini-SVO Installation and starting instructions